High-safety auxiliary purification control system for welding smoke of cable distribution box

A cable distribution box and control system technology, applied in welding/cutting auxiliary equipment, auxiliary equipment, welding equipment, etc., can solve the problems of welding equipment without dust purification, human health threats, and working environment pollution, etc., to achieve easy absorption Collect, prevent smoke and dust from spreading into the air, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

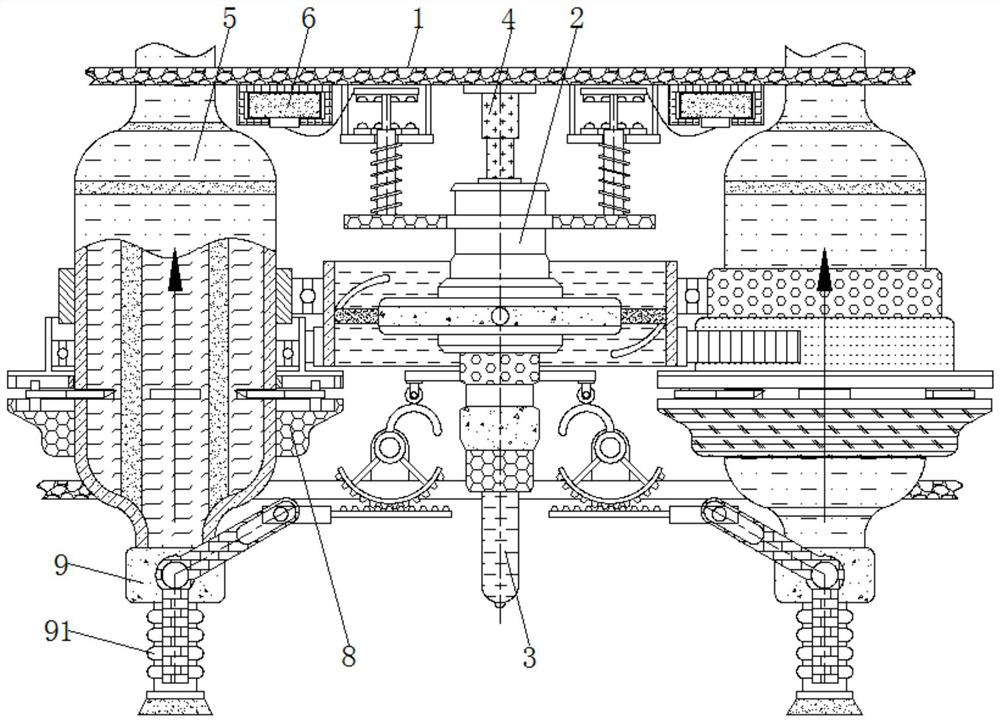

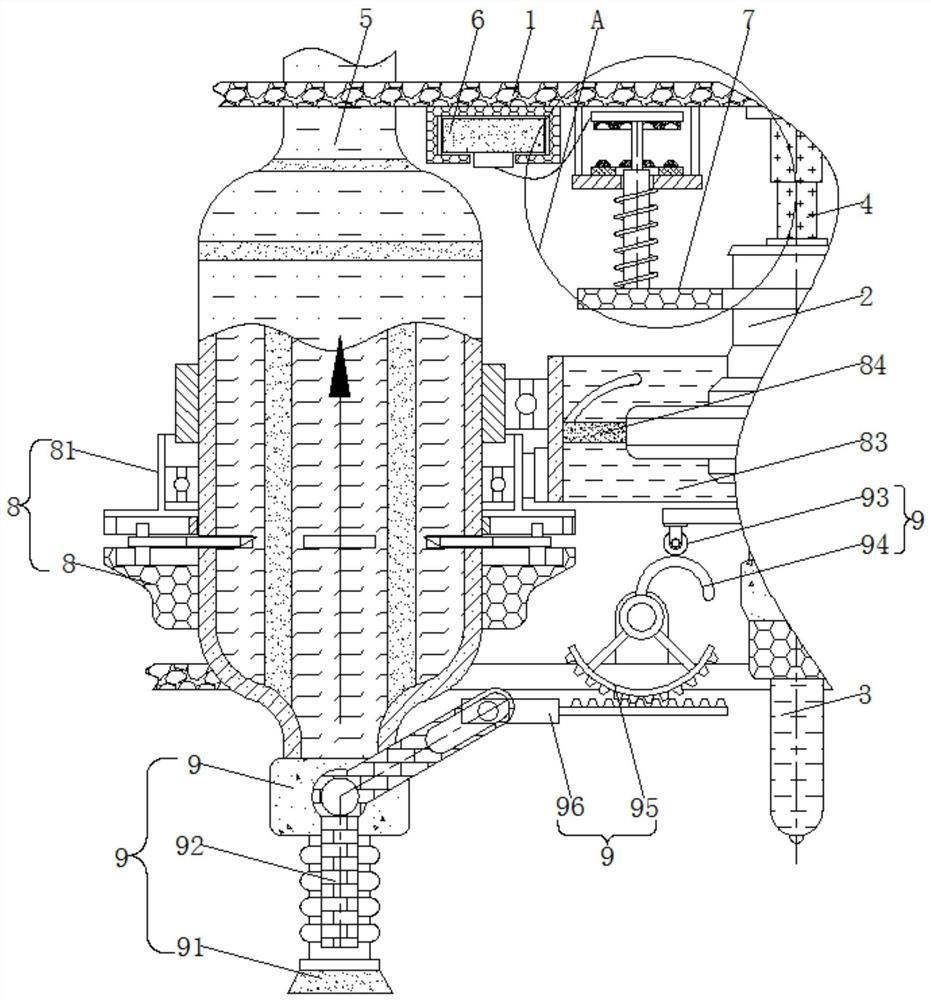

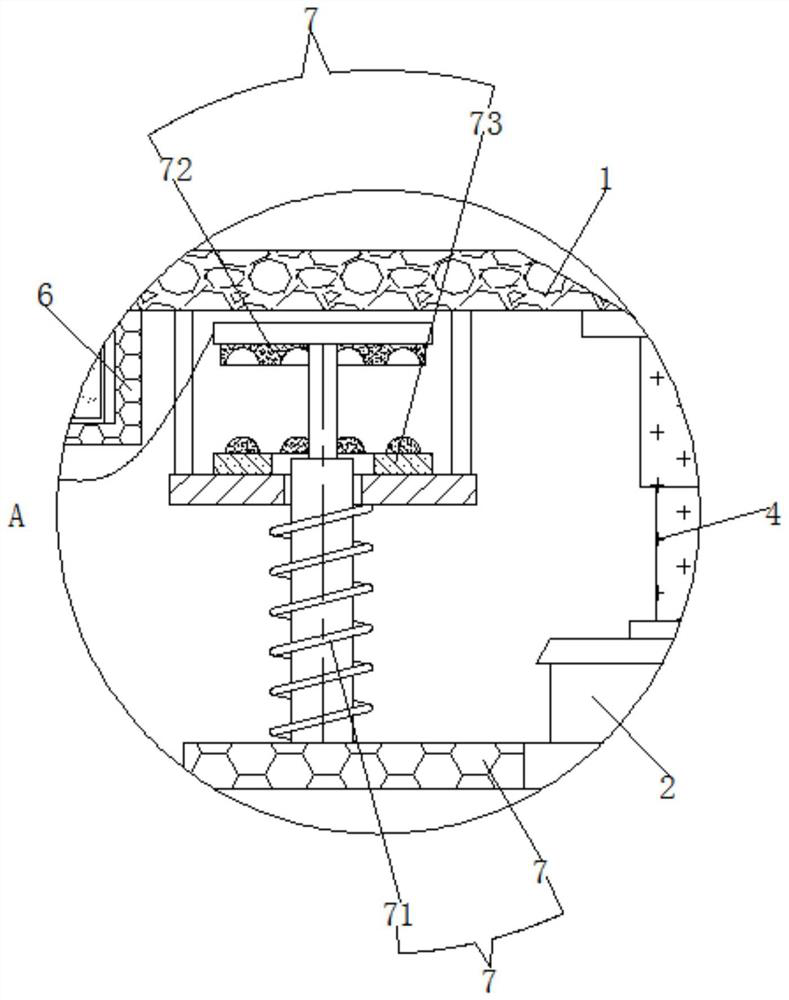

[0027] see Figure 1-4 , a highly safe welding fume auxiliary purification control system for cable distribution boxes, including a body 1, a welding bracket 2 is arranged inside the body 1, and is used to drive a welding head 3 to move, and a welding head 3 is arranged inside the welding bracket 2, It is used to weld the cable distribution box. The surface of the welding bracket 2 is provided with a driving rod 4, which is used to drive the welding bracket 2 to move. The inside of the body 1 is provided with a negative pressure tube 5, which is connected to the negative pressure equipment. , the negative pressure equipment and the control device 6 are electrically connected for absorbing and collecting the smoke.

[0028] The inside of the body 1 is provided with a control device 6, which is used to control the opening and closing of the negative pressure drive equipment connected to the negative pressure tube 5, and the surface of the welding bracket 2 is provided with a tri...

Embodiment 2

[0031] see Figure 1-4 , a highly safe welding fume auxiliary purification control system for cable distribution boxes, including a body 1, a welding bracket 2 is arranged inside the body 1, and is used to drive a welding head 3 to move, and a welding head 3 is arranged inside the welding bracket 2, It is used to weld the cable distribution box. The surface of the welding bracket 2 is provided with a driving rod 4, which is used to drive the welding bracket 2 to move. The inside of the body 1 is provided with a negative pressure tube 5, which is connected to the negative pressure equipment. , the negative pressure equipment and the control device 6 are electrically connected for absorbing and collecting the smoke.

[0032] The inside of the body 1 is provided with a control device 6, which is used to control the opening and closing of the negative pressure drive equipment connected to the negative pressure tube 5, and the surface of the welding bracket 2 is provided with a tri...

Embodiment 3

[0036] see Figure 1-4, a highly safe welding fume auxiliary purification control system for cable distribution boxes, including a body 1, a welding bracket 2 is arranged inside the body 1, and is used to drive a welding head 3 to move, and a welding head 3 is arranged inside the welding bracket 2, It is used to weld the cable distribution box. The surface of the welding bracket 2 is provided with a driving rod 4, which is used to drive the welding bracket 2 to move. The inside of the body 1 is provided with a negative pressure tube 5, which is connected to the negative pressure equipment. , the negative pressure equipment and the control device 6 are electrically connected for absorbing and collecting the smoke.

[0037] The inside of the body 1 is provided with a control device 6, which is used to control the opening and closing of the negative pressure drive equipment connected to the negative pressure tube 5, and the surface of the welding bracket 2 is provided with a trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com