Patents

Literature

38results about How to "Eliminate spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

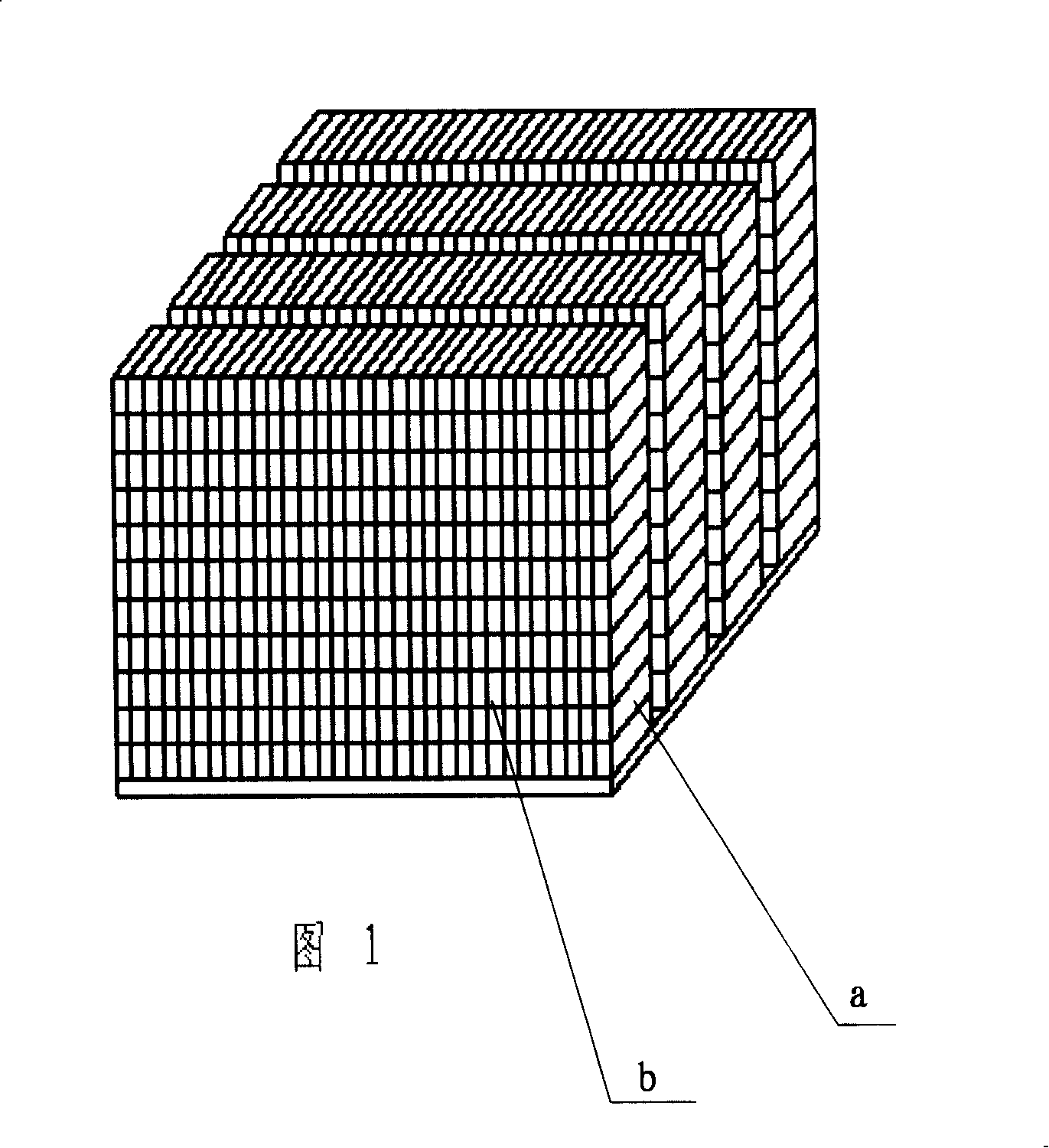

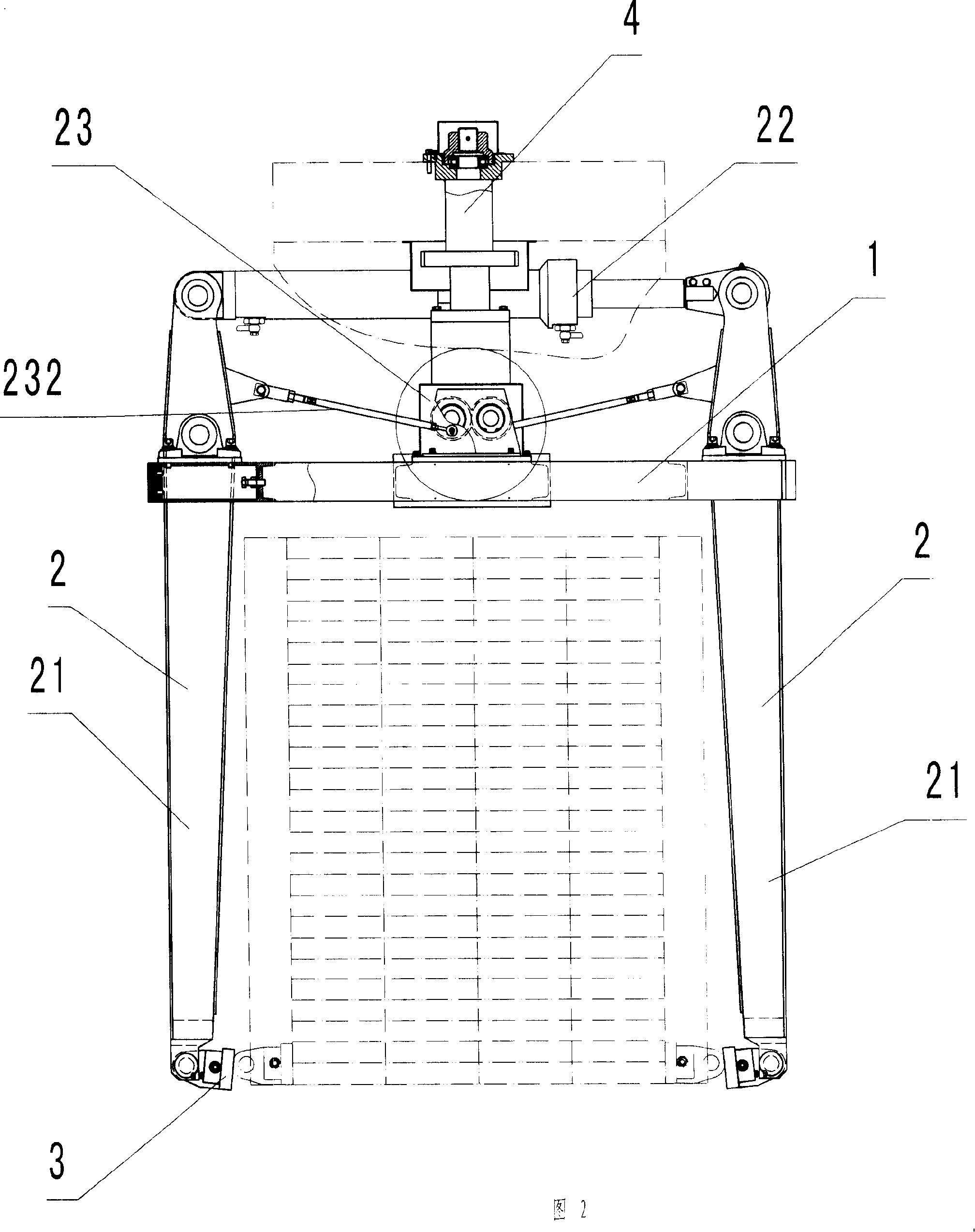

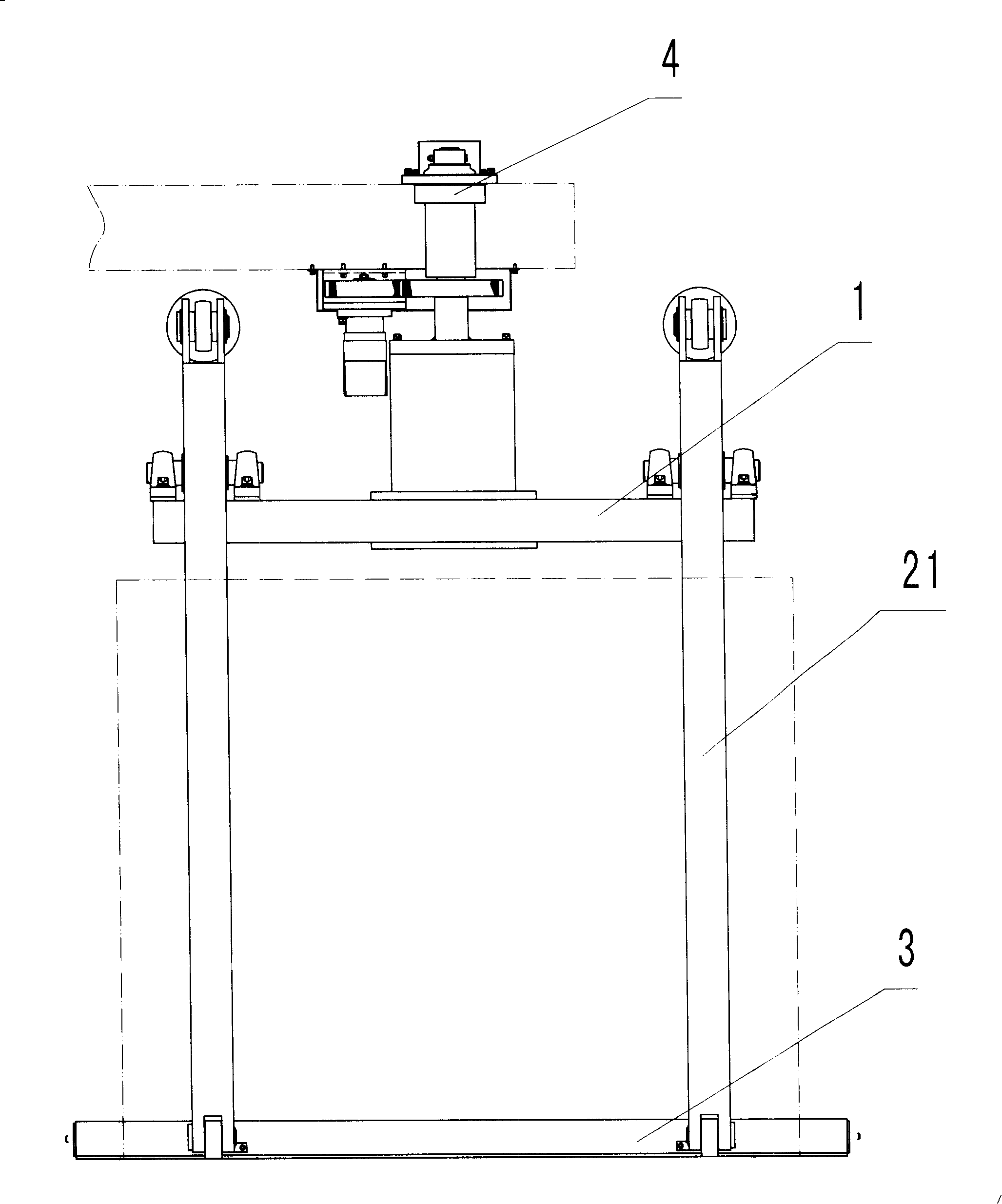

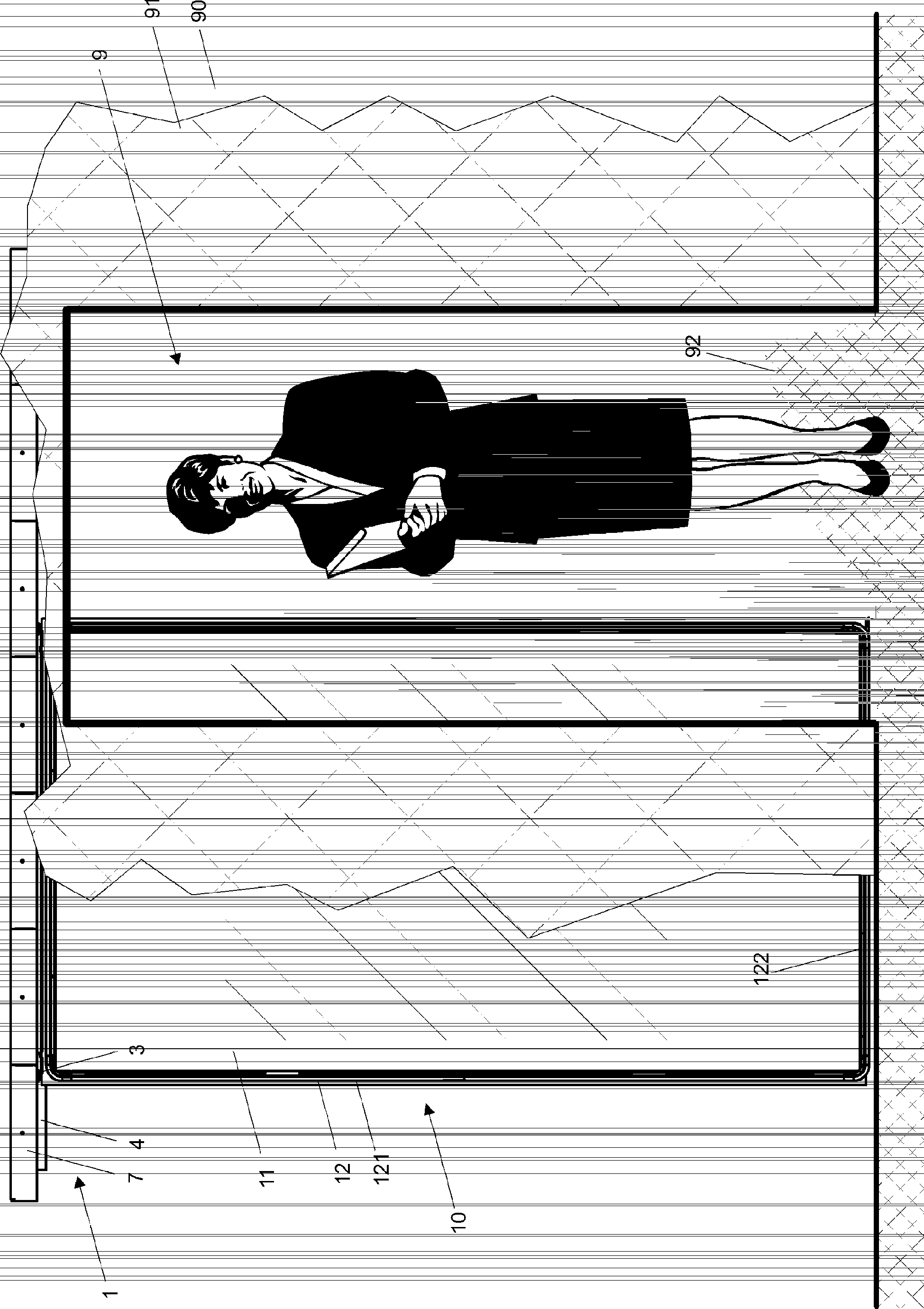

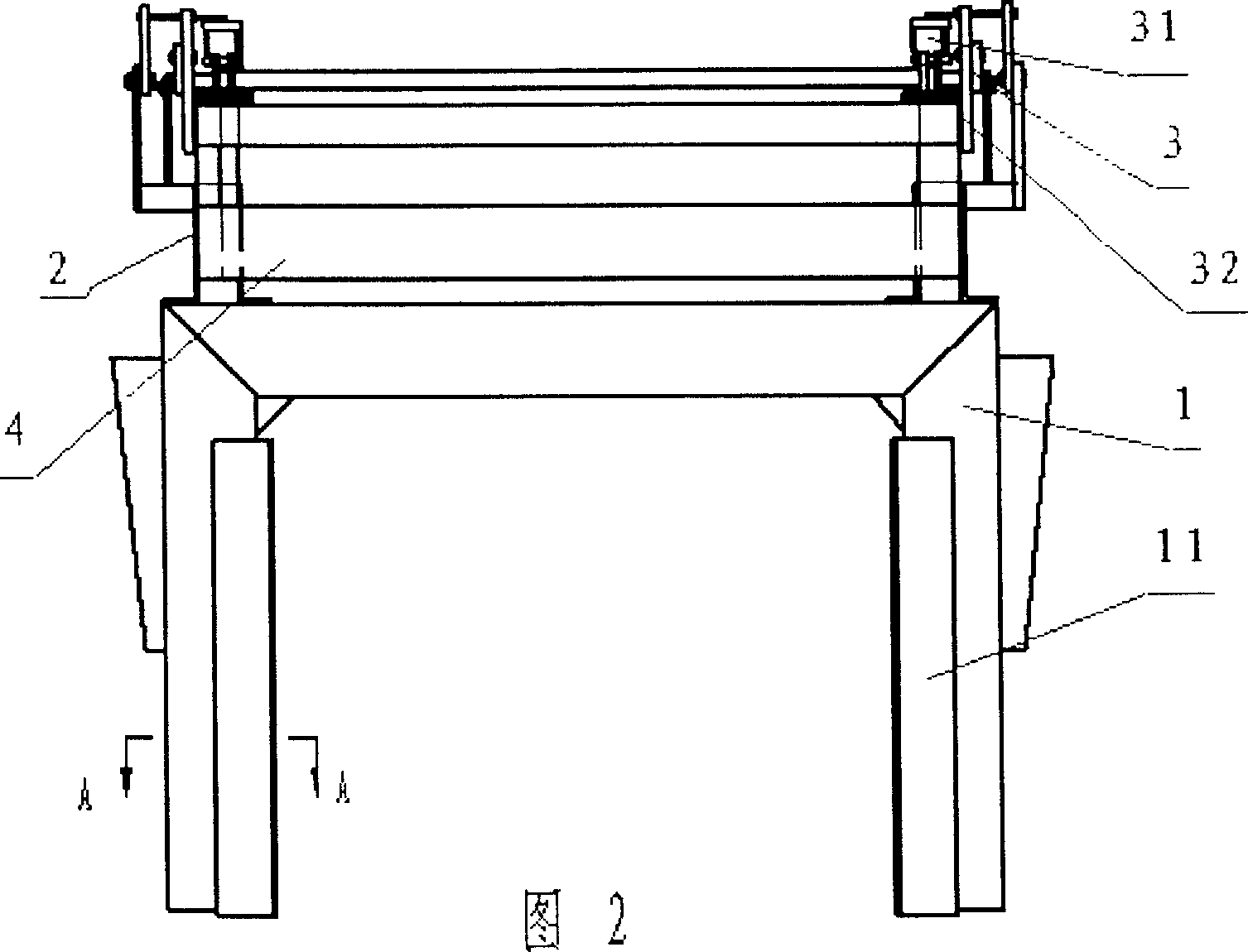

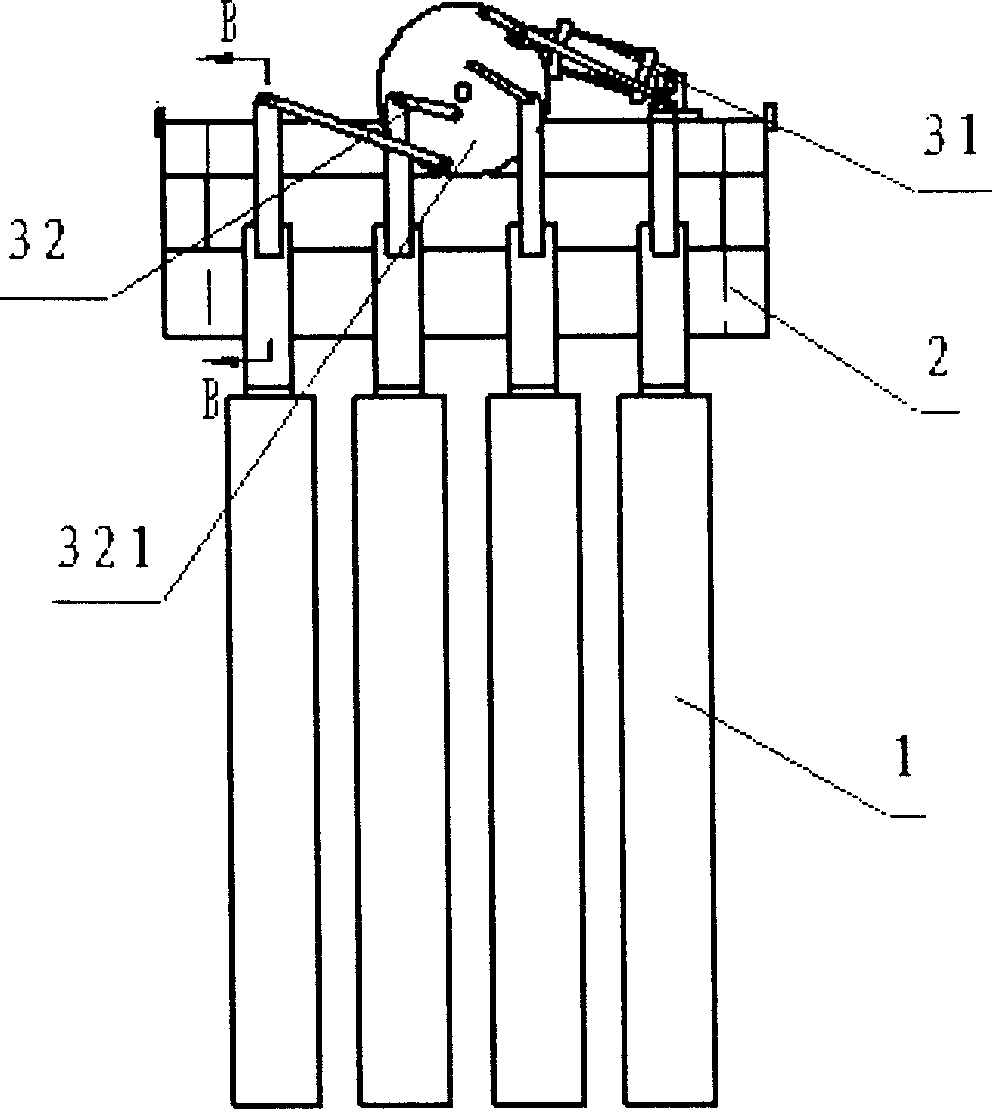

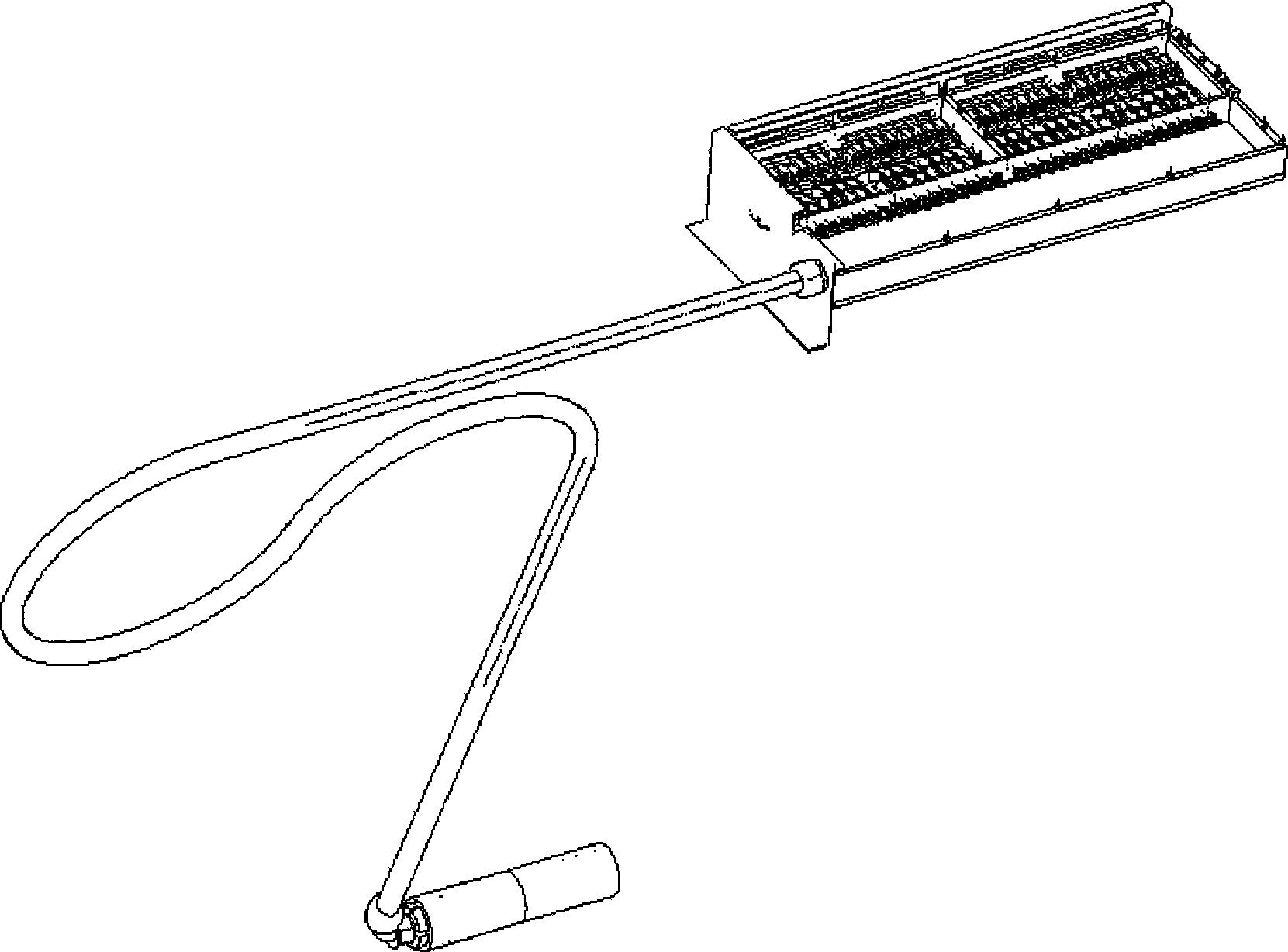

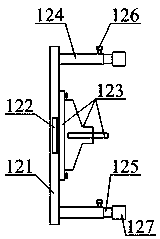

Brick discharging machine

The invention relates to a device for unloading formed products from apparatus, in particular to a brick-unloading machine, which comprises a frame and manipulators. The structural points of the invention are that at least two pairs of manipulators are mounted on the frame, one pair of the manipulator includes two arms, a first power mechanism and a synchronous locking apparatus, arms are hinged on the frame, the first power mechanism and the synchronous locking apparatus are connected in the position between the two arms, a plywood is arranged between the bottom ends of one arm of one pair of manipulator and the on-the-same-side arm of the other pair of manipulator, and the plywood is hinged with each arm. At the time of clamping bricks, the space among palletizing bricks is closed and removed, clamping bricks and closing are finished through the same mechanism, and the brick-unloading machine has simpler structure and more convenient use.

Owner:福建省海源智能装备有限公司

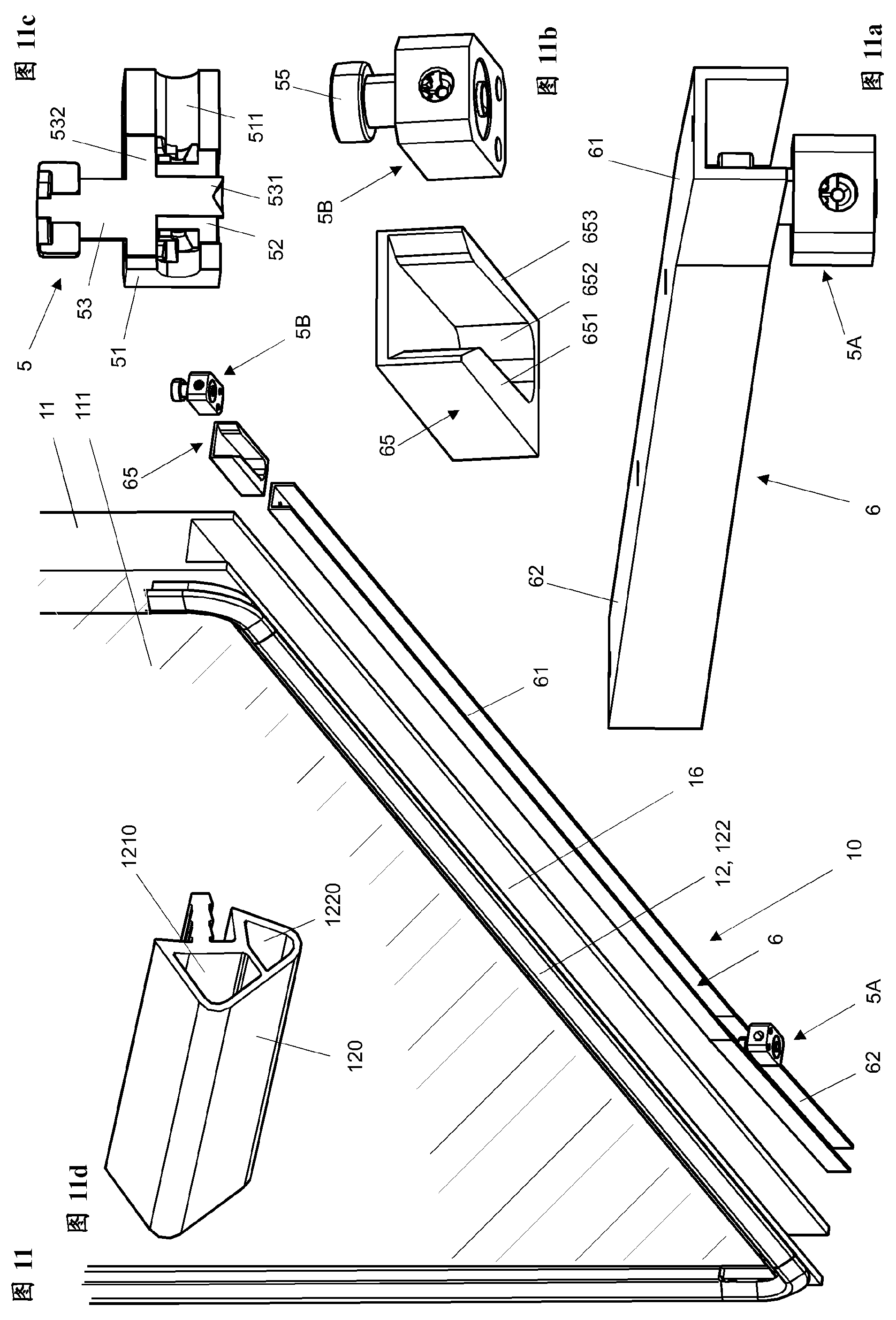

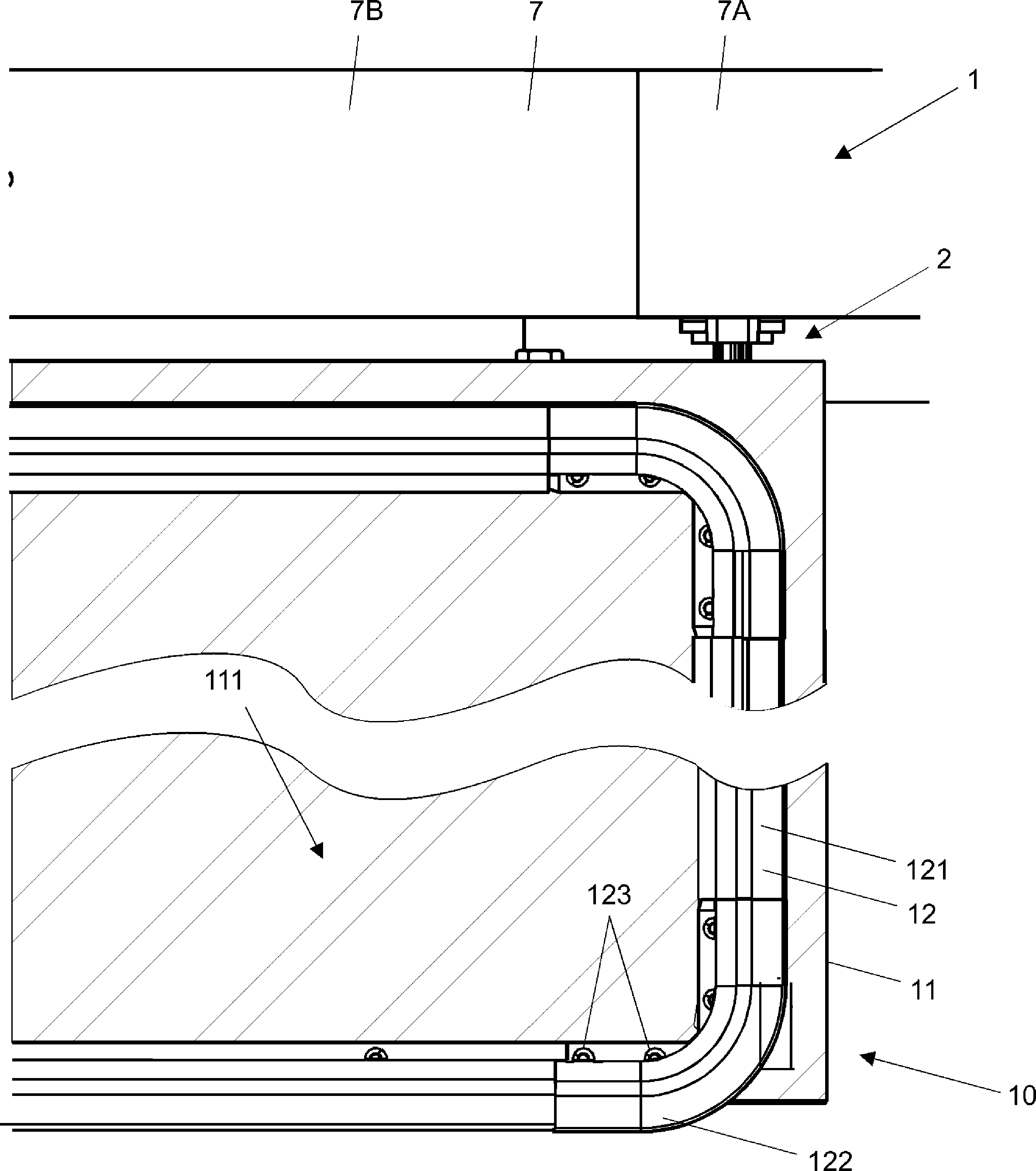

Guiding device, carriage and running rail

ActiveCN103541620AOrientation unchangedEliminate spacingSealing arrangementsWing arrangementsMechanical engineeringCarriage

The invention relates to a guiding device, a carriage and a running rail. The guiding device, which serves for guiding a sliding element, such as a sliding door provided with a door leaf, with which a room opening of a building part can be closed at least approximately tightly, comprises a running rail having a longitudinal axis (x) and at least one carriage that is guided along the running rail and that comprises a carriage body that is connected to a coupling device that is coupled or can be coupled with the sliding element. According to the invention, the running rail comprises a first and a second track that run in parallel and that are inclined towards one another. The carriage body holds first and second running elements that are inclined towards one another and that are supported by the corresponding first or second track, whereby at least one of said first and second tracks comprises a first track section running in parallel to the longitudinal axis (x) and a second track section, along which the carriage can be driven into a terminal position, running inclined to the longitudinal axis (x).

Owner:HAWA AG

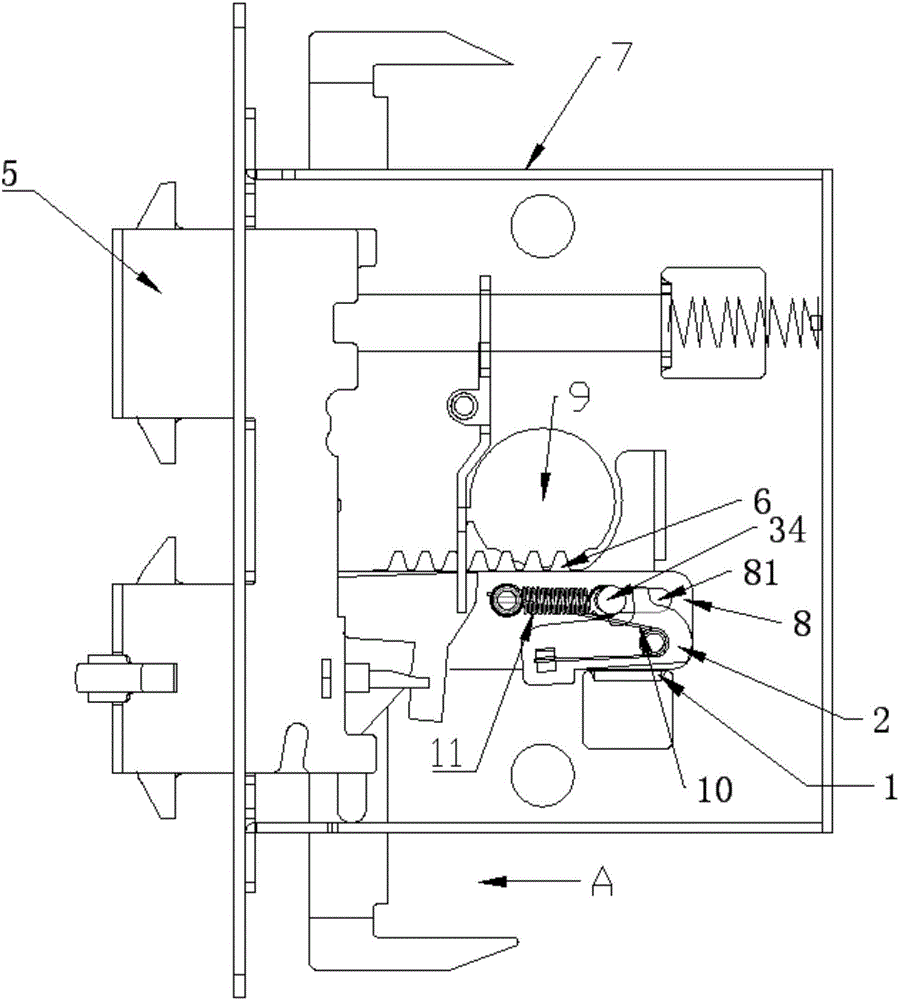

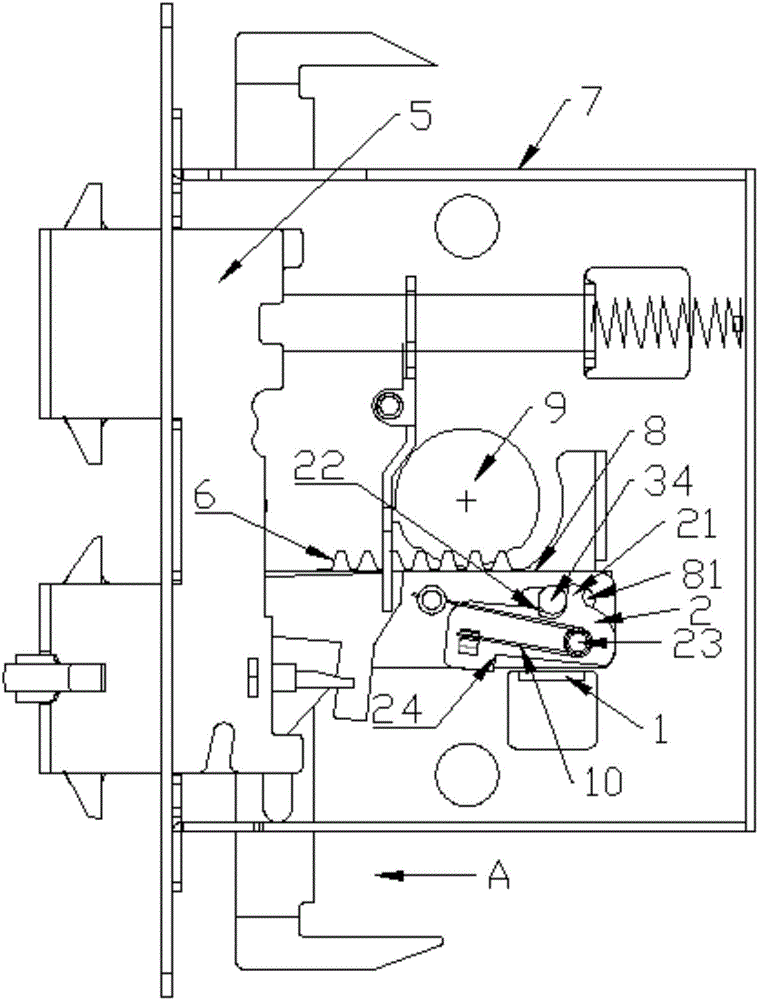

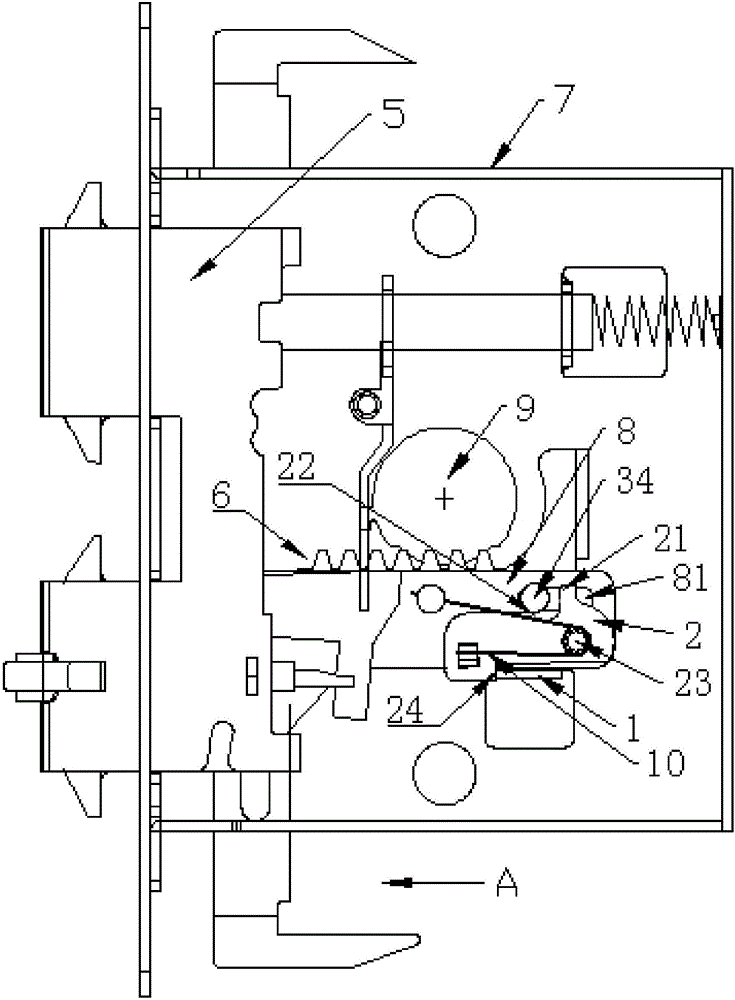

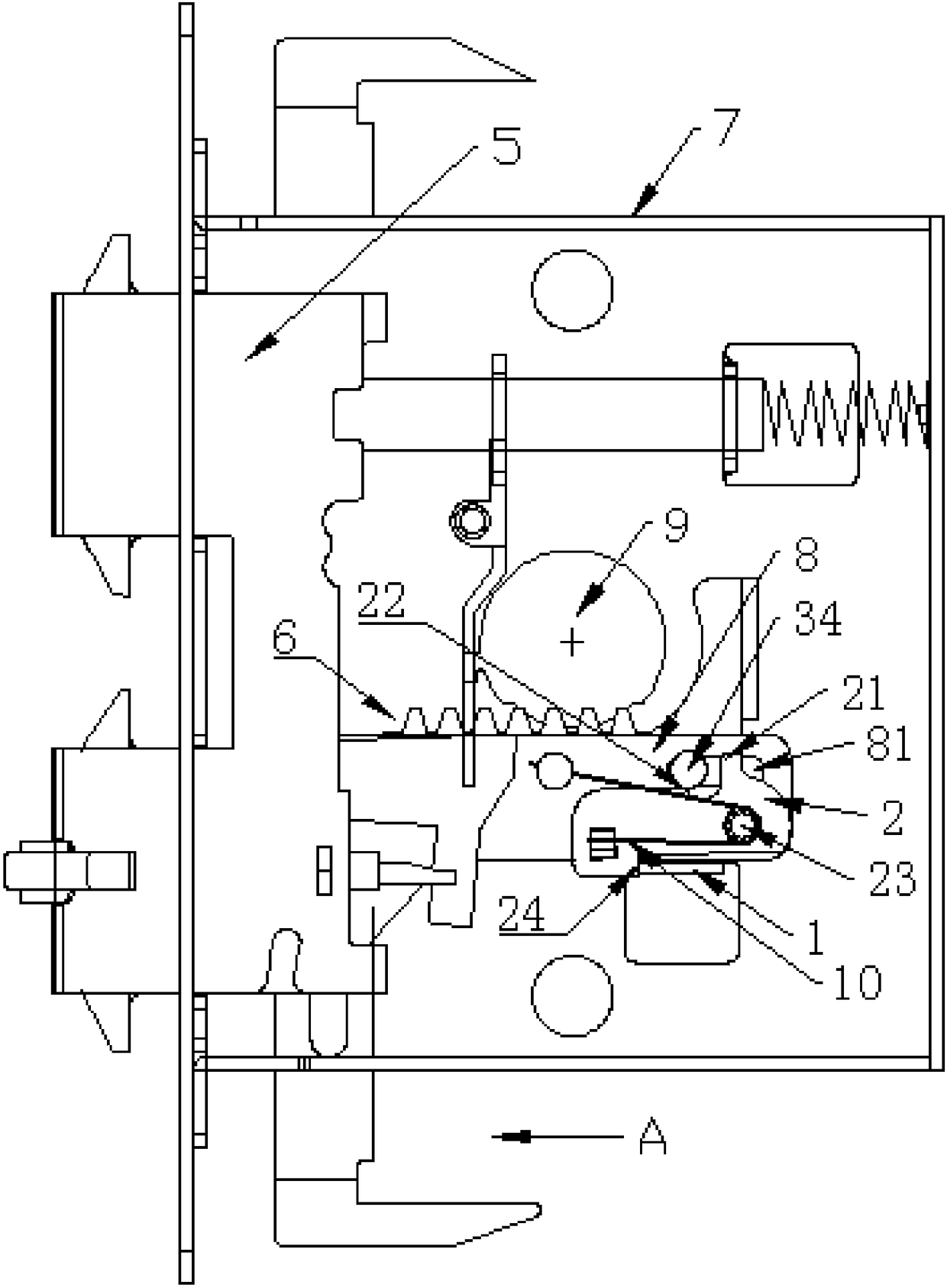

Antitheft opening mechanism used for automatic door lock

ActiveCN106150196AWon't lock upMeet normal anti-theft purposesBuilding locksEngineeringMechanical engineering

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

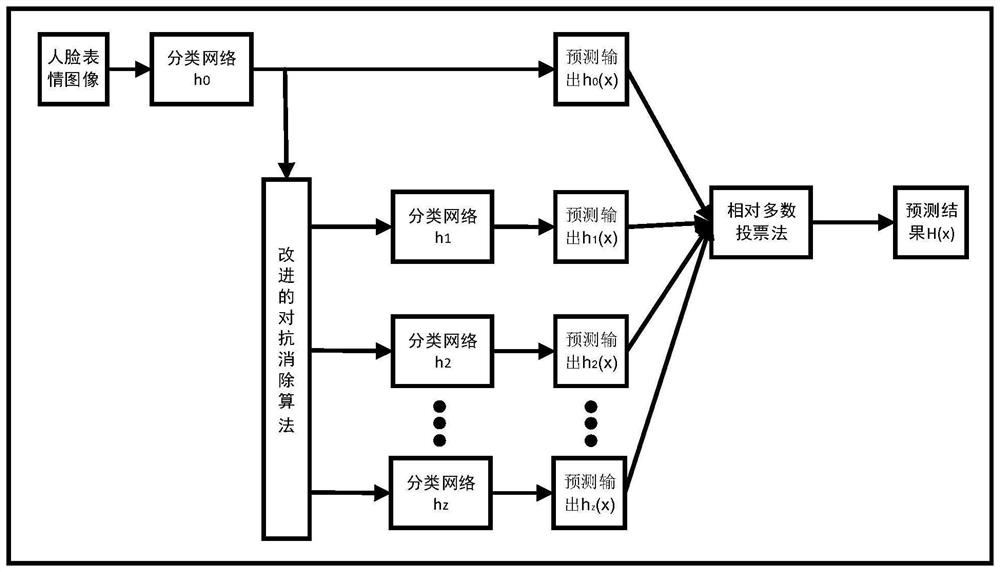

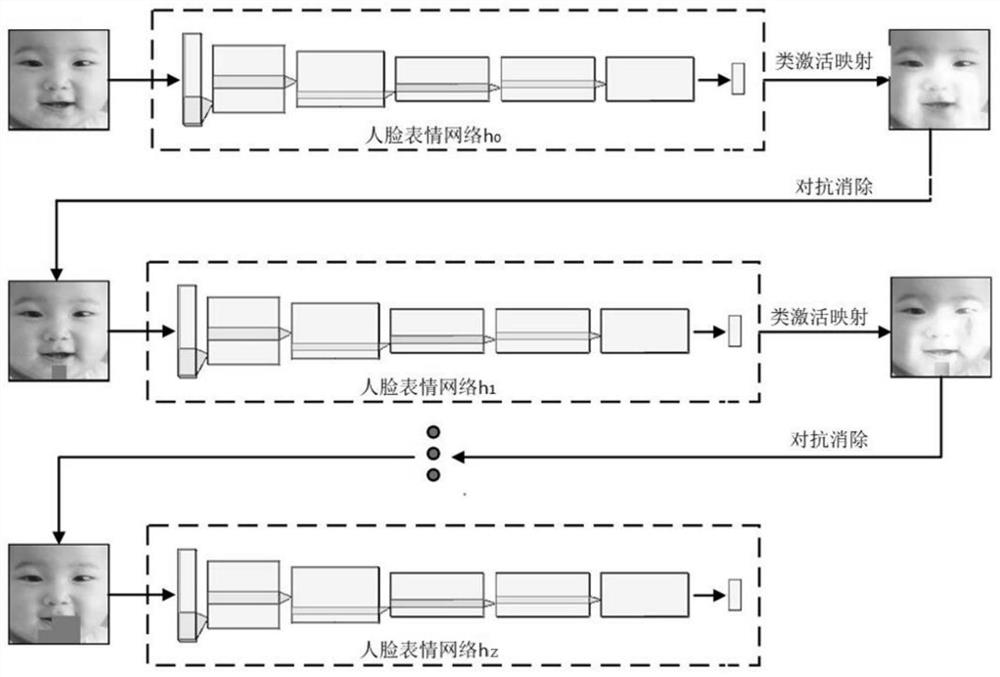

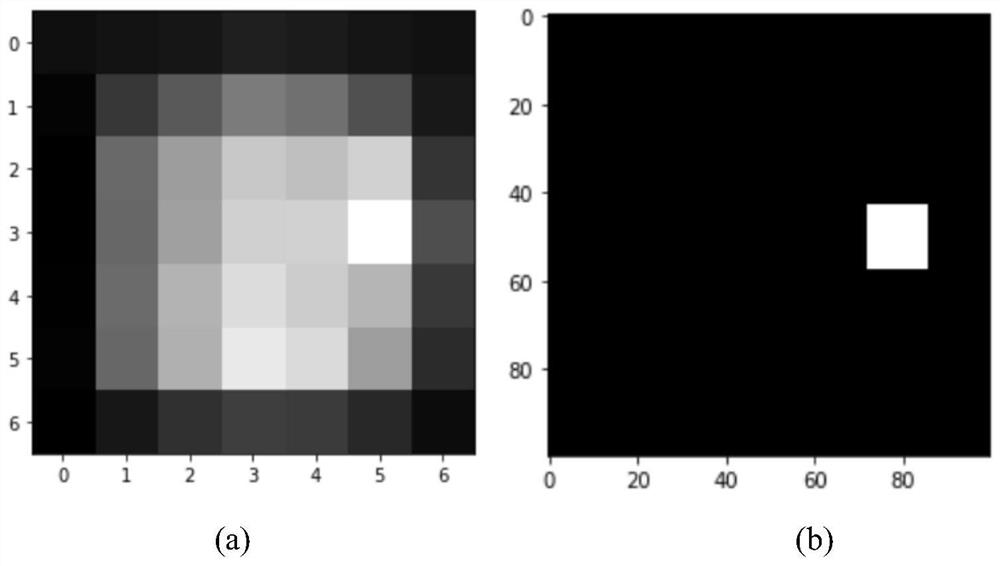

Facial expression recognition method based on confrontation elimination

ActiveCN112990097AEliminate some key featuresReduce the impact of recognition accuracyGeometric image transformationNeural architecturesData setNetwork integration

The invention relates to a face expression recognition method based on confrontation elimination, and relates to the field of computer vision. The method comprises the following steps: firstly, on the basis of a deep convolutional neural network, constructing a facial expression recognition network, and training the facial expression recognition network through a loss function on a natural human facial expression data set to enable facial expression features to be distinguished more easily; then, an improved adversarial elimination method being utilized to actively eliminate part of key features of an input image, a new data set being generated to train a new network with different weight distributions and feature extraction capabilities, and the network being forced to carry out expression classification discrimination according to more features; the influence of interference factors such as shielding on the network recognition accuracy is reduced, and the robustness of the facial expression recognition network is improved; and finally, obtaining a prediction result of final expression classification by adopting network integration and a relative majority voting method. According to the method, the accuracy of the facial expression recognition network is improved, and the interference of shielding factors on the network is effectively reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

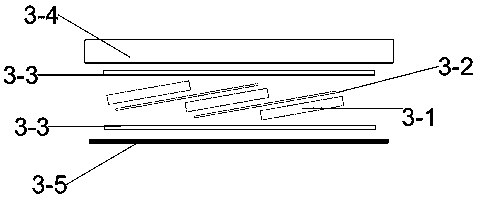

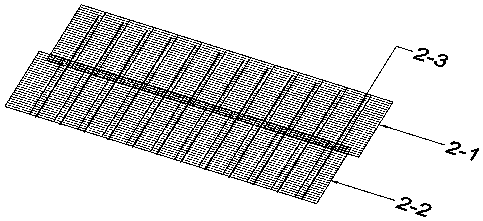

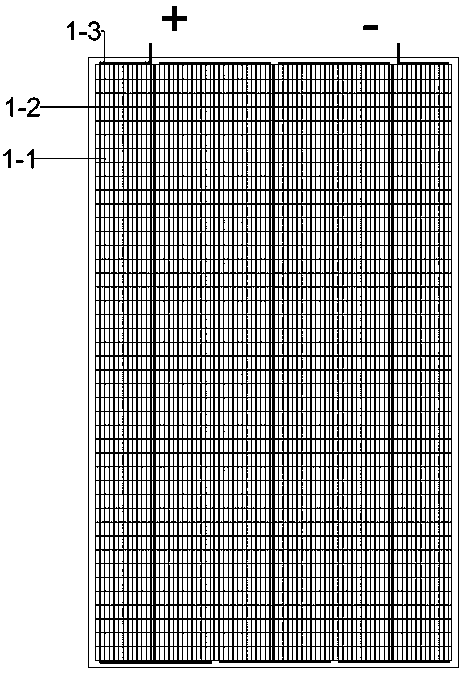

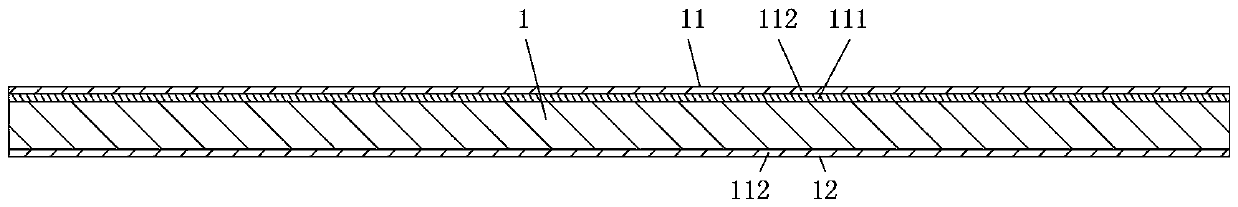

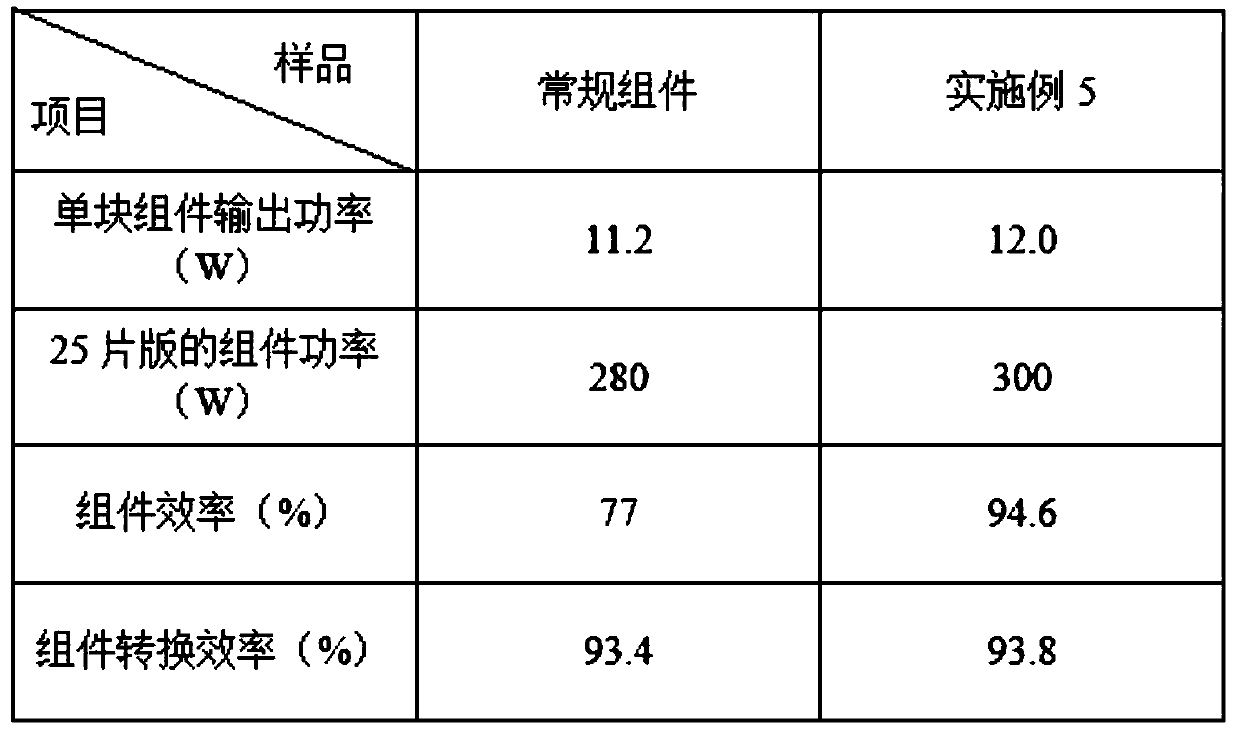

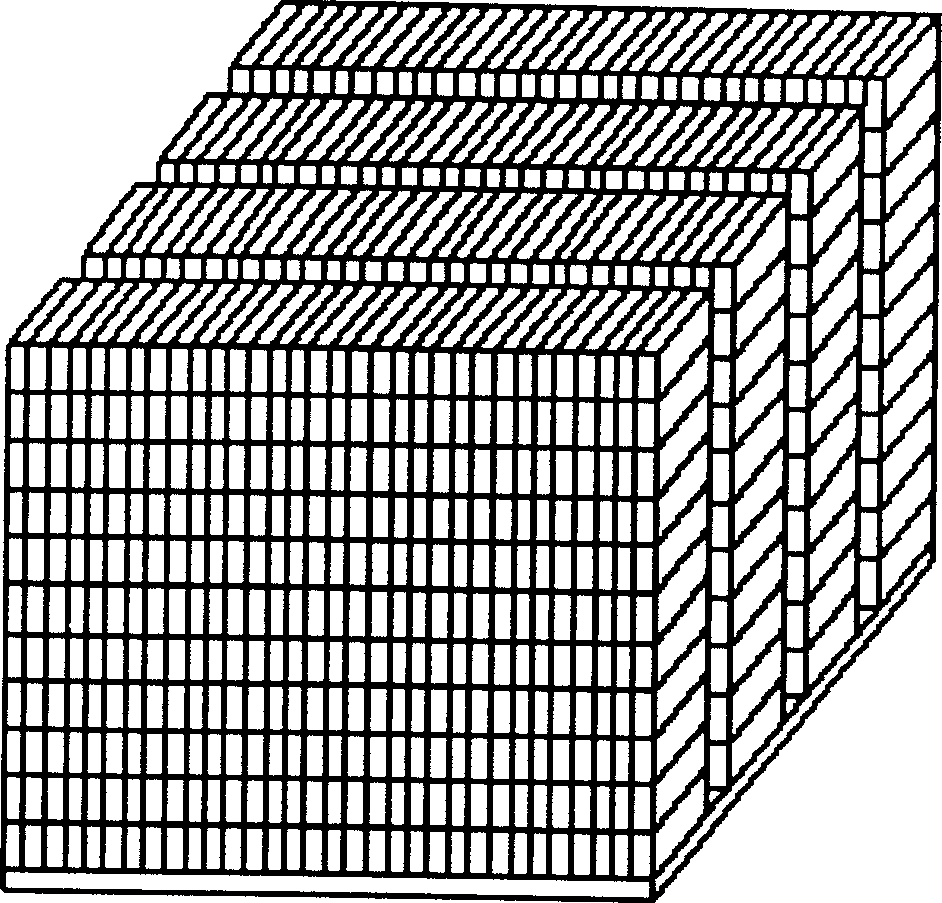

Novel lamination module

PendingCN109360863AImprove reliabilityIncrease powerLight-sensitive devicesFinal product manufactureEffective powerPerovskite solar cell

The invention discloses a novel lamination module. The novel lamination module has the advantages that lamination module design ideas are introduced on the basis of the traditional photovoltaic modules, scribing technologies and ultrathin welding strips are applied, scribed small photovoltaic cell pieces are linked with one another by the ultrathin welding strips in the front-rear directions, front and rear cell pieces are arranged in an overlapped tile manner, and the overlap widths range from 2 mm to 4 mm; the novel lamination module is applicable to solar cells such as crystalline silicon cells, thin film cells, dye-sensitized cells and perovskite solar cells; currents of the cell pieces further can be reduced by the aid of laser scribing technologies, the scribed cell pieces are arranged in the overlapped tile manner, accordingly, the piece distances of the novel lamination module can be eliminated, the effective power generation area of the novel lamination module can be enlarged,and power of the novel lamination module can be increased; the thicknesses of overlapped regions of the cell pieces can be reduced by the aid of the ultrathin welding strips, the fragment rates of overlapped tile cell strings can be reduced, and the reliability of the novel lamination module can be improved; the novel lamination module is compatible with merits of lamination technologies, research and development thoughts can be expanded, research spaces can be enhanced, and the development potential of the novel lamination module can be exploited.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

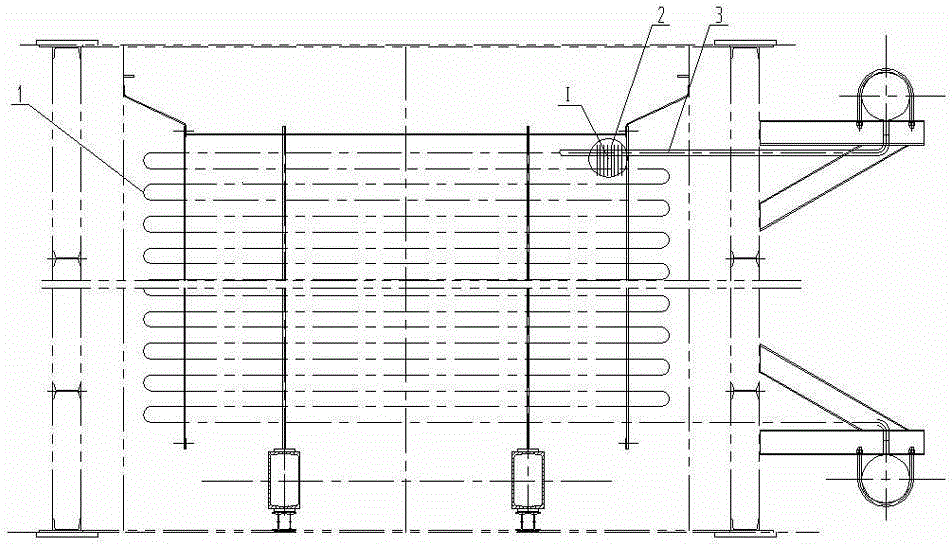

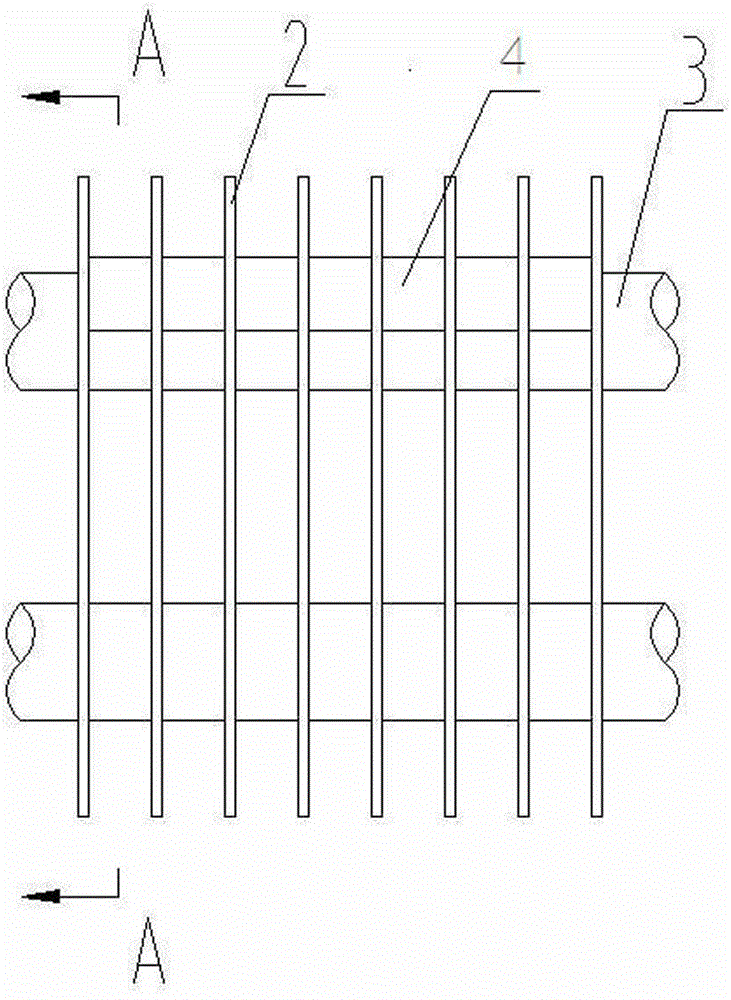

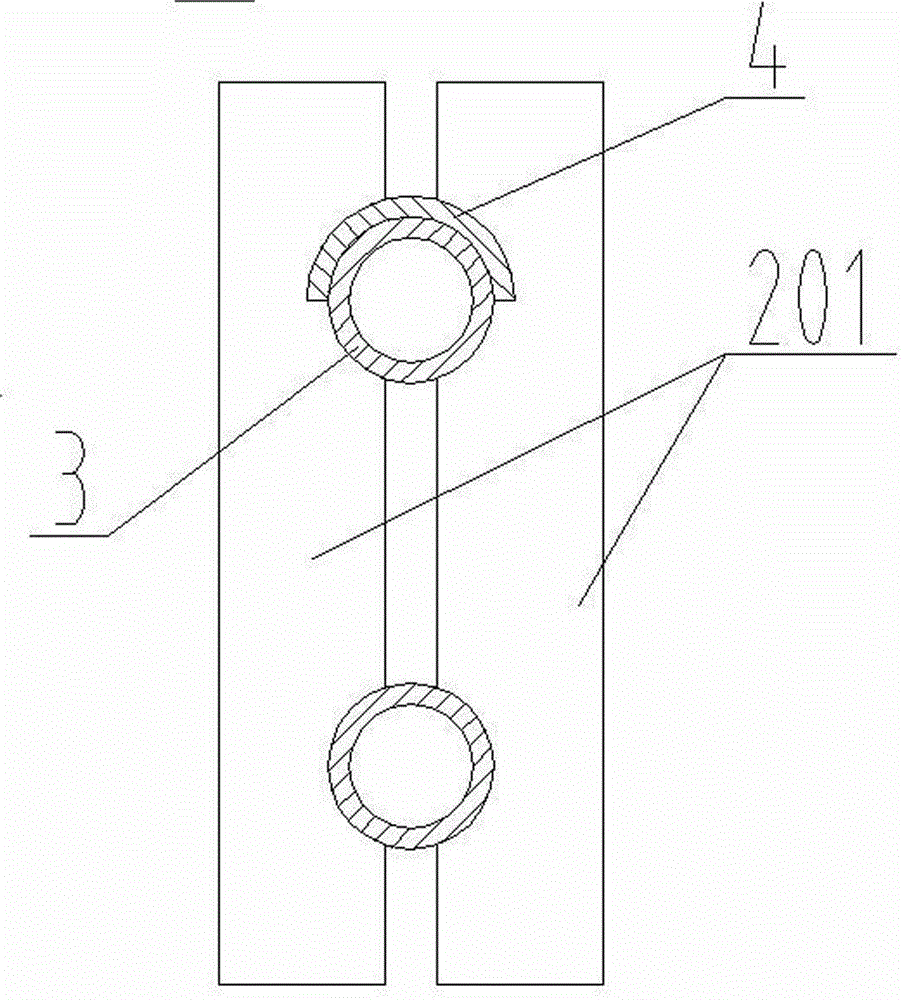

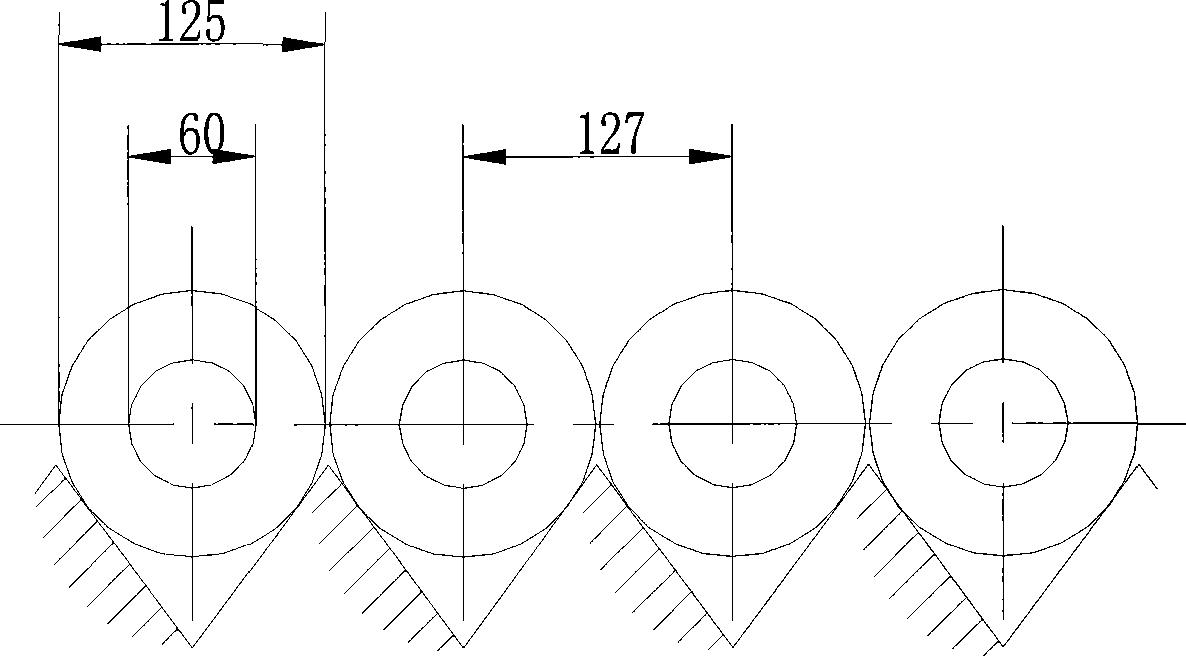

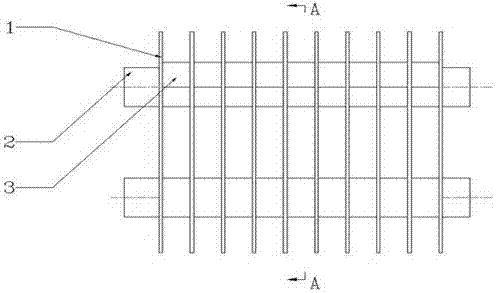

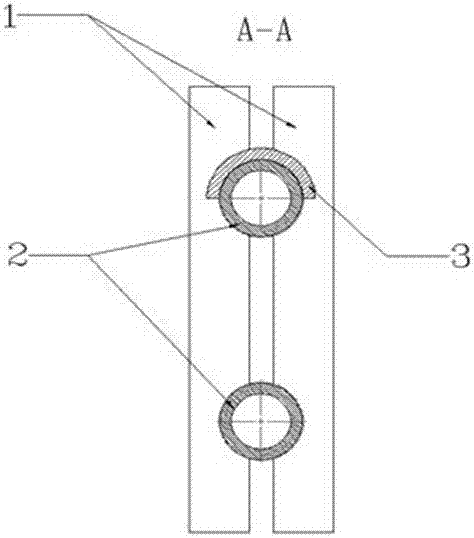

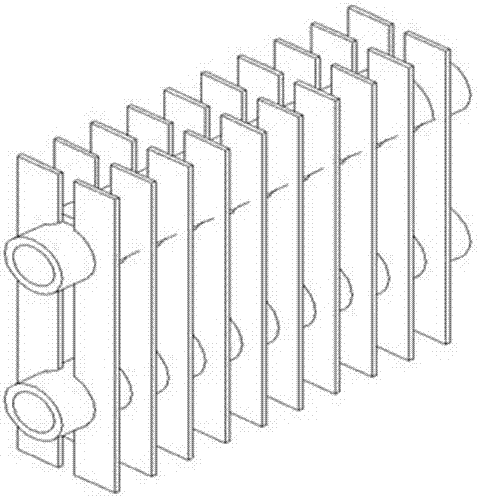

H-shaped finned tube economizer

InactiveCN104566329AAvoid wear and tearExtended service lifeFluid heatersFeed-water heatersEngineeringEconomizer

The invention relates to an H-shaped finned tube economizer, which comprises a plurality of light tubes arranged in parallel, wherein the same ends of the light tubes are alternatively connected together to enable the inner cavities of all light tubes to be communicated; fins are evenly distributed along the longitudinal direction of the light tubes; the sheet surface of each fin is vertical to the longitudinal direction of each light tube. The H-shaped finned tube economizer is characterized in that each fin comprises two long plates with the same length and the same width; arc-shaped grooves are evenly distributed on the longitudinal direction of one long edge of each long plate, wherein the shapes of the arc-shaped grooves are adaptive with the shapes of sections of all light tubes, and the number of the arc-shaped grooves is the same with the number of the light tubes; one edge, which is provide with the arc-shaped grooves, of one long plate and one edge, which is provided with the arc-shaped grooves, of the other long plate are oppositely connected to all light tubes to enable the fins on the same plane on each light tube to be formed into a whole. The economizer has the advantages of large heat exchange area and high heat exchange efficiency and is suitable for a coal-fired boiler.

Owner:WUXI DONGMA BOILER

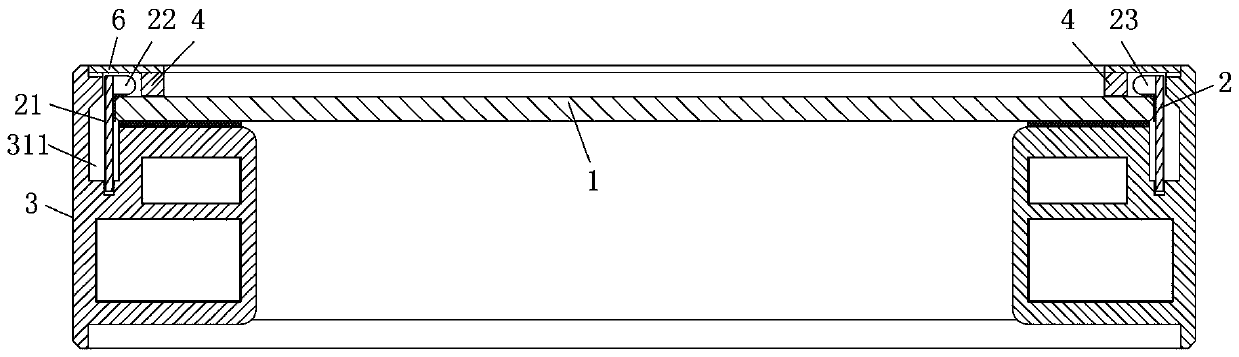

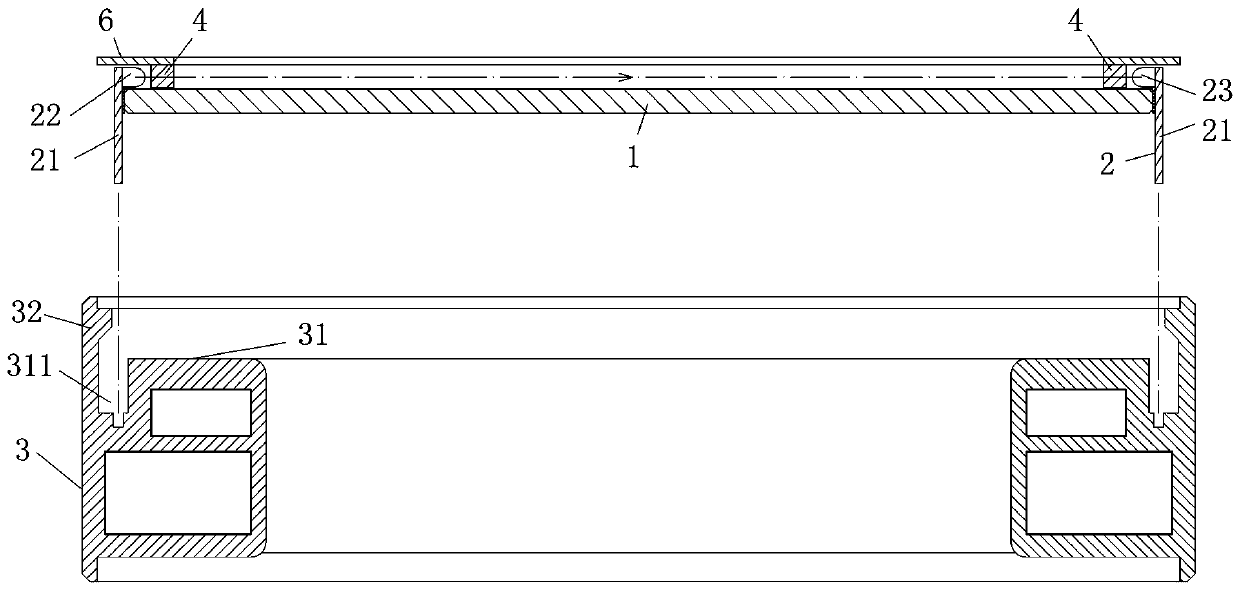

Infrared touch glass mounting structure, touch precision adjusting method and application

PendingCN110134291AMeet the sealing performanceSimple structureInput/output processes for data processingInfraredLiquid-crystal display

The invention discloses an infrared touch glass mounting structure. An infrared transmitting tube and an infrared receiving tube are respectively adhered to the periphery of the front surface of the glass reference plate; the touch effect can be adjusted during pasting; after the warping surface of the glass reference plate is measured, sand blasting etching processing is performed on the back surface of the warped surface, and finally chemical strengthening is performed, the warping degree of the glass can be corrected; the heights of all the infrared transmitting tubes and all the infrared receiving tubes of the infrared geminate transistors on the glass reference plane are further ensured to be the same; the infrared emission light path and the infrared receiving light path are both located in an infrared light channel of the infrared filtering strip, so that the touch height of the infrared touch control glass is equal to the radius of the infrared emission tube and the radius of the infrared receiving tube, and the touch control sensitivity is improved; the infrared touch screen and the back plate of the backlight module are attached to the screen supporting frame, and full sealing of the infrared touch liquid crystal display module is achieved.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

Preparation process of high-density imbricated module

InactiveCN109728131AImprove power generation efficiencySave spaceFinal product manufacturePhotovoltaic energy generationConductive pastePower flow

The invention discloses a preparation process of a high-density imbricated module. The preparation process comprises the following steps of: preparation of a slice without a main grid cell; preparation of a battery string; preparation of a long string of cells; preparation of an imbricated module; primary EL test; laminated packaging; framing and assembling of the junction box; and secondary LE test. The obtained high-density imbricated module improves the utilization rate of the defective pieces and improves the module power through a mode of reducing the battery area and reducing the currentmismatching loss, the battery pieces are sliced to be connected in series by employing conductive paste to remove the distance between the battery pieces so as to greatly save the assembling space, the innovative electrical design without the main grid is employed to reduce the internal loss of the module, effectively improve the output power of the single module and improve the module conversionefficiency, and therefore, the preparation process of the high-density imbricated module has an considerable competitiveness and is expected to occupy the mainstream position in the market.

Owner:JETION SOLAR HLDG

Brick-unloading machine

The invention relates to a device for discharging final product, especially providing a brick discharger, which comprises a straight guide rail, a folder, a frame and dual mechanical hands. Wherein, said mechanical hands are mounted with clampers; all mechanical hands are parallel arranged on the straight guide rail to connect the folder; said straight guide rail is fixed on the frame. With said invention, it can realize mechanical operation, and avoid the distance between bricks to reach more bricks in unit volume. And it can reduce the labor force, improve producing efficiency and reduce occupied area.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

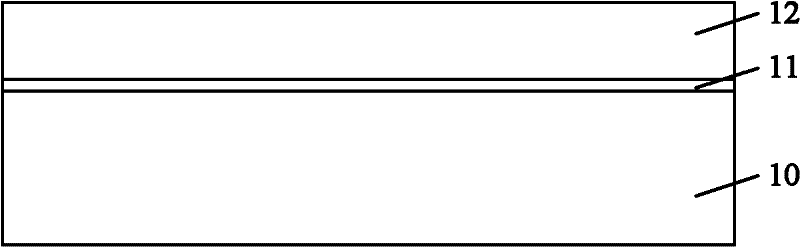

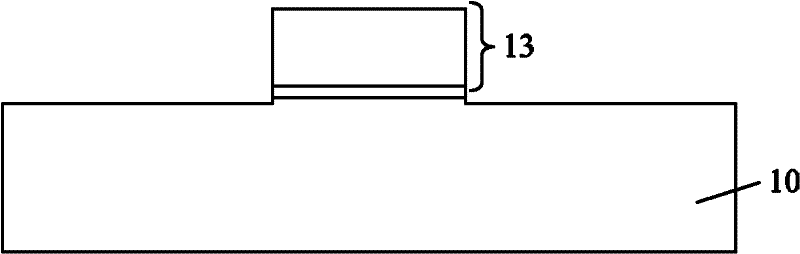

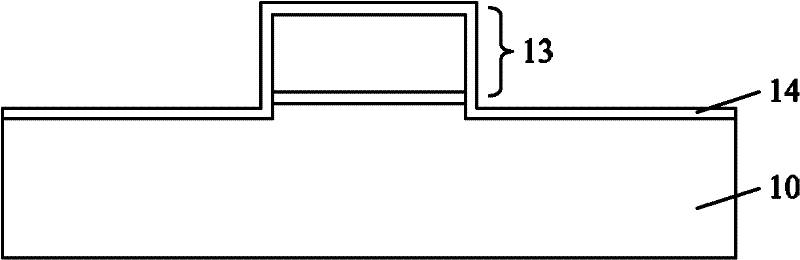

Manufacturing method of MOS (metal oxide semiconductor) device

InactiveCN102543743AEliminate spacingAvoid electrical influenceSemiconductor/solid-state device manufacturingGate dielectricHeight difference

The invention provides a manufacturing method of an MOS (metal oxide semiconductor) device. The manufacturing method comprises the following steps of: providing a semiconductor substrate and forming a hard mask layer on the surface of the semiconductor substrate; etching the hard mask layer and the semiconductor substrate to form a first groove, wherein the bottom surface of the first groove is lower than the surface of the semiconductor substrate, and the height difference exists between the two; forming a gate dielectric layer on the surface of the semiconductor substrate at the bottom of the first groove; filling the first groove to form a gate electrode; removing the hard mask layer; and forming a thin film oxidation layer on the surface of the semiconductor substrate through a heat oxidation process, wherein the bottom surface of the thin film oxidation layer is higher than or flush with that of the gate dielectric layer. According to the manufacturing method disclosed by the invention, the bottom of the gate electrode is lower than the surface of the semiconductor substrate, and the height difference exists between the two; and when the thin film oxidation layer is formed by heat oxidation, the thickness loss of the semiconductor substrate is not greater than the height difference, so that a spacing interval between the bottom of the gate electrode and a channel is further eliminated and a silicon recess can be further prevented from affecting the electrical properties of the MOS device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

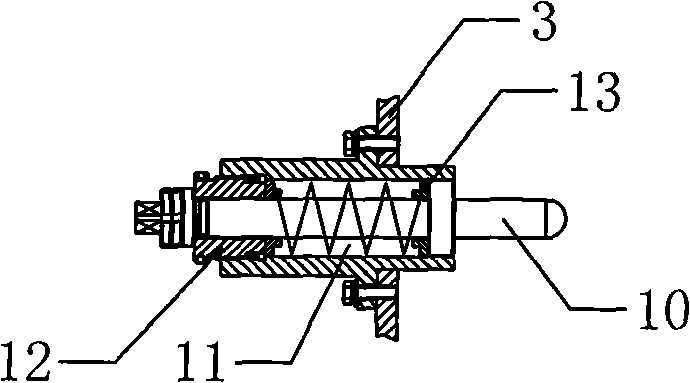

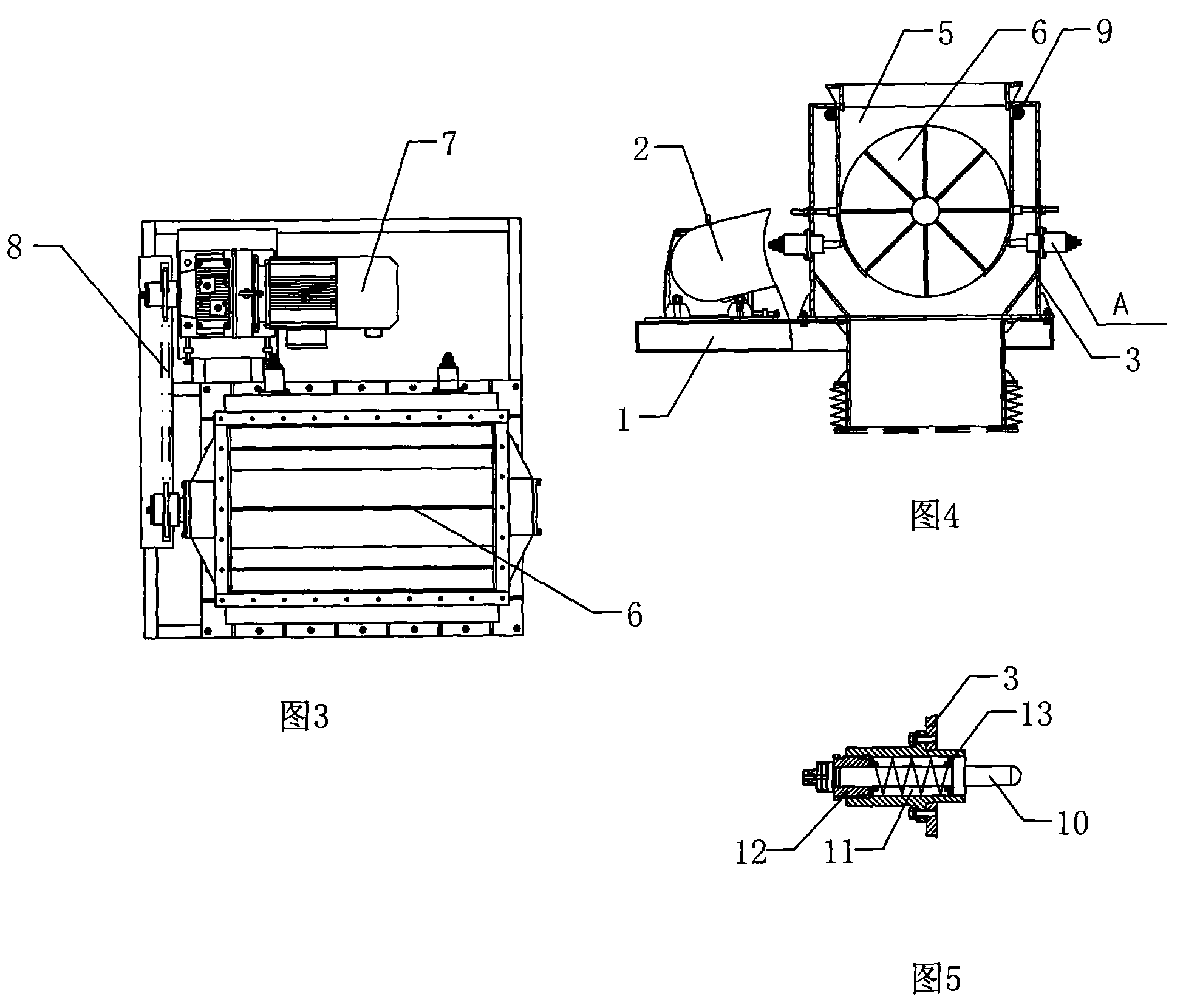

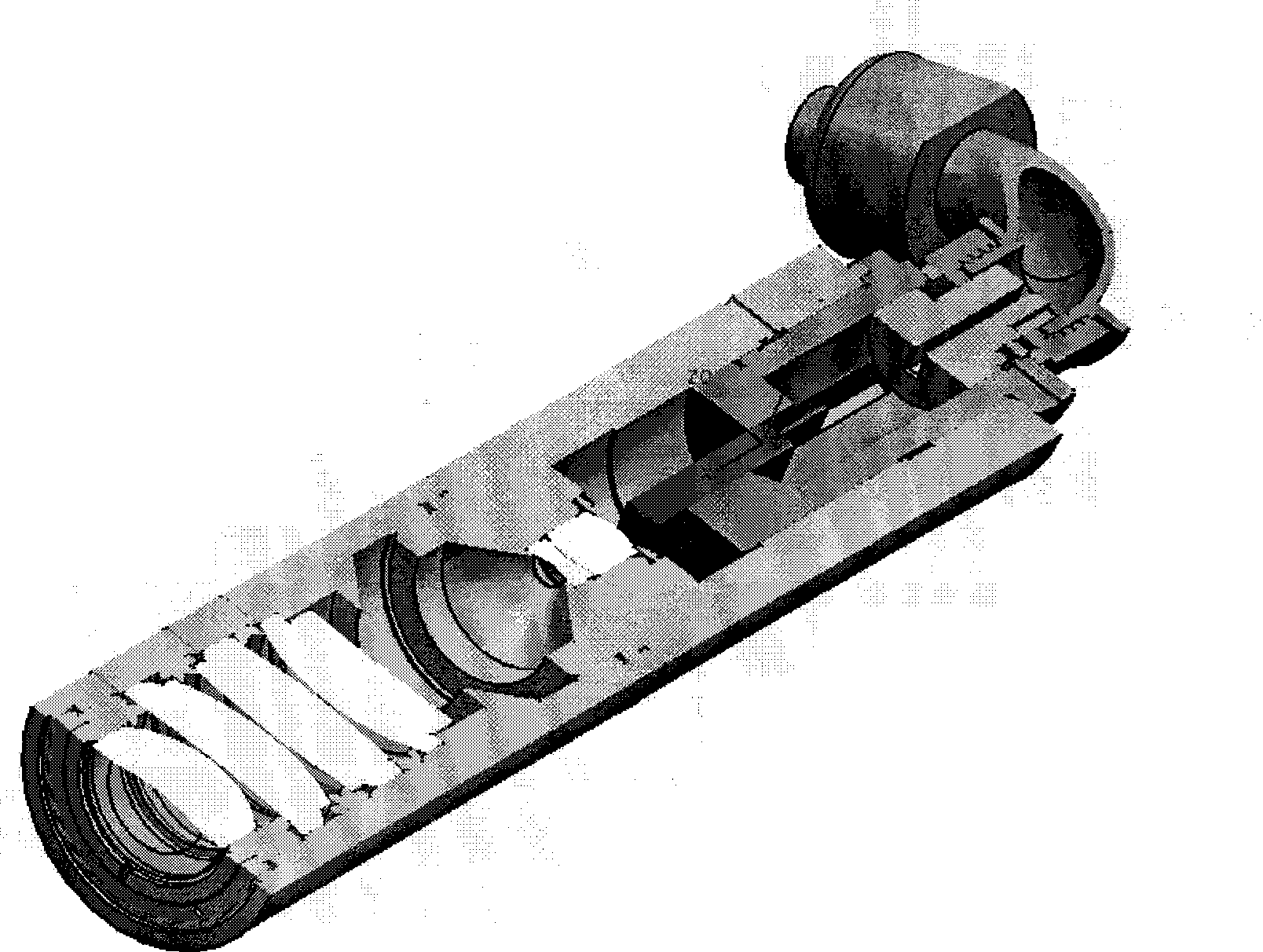

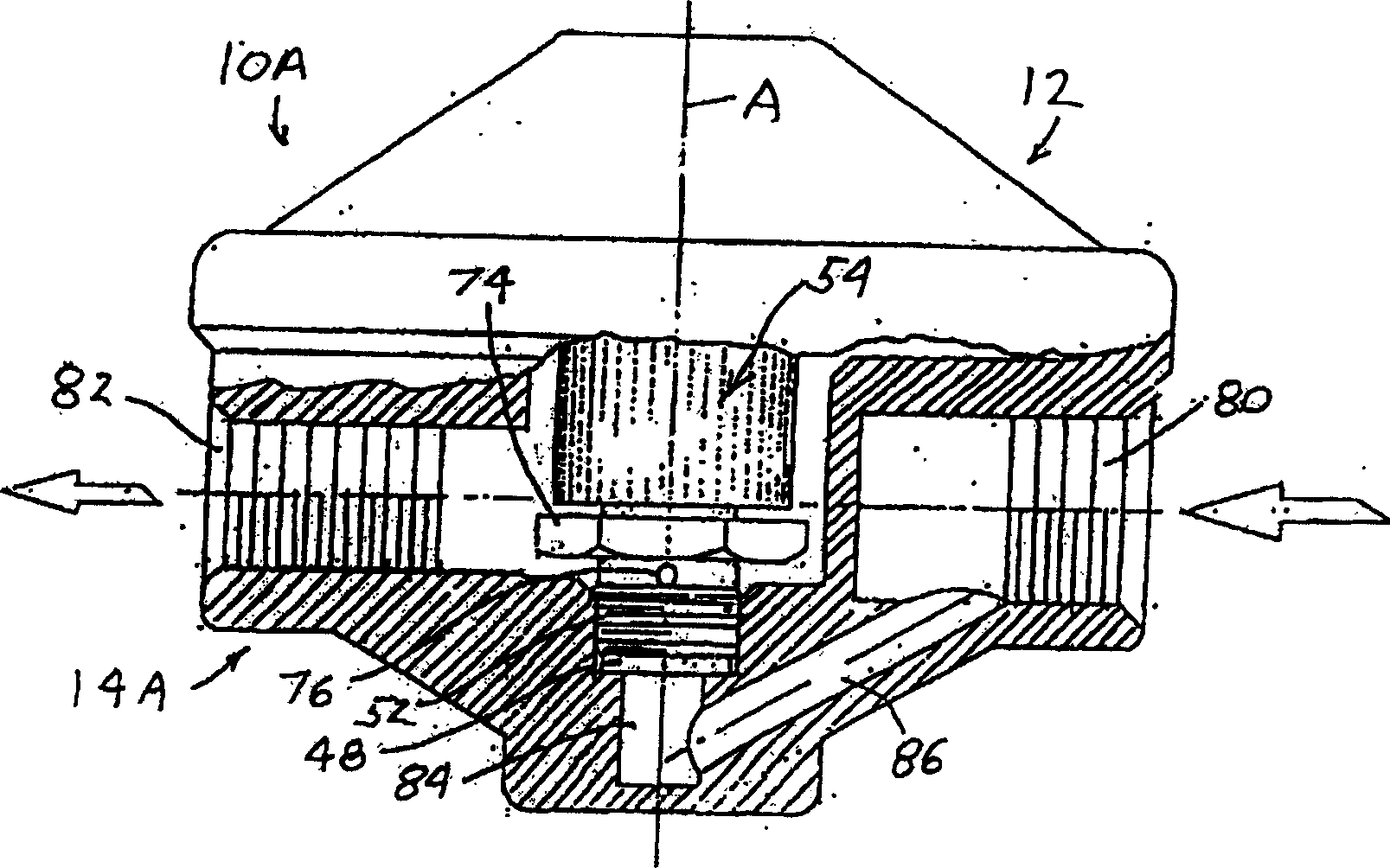

Improved anti-blockage device used for crushed straw aggregate feeding machine

InactiveCN101551113AMake sure to lock the airEliminate blockingLump/pulverulent fuel feeder/distributionEngineeringFlange

The invention relates to an improved anti-blockage device used for crushed straw aggregates feeding machine, which can timely close the space between a rotor and the U-shaped funnel so as to realize the air locking of the boiler and reduce the possibility of fire hazard. The device is characterized by comprising an apical axis which is installed on a bushing, the shoulder of the apical axis is matched with a clearance at one end of the bushing, a pot head is arranged between the other end of the apical axis and the other end of the bushing, a spring is arranged between the pot head and the axis shoulder in a pressing way, the axis shoulder at the end part of the apical axis is arranged on the pot head in a pressing way, and the external diameter of the flange of the pot head is larger than the internal diameter of the bushing.

Owner:WUXI XIDONG ENERGY TECH

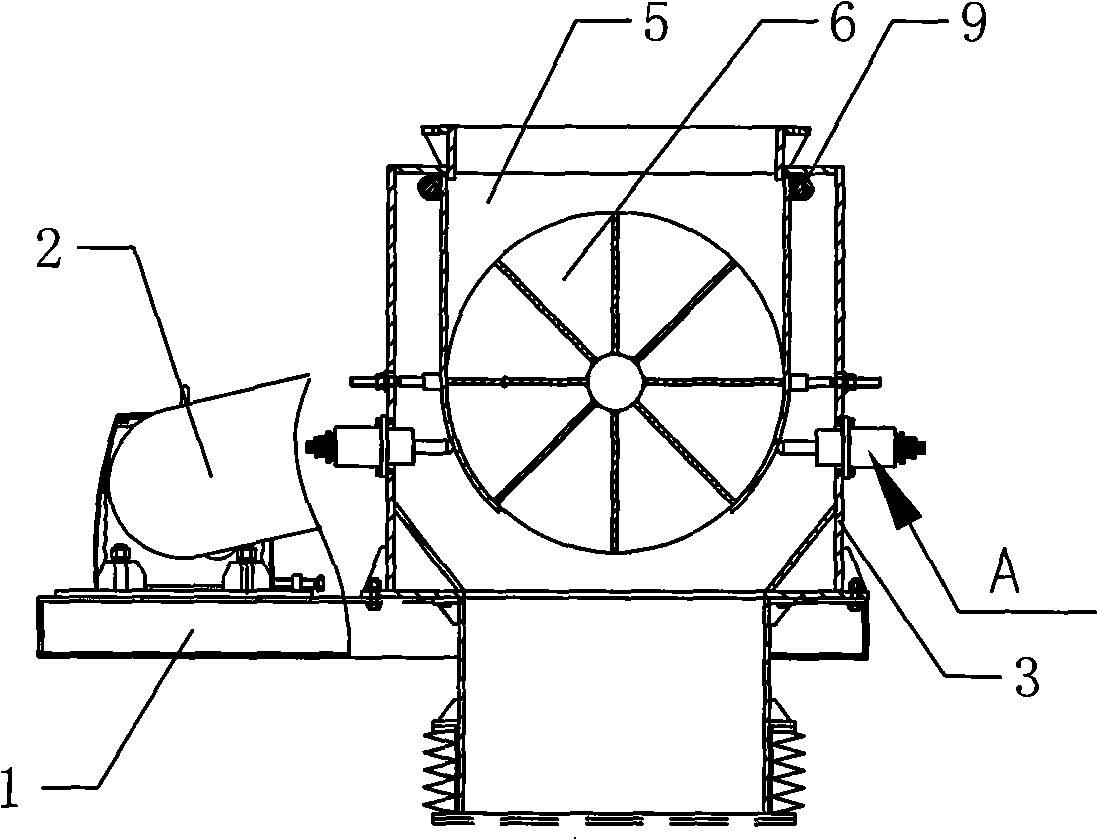

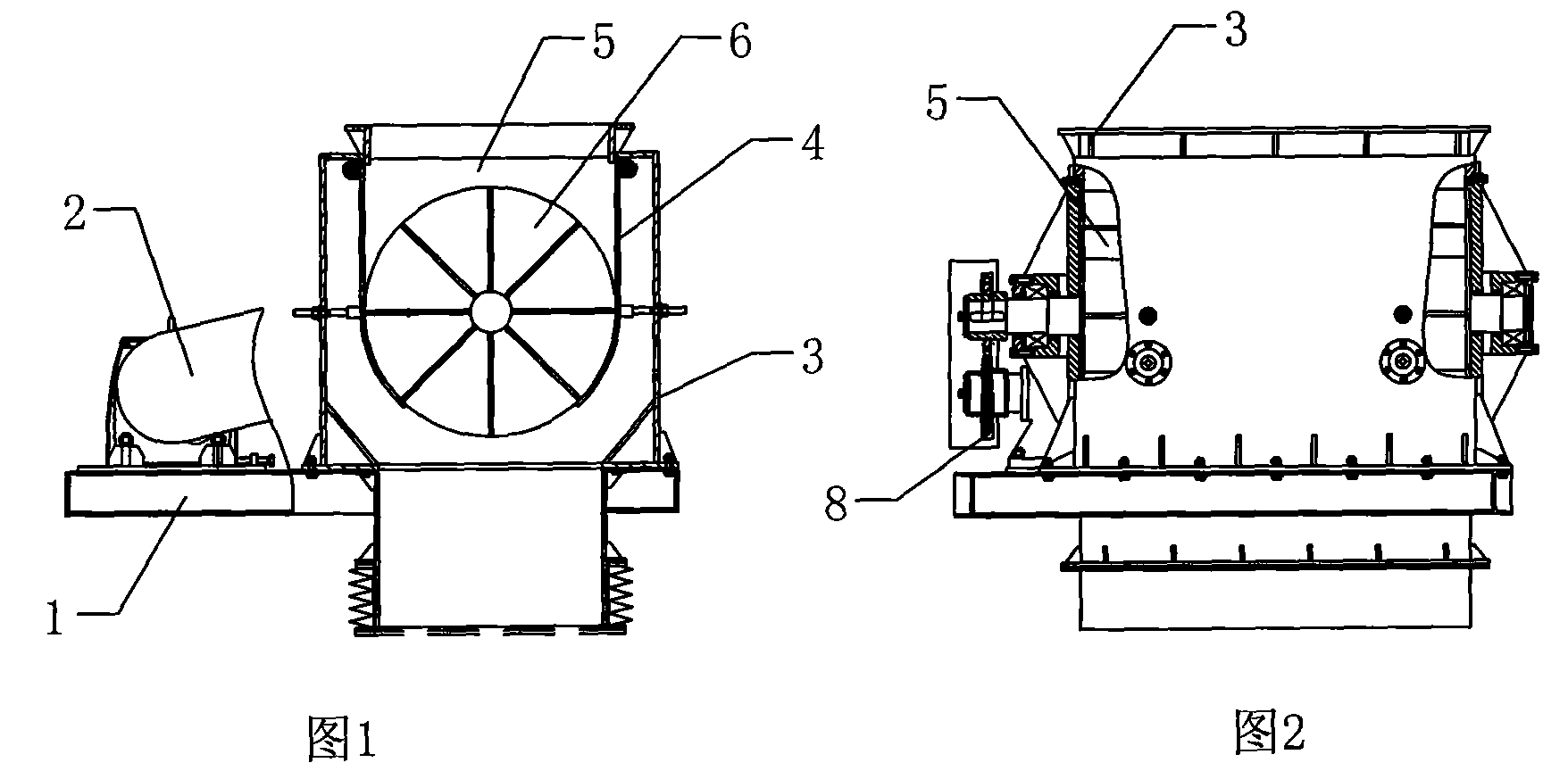

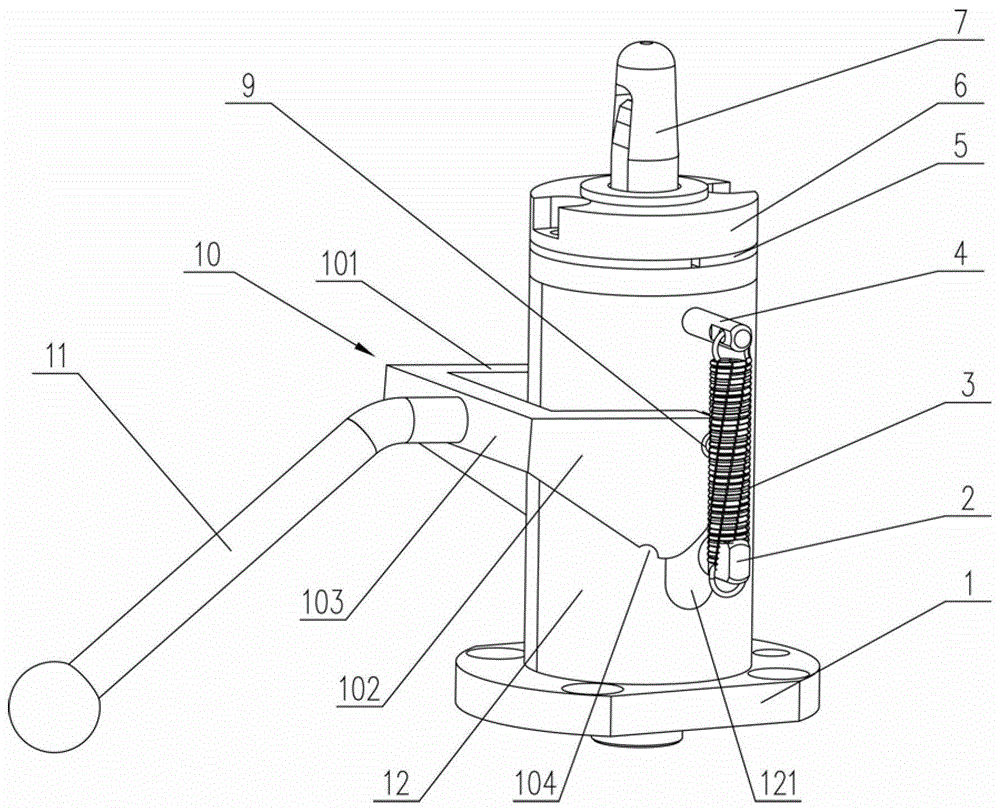

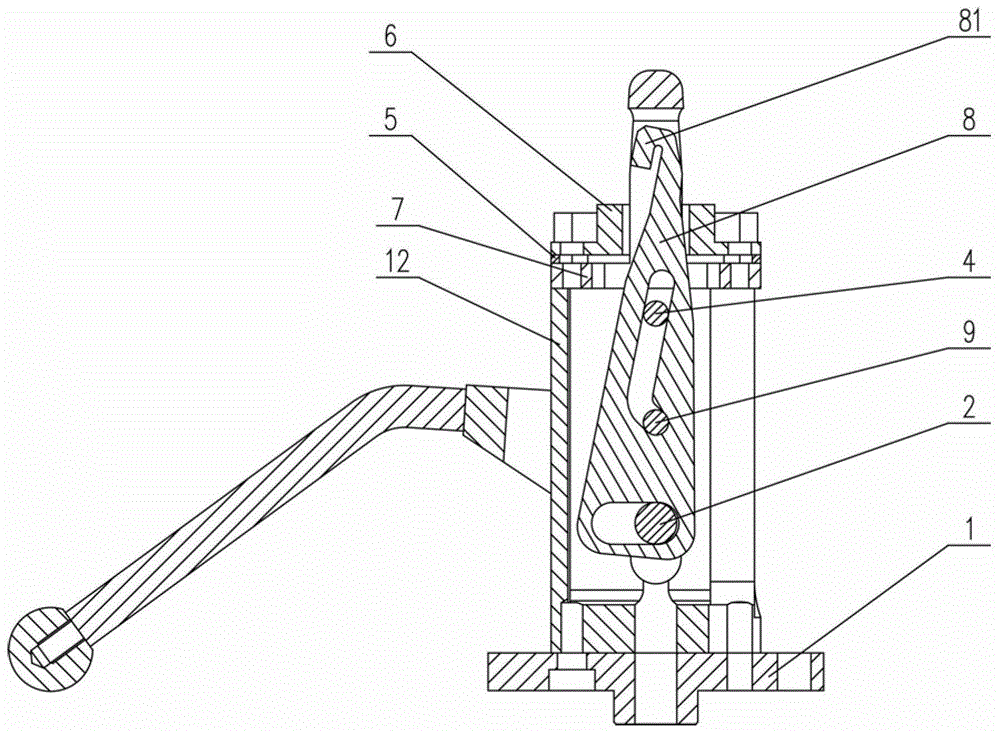

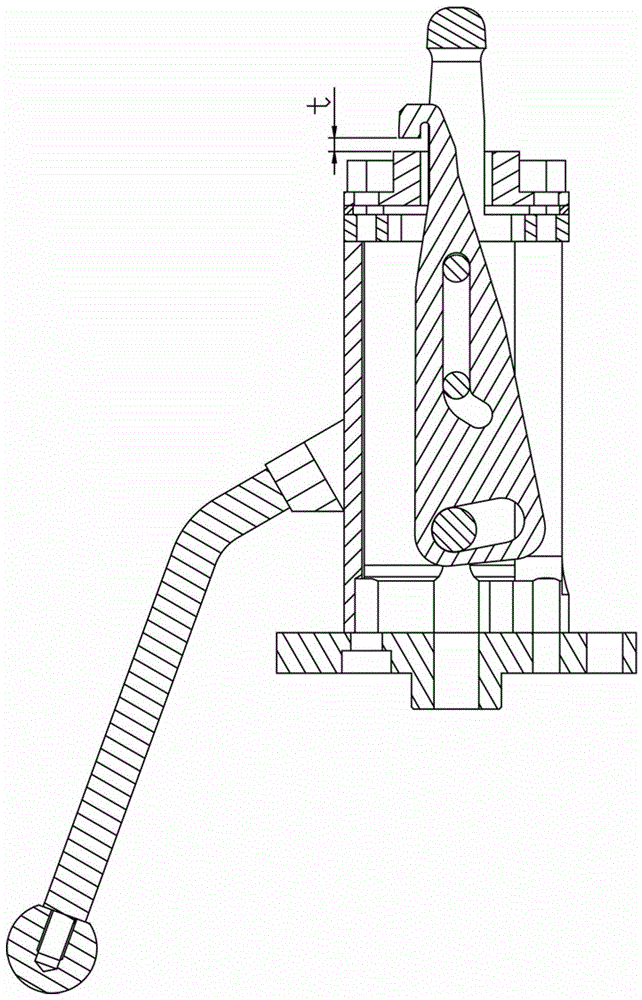

Improved star-shaped feeding machine

InactiveCN101551114AMake sure to lock the airEliminate blockingLump/pulverulent fuel feeder/distributionSprocketEngineering

The invention provides an improved star-shaped feeding machine which can quickly disperse materials stacked in blocks, lock the air of a boiler on the premise of meeting the use requirement of the boiler, and reduce the possibility of fire hazard. The feeding machine comprises a stander, a motor is installed on the stander which is provided with a feeding funnel; the feeding funnel is internally provided with a rotor which is connected with the motor by a chain and a chain wheel, the rotating shaft of the rotor is vertical to the center line of the funnel, a U-shaped funnel is arranged at the combination part of the rotor and the funnel, the bottom of the U-shaped funnel is open, and the outer edge of the rotating vane of the rotor is contacted with the U-shaped funnel. The feeding machine is characterized in that: the U-shaped funnel is installed on the funnel by a supporting rotating shaft, and an anti-blockage device is arranged outside the combination circular arc part of the rotor and the U-shaped funnel.

Owner:WUXI XIDONG ENERGY TECH

Multi-span energy saving sunlight greenhouse

InactiveCN101822180AEliminate spacingIncrease profitClimate change adaptationGreenhouse cultivationLand utilizationAgricultural engineering

The invention discloses a multi-span energy saving sunlight greenhouse which comprises ground ridge walls, gable walls, a back wall, a skeleton and greenhouse film. The multi-span energy saving sunlight greenhouse is formed by connecting a group of single-pitch sunlight greenhouses in tandem arrangement, and two rows of symmetrical support columns in parallel arrangement are arranged between neighboring greenhouses; a decking is installed at the top of each support column, the rear end of the front greenhouse skeleton is overlapped and fixed on the beam of the support columns in the front row through connecting seats, the front end of the rear greenhouse skeleton is overlapped and fixed on the beam of the support columns in the rear row through connecting seats, and then the single-pitch sunlight greenhouse is connected into a whole; as the distance between the front greenhouses and the rear greenhouses is eliminated, the utility ratio of land is enhanced greatly, the area of sunlight greenhouses increased greatly, and the utility ratio of land can reach 80% to 90%, which meets the requirements of large-scale production of sunlight greenhouses, realizes mechanized production, improves growing conditions for crops, enhances crop output and reduces warming expenses. The invention has the characteristics of low cost and high profit.

Owner:SHENYANG AGRI UNIV

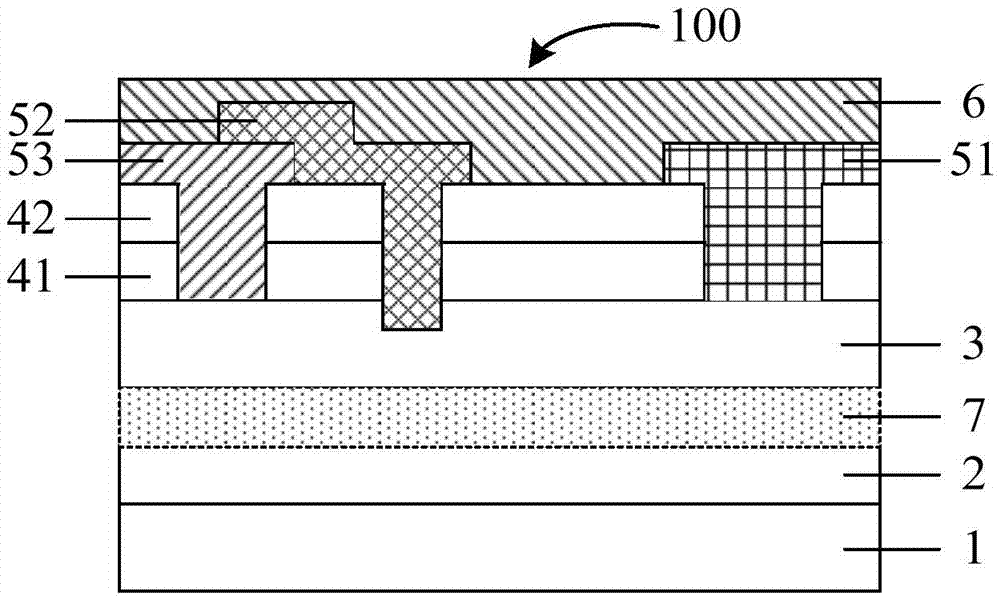

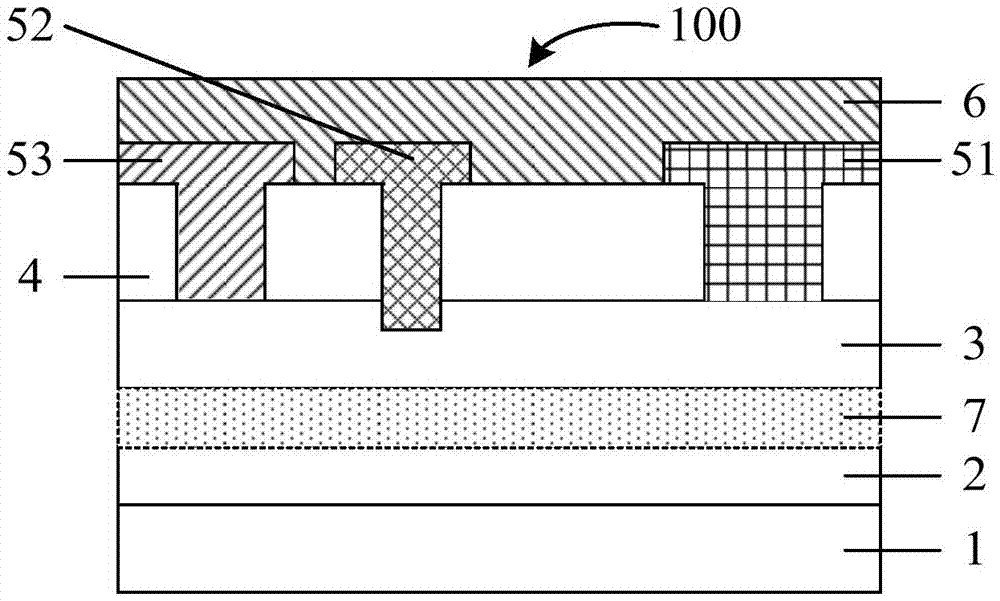

High-electron-mobility transistor and memory chip

InactiveCN106935642AEliminate spacingLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectron mobilityGallium nitride

The invention provides a high-electron-mobility transistor and a memory chip. The high-electron-mobility transistor comprises a substrate, a gallium nitride layer, a gallium nitride aluminum layer, an insulating layer and an electrode, wherein one side of the gallium nitride layer is compounded on a surface layer of the substrate and the other side of the gallium nitride layer is compounded on a bottom portion of the gallium nitride aluminum layer; the insulating layer is compounded on a top layer of the gallium nitride aluminum layer, and the insulating layer is provided with at least three cut-through contact holes; and the electrode includes a drain electrode, a gate electrode and a source electrode, and the drain electrode, the gate electrode and the source electrode are arranged in the corresponding contact holes of the at least three corresponding cut-through contact holes, the gate electrode is extended to the source electrode from a pole plate outside the contact holes so as to realize contact of the gate electrode and the source electrode. In the technical scheme, a space between the gate electrode and the source electrode is eliminated, a conduction resistance and power consumption of the high-electron-mobility transistor are effectively reduced and reliability of the high-electron-mobility transistor is increased.

Owner:PEKING UNIV +2

Optical head of computer-controlled plate making machine

ActiveCN101544093ASolving Power and Channel Count IssuesEasy to replace independentlyPhotographic composing devicesPhotoelectric composing devicesLight sourceEngineering

The present invention discloses an optical head of computer-controlled plate making machine, which comprises a lens, with optical fibers arranged in the lens for scanning; wherein, the optical fibers are fixed on a silicon wafer with a V-trough array, an optical fiber is placed in each V-trough, and the diameter of optical fiber is slightly smaller than the pitch of the V-trough; a laser diode is connected separately at the tail end of each optical fiber. In the present invention, the optical fibers in the V-trough array form a plurality of light sources, and each light source is modulated separately according to the image signals, the light sources are combined into one array and scan simultaneously; if the scanning interval of each time is set to be equal to the array width, the result of consecutive scans will form an integral image.

Owner:AMSKY TECHNOLOGY CO LTD

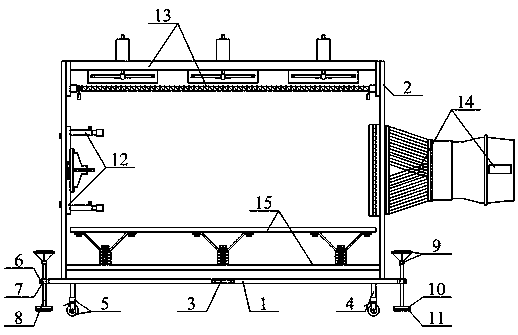

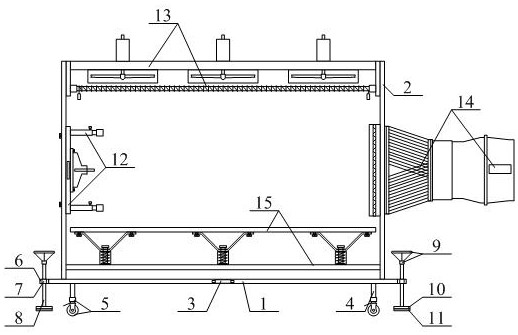

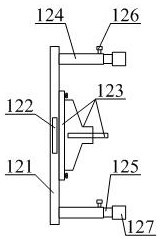

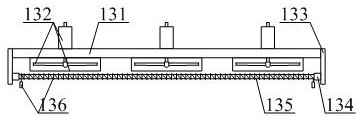

Electromechanical equipment static electricity and dust removal device

ActiveCN111330916AEliminate spacingGuarantee job stabilityDispersed particle filtrationTransportation and packagingVoltage generatorDust control

The invention provides an electromechanical equipment static electricity and dust removal device. The electromechanical equipment static electricity and dust removal device comprises a rack, a vertical base, a control switch, supporting legs, movable trundles, a connecting lining base, a fixing nut, a supporting screw, a hand wheel, a supporting base and an anti-skid pad. According to the electromechanical equipment static electricity and dust removal device, the connecting base, a high-voltage generator, an ion air gun, a fixing sleeve, an adjusting rod, an adjusting bolt and a static electricity elimination contact block are arranged, so that static electricity generated by electromechanical equipment can be eliminated; according to the size or the installation position of the electromechanical equipment, the adjusting bolt can be loosened, the distance between the fixing sleeve and the adjusting rod is adjusted, so that the static electricity elimination contact block is in contactwith the surface of the electromechanical equipment, and then the adjusting bolt is locked; and if the electromechanical equipment generates static electricity, the static electricity can be guided out; and meanwhile, the ion air gun is controlled to act through the high-voltage generator, ion air can be generated, dust on the surface of the electromechanical equipment can be blown, and meanwhile,the static electricity is removed so as to ensure the working stability of the electromechanical equipment.

Owner:合肥龙智机电科技有限公司

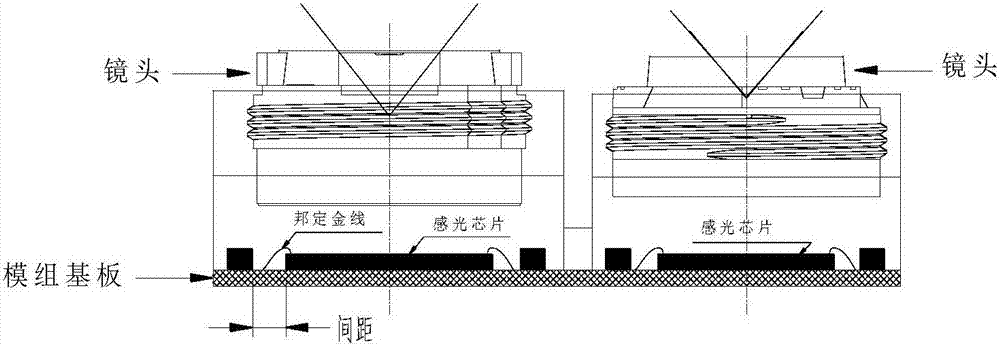

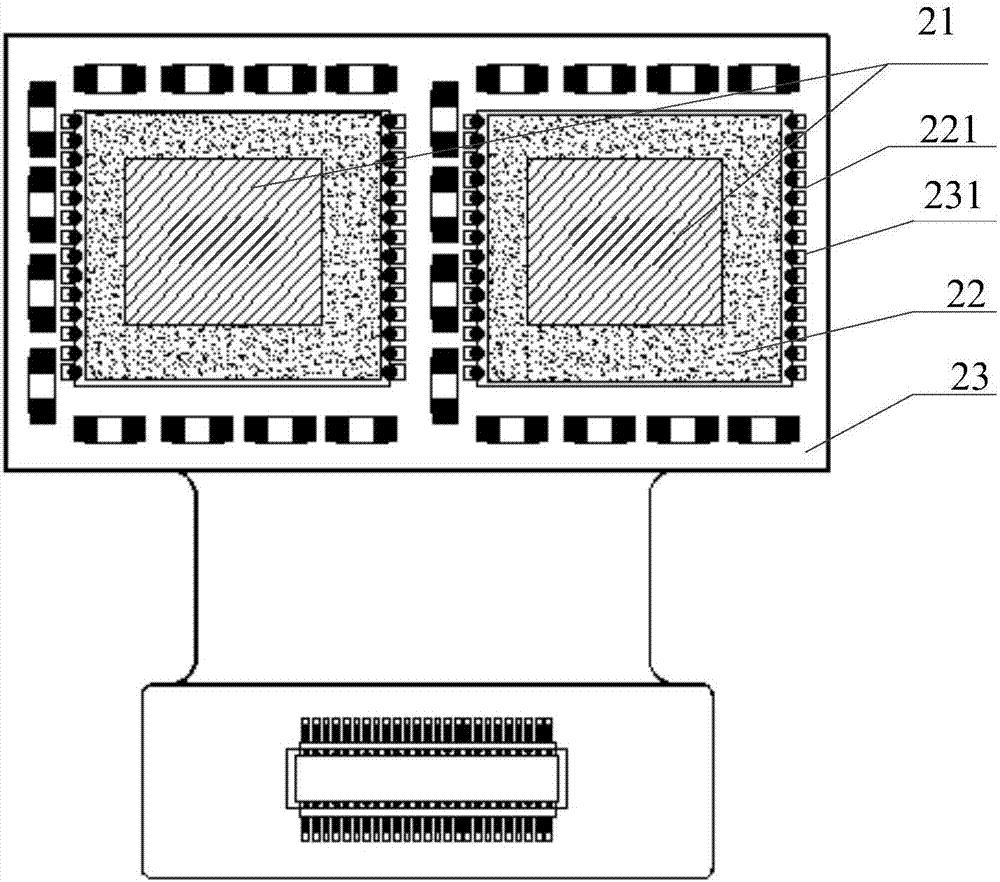

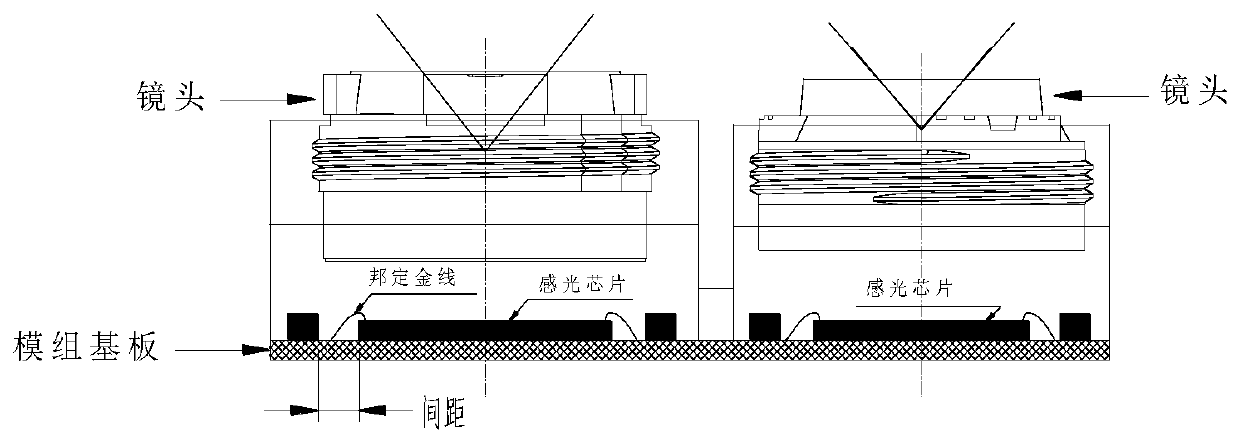

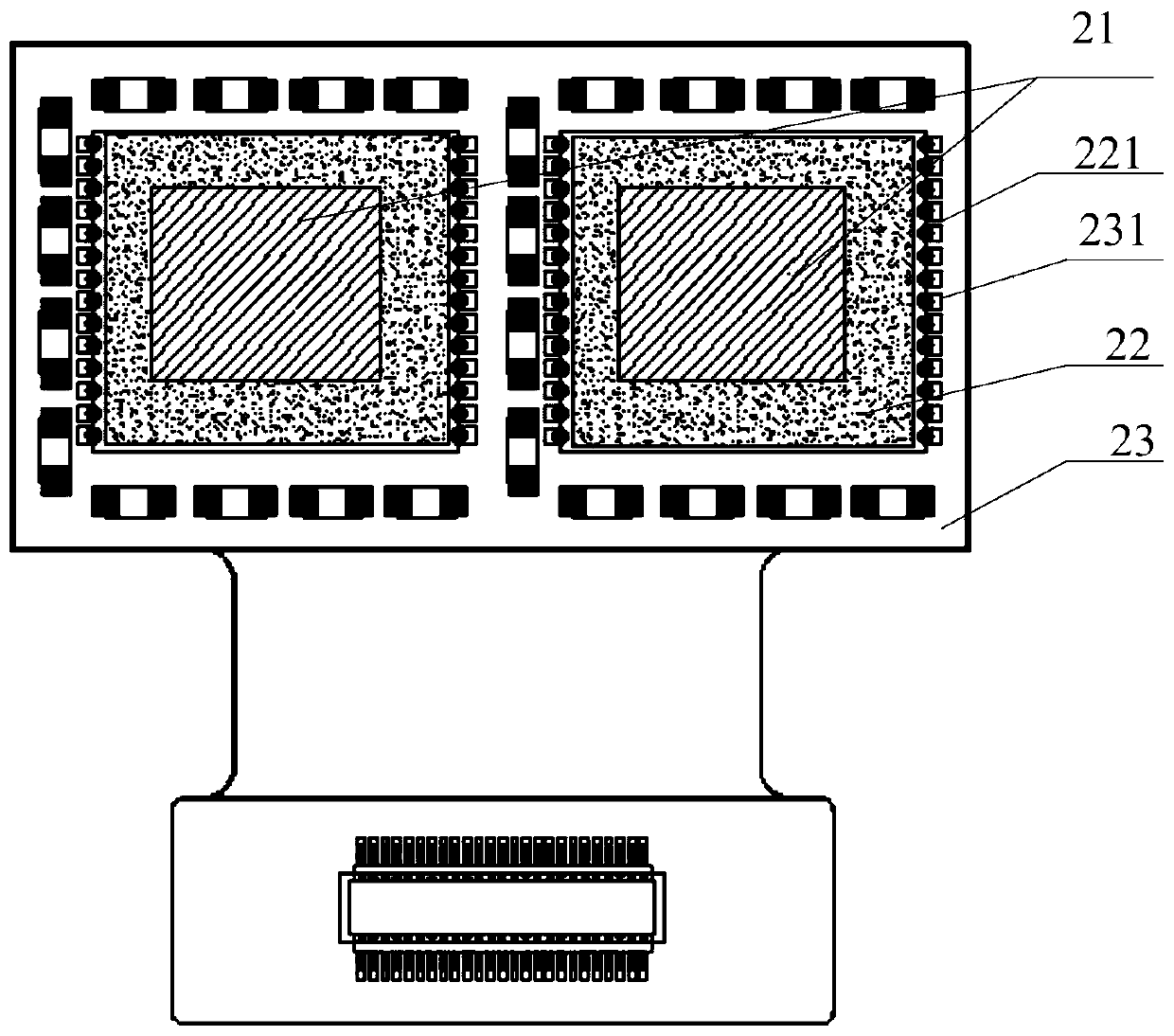

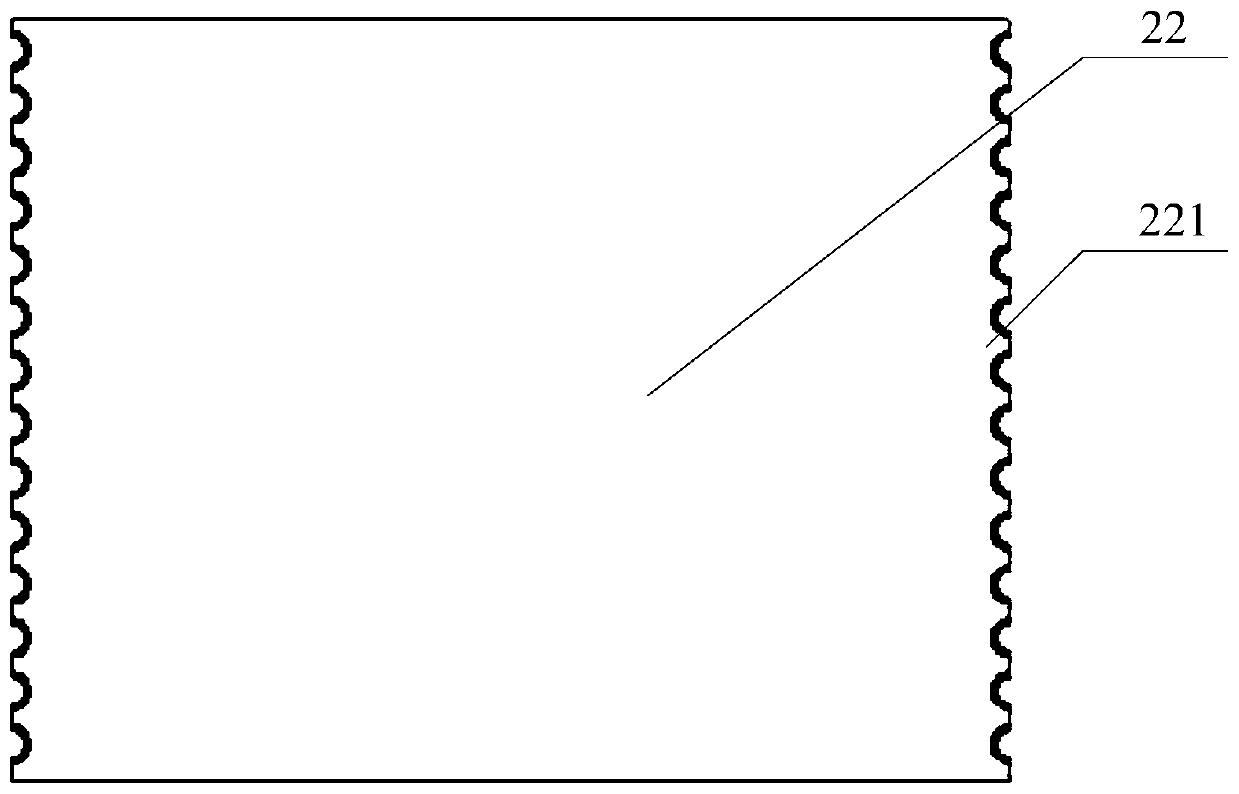

Multi-camera module

ActiveCN107994042AReduce volumeReduce investmentTelevision system detailsSolid-state devicesProduction lineSize difference

The embodiment of the invention discloses a multi-camera module, which comprises a bare chip, a packaging substrate and a module substrate. A side-edge bonding pad is arranged on the outer side edge of the packaging substrate, and a welding material is arranged on the side-edge bonding pad. The peripheral dimension of the packaging substrate is larger than that of the bare chip. The size difference of the packaging substrate and the bare chip does not exceed a preset threshold value. The bare chip is arranged on the packaging substrate. The functional pins of the bare chip are connected to theside-edge bonding pad through the semiconductor lead process, so that a packaging chip is formed. The packaging chip is attached to the surface of the module substrate, and is connected with the welding bonding pad of the module substrate through the side-edge bonding pad of the packaging chip. The image effect of the multi-camera module prepared by the method is equivalent to that of a module manufactured by the COB packaging technology. However, bonding gold wires in the traditional COB packaging process are avoided. The equipment investment of a production line is less, and the manufacturing cost is lower. The size of the whole multi-camera module is reduced, and the miniaturization trend development of the multi-camera module is facilitated.

Owner:TRULY OPTO ELECTRONICS

High-electron-mobility transistor and memory chip

InactiveCN106935643AEliminate spacingLower on-resistanceSemiconductor devicesMemory chipSurface layer

The invention provides a high-electron-mobility transistor and a memory chip. The high-electron-mobility transistor comprises a substrate, a gallium nitride layer, a gallium nitride aluminum layer, an oxide layer and an electrode, wherein one side of the gallium nitride layer is compounded on a surface layer of the substrate and the other side of the gallium nitride layer is compounded on a bottom portion of the gallium nitride aluminum layer; the oxide layer is compounded on a top layer of the gallium nitride aluminum layer, and the oxide layer is provided with at least three cut-through contact holes; and the electrode includes a drain electrode, a gate electrode and a source electrode, and the drain electrode, the gate electrode and the source electrode are arranged in the corresponding contact holes of the at least three corresponding cut-through contact holes. In the technical scheme, an interface defect between the gate electrode and the drain electrode is reduced and reliability of the high-electron-mobility transistor is increased.

Owner:PEKING UNIV +2

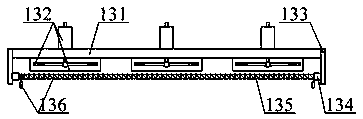

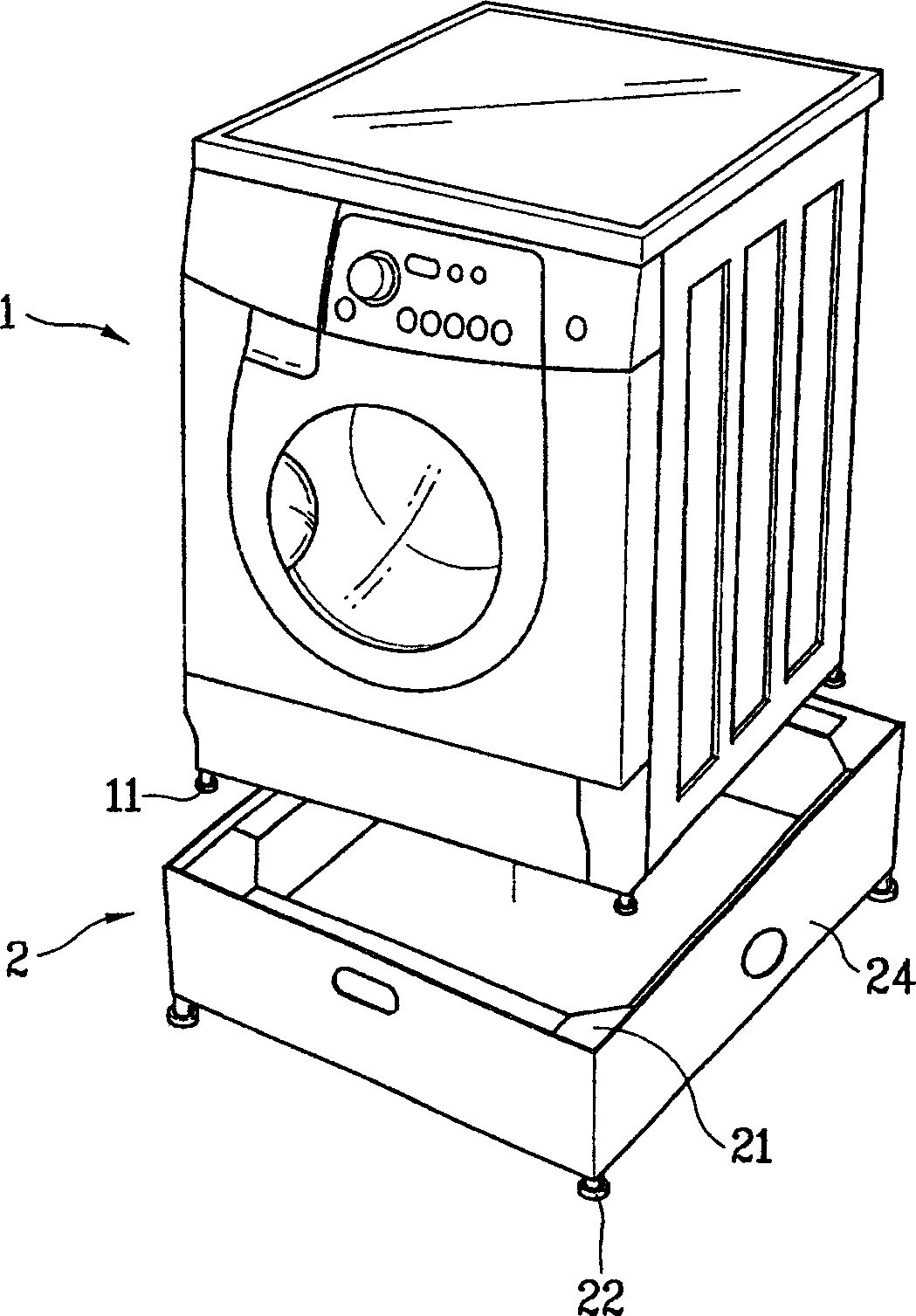

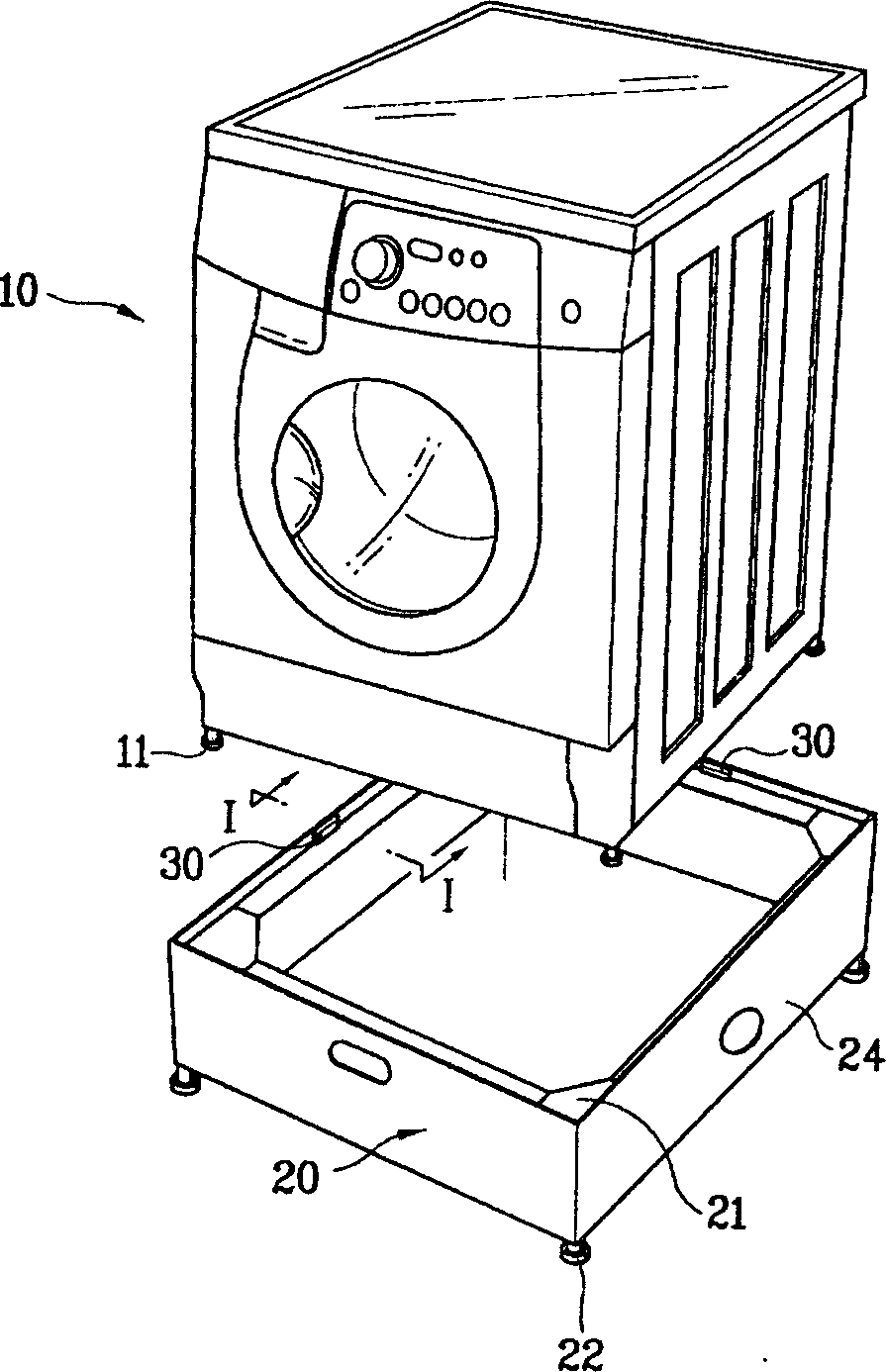

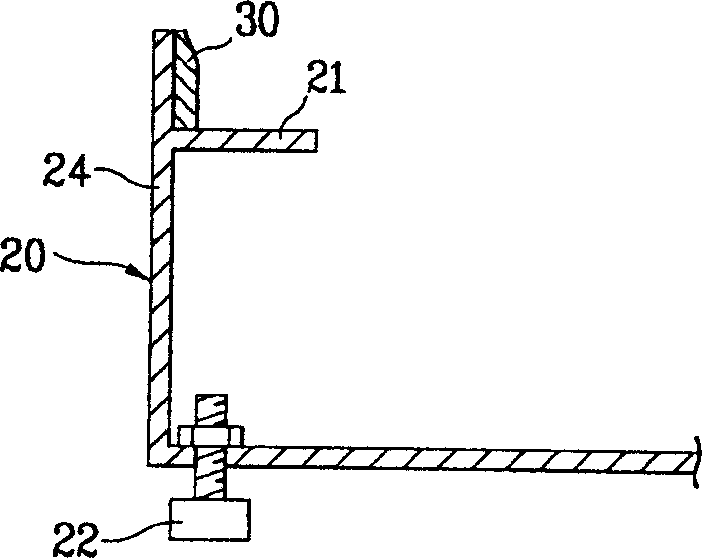

Arrangement bench for drum washing machine and assembly structure of drum washing machine and arrangement bench

InactiveCN1566735AEliminate spacingReduce vibrationOther washing machinesStands/trestlesEngineeringAssembly structure

The invention discloses a barrel washing machine placing bench and a assembling structure of barrel washing machine and the placing bench. That is: combining the rectangular plates orthogonality for forming a side plate with four edges and four corners, on the edges and corners, tie plates are arranged perpendicularly to the side plate and parallelly with the floor, and on the inner side surface of the side plate, buffer pads are added. On the side plate and buffer pads, holes are also formed, when the holes are lined up, the washing machine can be fixed on the placing bench by bolt and nut. The invention reduced the shocks or noises caused by the distance between the placing bench and the washing machine, and can prevent the washing machine from falling from the placing bench.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

H-shaped fin tube-type coal economizer with novel structure

InactiveCN107167017AIncrease the heat exchange areaAvoid wear and tearTubular elementsCoalEngineering

The invention discloses an H-shaped fin tube-type coal economizer with a novel structure. The H-shaped fin tube-type coal economizer with the novel structure comprises round tubes, fins, wearing bushes and the like. All the round tubes adopt a parallel arrangement way, the same ends of the round tubes are alternately connected together, and inner cavities of all the round tubes communicate with one another. The fins are evenly distributed in the longitudinal direction of the round tubes, and the surface of each fin is perpendicular to the axial direction of the corresponding round tube. The H-shaped fin tube-type coal economizer with the novel structure is characterized in that the fins evenly distributed on the round tubes comprise two identical rectangular thin plates, circular arc grooves are evenly formed on the two identical rectangular thin plates in the longitudinal direction of the two identical rectangular thin plates, and the circular arc grooves share the same cross-sectional shape and same number with the round tubes. The sides, provided with the circular arc grooves, of the two identical rectangular thin plates are symmetrically welded on the round tubes, and the H-shaped fin tube-type coal economizer with the novel structure is formed through combination.

Owner:HARBIN UNIV OF SCI & TECH

A multi-camera module

ActiveCN107994042BReduce volumeReduce investmentTelevision system detailsSolid-state devicesProduction lineMiniaturization

The embodiment of the invention discloses a multi-camera module, which includes a bare chip, a packaging substrate and a module substrate. The outer side of the packaging substrate is provided with side pads, and solder material is provided on the side pads; the peripheral size of the packaging substrate is larger than the size of the bare chip, and the size difference between the packaging substrate and the bare chip does not exceed the preset Threshold; the bare chip is set on the packaging substrate, and the functional pins of the bare chip are connected to the side pads using the semiconductor lead process to form a packaged chip; the packaged chip is mounted on the surface of the module substrate and soldered through the side of the packaged chip The pads are connected to the solder pads of the module substrate. The image effect of the multi-camera module prepared by this application is equivalent to that of the module produced by the COB packaging process, but it avoids the use of bonding gold wires in the traditional COB packaging process, and the investment in production line equipment is less, and the manufacturing cost is lower; The size of the entire multi-camera module is conducive to the development of the multi-camera module toward miniaturization.

Owner:TRULY OPTO ELECTRONICS

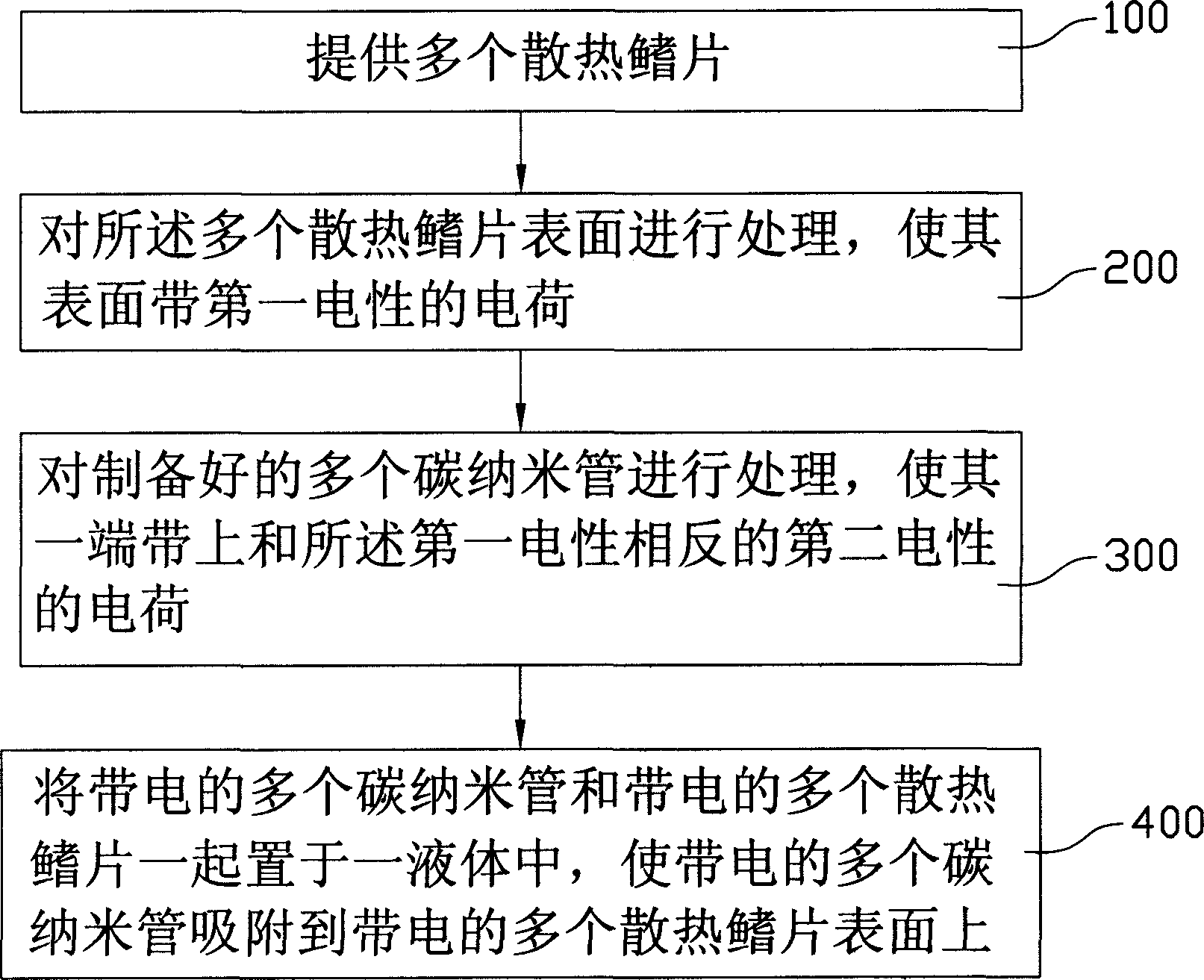

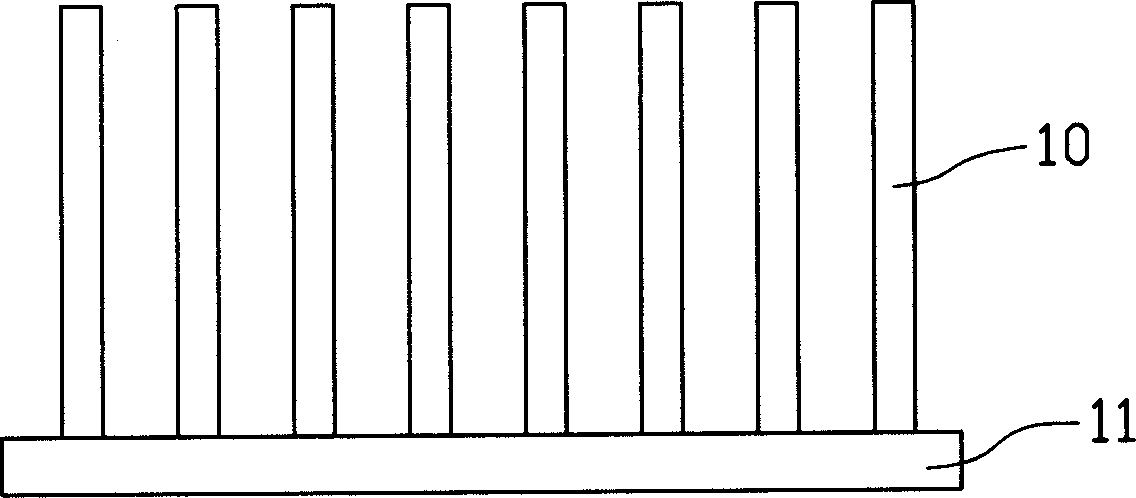

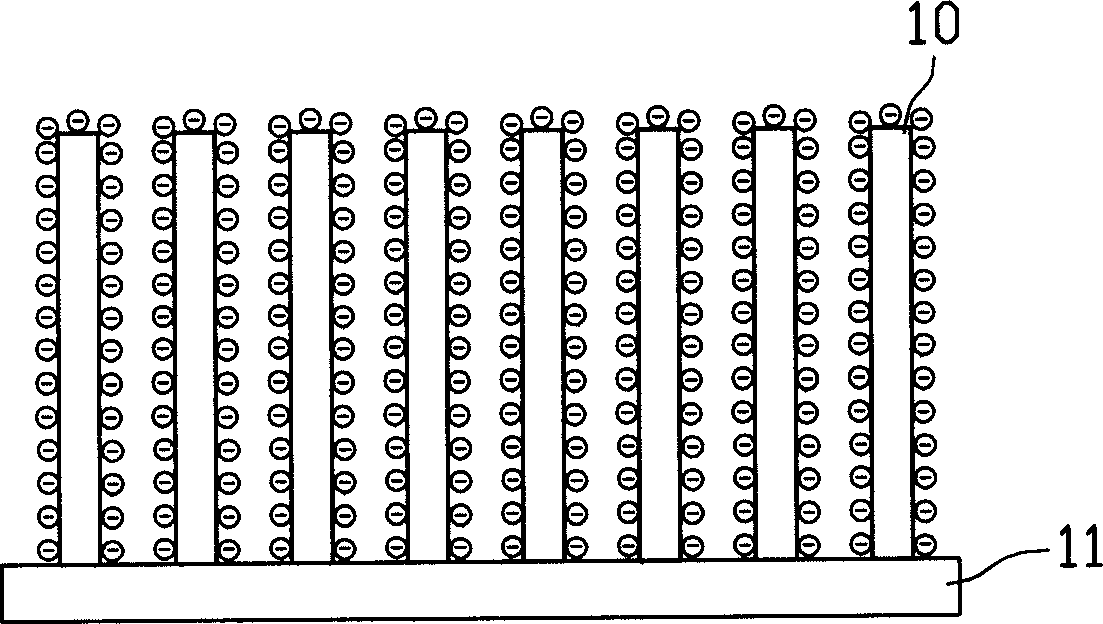

Method for producing heat radiator

InactiveCN1901175AEliminate spacingGive full play to the longitudinal thermal conductivity characteristicsNanostructure manufactureSemiconductor/solid-state device detailsElectricityCarbon nanotube

This invention provides a method for manufacturing radiators including the following steps: providing multiple radiating fins, processing the surfaces of them to let the surfaces have charges of a first kind of electricity, processing prepared multiple carbon nm tubes to let one end of which have charges of a second kind of electricity opposite to the first, putting the electric multiple carbon nm tubes and fins in a solution to adsorb the tubes to the surfaces of the radiating fins, which applies the static adsorption character to assemble the carbon nm tubes on the surfaces of the radiating fins to be distributed more uniformly on the fins.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

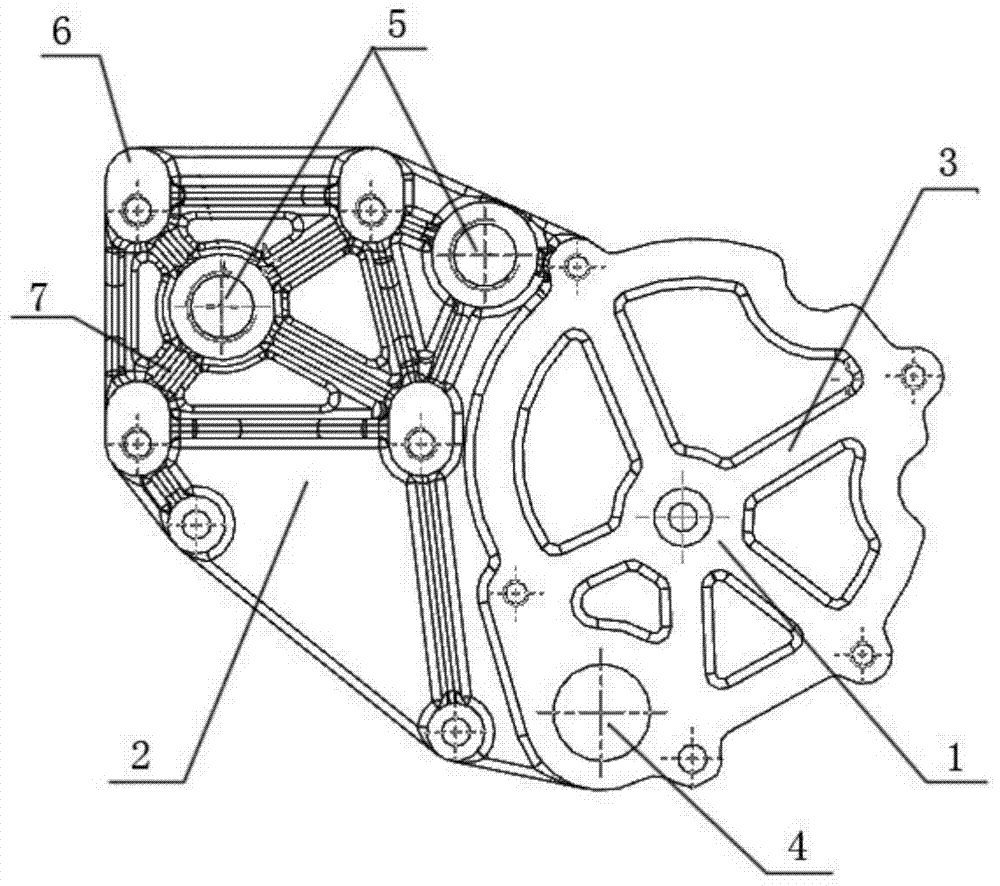

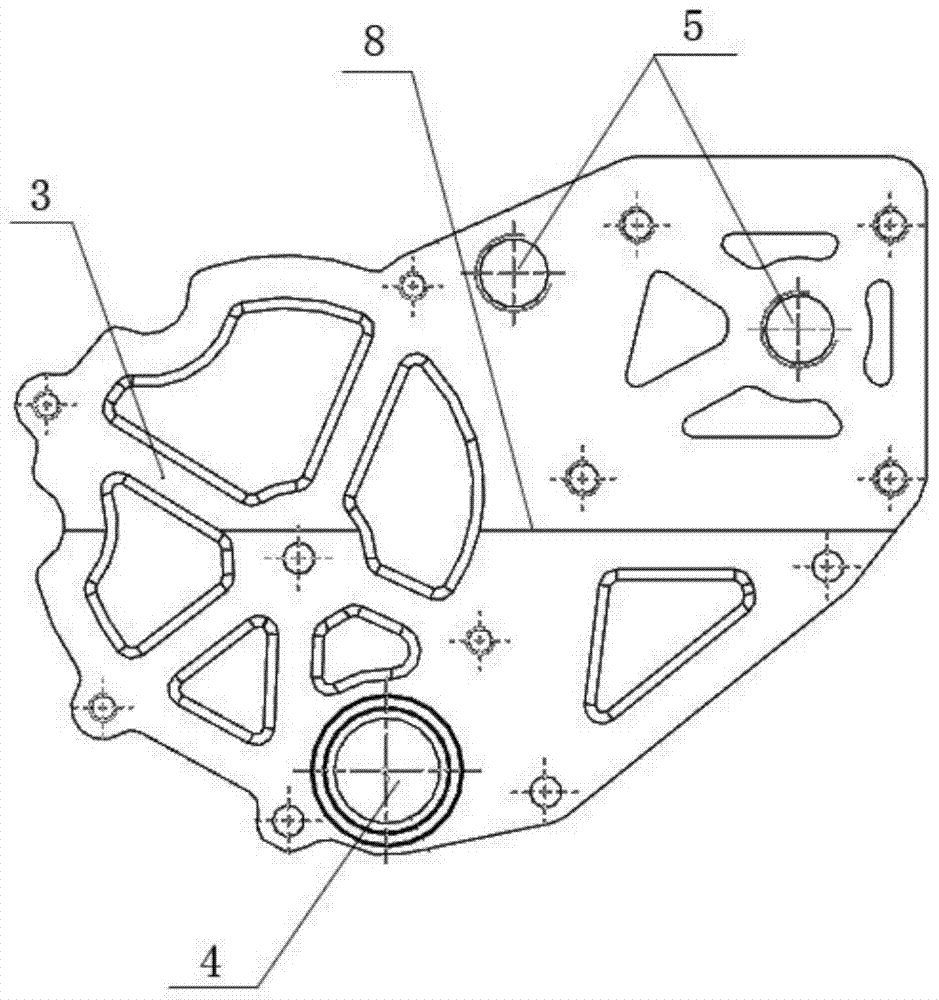

A water pump backing plate

ActiveCN105351073BReduce in quantityWide functionalityMachines/enginesEngine cooling apparatusCushioningAgricultural engineering

The invention discloses a water pump cushioning board. The water pump cushioning board comprises a cushioning board body used for installing a water pump on an engine body. The cushioning board body is provided with a water pump installation plate, and a fan installation plate is arranged at the part, on one side of the water pump installation plate, of the cushioning board body. The water pump cushioning board is light in mass, high in strength and good in universality, can be used for installing the water pump and a fan assembly, guarantees the arrangement reasonability of the water pump and the fan assembly and reduces the number of special parts for installing an engine assembly, and installation stress exerted on installation planes of the water pump cushioning board and the engine body is small.

Owner:GUANGXI YUCHAI MASCH CO LTD

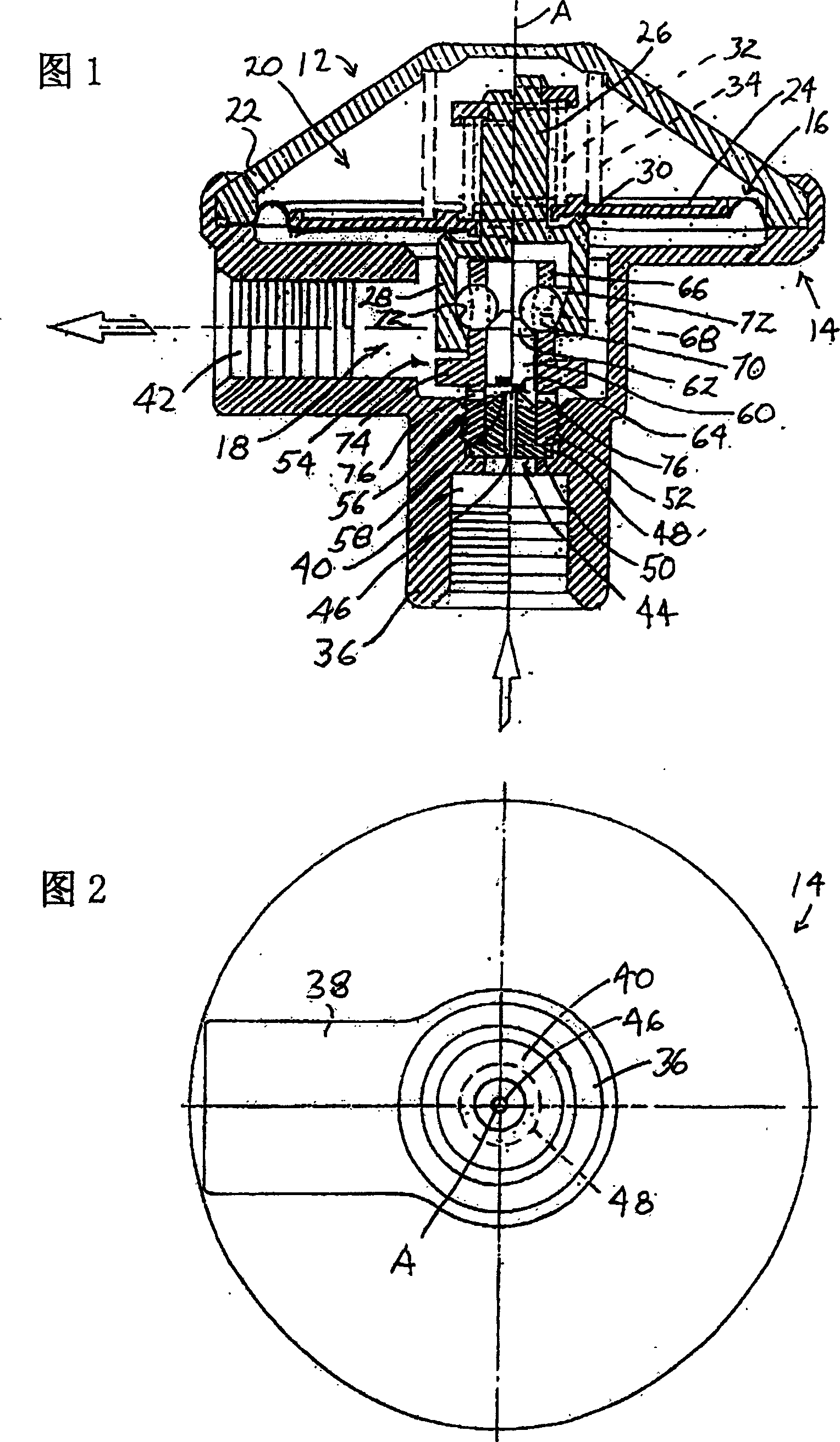

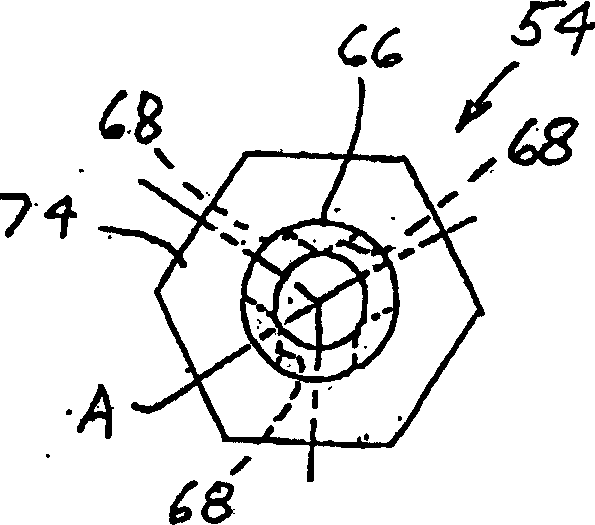

Diaphragm-operated pressure regulating valve

The invention relates to the field of fluid pressure regulating valves, in particular to an improved valve operating mechanism for a film actuated pressure regulating valve. The invention discloses a diaphragm actuated pressure regulating valve for connecting a gas source under pressure and a user end, which comprises an input port with an axis, a valve element coaxial with the input port and a valve element controlled by a diaphragm. A ball and cam valve element actuator in which the membrane is perpendicular to and coaxial with the input port.

Owner:GAAP GAS CONTROL

Body Fixtures

ActiveCN103884249BEliminate spacingGuaranteed accuracyMechanical measuring arrangementsEngineeringStationary state

The invention relates to the technical field of vehicle assembly part detection, and especially relates to a vehicle body fixation device. The vehicle body fixation device comprises a pressing element, a cylinder and a fixation arm. The pressing element has a three-frame structure. A first frame and a second frame which are opposite to each other are fixed on two sides of the cylinder respectively through a middle shaft. The pressing element is rotated around the middle shaft. The fixation arm is located inside the cylinder. One end of the fixation arm is provided with a compacting hook, and the other end of the fixation arm is connected with the cylinder through a lower shaft. The pressing element is rotated around the middle shaft to drive the swing of the fixation arm to make the compacting hook pressed onto the vehicle body floor so as to make the vehicle body floor and the detection surface maintained in the stationary state, so that the distance between the vehicle body floor and the detection surface in the vehicle body detection process can be eliminated to realize the clinging of the vehicle body floor and the detection surface, so the data detection accuracy and stability can be ensured.

Owner:BEIQI FOTON MOTOR CO LTD

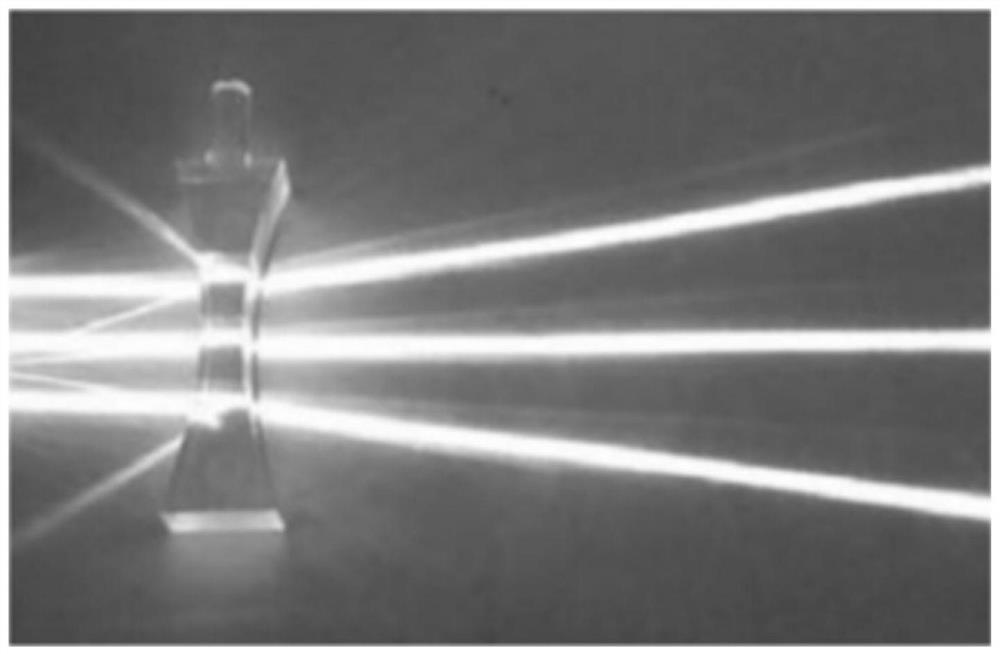

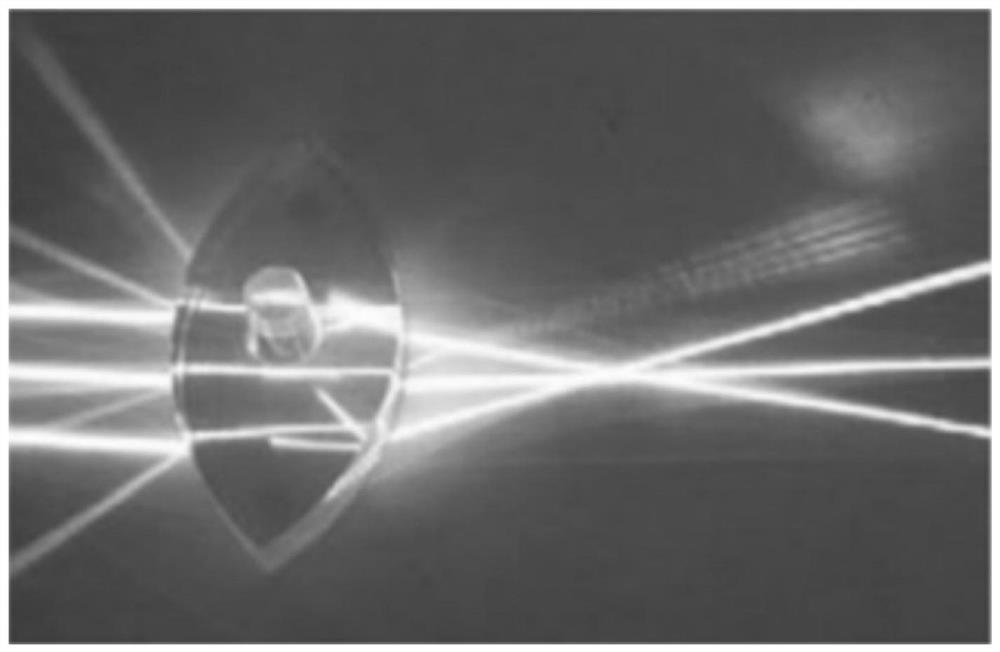

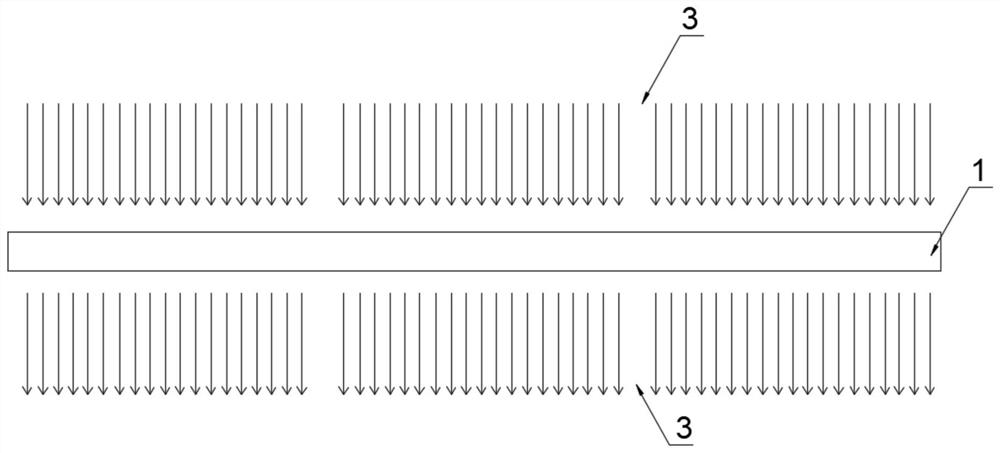

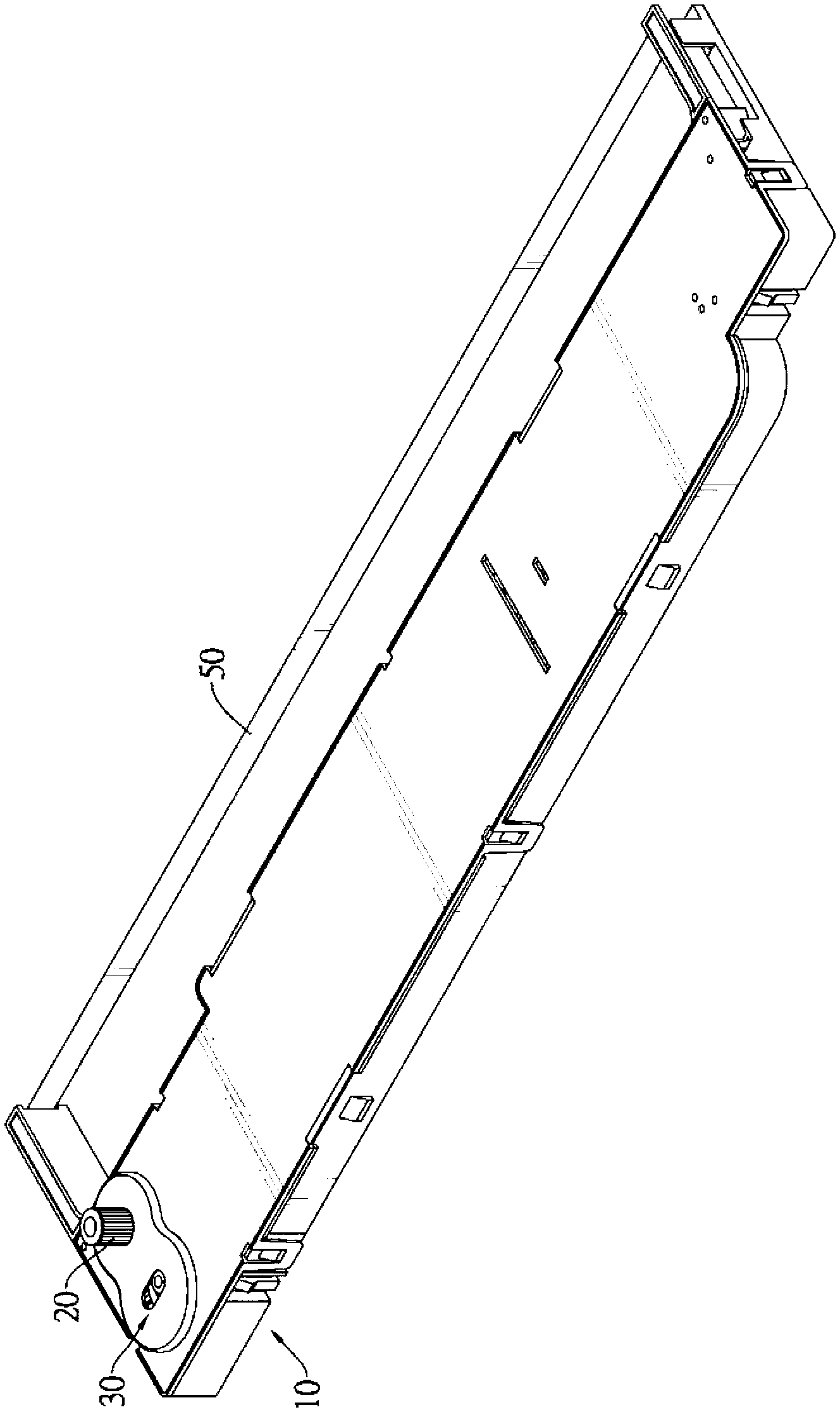

Transmission window and annealing device

PendingCN114563837AEliminate spacingIt will not cause the problem that the spacing position cannot be bakedFinal product manufactureSemiconductor/solid-state device manufacturingWaferEngineering

The invention provides a transmission window and an annealing device, and relates to the technical field of semiconductors, the transmission window comprises a window body, the window body is plate-shaped, and a plurality of transmission areas are uniformly arranged on the window body; wherein at least the inner side face of the transmission area is of a concave surface structure. According to the technical scheme, the transmission window is divided into a plurality of transmission areas, the structure of each transmission area is manufactured into a concave surface structure, and when vertically transmitted light passes through the transmission areas, the light is refracted into dispersed light, so that the vertical light can be transmitted out more dispersedly on the other side after passing through the concave mirror, and the light transmission efficiency is improved. Therefore, the spacing formed by the arrangement of the baking lamps is eliminated, when the baking lamps transmit to the wafer through the transmission window, the wafer can be uniformly baked, and the problem that the spacing position cannot be baked is avoided.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

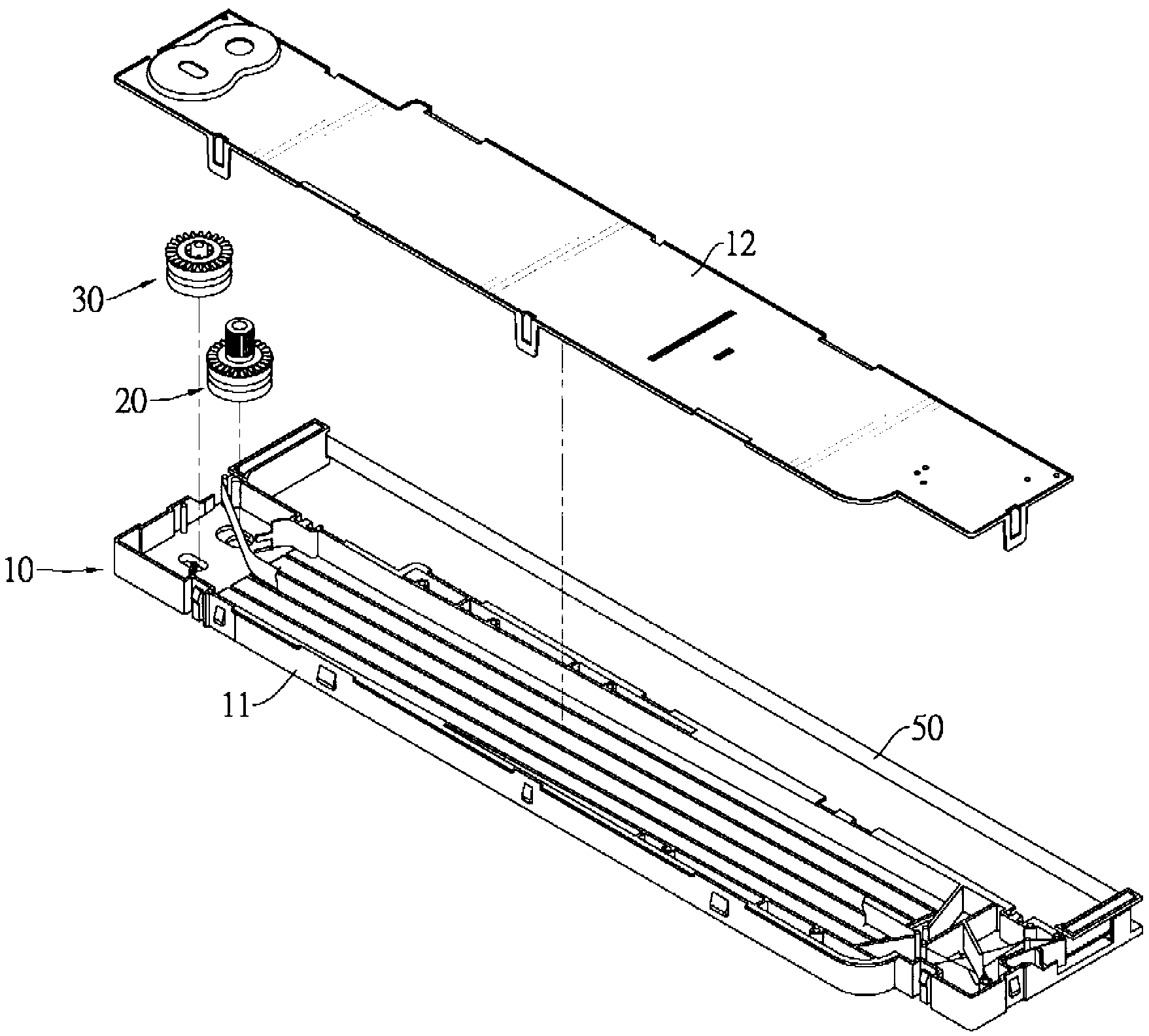

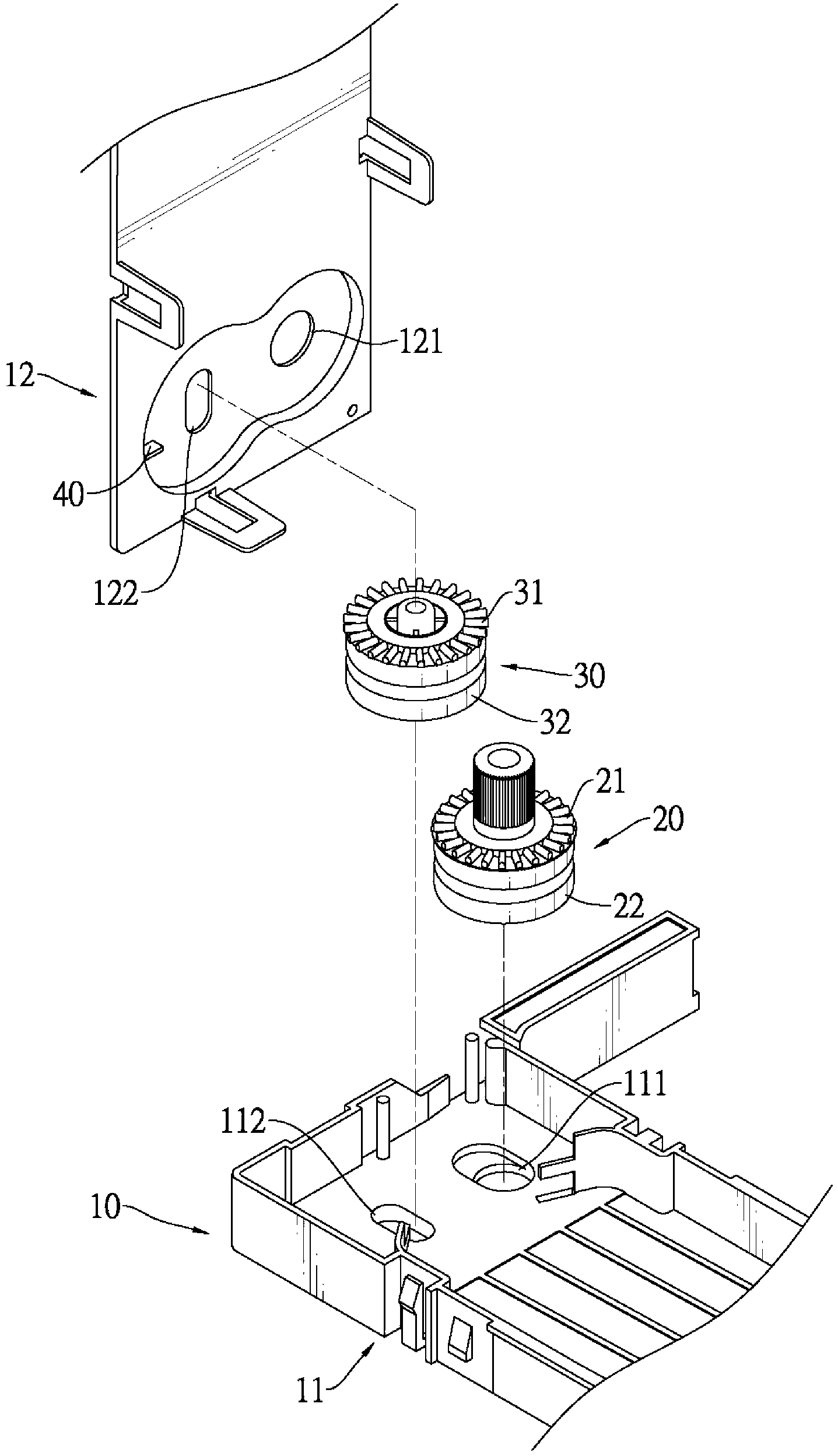

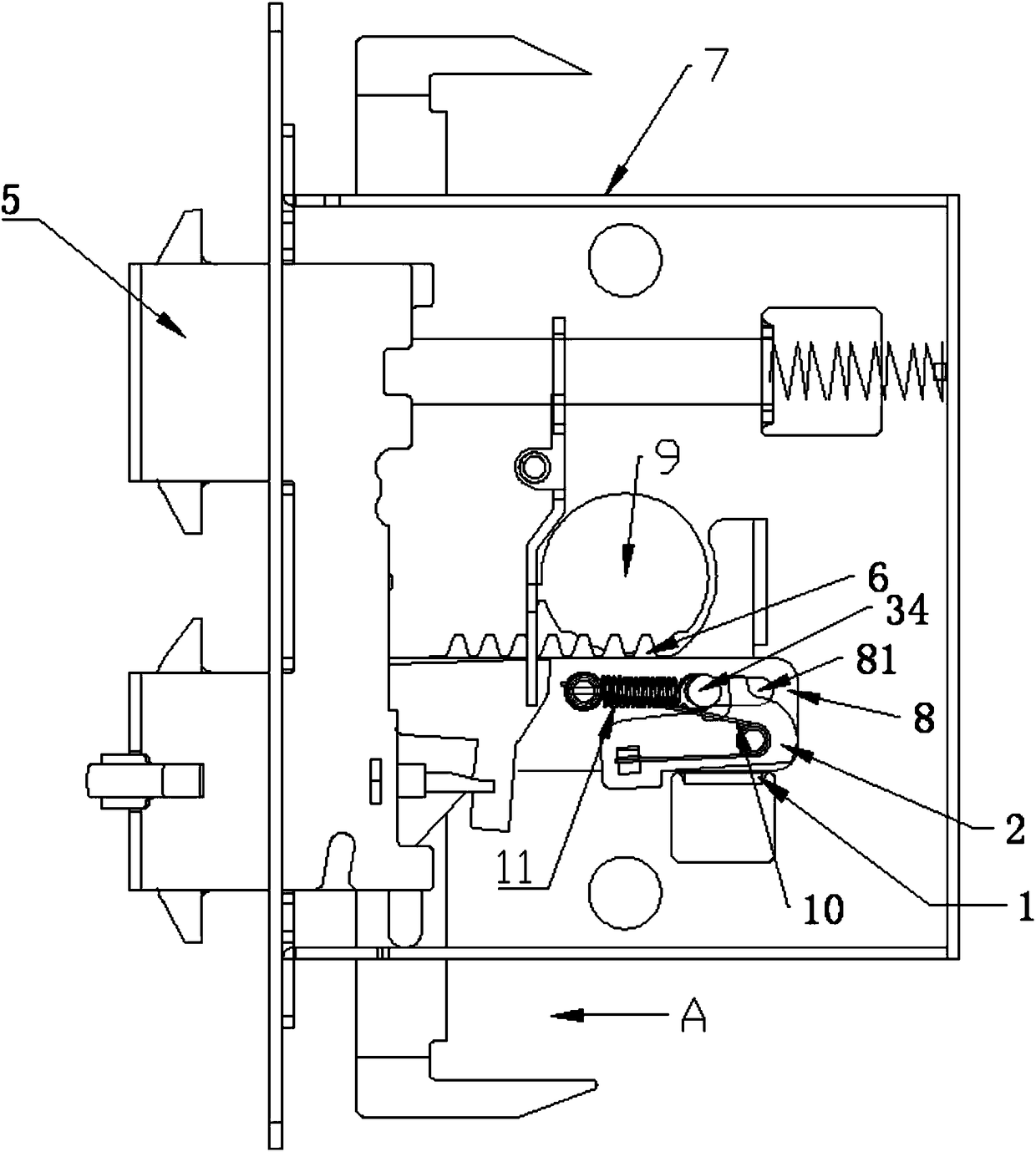

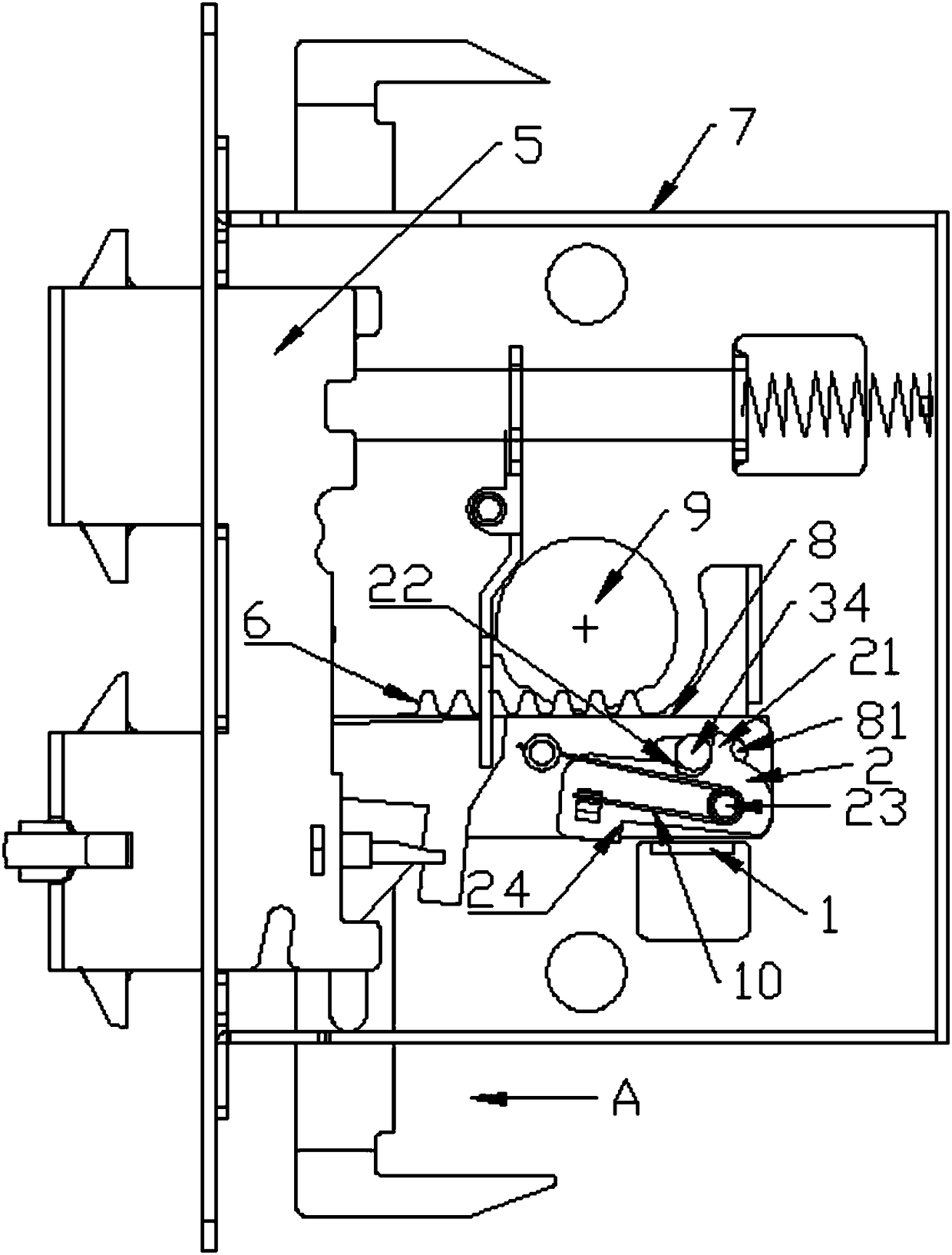

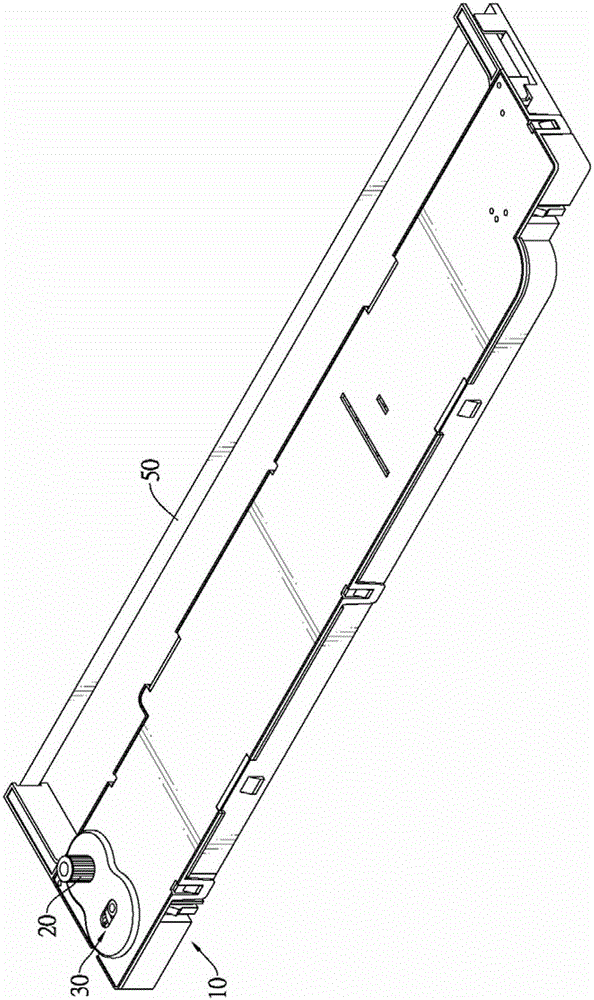

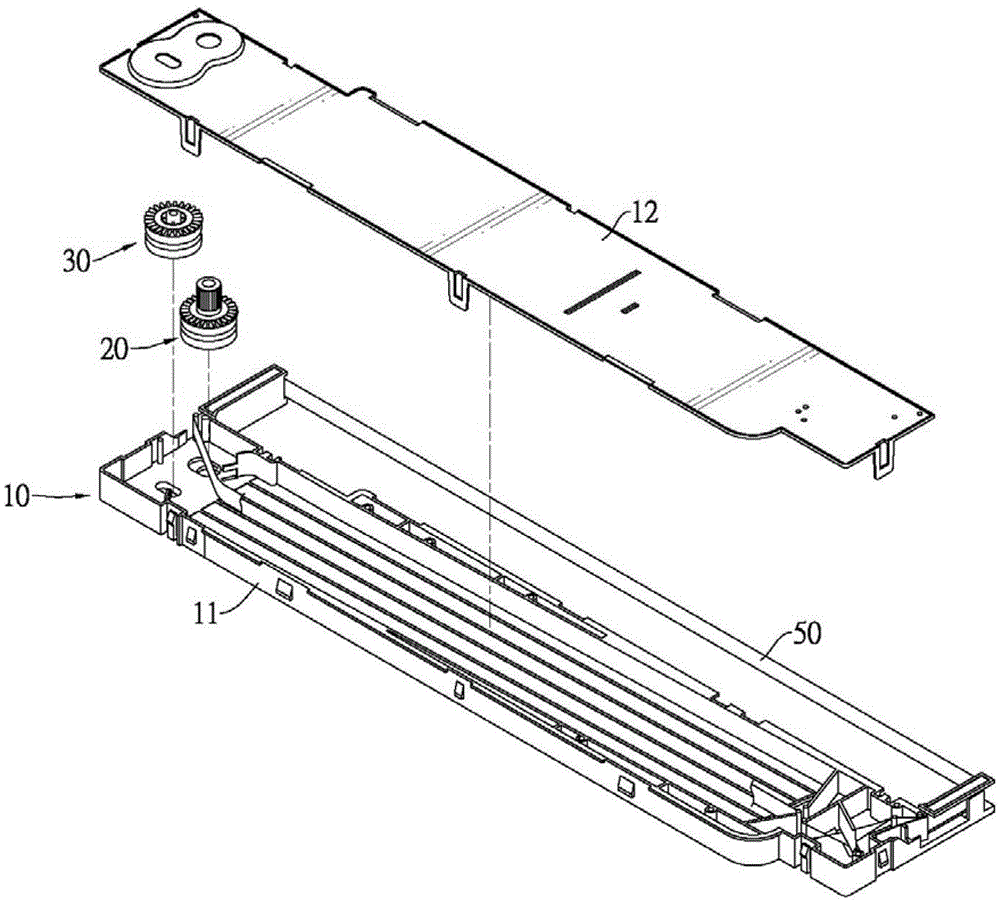

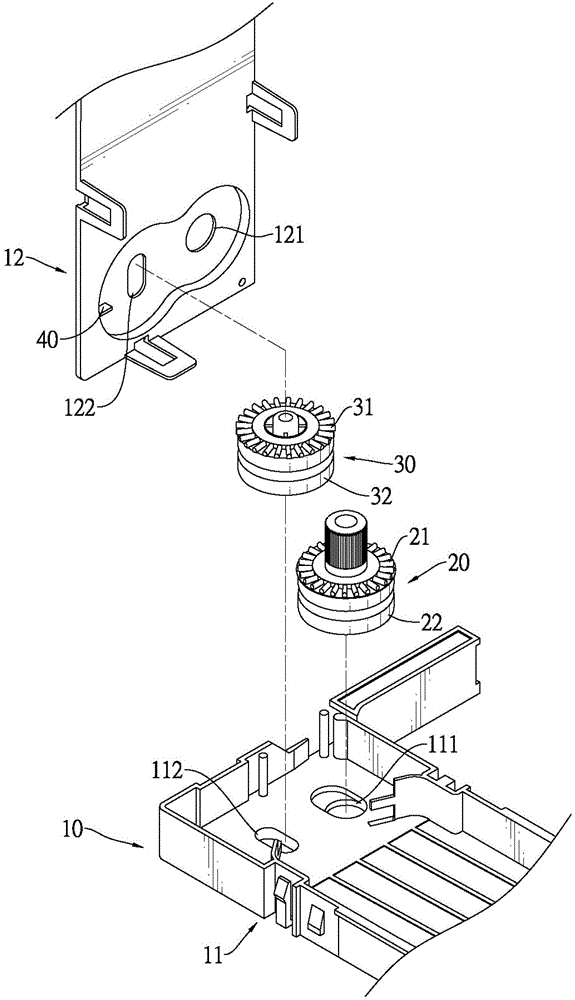

Colored tape box

The invention relates to a colored tape box used for a printer. The colored tape box comprises a shell body, a drive wheel, a driven wheel and a lever piece. Before the colored tape box is used for a first time, a clamping portion of the driven wheel and a clamping portion of the drive wheel do not make contact, and therefore the situation that the clamping portion of the drive wheel and the clamping portion of the driven wheel abut against at one point for a long time and deform or are damaged to be sticky can be avoided. When the colored tape box is used, after the drive wheel rotates, the driven wheel is driven by a gear part to rotate together with the drive wheel. Due to the fact that the lever piece which is fixedly arranged in the shell body is arranged between gear parts of the driven wheel in a penetrating mode, the driven wheel moves with the lever piece as a supporting point. After the driven wheel is separated from the lever piece, the driven wheel is continuously driven by the gear part of the drive wheel, so that the clamping portion of the drive wheel and the clamping portion of the driven wheel gradually abut against to clamp colored tapes. The colored tape box can remove the space distance between the clamping portion of the drive wheel and the clamping portion of the driven wheel without manual operation, improve use convenience, simplify the structure, reduce the number of assemblies, and greatly reduce cost.

Owner:红石电脑(上海)有限公司

An anti-theft opening mechanism for automatic door locks

ActiveCN106150196BWon't lock upMeet normal anti-theft purposesBuilding locksEngineeringMechanical engineering

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

Electrostatic dust removal device for electromechanical equipment

ActiveCN111330916BEliminate spacingGuarantee job stabilityDispersed particle filtrationTransportation and packagingVoltage generatorIon wind

The invention provides a static electricity and dust removal device for electromechanical equipment, which includes a frame, a stand, a control switch, a supporting leg, a movable caster, a connecting bushing, a fixing nut, a supporting screw, a hand wheel, a supporting base and an anti-skid pad. The arrangement of the connecting seat, high voltage generator, ion air gun, fixed sleeve, adjusting rod, adjusting bolt and static elimination contact block of the present invention is beneficial to eliminate static electricity generated by electromechanical equipment, and can be carried out according to the size or installation position of the electromechanical equipment. Loosen the adjusting bolt, adjust the distance between the fixed sleeve and the adjusting rod, so that the static electricity elimination contact block contacts the surface of the electromechanical equipment, and then lock the adjusting bolt, if the electromechanical equipment generates static electricity, the static electricity can be exported, and at the same time, the ion is controlled by the high voltage generator The action of the air gun can generate ion wind, which can blow the dust on the surface of the electromechanical equipment and remove static electricity at the same time to ensure the stability of the electromechanical equipment.

Owner:合肥龙智机电科技有限公司

Ribbon Cassette

The invention relates to a colored tape box used for a printer. The colored tape box comprises a shell body, a drive wheel, a driven wheel and a lever piece. Before the colored tape box is used for a first time, a clamping portion of the driven wheel and a clamping portion of the drive wheel do not make contact, and therefore the situation that the clamping portion of the drive wheel and the clamping portion of the driven wheel abut against at one point for a long time and deform or are damaged to be sticky can be avoided. When the colored tape box is used, after the drive wheel rotates, the driven wheel is driven by a gear part to rotate together with the drive wheel. Due to the fact that the lever piece which is fixedly arranged in the shell body is arranged between gear parts of the driven wheel in a penetrating mode, the driven wheel moves with the lever piece as a supporting point. After the driven wheel is separated from the lever piece, the driven wheel is continuously driven by the gear part of the drive wheel, so that the clamping portion of the drive wheel and the clamping portion of the driven wheel gradually abut against to clamp colored tapes. The colored tape box can remove the space distance between the clamping portion of the drive wheel and the clamping portion of the driven wheel without manual operation, improve use convenience, simplify the structure, reduce the number of assemblies, and greatly reduce cost.

Owner:红石电脑(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com