Infrared touch glass mounting structure, touch precision adjusting method and application

A technology of infrared touch and installation structure, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of increasing the thickness of the main frame, the lamp head is prone to fog and dust, and the touch is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

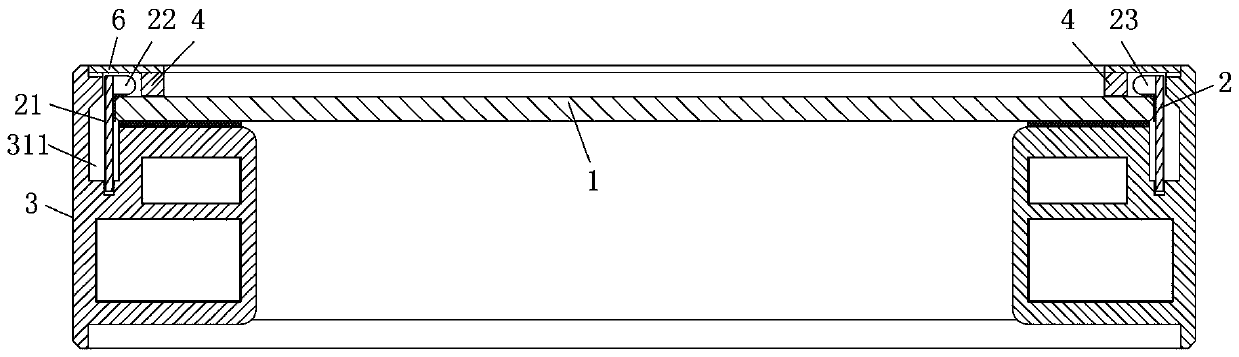

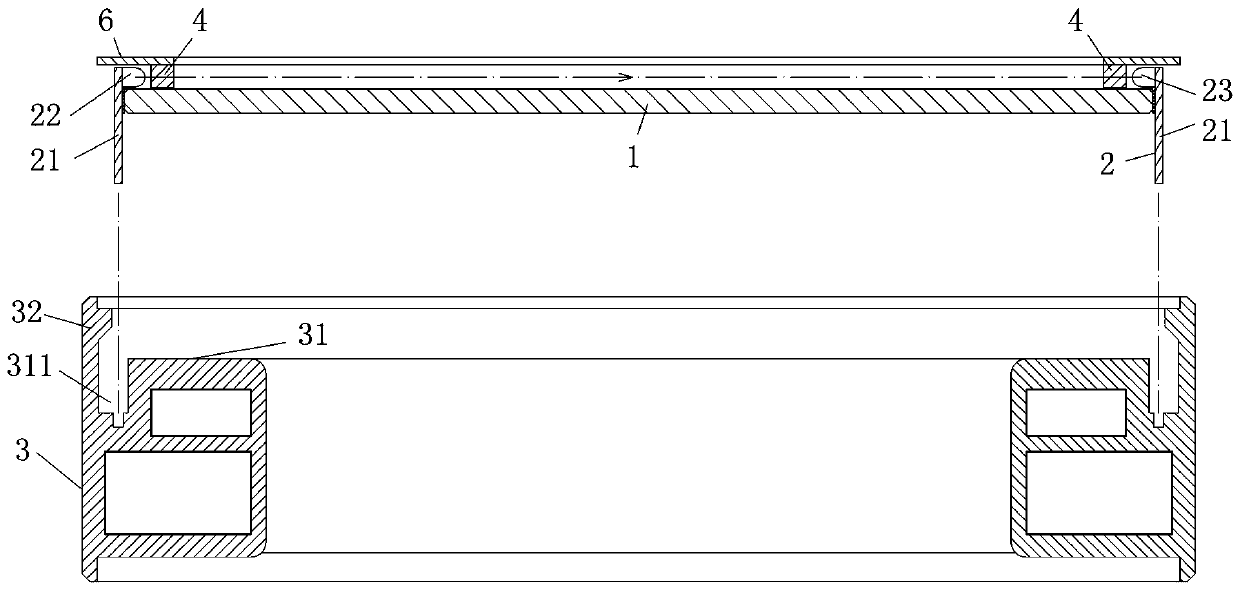

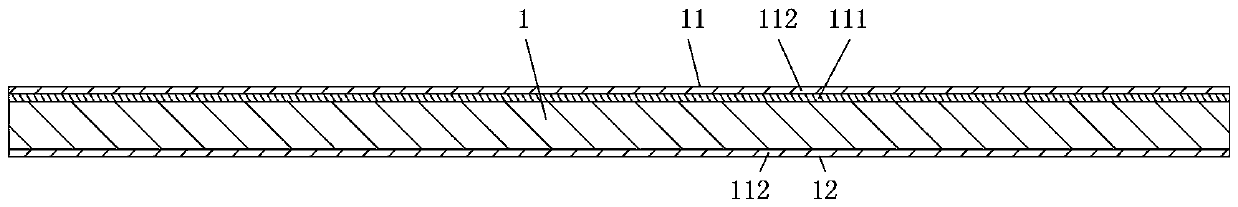

[0037] Such as Figure 1 to Figure 4 As shown, an infrared touch glass installation structure includes a glass reference plate 1, an infrared touch module 2 and a screen support frame 3, and the infrared touch module 2 includes The circuit board 21 of each circuit board 21 is correspondingly welded with one of the infrared tubes on the edge of each circuit board, and the infrared emitting tube 22 and the infrared receiving tube 23 between the opposite circuit boards correspond one by one; the back side 12 of the glass reference plate 1 is Warped surface, the front side 11 of the glass reference plate is provided with an anti-glare layer 111 made by sandblasting and etching, and the surface of the warped surface and the anti-glare layer has a compressive stress layer 112 formed by chemical strengthening; the infrared pair tubes are all made of solid ultraviolet flexible The glue is pasted around the front of the glass reference plate 1 and forms an infrared touch glass with the...

Embodiment 2

[0045] Such as figure 1 , Figure 5 with Image 6 As shown, a high-sensitivity fully sealed infrared touch all-in-one machine includes an infrared touch glass 10, a screen support frame 20, a liquid crystal panel 30, and a backlight module 40. The infrared touch glass 10 and the screen support frame 20 The structure is as described in Embodiment 1, the liquid crystal panel 30 is pasted on the back of the glass reference plate 1, the circuit board 21 of the infrared touch glass 10 is inserted into the sinker 202, and the glass reference plate 1 is placed on the screen installation platform 201 and fixed with the screen mounting table 201; the opposite sides of the infrared emitting tube 22 and the infrared receiving tube 23 are equipped with infrared filter strips 50, the bottom of the infrared filter strips 50 and the glass reference plate 101 The surface is bonded and fixed, and an opaque cover plate 60 is respectively installed above the infrared emitting tube 22 and the i...

Embodiment 3

[0048] Such as figure 1 with Figure 7 As shown, a high-sensitivity fully sealed infrared touch all-in-one machine includes an infrared touch screen 10, a screen support frame 20, a liquid crystal panel 30, and a backlight module 40. The infrared touch screen 10 and the screen support frame 20 The structure is as described in Embodiment 1. The circuit board 21 of the infrared touch screen 10 is inserted into the sinker 202, and the glass reference plate 101 is placed on the screen installation platform 201 and fixed with the screen installation platform 201; The opposite sides of the infrared emitting tube 22 and the infrared receiving tube 23 are equipped with an infrared filter strip 50, the bottom of the infrared filtering strip 50 is bonded and fixed to the surface of the glass reference plate 101, and the infrared emitting tube 22 and the infrared receiving tube 23 Opaque cover plates 60 are respectively installed on the top of the backlight module 40; the liquid crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com