Solid insulation full-sealed three-position disconnecting switch

A technology of solid insulation and isolating switches, applied in the direction of air switch components, etc., can solve the problems of increasing fracture breakdown, electrification of power failure line sections, etc., and achieves the effect of high insulation strength and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

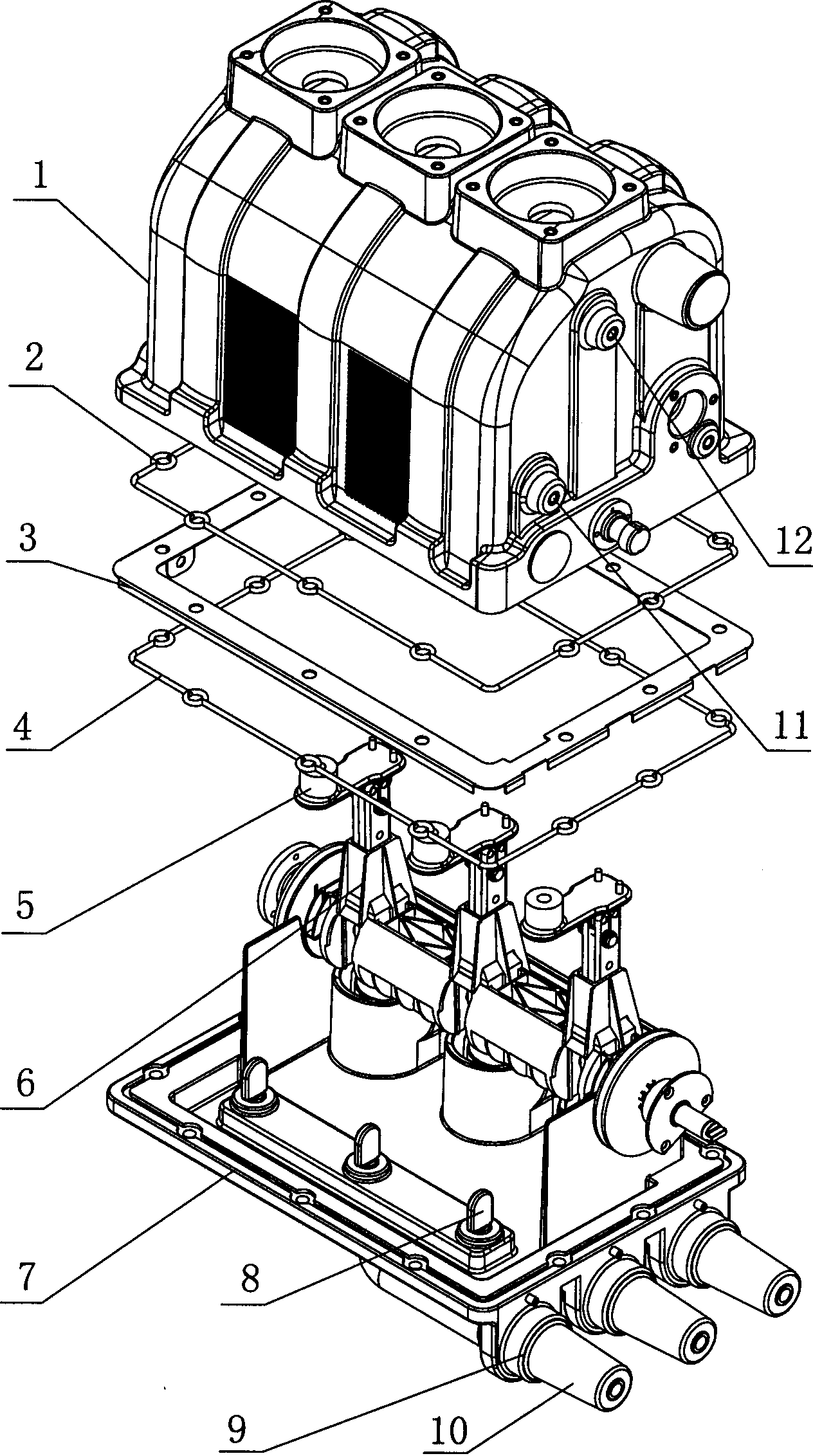

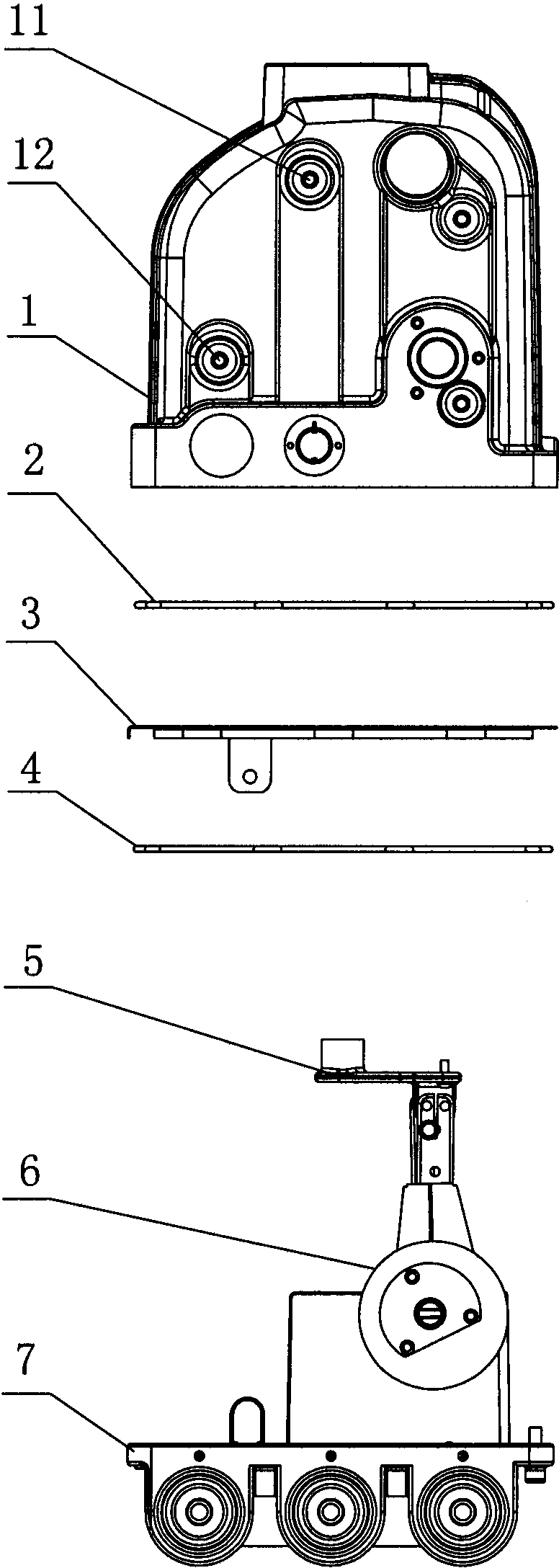

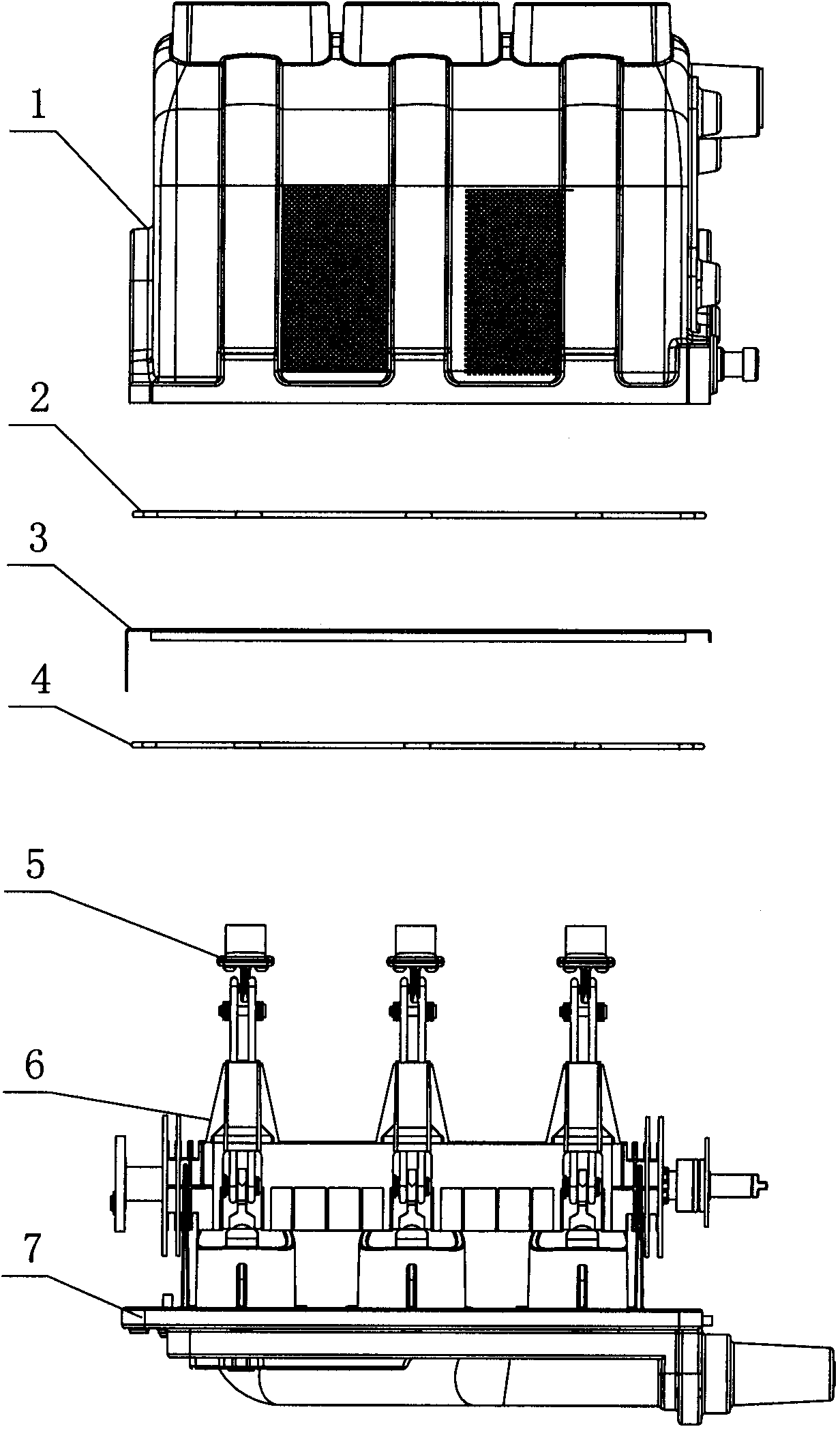

[0014] according to Figure 1~3 The specific structure and working process of the present invention will be described in detail. The solid-insulated fully-sealed three-position isolating switch includes an insulating arc shield 1, an insulated one-piece outlet base plate 7, an isolated static contact seat 5 and an isolated movable contact seat 6 with functions of closing, opening, isolation, and grounding. Wherein the insulated arc shield 1 and the insulated one-piece outlet base plate 7 are fastened and butted together by bolts. On the insulator of the insulating arc shield 1 equipped with the isolated static contact seat 5, the conductive part of the isolated static contact seat 5 passes through the insulator, and the creepage distance along the surface of the insulator meets the creepage distance of more than 240mm stipulated in the national standard creepage distance. On the insulator equipped with the isolated movable contact seat 6 and the insulated connected outlet ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com