Novel lamination module

A laminated component and a new type of technology, applied in electrical components, semiconductor devices, capacitor parts, etc., can solve the problems of the stability of welding equipment and the immaturity of the matching degree of conductive materials, the limited power improvement of MBB technology, and the thin grid of cells. The problem of high line resistance can meet the requirements of high-efficiency components, improve market competitiveness, and expand the research and development route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

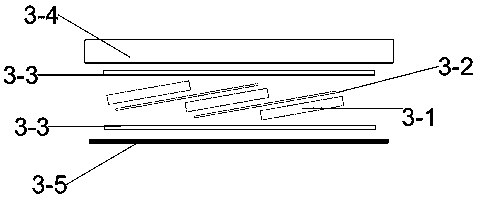

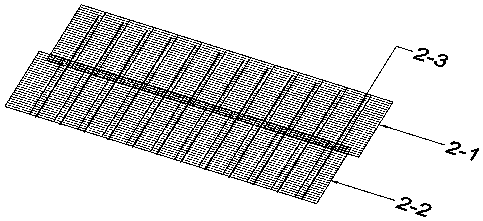

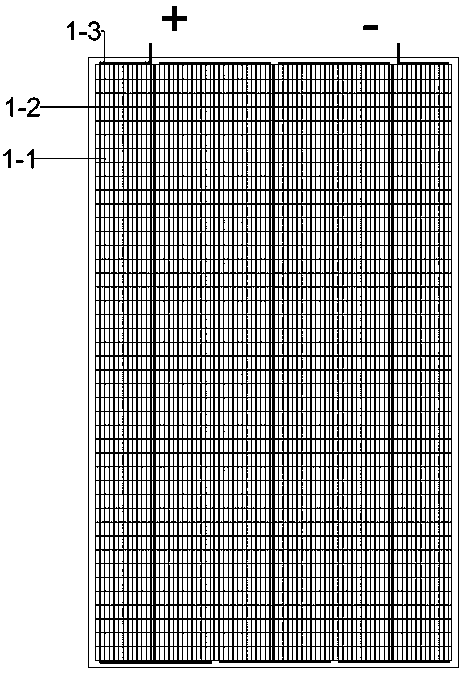

[0019] On the basis of traditional photovoltaic modules, the present invention introduces the design concept of laminated modules, and divides photovoltaic cells into 1 / 2, 1 / 3, 1 / 4, 1 / 5 or even smaller cells by using laser scribing means Slices, through ultra-thin ribbons, the diced battery slices are connected in series in a shingled manner to form a stacked battery string wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com