Preparation process of high-density imbricated module

A preparation process, high-density technology, applied in sustainable manufacturing/processing, electrical components, semiconductor devices, etc., can solve the problems of low effective output power, long production line, and many production steps of photovoltaic components, so as to improve optical gain. , Low internal loss, and the effect of improving component power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

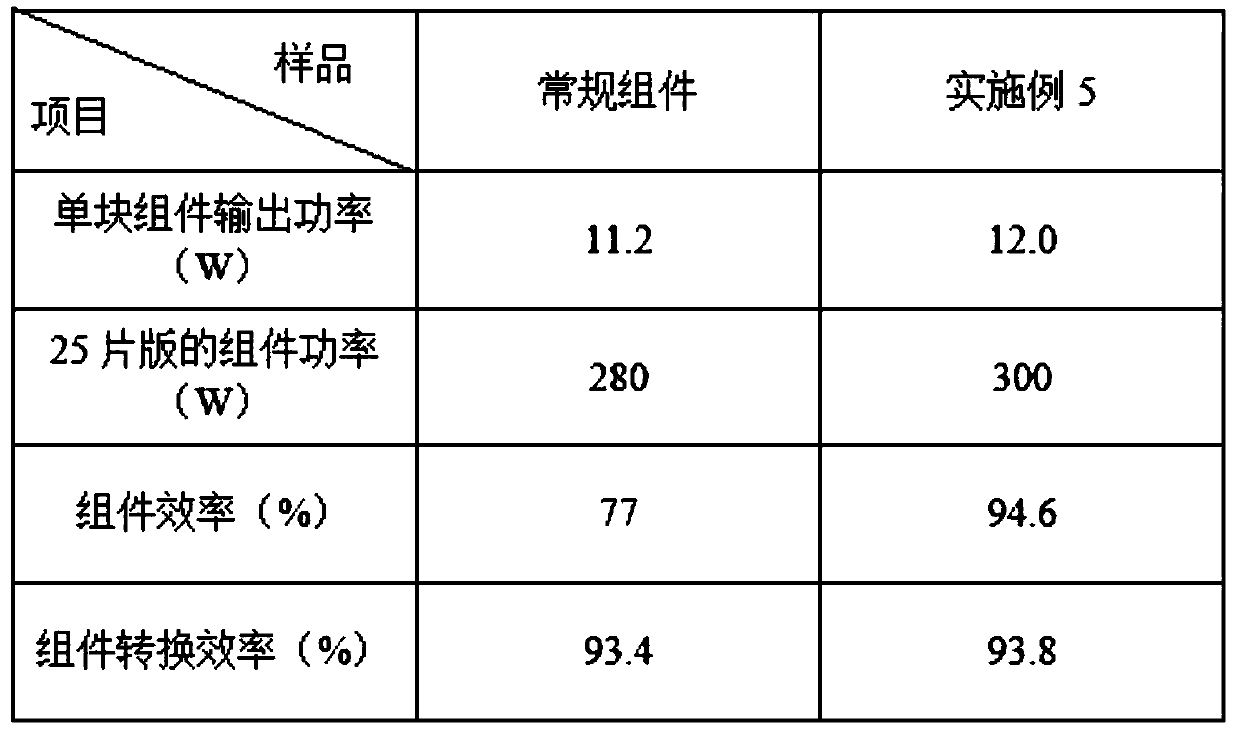

Examples

Embodiment 1

[0046] A preparation process for high-density shingled components, the preparation process comprising the following steps:

[0047] (1) Prepare a number of busbar-free cells, and use a laser scribing machine to cut the busbar-free cells to obtain a number of busbar-free cell slices;

[0048] (2) The two busbar-free cell slices obtained in step (1) are overlapped and serially connected from the beginning to the end to obtain a battery string. The front and back sides of the busbar-free cell slices include overlapping areas. The area is coated with conductive glue, and the battery slices without busbar are connected in series through conductive glue to obtain battery strings, and two battery strings are obtained according to the above method;

[0049] (3) Connect the two strings of battery strings obtained in step (2) into a long string of batteries through copper wire ribbons, and weld one end of the copper wire ribbon to the front side of the last battery slice without busbar ...

Embodiment 2

[0056] A preparation process for high-density shingled components, the preparation process comprising the following steps:

[0057] (1) Prepare a number of busbar-free cells, and use a laser scribing machine to cut the busbar-free cells to obtain a number of busbar-free cell slices;

[0058] (2) The six busbar-free battery slices obtained in step (1) are overlapped and connected in series from the beginning to the end to obtain a battery string. The front and back sides of the busbar-free battery slices include overlapping areas. The area is coated with conductive glue, and the battery slices without busbar are connected in series through conductive glue to obtain a battery string, and 6 battery strings are obtained according to the above method;

[0059] (3) Solder the 6 battery strings obtained in step (2) into a long string of batteries through tinned copper wire ribbons, and connect one end of the tinned copper wire ribbon to the last non-busbar cell of a string of battery...

Embodiment 3

[0066] A preparation process for high-density shingled components, the preparation process comprising the following steps:

[0067] (1) Prepare a number of busbar-free cells, and use a laser scribing machine to cut the busbar-free cells to obtain a number of busbar-free cell slices;

[0068] (2) The 10 busbar-free battery slices obtained in step (1) are overlapped and serially connected from the beginning to the end to obtain a battery string. The front and back sides of the busbar-free battery slices include overlapping areas. The area is coated with conductive glue, and the battery slices without busbar are connected in series through conductive glue to obtain battery strings, and 10 battery strings are obtained according to the above method;

[0069] (3) The 10 battery strings obtained in step (2) are serially welded into a long string of batteries through tin-lead copper wire ribbons, and one end of the tin-lead copper wire ribbon is connected to the last piece of battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com