Optical head of computer-controlled plate making machine

A plate-making machine and computer technology, applied in the field of scanning optical heads, can solve the problems of slow scanning speed and inability to achieve high power, and achieve the effect of solving power and channel number problems and being easy to replace independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

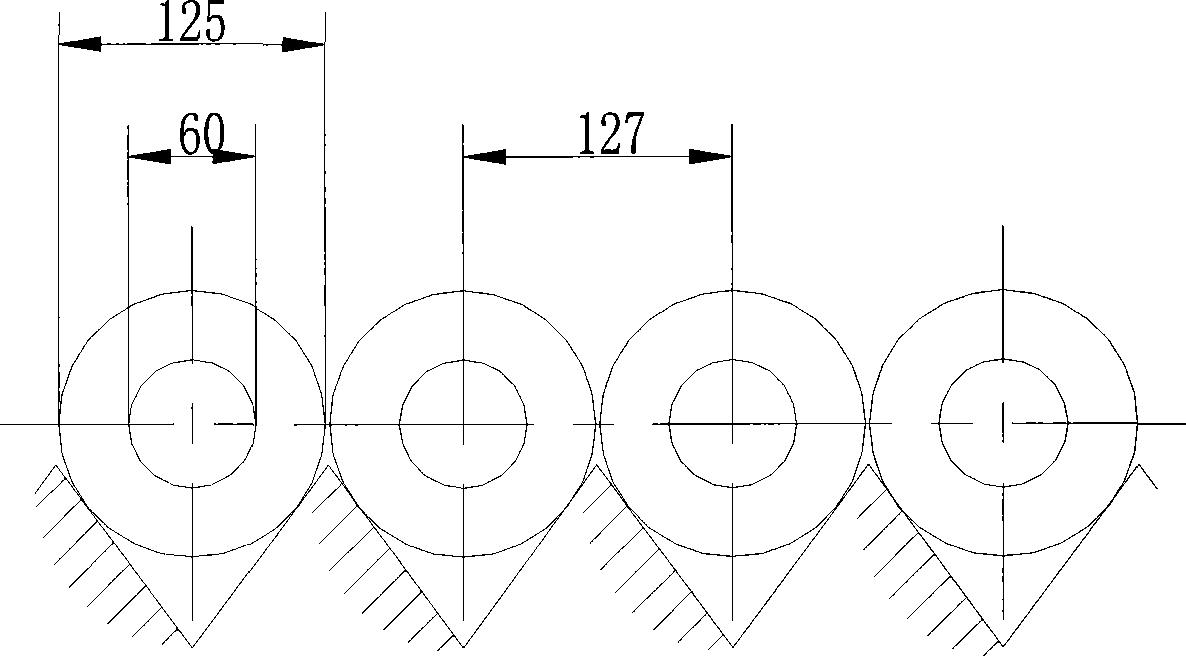

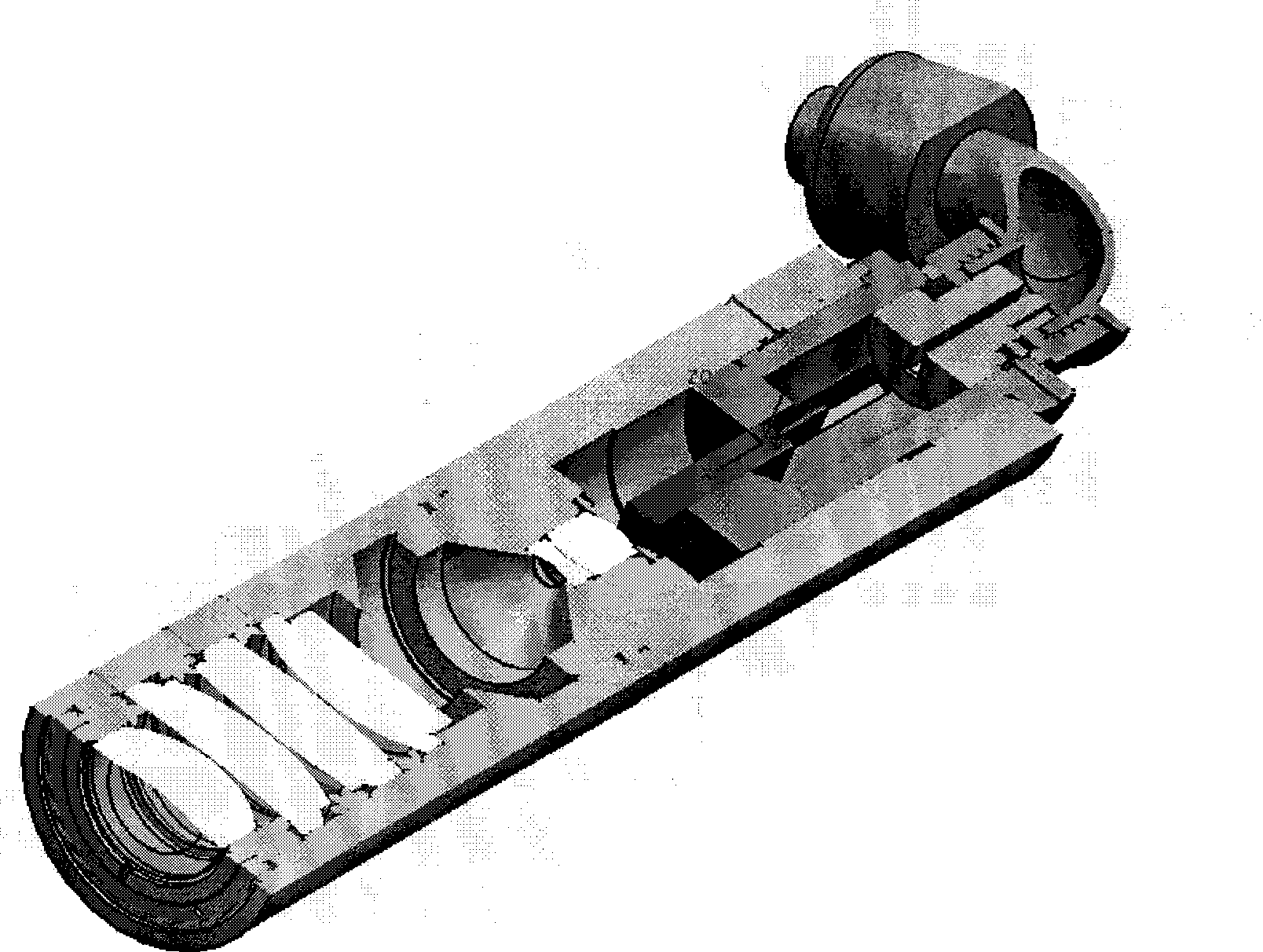

[0019] The invention is an optical head device of a computer-to-plate-making machine, which has a lens, and an optical fiber for scanning is arranged in the lens. The optical fiber is fixed on a silicon chip, and a V-shaped groove array is engraved on the silicon chip. An optical fiber is placed in the V-shaped groove, the diameter of the optical fiber is slightly smaller than the spacing of the V-shaped groove, and a laser diode is independently connected to the tail of each optical fiber. The plane of the V-groove array has a certain angle θ with the scanning direction.

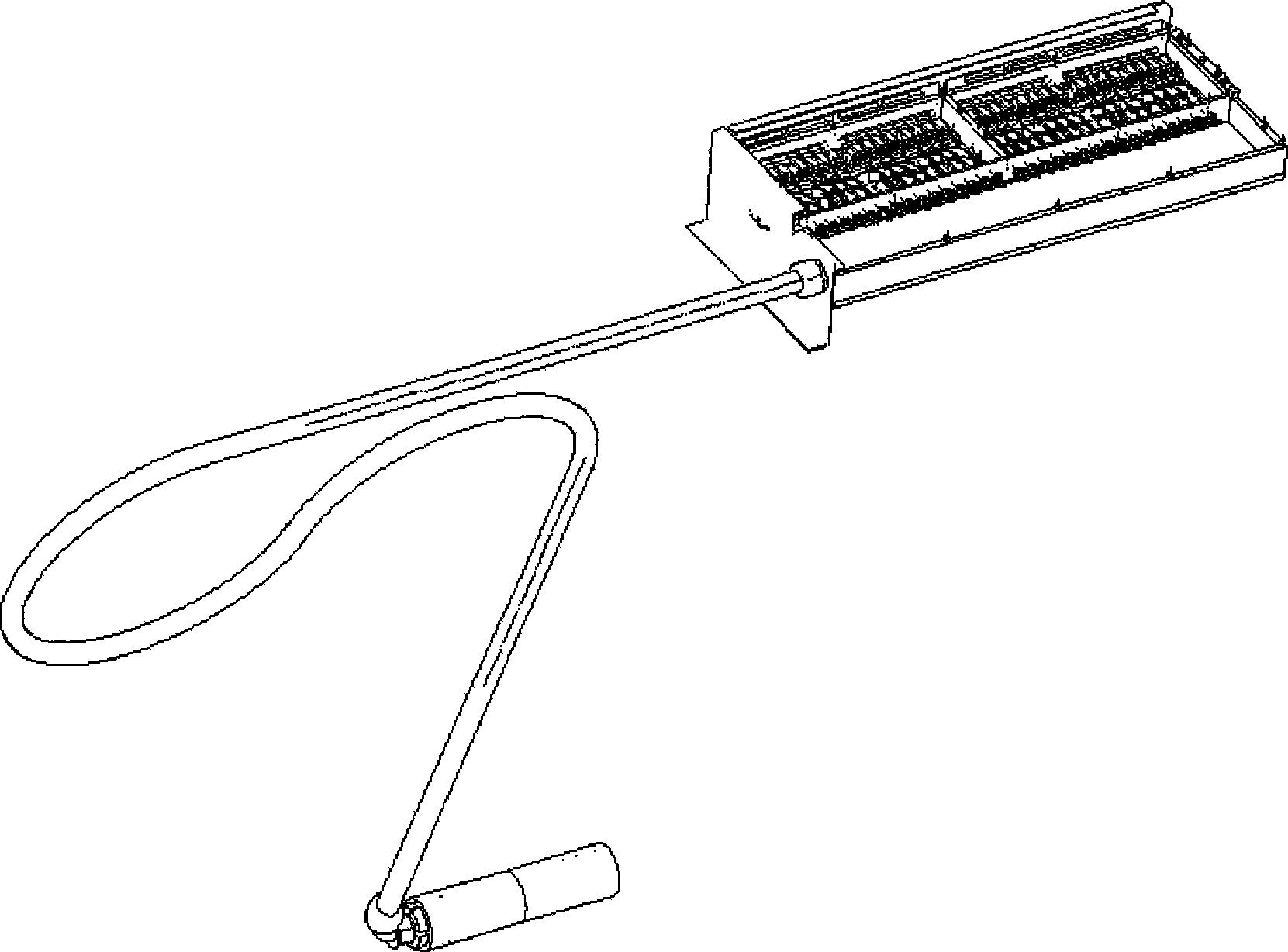

[0020] figure 1 A laser diode with 32 independent pigtailed outputs is shown along with the modulation circuit, optical fiber, V-groove and lens.

[0021] figure 2 An example of a fiber V-groove array is shown. The V-groove can be obtained by wet etching after exposure of the silicon wafer. The natural V-shaped groove is obtained by using the slow etching speed of the 111 side of silicon. It can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com