Integrated motor

A one-piece motor casing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as inability to guarantee integrity and stability, inconvenient parts to be replaced independently, complicated motor installation and disassembly, etc., to achieve Increase the effect of heat dissipation, increase the scope of application, and save power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

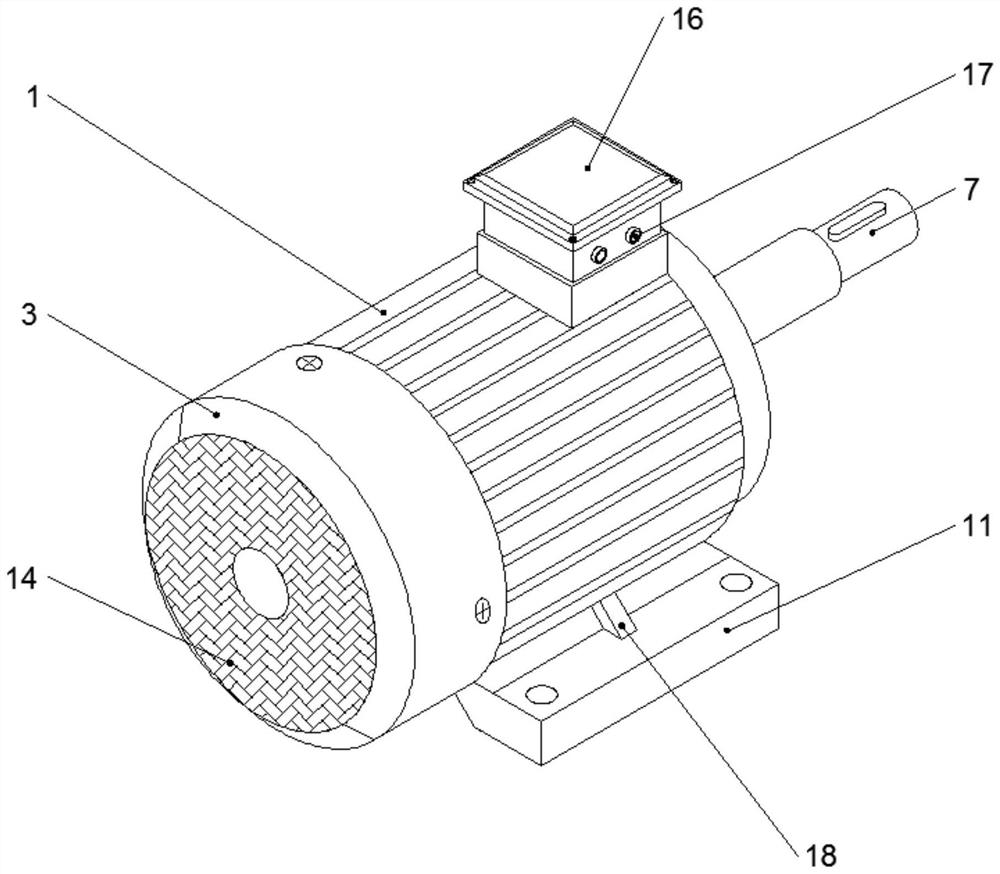

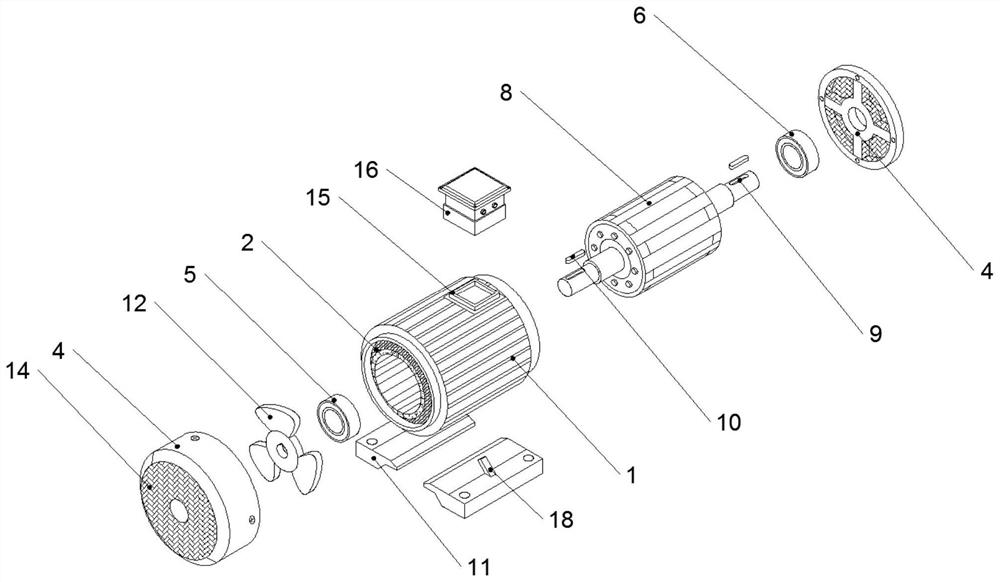

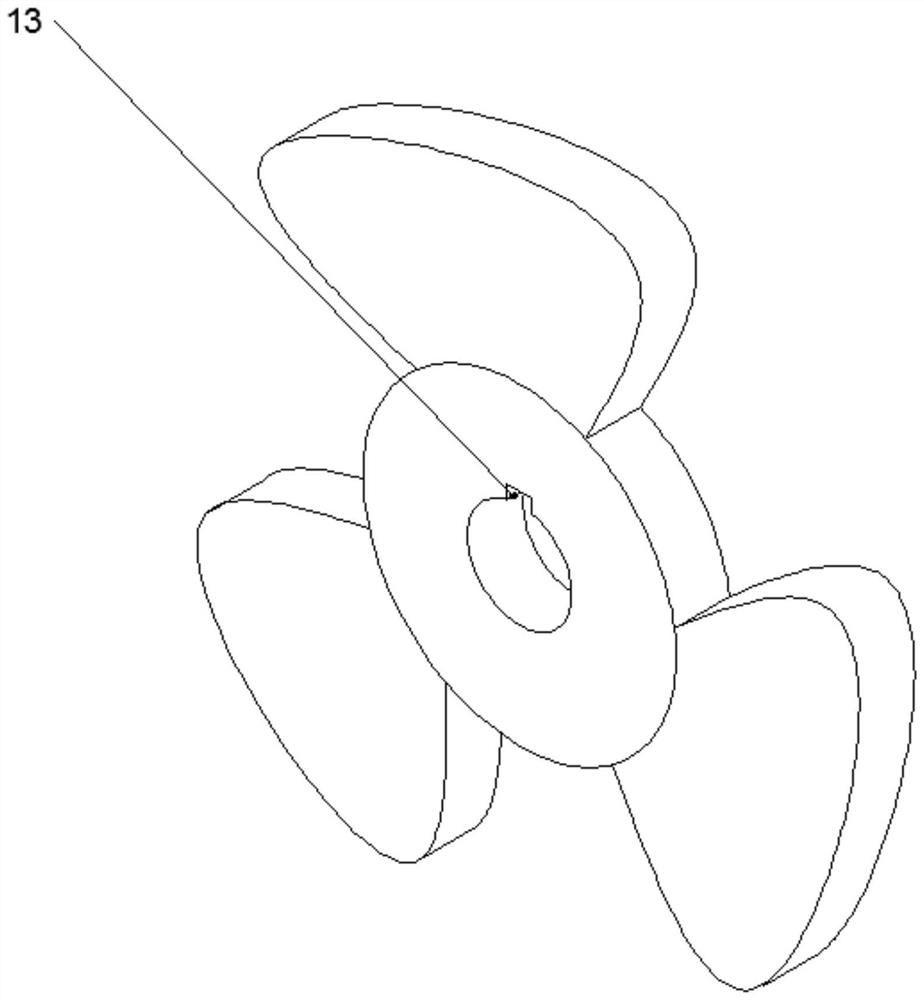

[0020] Example: such as Figure 1-3 As shown, a one-piece motor of the present invention includes an electric compartment wall 1, and a magnetic block ring 2 is fixed inside the electric compartment wall 1, and one end of the electric compartment wall 1 is fixedly connected to the motor casing 3 by bolts, and the electric compartment wall The other end of 1 is fixedly connected to the motor cover 4 by bolts, the middle part of the motor case 3 is provided with a rotating shaft bearing 5, the middle part of one side of the motor cover 4 is fixedly connected to the auxiliary rotating bearing 6, and the inner part of the magnet ring 2 is fixedly provided with a rotating shaft 7. A rotor 8 is fixed on the outer side of the middle part of the rotating shaft 7 and the corresponding position of the magnetic block ring 2. The two ends of the rotating shaft 7 are fixedly provided with a keyway 9, and the inside of the keyway 9 is fixedly provided with a key 10. Both sides of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com