Diaphragm-operated pressure regulating valve

A technology of pressure regulator and membrane, which is applied in the direction of fluid pressure control without auxiliary power, fluid pressure control, control/regulation system, etc. It can solve the problems of difficult to obtain reliable sealing of seals, gas fluctuations, performance limitations, etc., to achieve Effects of eliminating spacing, increasing load, and promoting uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Objects and advantages of the present invention will be better understood by referring to the following description of preferred embodiments and accompanying drawings.

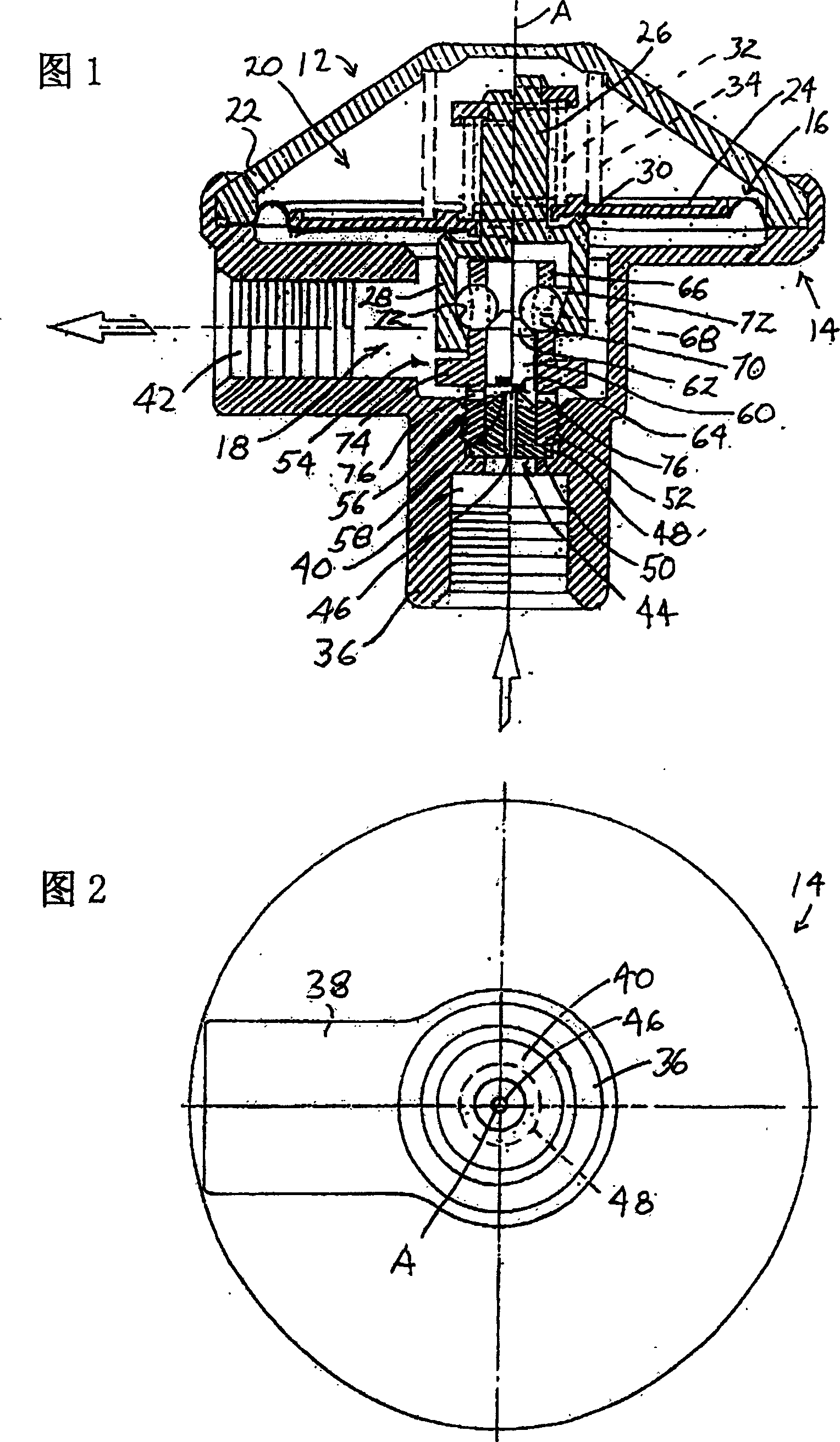

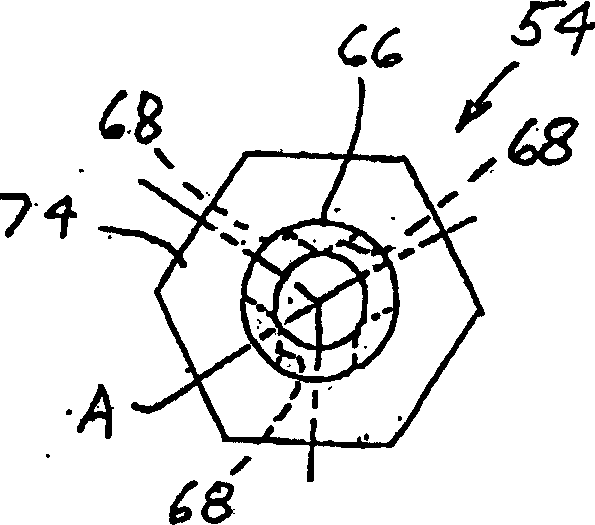

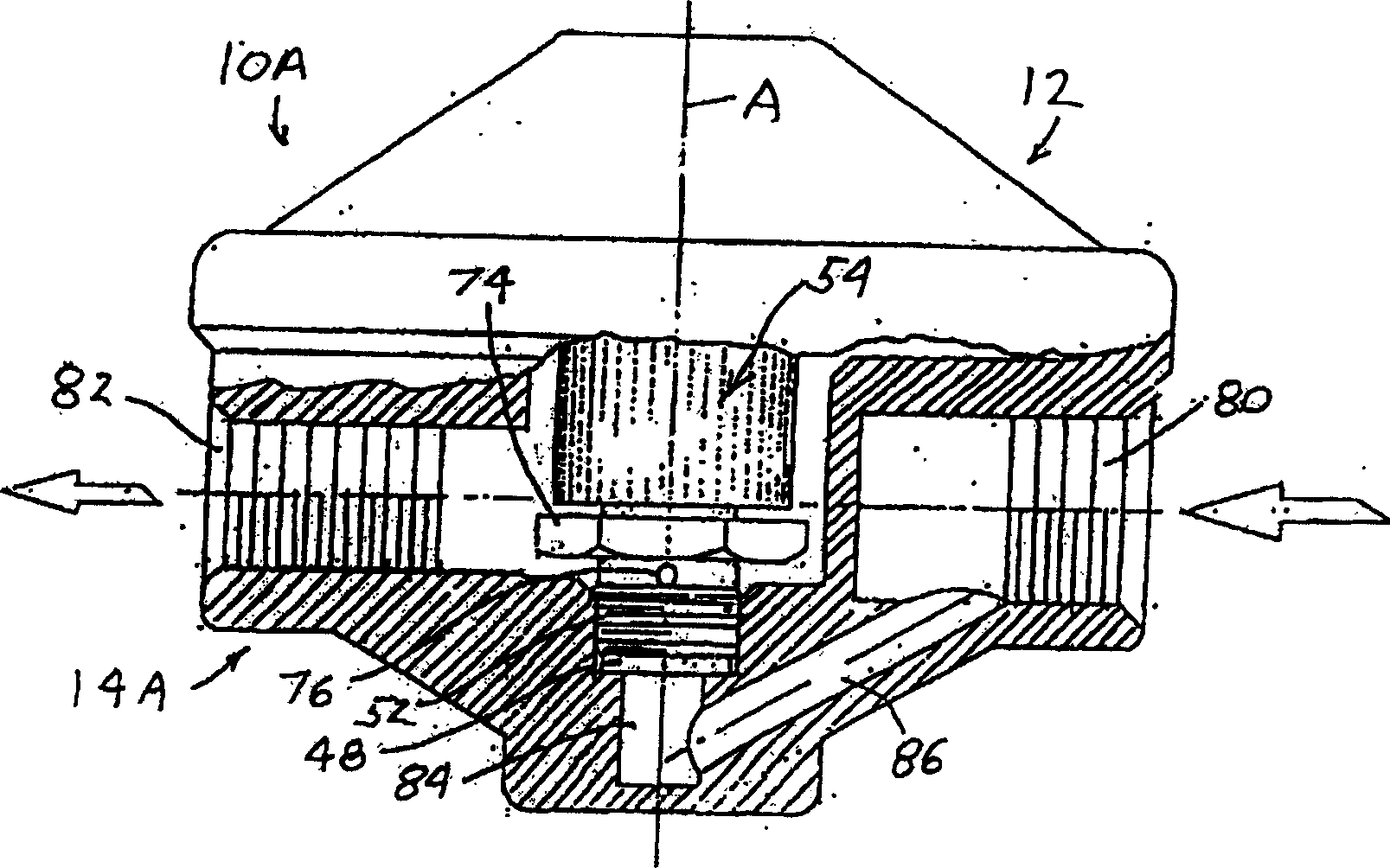

[0016] The present invention will now be described in more detail with reference to the accompanying drawings. It should be clear that this is only for illustrating preferred embodiments of the present invention, and cannot limit the scope of the present invention. Figures 1-3 show a fluid pressure regulating valve 10 of the present invention comprising upper and lower housings 12 and 14, and a flexible membrane 16 clamped between the outer circumferences of the two housings, the membrane 16 enclosing the inner circumference of the housing. Partly forms a pressure chamber 18 and an outlet chamber 20 , which communicates with the surrounding atmosphere via an outlet hole 22 in the housing 12 . Said valve has an axis A to which the membrane is not only perpendicular but also coaxial with axis A; the membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com