Multi-span energy saving sunlight greenhouse

A solar greenhouse and multi-span technology, applied in the field of solar greenhouses, can solve the problems of inconvenient large-scale production of solar greenhouses, inability to meet large-scale production on sloping land, and inability to adopt mechanized production, etc., and achieve low cost, eliminate spacing, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

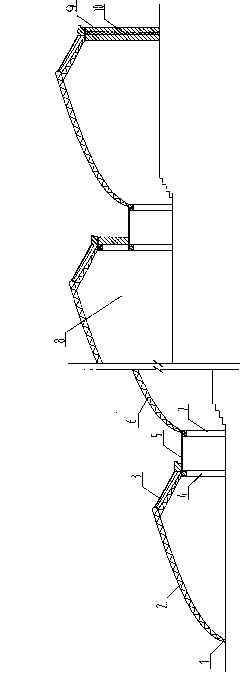

[0009] exist figure 1 In the multi-span energy-saving solar greenhouse, two or more single-slope solar greenhouses are connected. The ridge wall 1 is the front bottom corner of the greenhouse. Outside the ridge wall 1, there is a cold-proof ditch. The cold-proof ditch is provided with a thermal insulation benzene board with a thickness of 50-80mm and a height of 800-1000mm to prevent the heat loss of the greenhouse surface. Gables 8 are built on the left and right ends between the rear wall and the ridge wall 1 . The ridge wall 1, the gable wall 8 and the rear wall constitute a permanent protective wall of the multi-span greenhouse. Both the gable 8 and the rear wall are composite thermal insulation walls, a 120mm or 90mm thick benzene board thermal insulation layer 10 is sandwiched between the gable 8 and the rear wall, and 240mm thick brick wall layers 9 are built on both sides of the thermal insulation layer 10, forming a A composite thermal insulation wall with better th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com