A water pump backing plate

A backing plate and water pump technology, which is applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of water pump backing plate installation stress deformation, inability to meet different vehicle matching, shorten service life, etc., to ensure the board surface Strength, small thickness, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

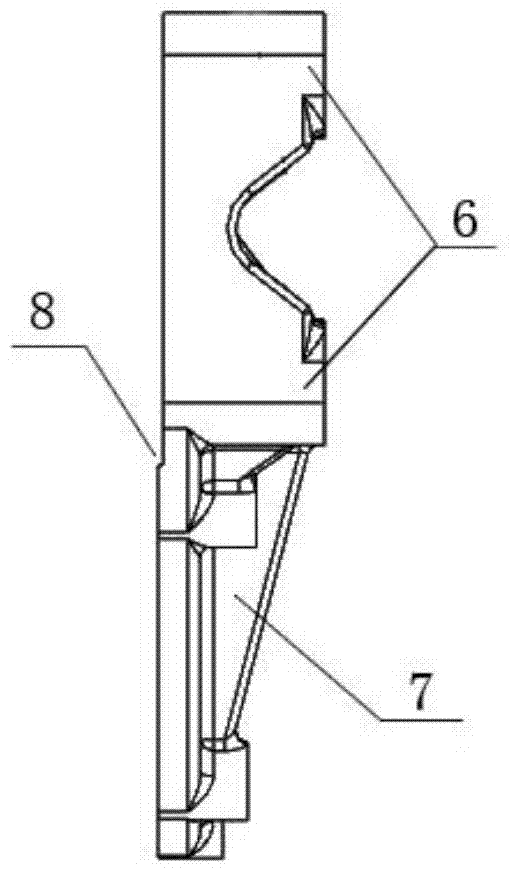

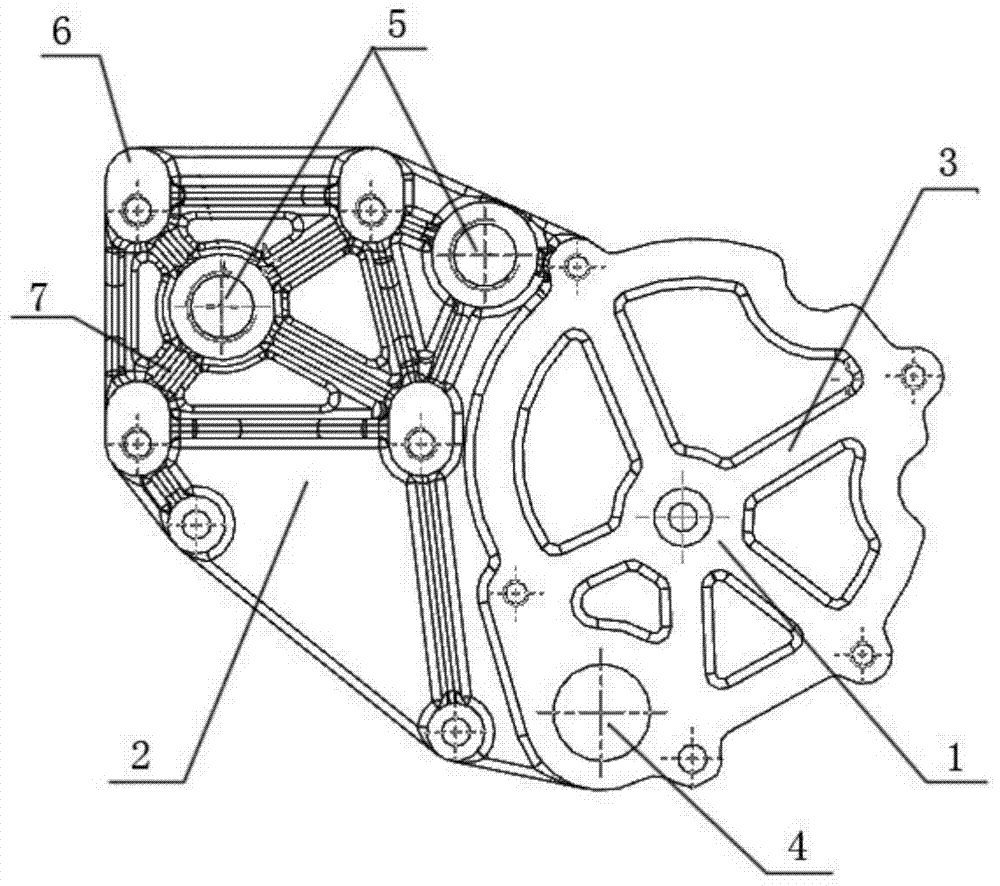

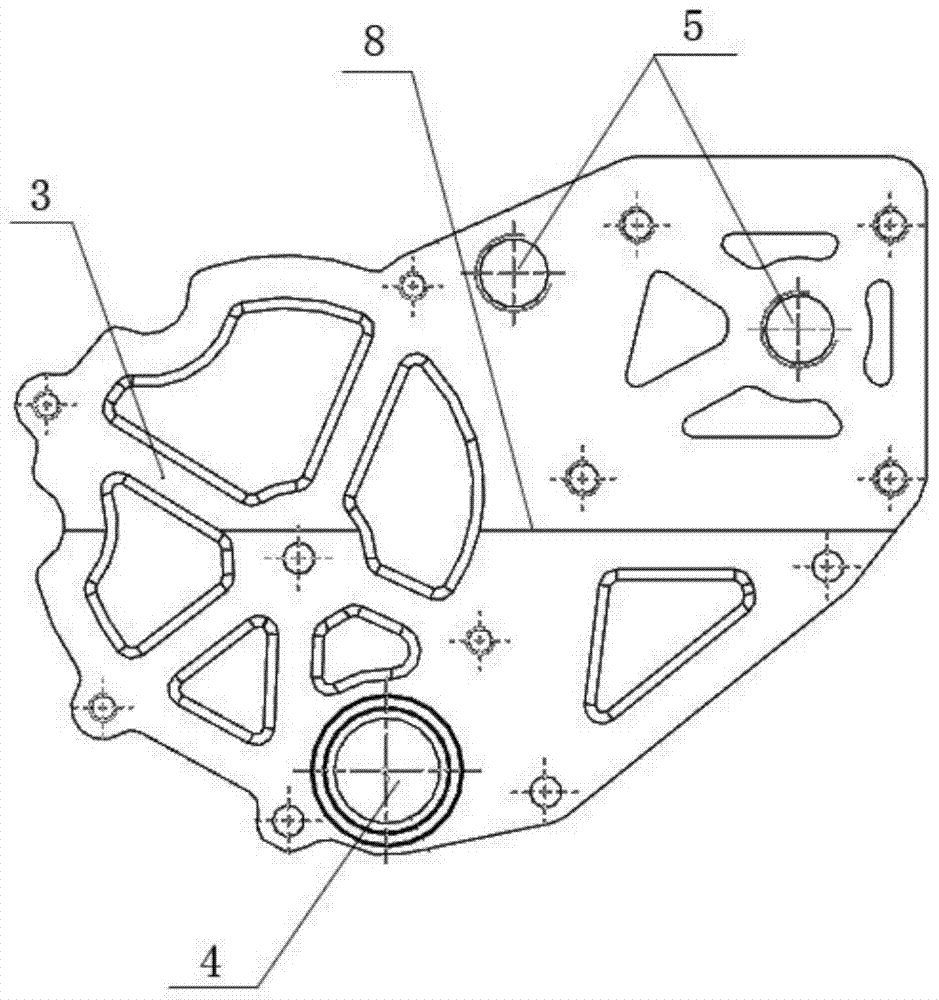

[0028] The specific embodiments of the present invention are as Figure 1 to Figure 3 Shown is a water pump backing plate. The backing plate body is fixed on one side of the engine body by 4 M8 bolts. It includes a water pump mounting plate 1 for installing the water pump. The backing plate body on the side of the water pump mounting plate 1 is also A fan mounting plate 2 is provided for installing a fan. This type of arrangement can reduce the special parts used when installing the engine while ensuring the rationality of the arrangement of parts and save costs.

[0029] The side of the backing plate body of the water pump backing plate that is in contact with the engine cylinder head and cylinder block is provided with a step surface 8 that makes the upper and lower parts of the backing plate not coplanar. The lower part of the backing plate near the water inlet of the engine body is the base surface; Two adjusting screw holes 5 are arranged on the upper part of the backing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com