Improved anti-blockage device used for crushed straw aggregate feeding machine

A technology of feeder and crushed material, which is applied in the field of improved anti-jamming device for straw crushed material feeder, which can solve the problems of boiler tempering and fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

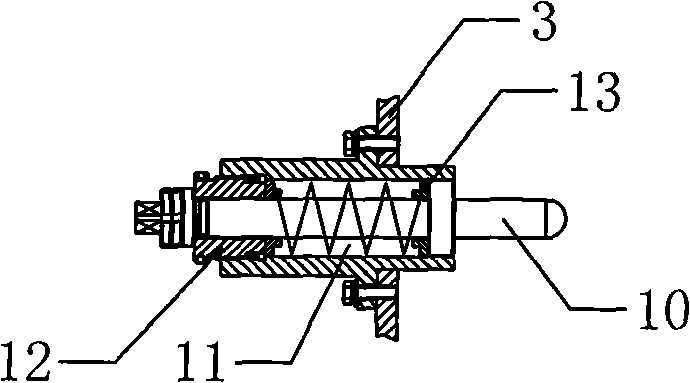

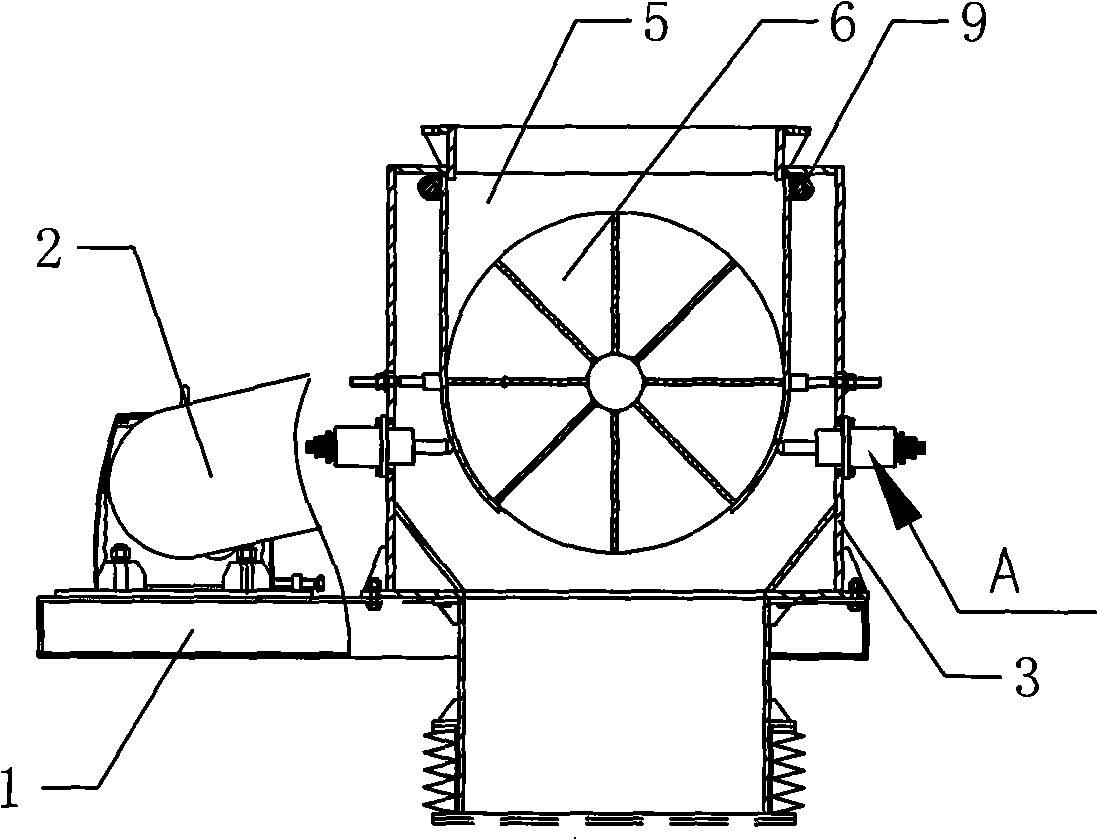

[0008] see figure 1 , figure 2 , The present invention includes the jack shaft 10, the jack shaft 10 is mounted on the shaft sleeve 13, the shoulder of the jack shaft 10 is in clearance fit with one end of the shaft sleeve 13, and an end sleeve is provided between the other end of the jack shaft 10 and the other end of the shaft sleeve 13 12. A spring 11 is press-fitted between the end sleeve 12 and the shaft shoulder. The end shoulder of the top shaft 10 is press-fitted on the end sleeve 12, and the flange outer diameter of the end sleeve 12 is larger than the inner diameter of the shaft sleeve 13. The working process of the present invention is described below in conjunction with the drawings: a large amount of material is poured from the hopper mouth, the rotor is driven by the motor to rotate rapidly, after the blades disperse the material, the material is stored between the rotor blades 6, under the rotation of the rotor 6 Bring it out to realize the feeding of the boiler. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com