Star feeder

A star-shaped feeder and material feeding technology, applied in the direction of fuel supply, combustion method, block/powder supply/distribution, etc., can solve the problems of potential safety hazards, lack of reliable support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

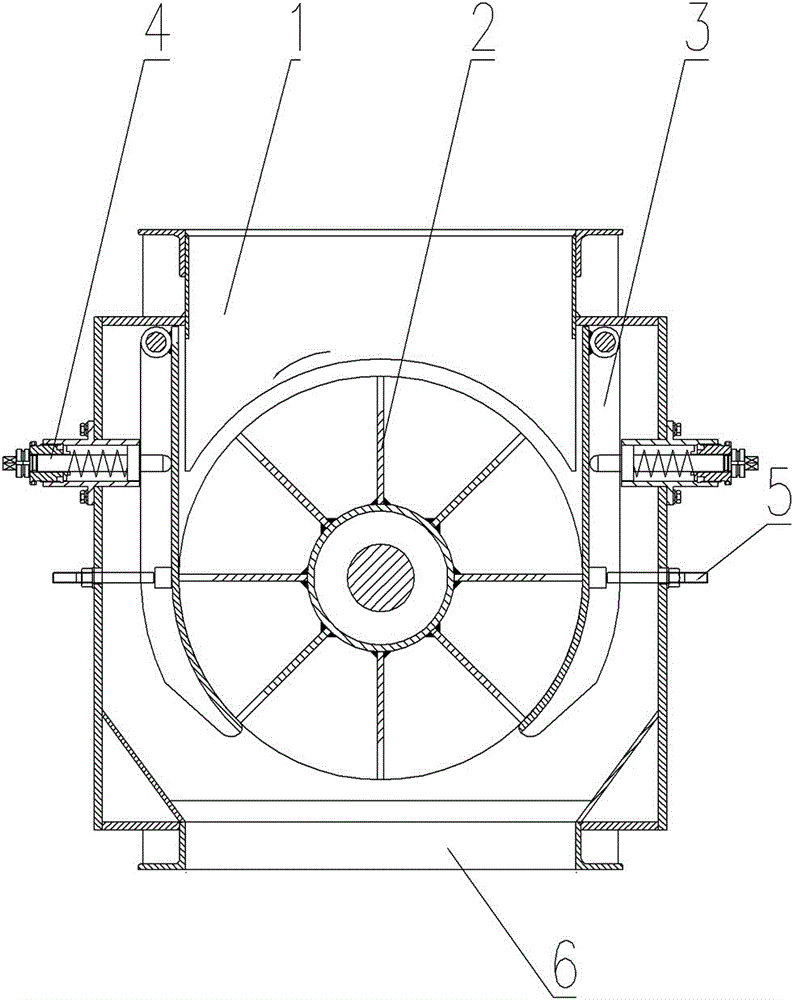

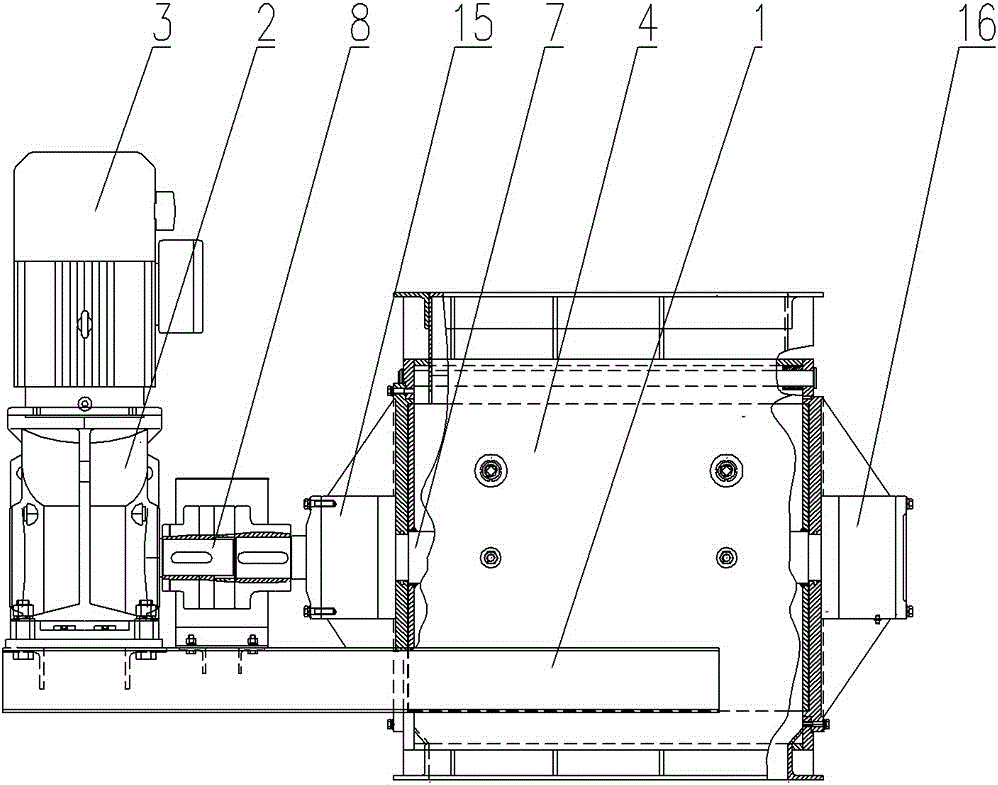

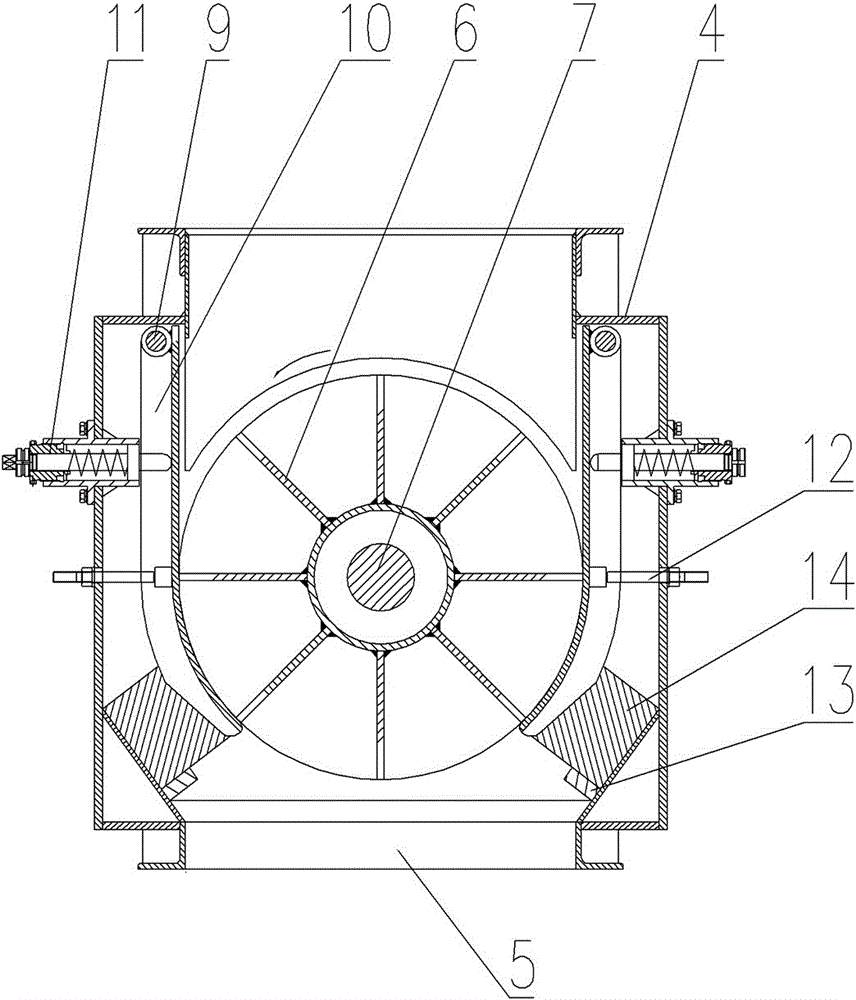

[0011] See figure 2 , image 3 As shown, a star feeder includes a frame 1, a reducer 2, and a drive motor 3. A feeding funnel 4 is installed on the frame 1. A discharge port 5 is arranged at the bottom of the feeding funnel 4. The inside of the feeding funnel 4 is provided with There is a rotor 6, the rotating shaft 7 of the rotor 6 is perpendicular to the centerline of the feeding funnel 4, the rotating shaft 7 is connected to the reducer 2 through a coupling 8, and the two sides of the rotor 6 are respectively provided with movable sealing plates 10 through the supporting rotating shaft 9, and the two movable sealing plates The plate 10 forms a U-shaped bucket, and the bottom of the U-shaped bucket is hollowed out. An anti-jamming device 11 is arranged on the outer upper part of the movable sealing plate 10, and a stud bolt 12 is arranged on the outer middle part of the movable sealing plate 10. A support block 13 is also installed in the feeding funnel 4. , the support bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com