Arrangement bench for drum washing machine and assembly structure of drum washing machine and arrangement bench

A technology of a drum washing machine and an assembly structure, which is applied to other washing machines, washing devices, mechanical equipment, etc., can solve problems such as dumping, the drum washing machine 1 cannot be stably placed, and the washing machine is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Before explaining the structure of the present invention, in order to avoid duplication of description, for parts consistent with the original technology, the symbols in the original drawings are directly quoted.

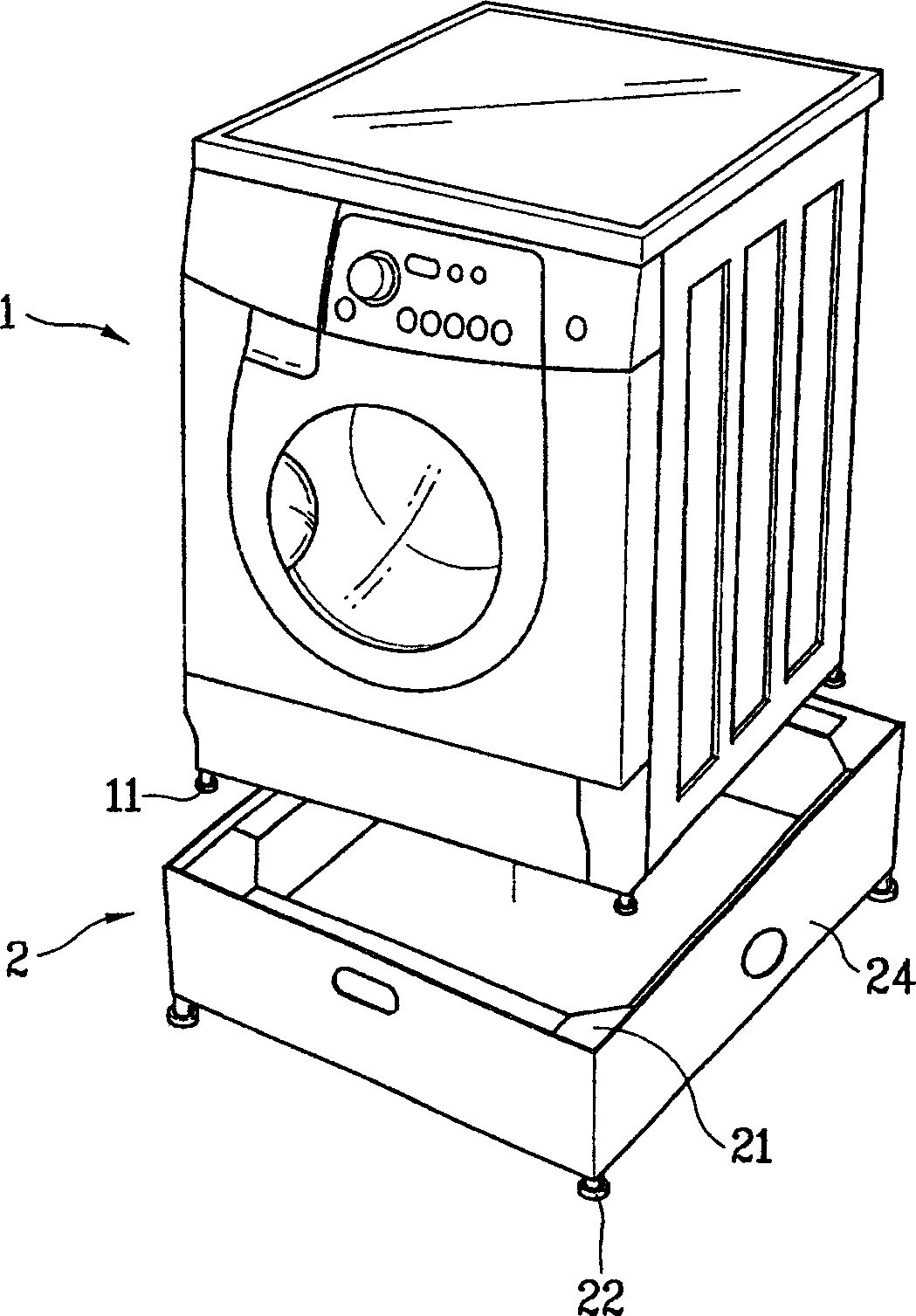

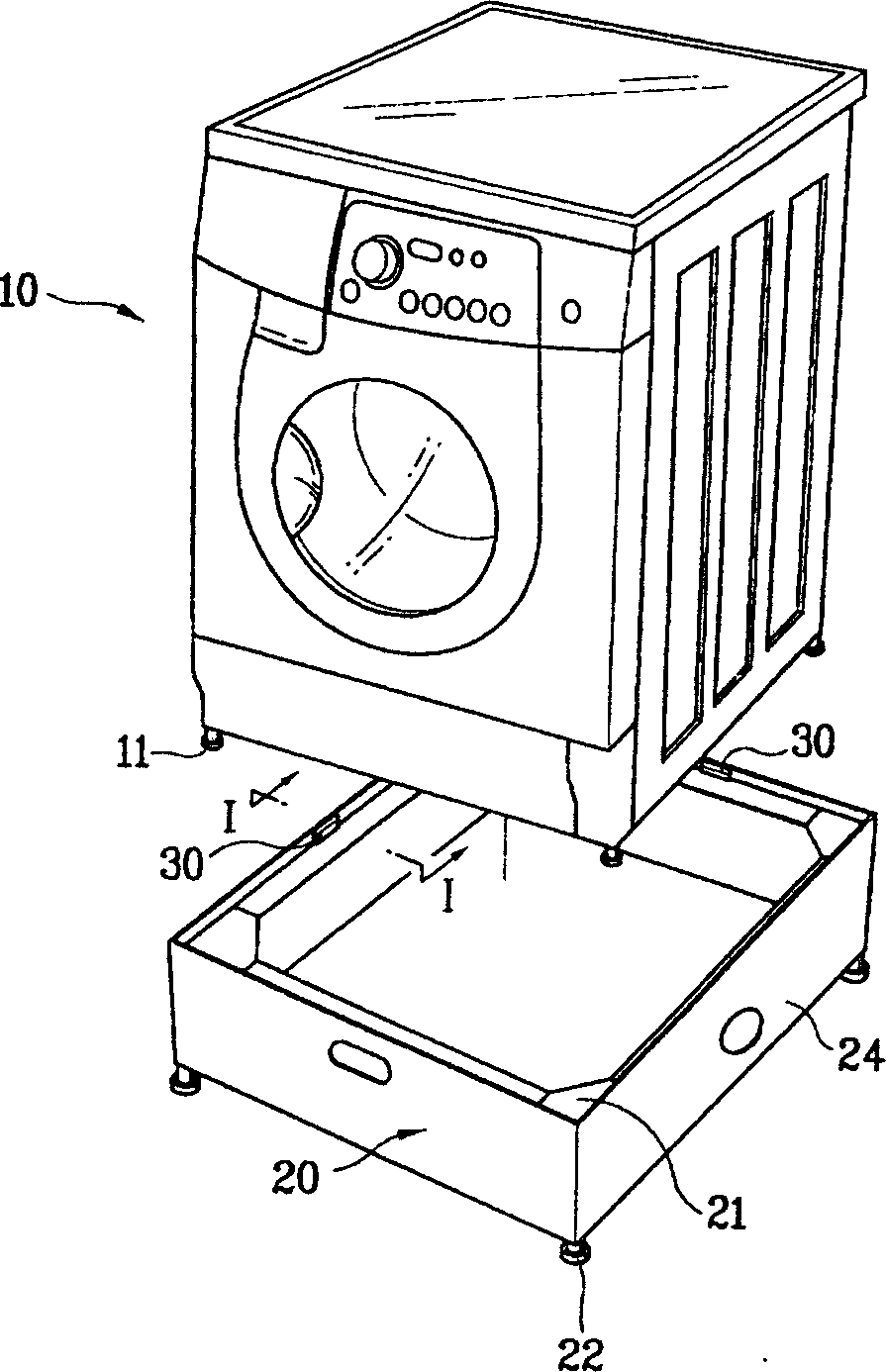

[0034] figure 2 It is a perspective view of an example of the installation stand of the front-loading washing machine of the present invention.

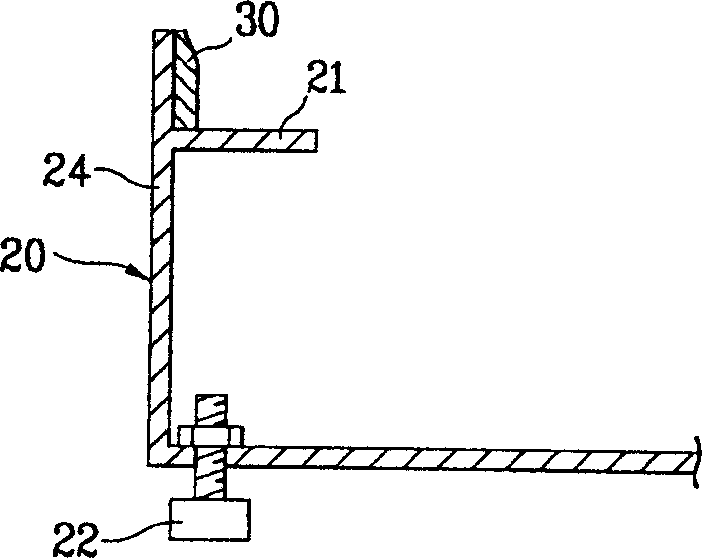

[0035] Such as figure 2 As shown, four rectangular right square plates are used to form side walls, and backing plates 21 are formed on the corners where the plates forming the side walls (ie, the lower side panels) intersect each other. Backing plate 21 is the place to place drum washing machine 10, and it is arranged on 4 corners respectively.

[0036] On the bottom surface of the installation table 20, the support legs 22 of the installation table 20 are provided respectively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com