Dynamic filtering apparatus

A technology for dynamic filtration and filtration components, which is used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inaccurate closed position positioning, complex structure, and oil fume backflow, and achieve uniform airflow and flow field. The effect of large interception area and reduced flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

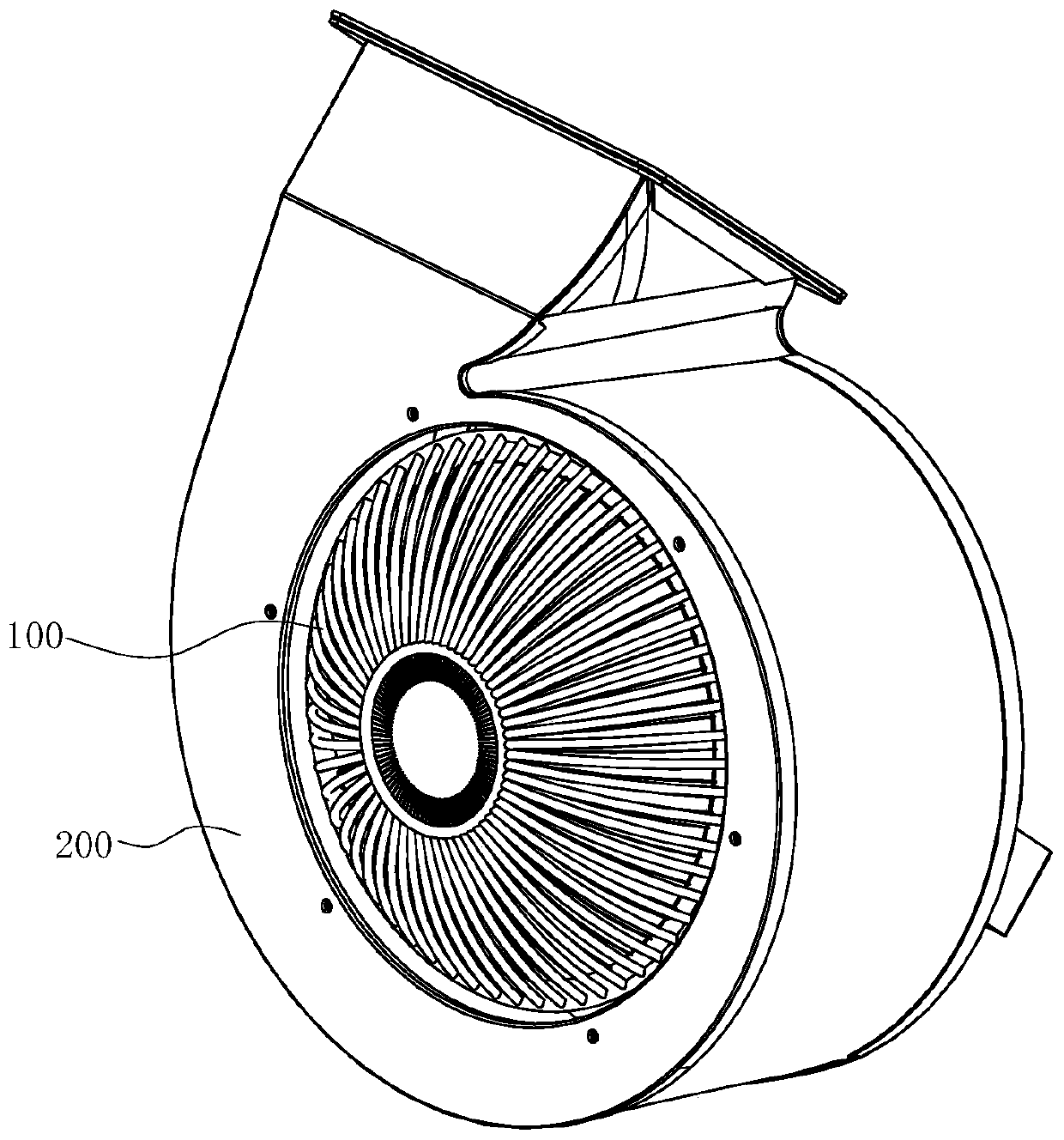

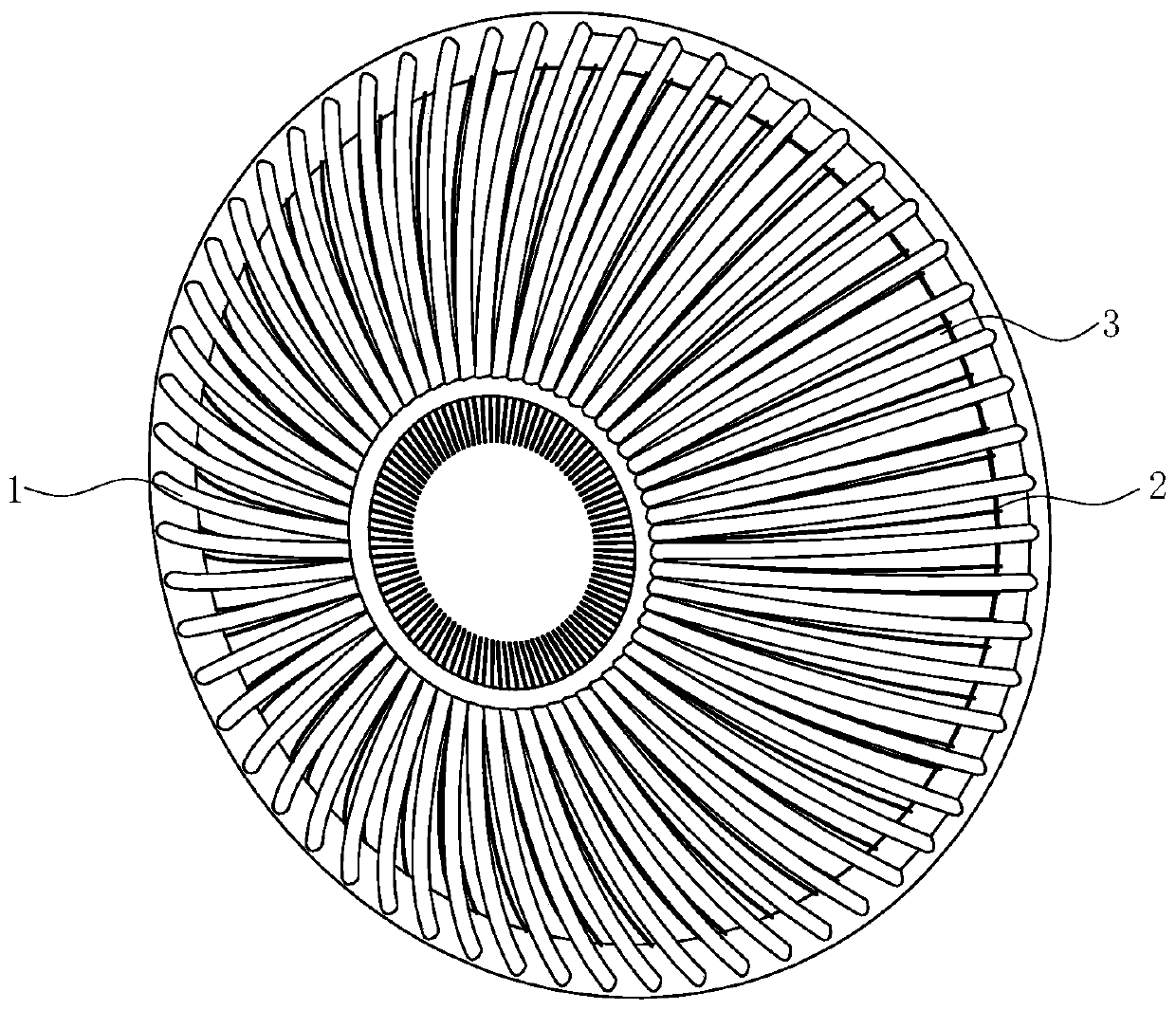

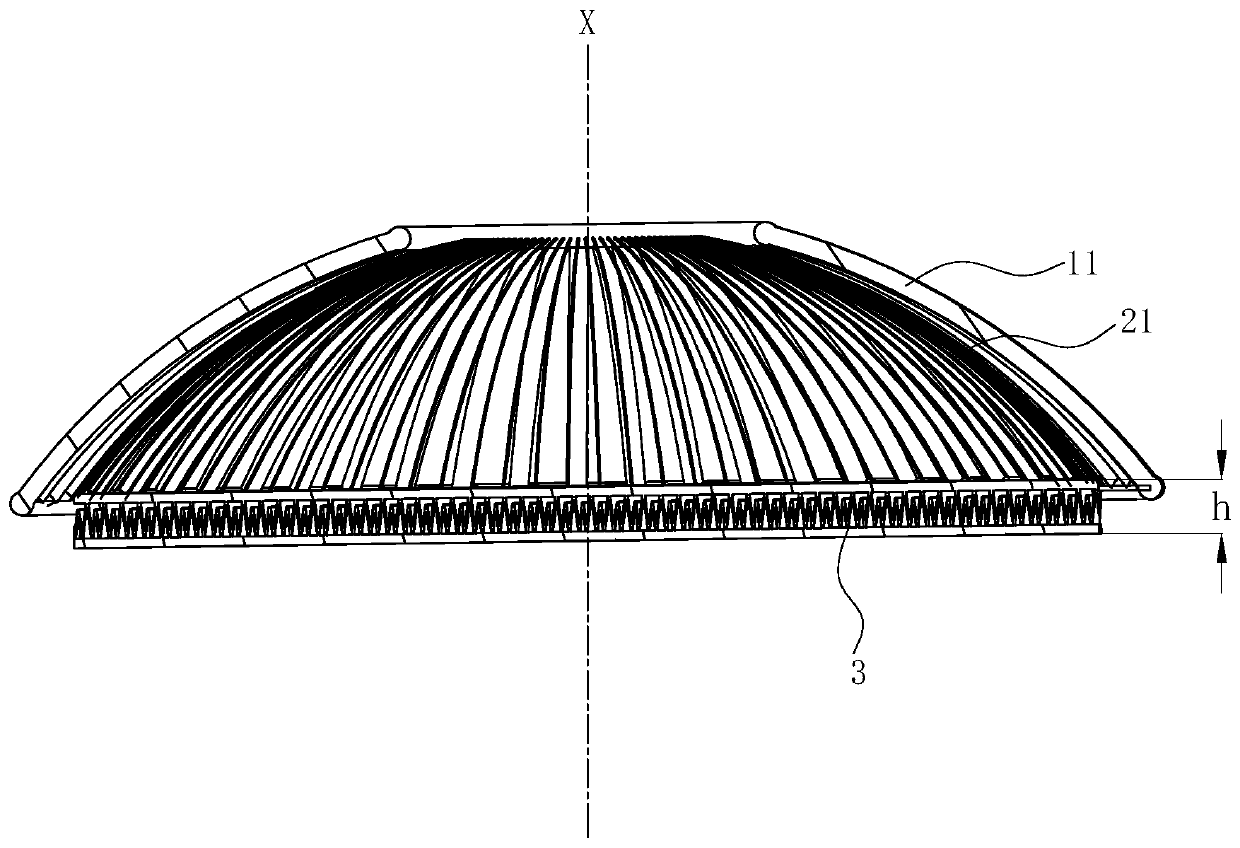

[0026] see Figure 1 to Figure 6 , a dynamic filtering device 100, including an intercepting assembly 1, a cutting assembly 2 and a filtering assembly 3. On the flow path of oil fume, the above three components are arranged sequentially from upstream to downstream, and combined into one body with an axis X. The three components of the dynamic filter are driven by the same external power mechanism, such as the motor of the fan. For this reason, the dynamic filtering device of this embodiment can be welded at the air inlet of the fan 200 and connected with the impeller. Of course, it can also be used as an independent component, and a separate driving motor can be provided. The dynamic filtering device adopts fan power or independent power, and the above-mentioned intercepting assembly 1, cutting assembly 2 and filtering assembly 3 all rotate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com