Method for processing production waste liquid of ketene dimer by composite bacteria

A technology of diketene and compound bacteria, which is applied in anaerobic digestion treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, unpleasant smell, and excessive solid waste, save energy and overcome odor. unpleasant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

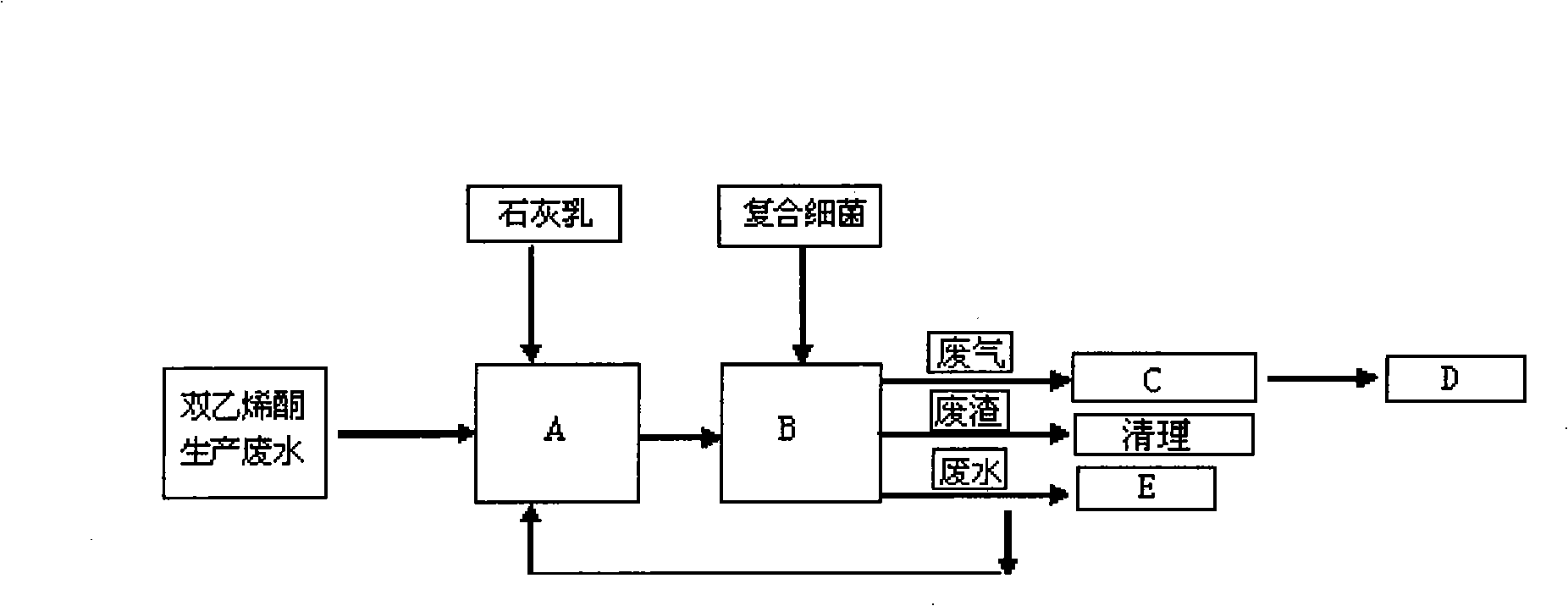

[0010] Input the diketene production waste liquid into the waste liquid adjustment pool A, adjust the pH to 7-8 with a small amount of lime milk and water (UASB reuse water and domestic water), the COD is 12000-15000mg / L, and use the pump to pump the pH-adjusted The waste liquid is sent to the UASB anaerobic reaction tank B, and treated with composite bacteria, the effluent COD is 600mg / L, and more than 96% are removed. The composite bacteria treatment is the application of conventional activated sludge from domestic sewage treatment plants and lemon Special activated sludge for acid plant sewage treatment with methane bacteria. The waste gas is discharged from the top of the UASB pool and enters the waste gas collector C, and the generated secondary waste gas (mainly containing combustible gases such as methane) is sent to the heating furnace D as fuel. A small amount of residue in the waste liquid adjustment tank is cleaned regularly. Part of the waste water is reused as wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com