Preparation method of terminal hydrogen-containing silicone oil

A technology of terminal hydrogen-containing silicone oil and methyl silicone oil, which is applied in the field of silicone softeners, can solve the problems of difficult treatment, high solid waste, poor stability, etc., achieve low boiling and electrolyte content, simplify the synthesis process, The effect of less catalyst usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

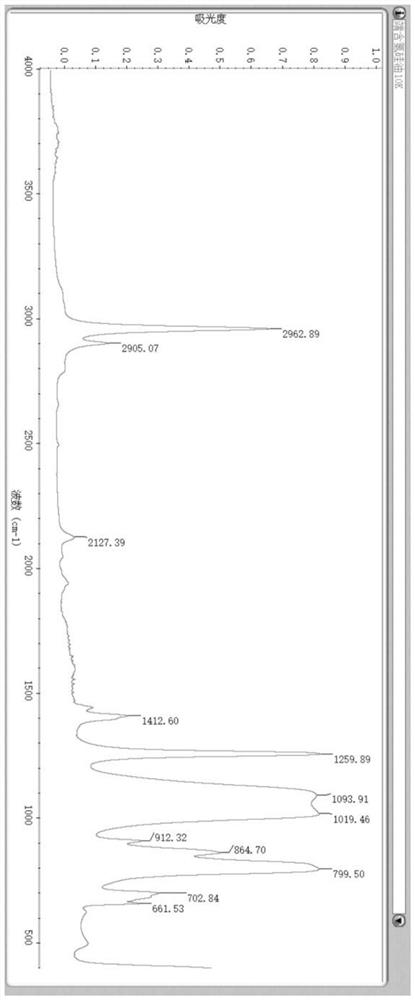

Image

Examples

Embodiment

[0036] Hydrogen-containing silicone oil prepared by traditional process: add DMC or D4, hydrogen-containing double-head, and concentrated sulfuric acid into the container in turn, start stirring, first heat up to 30-35 ° C, and keep reacting for 6 hours. Then add soda ash to neutralize the reaction for 1 hour, make the PH value of the material 6, make the material pass through the filtration device, and remove the generated solid waste. Then the temperature was raised to 100-130°C, and the low boilers were removed by vacuuming. Finally, the material is cooled and discharged to obtain terminal hydrogen-containing silicone oil with a solid content of about 90%.

[0037] The hydrogen-containing silicone oil at the preparation end of the new process: the measured high-viscosity methyl silicone oil and the hydrogen-containing double-head are used as raw materials, put into the container in turn, fully mixed and stirred evenly, and then the linear catalyst H is added. Incubate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com