Green preparation method of two-dimensional hydroxide nano-sheets

A hydroxide and nanosheet technology, applied in the directions of nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, iron oxide/iron hydroxide, etc. Macro-scale preparation, low stripping efficiency and other problems, to achieve good prospects for industrial synthesis, easy to scale up synthesis, and save energy costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) In a 1L glass beaker, add 10g of nickel nitrate nonahydrate into 1L of water and dissolve until clear.

[0033] (2) Add 10 g of commercial magnesium oxide nanopowder to the clarified solution prepared in step (1), ultrasonically disperse for 10 min, then continue to stir at room temperature, and then let stand at room temperature after 1 h.

[0034] (3) Wash the precipitate in step (2) with water and ethanol repeatedly for 3 times.

[0035] (4) The precipitate obtained in step (3) was dried at 60° C. for 12 hours to obtain the target product.

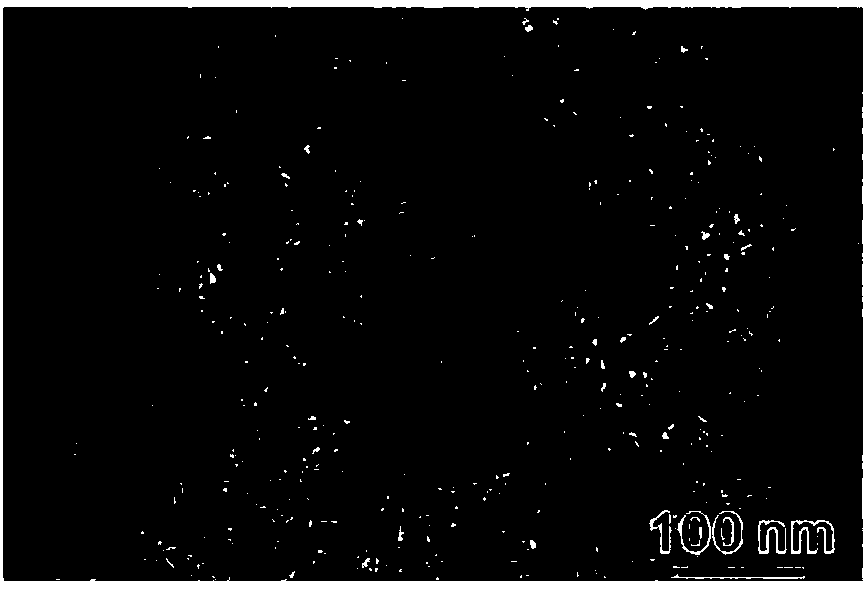

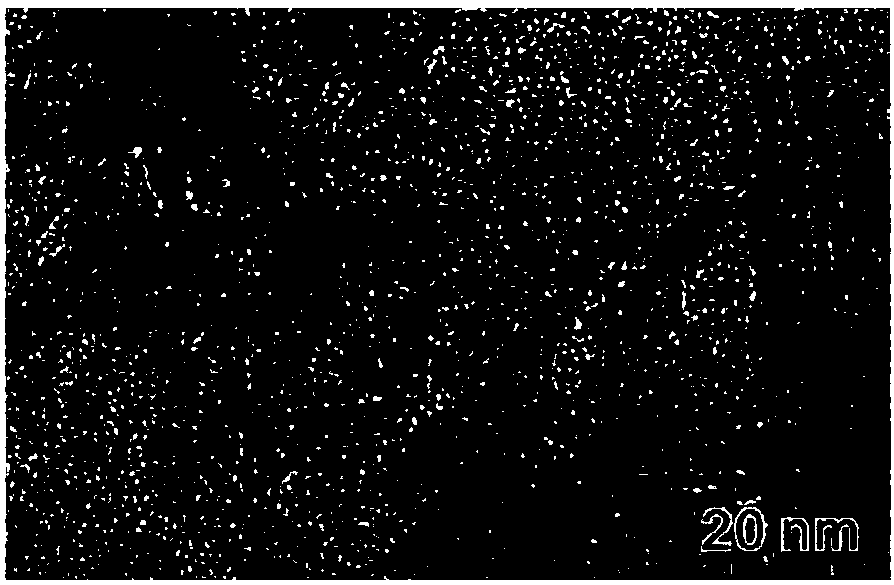

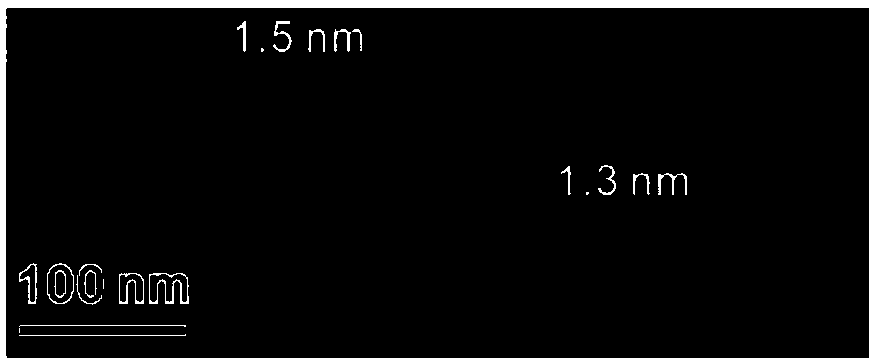

[0036] From figure 1 and 2 It can be seen that the obtained product is a uniform ultrathin nanosheet structure, image 3 further pointing out that the thickness of these ultrathin nanosheets is about 1.3 nm, Figure 4 It shows that the crystallinity of the obtained product is good, with typical α-Ni(OH) 2 structure, without other impurity phases, the resulting two-dimensional Ni(OH) 2 The nanosheets have the characteris...

Embodiment 2

[0038] (1) In a 1L glass beaker, add 10g of cobalt chloride hexahydrate into 1L of water and dissolve until clear.

[0039] (2) Add 10 g of commercial magnesium oxide nanopowder to the clarified solution prepared in step (1), ultrasonically disperse for 10 min, then continue to stir at room temperature, and then let stand at room temperature after 1 h.

[0040] (3) Wash the precipitate in step (2) with water and ethanol repeatedly for 3 times.

[0041] (4) The precipitate obtained in step (3) was dried at 60° C. for 12 hours to obtain the target product.

[0042] From Figure 5 It can be seen that the obtained product is a uniform ultrathin two-dimensional cobalt hydroxide nanosheet.

Embodiment 3

[0044] (1) In a 1L glass beaker, add 10g of ferrous sulfate heptahydrate into 1L of water and dissolve until clear.

[0045] (2) Add 10 g of commercial magnesium oxide nanopowder to the clarified solution prepared in step (1), ultrasonically disperse for 10 min, then continue to stir at room temperature, and then let stand at room temperature after 1 h.

[0046] (3) Wash the precipitate in step (2) with water and ethanol repeatedly for 3 times.

[0047] (4) The precipitate obtained in step (3) was dried at 60° C. for 12 hours to obtain the target product.

[0048] From Figure 6 It can be seen that the obtained product is a uniform ultrathin two-dimensional iron hydroxide nanosheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com