Sealing method for curtain type hollow fiber membrane

A fiber membrane and fiber membrane bundle technology, which is applied in the sealing field of curtain hollow fiber membranes, can solve the problems of high operation precision, complicated operation process and low utilization rate of membrane filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

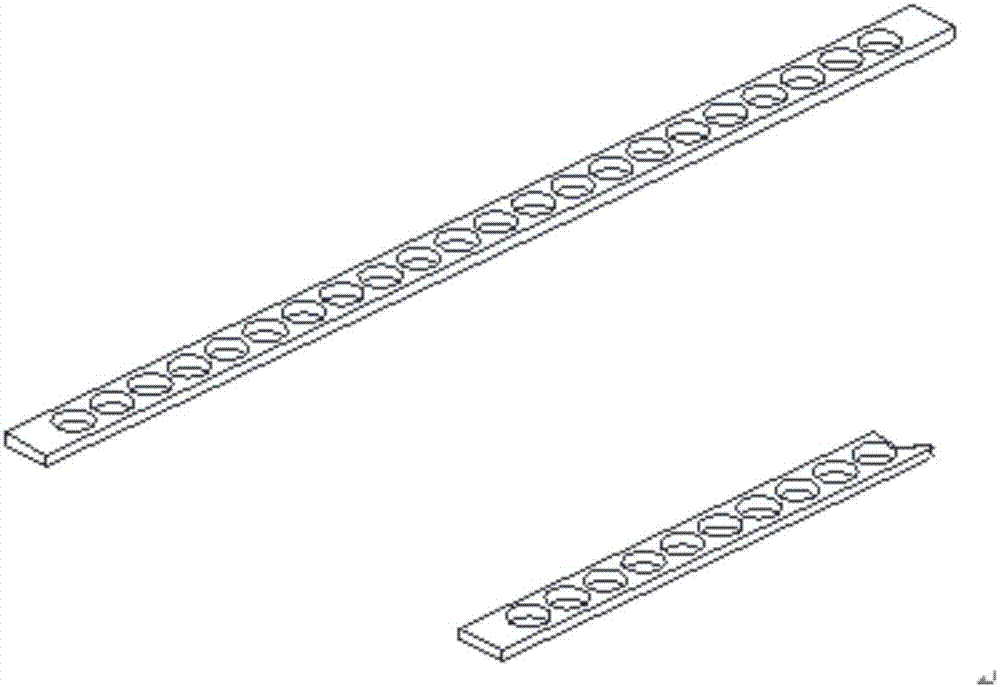

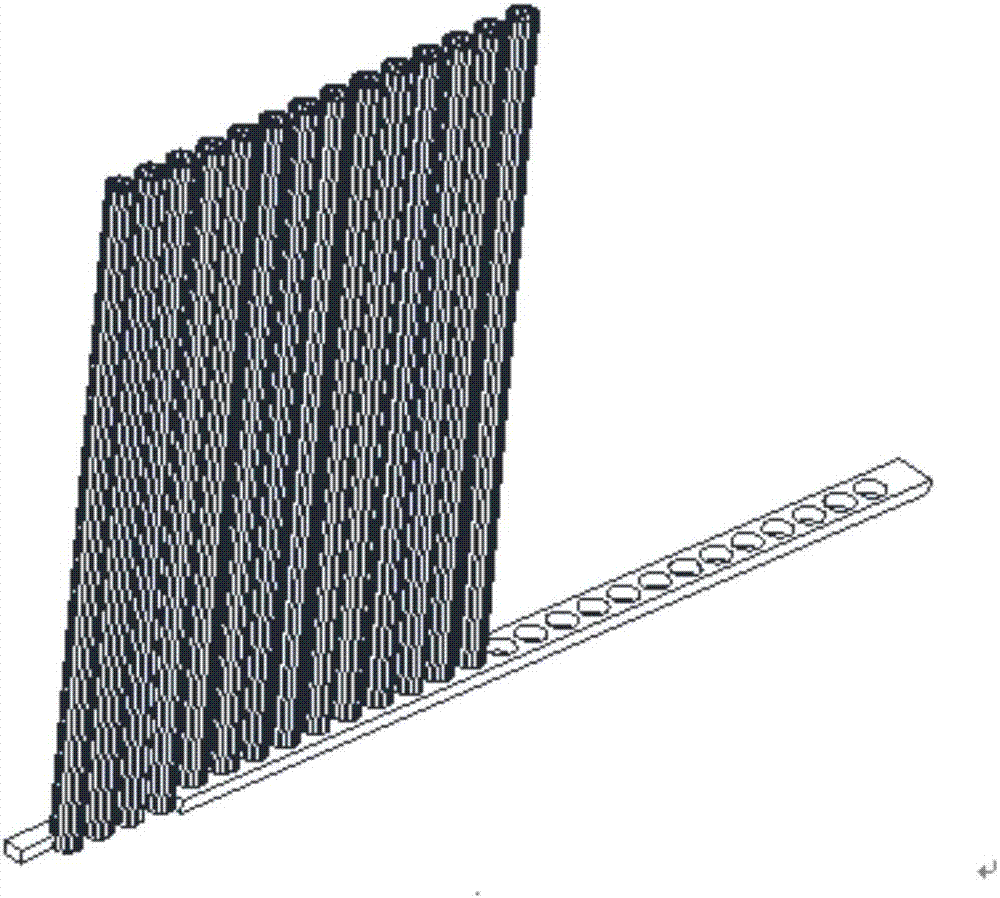

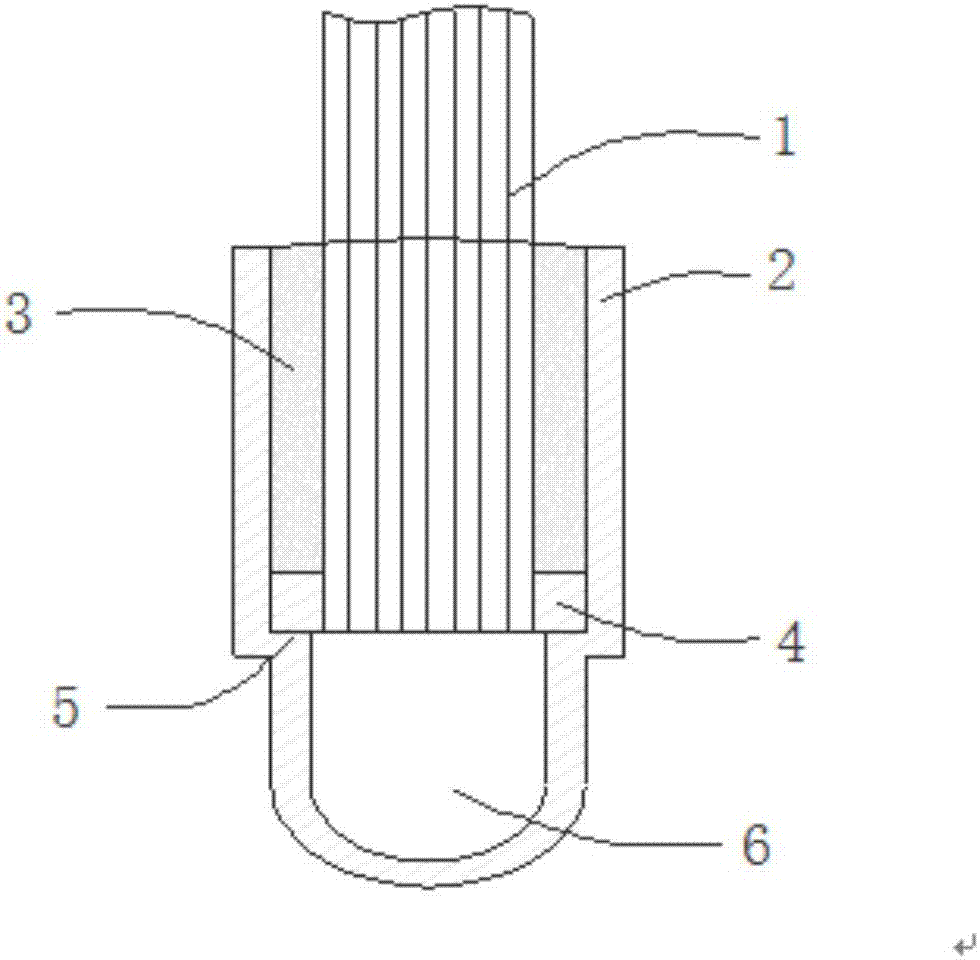

[0055] A curtain-type hollow fiber membrane encapsulation method is carried out according to the following steps: (1) cut the hollow fiber membrane wires into uniform lengths according to a known method, and tighten the two ends with cable ties; (2) insert the hollow fiber membrane bundle into a uniform distribution plate In the hole; the uniformly distributed plate with the hollow fiber membrane bundle is immersed in the gelatin solution, that is, the water outlet hole of the hollow fiber membrane bundle is immersed, and the water outlet hole is immersed in the gelatin solution for 5 minutes, and then cured for 30 minutes; (3) The evenly distributed plate with hollow fiber membrane bundles stretches into the raised steps of the MBR water collection pipe; (4) add X (weight) polyurethane glue between the MBR water collection pipe and the hollow fiber membrane bundles; (5) let it stand for X hours After the glue is completely hardened, rotate 180°, and repeat steps (1)(2)(3)(4) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com