Treatment method of radioactive solid waste

A treatment method and technology for solid waste, applied in radioactive purification, nuclear engineering, etc., can solve the problems of low strength, low durability of solidified body, and a large amount of addition, and achieve a strong applicability, good stability, and wide compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

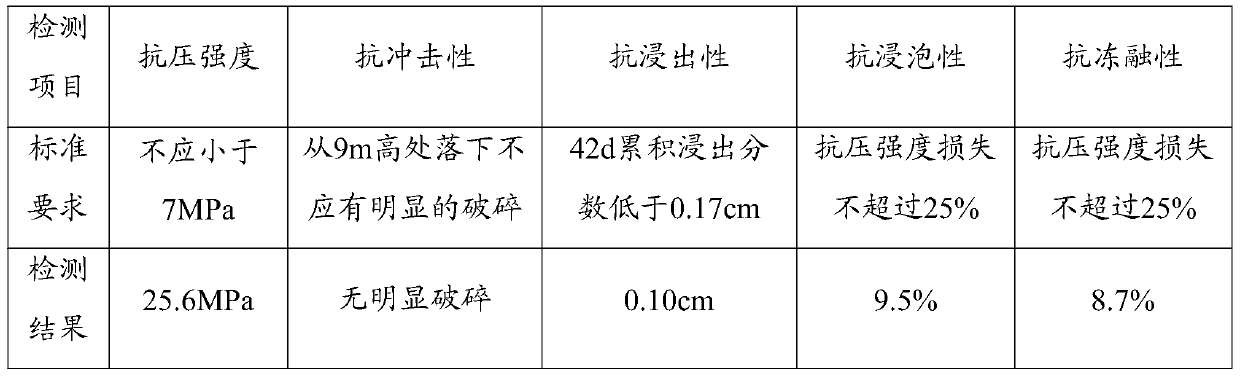

Embodiment 1

[0060] In this embodiment, the slag of a certain uranium mine waste dump in Hunan is taken as a sample.

[0061] Process the sample according to the following steps to obtain a cured body:

[0062] (1) Crushing: Use a jaw crusher to crush the slag to a particle size of 0-5 mm, which is a continuous gradation without screening.

[0063] (2) Preparation of mixed acid: use industrial sulfuric acid to dilute to a concentration of 75% dilute sulfuric acid; select industrial phosphoric acid to dilute to a concentration of 75% dilute phosphoric acid; dilute sulfuric acid according to the proportion: dilute phosphoric acid=8.8:1.2 to prepare mixed acid .

[0064] (3) Quenching and tempering: select brand LGY402, liquid sodium silicate (water glass) whose modulus is 3.20~3.40 for use, its technical parameters are as shown in Table 1; under stirring conditions, water glass by mass ratio: mixed acid = 85:15 mixed to obtain modified water glass.

[0065] Table 1 technical parameters of...

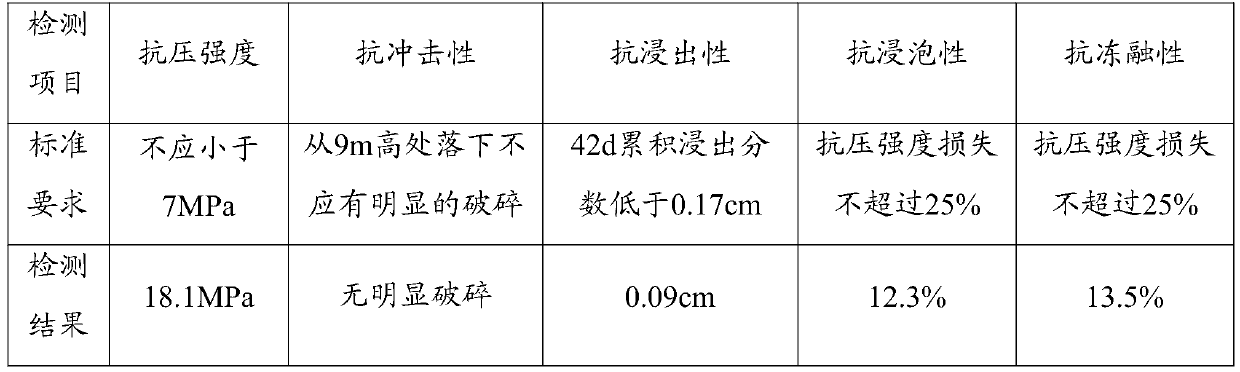

Embodiment 2

[0075] In this embodiment, the leaching slag of a uranium ore wet smelting plant in Hunan is taken as a sample, the particle size of the sample is 0-1.0mm, and the water content is 8%-15%.

[0076] Process the sample according to the following steps to obtain a cured body:

[0077] (1) Crushing: Dry the sample until the water content is less than 5%, and then crush and disperse the leached slag with a hammer crusher.

[0078] (2) preparation mixed acid: same as embodiment 1.

[0079] (3) Quenching and tempering: select brand LGY403, liquid sodium silicate (water glass) whose modulus is 3.20~3.40 for use, its technical parameters are as shown in Table 1; under stirring conditions, water glass by mass ratio: mixed acid = 88:12 mixed to obtain modified water glass.

[0080] (4) Preparation of admixtures: select FeSi65 ferrosilicon powder and bentonite, steel slag powder, and fly ash as blending raw materials, and the particle size of the blended raw materials is -0.045mm, 100%;...

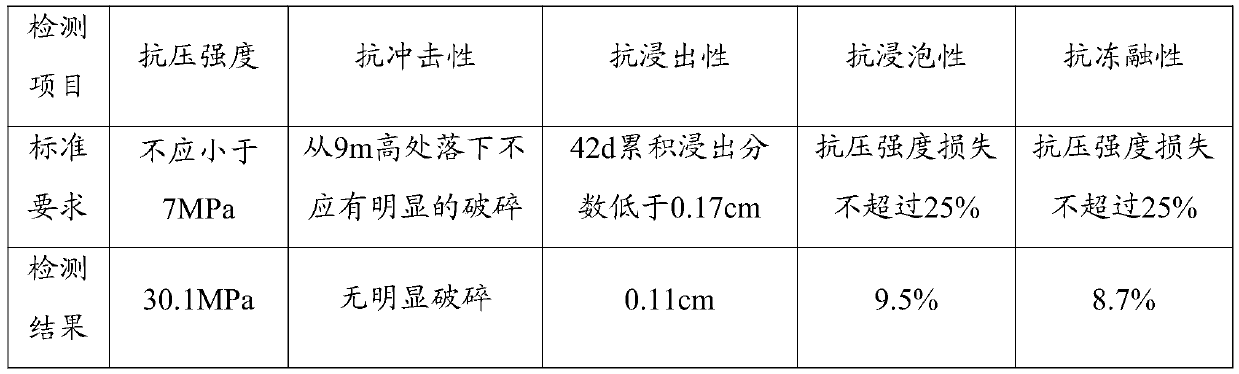

Embodiment 3

[0088] In this embodiment, vanadium slag from a certain shale vanadium mine in Hunan is taken as a sample. The particle size of the sample is 0-12mm. The uranium content is 0.01%wt and the moisture content is 3%-4%.

[0089] Process the sample according to the following steps to obtain a cured body:

[0090] (1) Crushing: use a hammer crusher to crush the slag to a particle size of 0-2 mm, which is a continuous gradation without screening.

[0091] (2) preparation mixed acid: same as embodiment 1.

[0092] (3) Refined and tempered: the same as in Example 2.

[0093] (4) Preparation of admixture: use 100% reduced iron powder, silica fume, fly ash, and granulated blast furnace slag powder with a particle size of -0.045mm as the blending raw material, according to reduced iron powder: silica fume: fly ash : The ratio of granulated blast furnace slag powder = 1:2:3:4 is used as admixture.

[0094] (5) Prepare batching material: select the liquid sodium hydroxide of IL-II grade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com