Urban domestic waste deep resource utilization system and method

A technology for recycling municipal solid waste, which is applied in the system field of deep resource utilization of municipal solid waste, to achieve the effects of protecting the environment, high calorific value, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

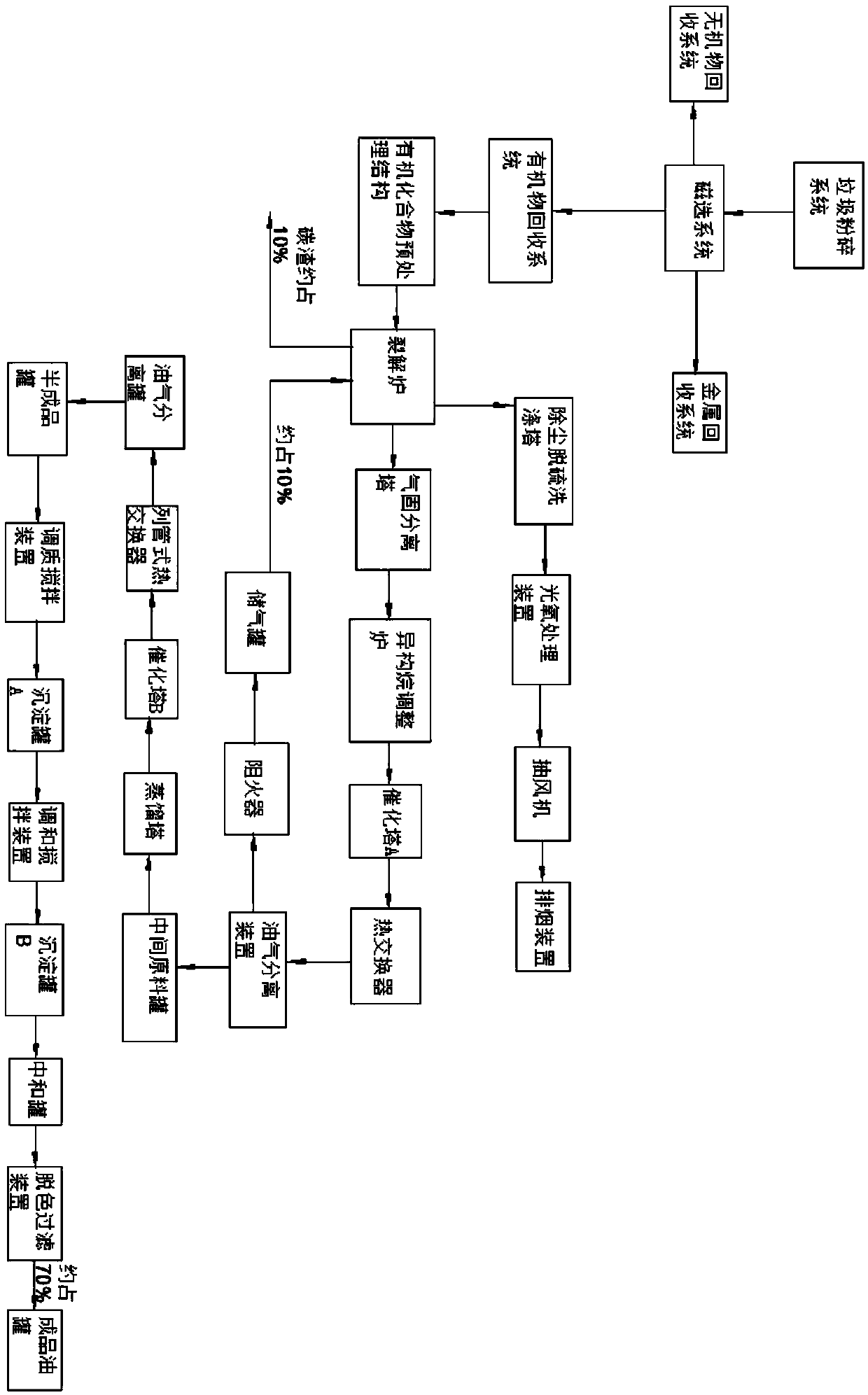

[0033] Such as figure 1 As shown, a system for deep resource utilization of municipal solid waste in this embodiment includes a garbage sorting system and a resource utilization system;

[0034] Wherein, the garbage sorting system includes a garbage crushing system and a magnetic separation system connected in sequence, and the magnetic separation system is respectively connected with a metal recycling system, an inorganic recycling system and an organic recycling system, and the organic recycling system is connected to the The resource utilization system connection mentioned above;

[0035] The resource utilization system includes a cracking system and an oil purification system, the cracking system includes an organic compound pretreatment structure, and the organic compound pretreatment structure is connected to a cracking furnace, and the cracking furnace is respectively connected to a waste gas Processing device, gas-solid separation tower and gas storage tank, described...

Embodiment 2

[0049] A kind of method for the deep resource utilization of municipal solid waste described in this embodiment comprises the following steps:

[0050] (1) Put the municipal solid waste into the garbage sorting system first, and then divide the municipal solid waste into inorganic matter, metal and organic matter through the waste crushing system and magnetic separation system, and then enter the inorganic matter recovery system, metal recovery system and organic matter respectively recycling system for recycling;

[0051] (2) The organic recovery system is connected with the resource utilization system, and the organic compound is uniformly and continuously placed in the organic compound pretreatment structure at 1 ton / hour for crushing treatment, and then enters the cracking furnace through the hopper warehouse for the cracking reaction, at 250 Reversible reaction at -300°C, cracking into high temperature oil and gas;

[0052] (3) High-temperature oil and gas sequentially p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com