Novel carboxylic acid functional rhenium iron liquid and preparation method and application thereof

An ionic liquid and functional technology, applied in chemical instruments and methods, refining with oxygen-containing compounds, organic chemistry, etc., can solve problems such as poor effect and catalyst deactivation, and achieve the effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

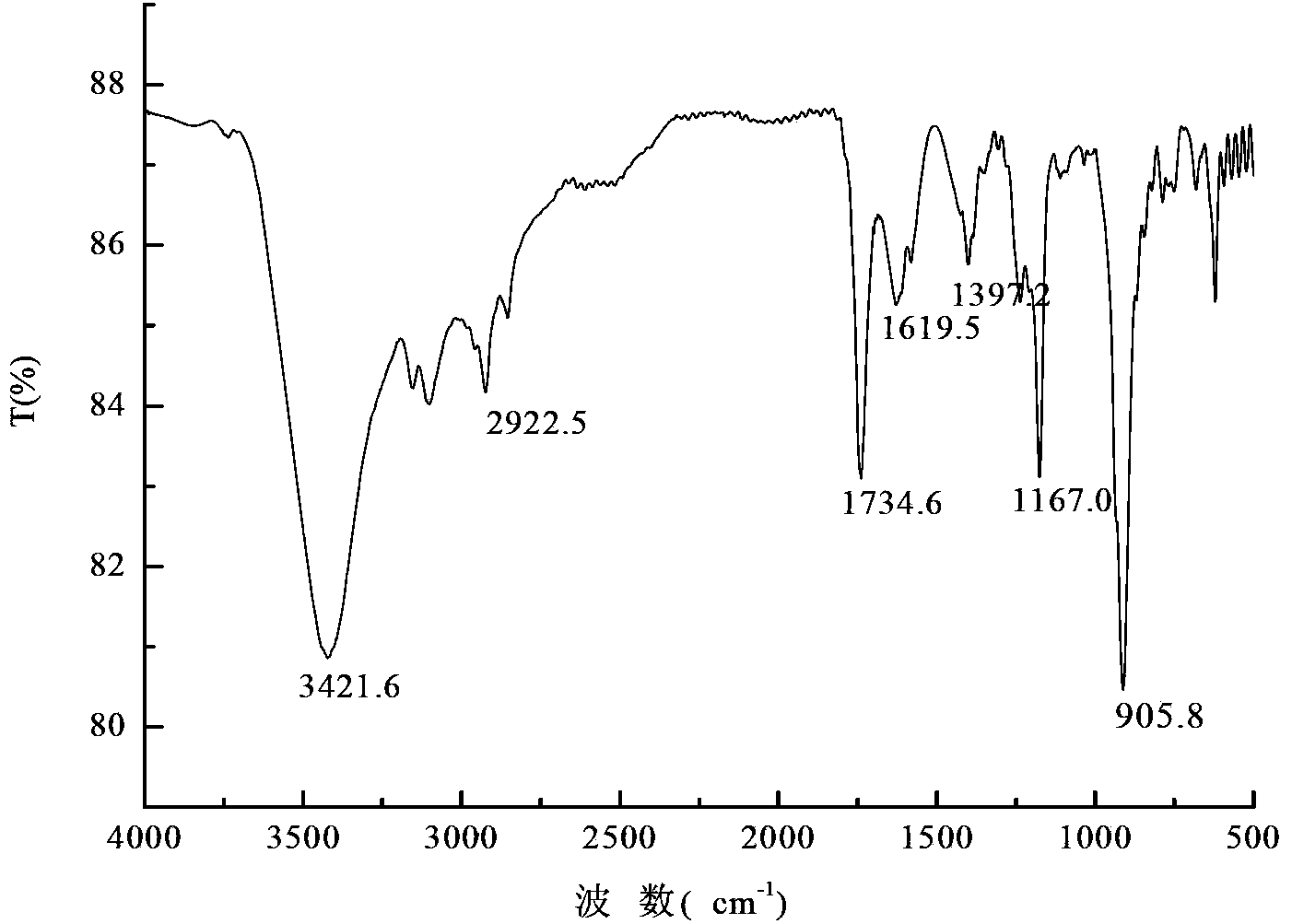

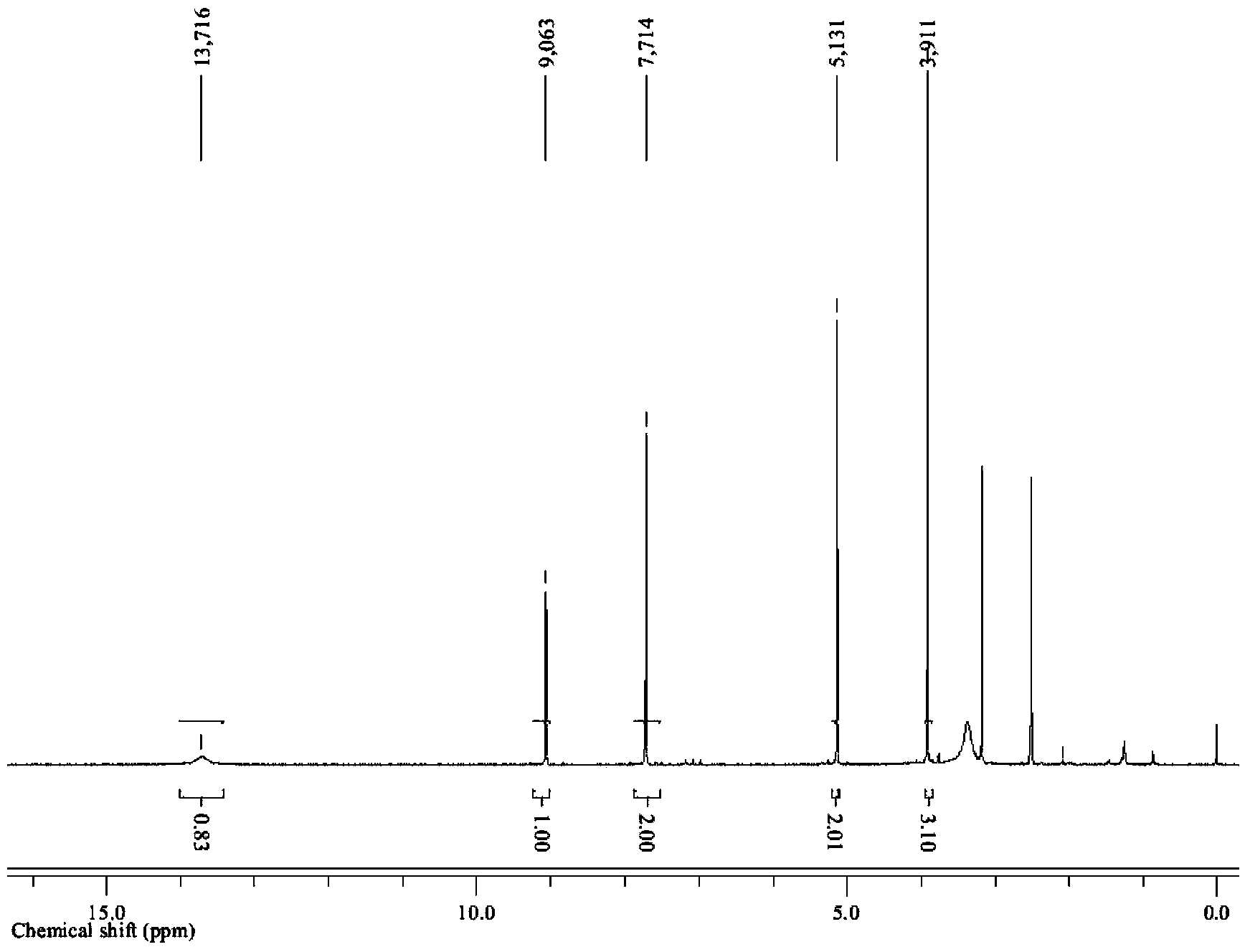

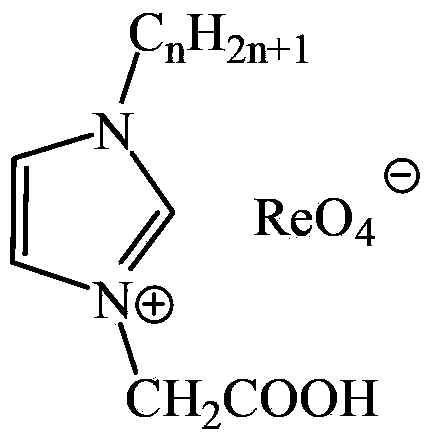

[0024] Example 1: 1-(α-carboxylic acid)methyl-3-methylimidazolium perrhenate ionic liquid

[0025] (1) Preparation of carboxylic acid functionalized rhenium ionic liquid

[0026] (1) Dissolve 0.1 mol of N-methylimidazole in absolute ethanol, add 0.1 mol of ethyl chloroacetate, reflux at 70°C for 24 hours, wash with ether, evaporate the solvent with a rotary evaporator, and dry in vacuo to obtain ions liquid intermediate A;

[0027] (2) Dissolve 0.05mol of ionic liquid intermediate A in (1), 5mL of 37% concentrated hydrochloric acid in acetonitrile, react at 70°C for 12h, cool, filter out the product, wash with ether, and dry in vacuo to obtain Intermediate B after acidification;

[0028] (3) Weigh 0.03 mol of silver perrhenate and dissolve it in acetonitrile to make it completely dissolved, add 0.03 mol of the acidified intermediate B obtained in (2), react at room temperature for 24 hours, remove the AgCl precipitate by filtration, and filter the filtrate Evaporate acetoni...

Embodiment 2

[0035] Example 2 1-(α-carboxylic acid)methyl-3-ethylimidazolium perrhenate ionic liquid

[0036] (1) Preparation of carboxylic acid functionalized rhenium ionic liquid

[0037] (1) Dissolve 0.1 mol of N-ethylimidazole in absolute ethanol, add 0.1 mol of ethyl chloroacetate, reflux at 70°C for 24 hours, wash with ether, evaporate the solvent with a rotary evaporator, and dry in vacuo to obtain ions Liquid Intermediate A.

[0038] (2) Dissolve 0.05mol of intermediate A in (1) and 5mL of 37% concentrated hydrochloric acid in acetonitrile, react at 70°C for 12h, cool, filter out the product, wash with ether, and dry in vacuo to obtain acidified Intermediate B is 1-(α-carboxylic acid)methyl-3-ethylimidazolium chloride salt.

[0039](3) Weigh 0.03 mol of silver perrhenate and dissolve it in acetonitrile to make it completely dissolved, add 0.03 mol of intermediate B obtained in (2), react at room temperature for 24 hours, filter to remove the AgCl precipitate, and rotate the filtr...

Embodiment 3

[0046] Example 3: 1-(α-carboxylic acid)methyl-3-butylimidazolium perrhenate ionic liquid

[0047] (1) Preparation of carboxylic acid functionalized rhenium ionic liquid

[0048] (1) Dissolve 0.1 mol of N-butylimidazole in absolute ethanol, add 0.1 mol of ethyl chloroacetate, reflux at 70°C for 24 hours, wash with ether, evaporate the solvent with a rotary evaporator, and dry in vacuo to obtain ions Liquid Intermediate A.

[0049] (2) Dissolve 0.05mol of intermediate A in (1) and 5mL of 37% concentrated hydrochloric acid in acetonitrile, react at 70°C for 12h, cool, filter out the product, wash with ether, and dry in vacuo to obtain acidified Intermediate B is 1-(α-carboxylic acid)methyl-3-butylimidazolium chloride.

[0050] (3) Weigh 0.03 mol of silver perrhenate and dissolve it in acetonitrile to make it completely dissolved, add 0.03 mol of intermediate B obtained in (2), react at room temperature for 24 hours, filter to remove the AgCl precipitate, and rotate the filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com