Method for removing free sulphur in enoxaparin sodium raw material

A technology of enoxaparin sodium and free state, which is applied in the field of removing free sulfur in enoxaparin sodium raw materials, can solve the problems of high cost, group shedding, hidden dangers of drug use, etc., achieve good industrial application value, and improve the effect of clinical drug safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation before ultrafiltration:

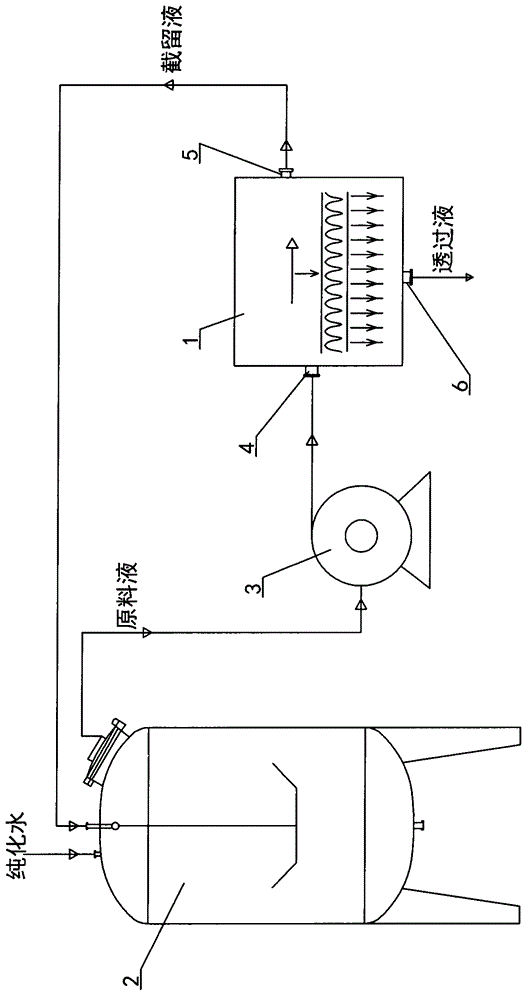

[0026] Main equipment: ultrafiltration machine 1 (1KD molecular weight polyethersulfone plate ultrafiltration membrane 5m 2 ), enamel tank 2 with stirring, pump 3.

[0027] Initial material: raw material of enoxaparin sodium (30kg)

[0028] Initial material related quality indicators:

[0029] ①Average molecular weight——4184

[0030] ②Molecular weight distribution——<2K: 22.0%; 2K~8K: 67.5%

[0031] ③Mass percentage content of free sulfur——0.60%

[0032] 2. Specific operation

[0033] 1. Dissolve and dilute enoxaparin sodium raw material to 300L, filter through 0.22μm micropore to obtain raw material solution A;

[0034] 2. Adjust the ultrafiltration machine 1, set the pump speed, open the feed port 4, the retained liquid outlet 5, and the permeate outlet 6, and place the catheter in the raw material liquid A, and circulate for 30 minutes (pump speed 40r / min) ;

[0035] 3. Start ultrafiltration: reduce the pump speed to 30...

Embodiment 2

[0050] 1. Preparation before ultrafiltration:

[0051] Main equipment: the same as the main equipment in Embodiment 1, the ultrafiltration machine adopts the plate membrane of 1KD molecular weight polyethersulfone

[0052] Initial material: raw material of enoxaparin sodium (25kg)

[0053] Initial material related quality indicators:

[0054] ①Average molecular weight——4100

[0055] ②Molecular weight distribution——<2K: 22.0%; 2K~8K: 67.5%

[0056] ③Free sulfur content——0.60%

[0057] 2. Specific operation

[0058] 1. Dissolve and dilute enoxaparin sodium raw material to 250L, filter through 0.22μm micropore to obtain raw material solution A;

[0059]2. Adjust the ultrafiltration machine 1, set the pump speed, open the feed port 4, the retained liquid outlet 5, and the permeate outlet 6, and place the catheter in the raw material liquid A, and circulate for 40 minutes (pump speed 40r / min) ;

[0060] 3. Start ultrafiltration: reduce the pump speed to 35r / min, the inlet pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com