Multifunctional desulphurization auxiliary agent of distillate of FCC device and preparation method thereof

A desulfurization aid and distillate oil technology, which is applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems that the passivating agent and desulfurizing agent cannot be used together, and block the feed pipeline, etc., and achieve low refining cost, less equipment, and advanced technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

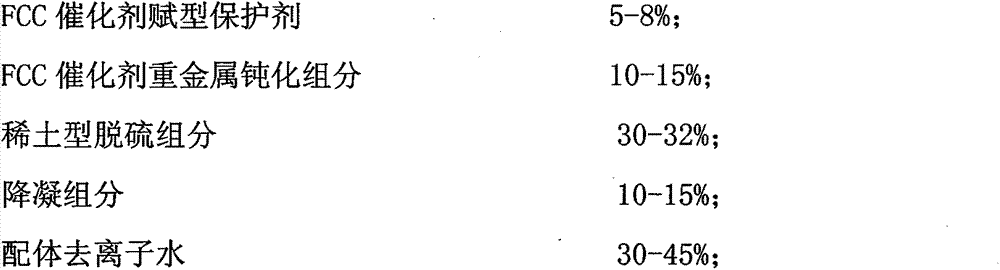

[0037] A method for preparing a multifunctional desulfurization aid for distillate oil in an FCC unit, comprising the following sequence and steps:

[0038] a. Under normal pressure at 40°C, mix 5-8% FCC catalyst excipient protecting agent and 10-15% FCC catalyst heavy metal passivation component with ligand deionized water 30-45% according to mass percentage

[0039] b. After standing for 20-30 minutes, add 30-32% rare earth type desulfurization components into the mixture;

[0040] c. After circulating the mixed liquid for 5-10 minutes, add 10-15% pour point depressant components, and recirculate for 5-10 minutes to make a multifunctional desulfurization aid for distillate oil in FCC unit.

[0041] d. Quantitative canning under normal temperature conditions.

[0042] The purpose of the present invention can also be achieved through the following technical solutions:

Embodiment 1

[0044] A preparation method of a multifunctional desulfurization aid for distillate oil of an FCC unit, comprising the following sequence and steps:

[0045] a. Under the normal pressure condition of 40°C, mix 5% FCC catalyst excipient protecting agent and 10% FCC catalyst heavy metal passivation component with ligand deionized water 45% according to mass percentage

[0046] b. After standing for 20-30 minutes, add 30% rare earth type desulfurization components into the mixture;

[0047] c. After circulating the mixed solution for 5-10 minutes, add 10% pour point depressant component, and recirculate for 5-10 minutes to make a multi-functional desulfurization aid for distillate oil in the FCC unit.

[0048] d. Quantitative canning under normal temperature conditions.

Embodiment 2

[0050] A preparation method of a multifunctional desulfurization aid for distillate oil of an FCC unit, comprising the following sequence and steps:

[0051] a. Under the normal pressure condition of 40°C, mix 6% FCC catalyst excipient protecting agent and 12% FCC catalyst heavy metal passivation component with ligand deionized water 40% according to mass percentage

[0052] b. After standing still for 20-30 minutes, add 32% rare earth type desulfurization components into the mixture;

[0053] c. After circulating the mixed solution for 5-10 minutes, add 10% pour point depressant component, and recirculate for 5-10 minutes to make a multi-functional desulfurization aid for distillate oil in the FCC unit.

[0054] d. Quantitative canning at room temperature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com