A kind of ionic liquid is used for fcc gasoline oxidation desulfurization method

An ionic liquid and oxidative desulfurization technology, which is applied in the direction of refining oxygen-containing compounds, can solve the problems of high acidity of inorganic acids, harsh equipment and process requirements, and non-compliance with green chemical industry, and achieve the effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

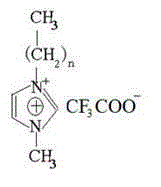

[0014] Example 1 : 1-Ethyl-3-methyl-imidazole trifluoroacetate ionic liquid for simulating FCC gasoline desulfurization method

[0015] In the reaction kettle, 1-ethyl-3-methyl-imidazole trifluoroacetate ionic liquid is used as catalyst, the amount added is 1 / 25 (volume ratio) of simulated FCC gasoline, and hydrogen peroxide of equal volume to the ionic liquid is added As an oxidizing agent, the reaction temperature is controlled at 80°C, and the reaction time is 1 hour. After the reacted system is separated, the oil phase is taken, which is desulfurized gasoline.

[0016] The sulfur content in the oil phase was measured by gas chromatography, and the desulfurization rate was over 95%, and the sulfur content was reduced to below 10ppm, meeting the Euro V emission standard.

Embodiment 2

[0017] Example 2: 1-butyl-3-methyl-imidazole trifluoroacetate ionic liquid is used to simulate FCC gasoline desulfurization method

[0018] In the reaction kettle, use 1-butyl-3-methyl-imidazole trifluoroacetate ionic liquid as catalyst, add 1 / 50 (volume ratio) of simulated FCC gasoline, add 0.5 times the volume of ionic liquid hydrogen peroxide As an oxidizing agent, the reaction temperature is controlled at 60°C, and the reaction time is 0.5 hours. After the reaction system is separated, the oil phase is taken, which is desulfurized gasoline.

[0019] The sulfur content in the oil phase was measured by gas chromatography, and the desulfurization rate reached over 97%, and the simulated FCC gasoline sulfur content was reduced from the initial concentration of 1000ppm to below 10ppm, meeting the Euro V emission standard.

Embodiment 3

[0020] Example 3 1-hexyl-3-methyl-imidazole trifluoroacetate ionic liquid used in FCC gasoline desulfurization method

[0021] In the reaction kettle, 1-hexyl-3-methyl-imidazole trifluoroacetate ionic liquid is used as catalyst, the amount added is 1 / 35 (volume ratio) of FCC gasoline (commercially available product), and 2 times of ionic liquid is added The volume of hydrogen peroxide is used as oxidant, the reaction temperature is controlled at 70°C, and the reaction time is 1.5 hours. After the reaction system is separated, the oil phase is taken, which is desulfurized gasoline.

[0022] The sulfur content in the oil phase was measured with a TS-2000 ultraviolet fluorescent sulfur analyzer, and the desulfurization rate reached over 96%, and the sulfur content was reduced to below 10ppm, meeting the Euro V emission standard.

[0023] The performance indicators of FCC gasoline after desulfurization, such as octane number, distillation range, saturated vapor pressure, chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com