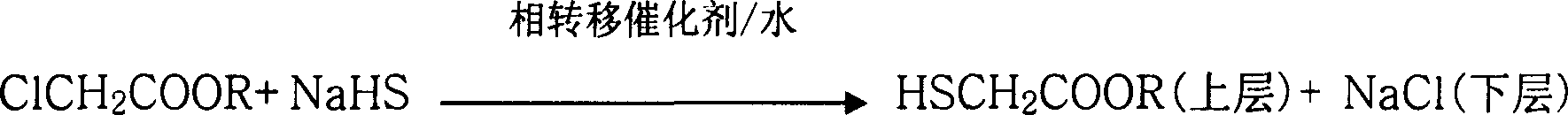

Method for preparing hydrosulfuryl acetate using phase transfer catalytic method

A phase transfer catalysis method and thioglycolic acid ester technology are applied in the preparation of mercaptans, organic chemistry and other directions, which can solve the problems of difficult reaction, limited types, and high cost, and achieve simple and easy process, easy availability of raw materials, and applicable aspects. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 500ml three-necked flask equipped with mechanical stirring, a thermometer, and a dropping funnel, add 80g (1.0mol) of 70% solid sodium hydrosulfide (industrial product, the same below), 32g of deionized water and 1g of triethylbenzyl ammonium chloride , cooled to 5°C, added 121g (0.9mol) propenyl chloroacetate dropwise under vigorous stirring, and continued to react for 2 hours after dropping, the internal temperature did not exceed 15°C; the lower layer was separated, and the upper layer was washed with deionized water until neutral. Distilled under reduced pressure to obtain 108 g of a colorless transparent liquid with a yield of 91%.

[0021] Elemental analysis (%): C: 45.8 (45.5); H: 6.12 (6.06); O: 24.1 (24.2).

[0022] Note: The theoretical values in brackets are the same below.

Embodiment 2

[0024] The device is the same as in Example 1, add 187g (1.0mol) of 30% industrial sodium hydrosulfide solution and 1.5g of cetyltrimethylammonium bromide, cool to 10°C, and add dropwise 175g (0.85mol) of chlorine under vigorous stirring 2-Ethylhexyl acetate, continue to stir for 5 hours after dripping, the internal temperature does not exceed 20 ° C, the post-treatment method is the same as that of Example 1, and 163 g of a colorless transparent liquid is obtained, and the yield is 94%.

[0025] Elemental analysis (%): C: 58.4 (58.8); H: 10.12 (9.8); O: 15.9 (15.7).

Embodiment 3

[0027] The device is the same as in Example 1, add 80g (1.0mol) of 70% sodium hydrosulfide, 32g of deionized water and 1.2g of tetrabutylammonium bisulfate, and drop 159g (0.9mol) of chloroacetic acid at room temperature (20-25°C) Cyclohexyl ester was stirred and reacted for 5 hours after the dripping was completed, and the internal temperature was not more than 30° C., left to stand, and the post-treatment method was the same as in Example 1 to obtain 150.3 g of a colorless transparent liquid with a yield of 96%.

[0028] Elemental analysis (%): C: 55.3 (55.2); H: 8.14 (8.05); O: 18.2 (18.4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com