Method for treating chloroacetic acid heavy component based on chloroacetic acid recovery

A treatment method, the technology of chloroacetic acid, applied in the preparation of carboxylate/lactone, organic chemistry, etc., can solve the problems of long capital occupation period, harmful gas generation, greenhouse effect, etc., to reduce the generation of three wastes and reduce the pressure on environmental protection , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

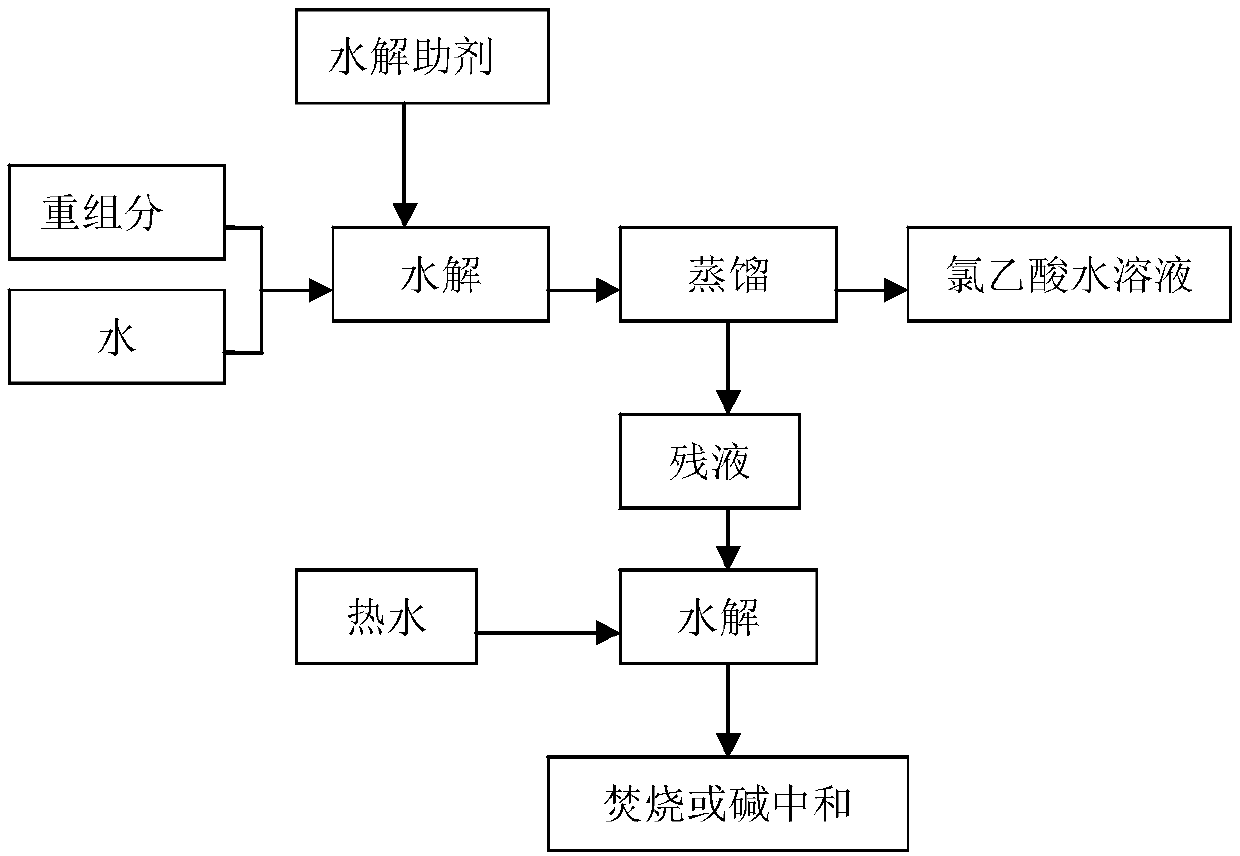

Image

Examples

Embodiment 1

[0025] Take 150g of the stock solution of the heavy fraction of chloroacetic acid and put it into a 500mL three-neck flask, add 150g of water, add 3g of beryllium chloride, gradually heat up to 80°C under magnetic stirring, keep the hydrolysis reaction at 80°C for 20h, filter, and keep for use.

[0026] Take 300g of the heavy component solution of chloroacetic acid after hydrolysis and filtration and add it to a 500mL three-necked flask, heat it in an oil bath at 185°C, and distill under a pressure of -0.095MPa under a pressure of -0.095MPa under a pressure of magnetic force. At 138°C, when the top temperature dropped to 90°C, the reaction was stopped, and the distillate was weighed, that is, the quality of the chloroacetic acid aqueous solution was 243.3g, and the content of chloroacetic acid in the chloroacetic acid aqueous solution was 92.83g. At this time, the temperature of the oil bath was kept constant, the raffinate was stirred in vacuum for 30 minutes, and then the tem...

Embodiment 2

[0028] Take 100g of the stock solution of the heavy fraction of chloroacetic acid and add it to a 500mL three-neck flask, add 60g of water, add 1g of aluminum chloride, gradually heat up to 90°C under magnetic stirring, keep the hydrolysis reaction at 90°C for 7h, filter, and keep for use.

[0029] Take 160g of the heavy component solution of chloroacetic acid after hydrolysis and filtration and add it to a 500mL three-necked flask, heat it in an oil bath at 185°C, and distill under a pressure of -0.095MPa under a pressure of -0.095MPa under a pressure of magnetic force. At 130°C, when the top temperature dropped to 90°C, the reaction was stopped, and the weight of the distillate, chloroacetic acid aqueous solution, was weighed to be 111.1g, wherein the content of chloroacetic acid in the chloroacetic acid aqueous solution was 53.33g. At this time, the temperature of the oil bath was kept constant, the raffinate was stirred in vacuum for 30 minutes, and then the temperature was...

Embodiment 3

[0031] Take 100g of the stock solution of the heavy fraction of chloroacetic acid and add it to a 500mL three-neck flask, add 80g of water, add 2g of magnesium nitrate, gradually heat up to 90°C under magnetic stirring, keep the hydrolysis reaction at 90°C for 7h, filter, and keep for use.

[0032] Take 180g of the heavy component solution of chloroacetic acid after hydrolysis and filtration and add it to a 500mL three-necked flask, heat it in an oil bath at 185°C, and distill it under a pressure of -0.095MPa under a pressure of -0.095MPa under a pressure of magnetic force. At 130°C, when the top temperature dropped to 90°C, the reaction was stopped, and the distillate was weighed, that is, the quality of the chloroacetic acid aqueous solution was 132.3g, and the content of chloroacetic acid in the chloroacetic acid aqueous solution was 54.00g. At this time, the temperature of the oil bath was kept constant, the raffinate was stirred in vacuum for 30 minutes, and then the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com