Patents

Literature

44 results about "Imidazole acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supported ionic liquid catalyst and preparation method and application thereof

InactiveCN101773852ANot easy to loseExtended service lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveActive component

The invention provides a supported ionic liquid catalyst for preparing vinyl acetate in an acetylene method, the catalyst adopts mesoporous molecular sieve as a carrier and adopts zinc acetate as an active component, and the carrier and the active component are connected by imidazole acetate ionic liquid. The invention further provides a preparation method of the catalyst and an application in preparing the vinyl acetate in the acetylene method. The active component of the zinc acetate of the supported ionic liquid catalyst is bond-coupled on the surface of the carrier in a chemical method and is not easy to be lost in the reaction process; the carrier of the mesoporous molecular sieve provides suitable reaction space for catalytic reaction, and carbon deposition is not easy to be generated; the ionic liquid forms a pseudophase liquid microenvironment on the surface of the catalyst, thus improving the mass transfer and heat transfer in the reaction process; and the catalyst has good stability, long service life, high activity and good selectivity.

Owner:TSINGHUA UNIV

Application of ionic liquid in synthesis of propylene glycol ether and propylene glycol ether synthesis method

InactiveCN105921172ASimple preparation processReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlcoholSynthesis methods

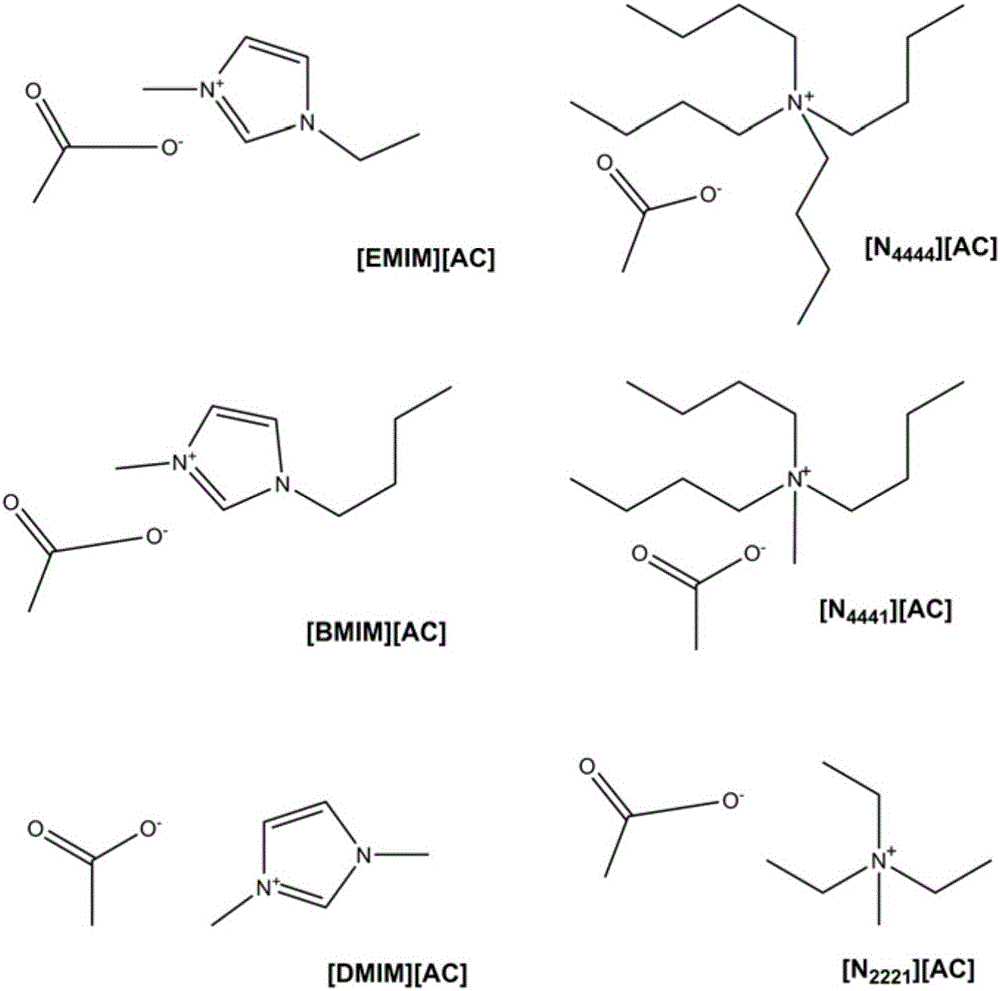

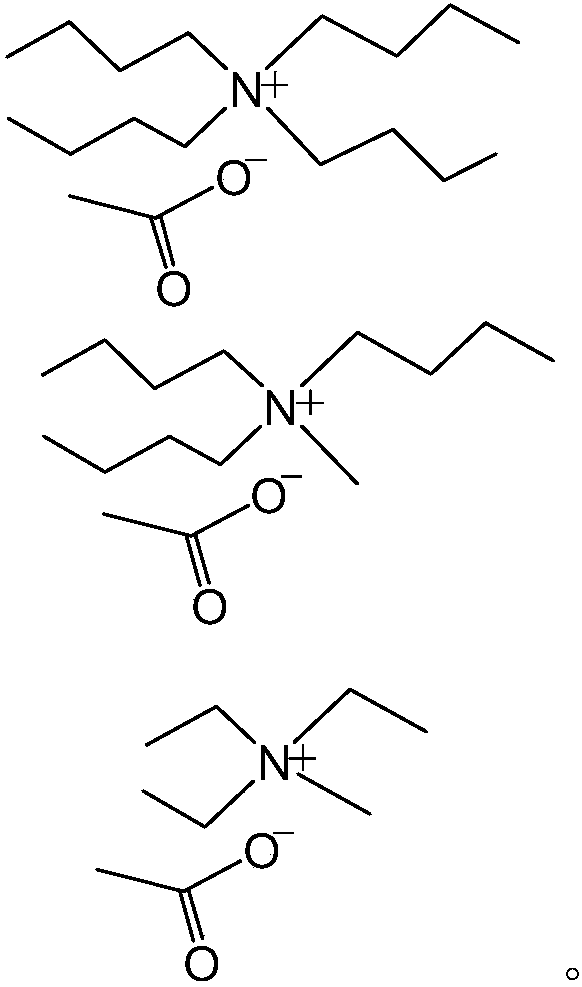

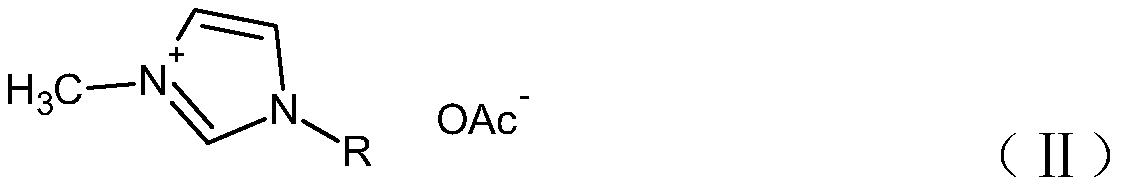

The invention relates to the technical field of chemical catalysis and provides application of ionic liquid in synthesis of propylene glycol ether and a propylene glycol ether synthesis method. The ionic liquid is imidazole acetate ionic liquid and / or quaternary amine acetate ionic liquid, serves as a catalyst for catalyzing synthesis of the propylene glycol ether. The propylene glycol ether synthesis method includes the following steps that epoxy propane and alcohol are added to a reactor to be in contact with the catalyst, heating is performed in a closed environment to reach 50-200 DEG C, the propylene glycol ether is obtained, wherein the catalyst is the acetate ionic liquid and / or the quaternary amine acetate ionic liquid. The propylene glycol ether synthesis method is a green synthesis process, has not special production equipment requirements and facilitates industrial production and application, and the process is simple and easy to control.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Extraction method of ginger essential oil

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting cellulose from straw by adopting ionic liquid

The invention relates to a method for extracting cellulose from straw by adopting an ionic liquid, which comprises the following steps: firstly, crushing the straw into powder, then performing ammonia water low-voltage blasting processing on the straw, and finally, adopting the ionic liquid 1-allyl-3-methyl imidazole acetate (AMIMOAc) to extract the cellulose. The invention has the advantages that the method adopts the ionic liquid to extract the cellulose from the straw powder through the ammonia water low-voltage blasting processing, functionalizes the ionic liquid to enable the ionic liquid to be an effective solvent of the cellulose, and reuses the ionic liquid, so as to realize direct and quick dissolving of fiber and efficient processing of the straw, improve the utilization efficiency of biomass resources, solve the problems that the straw is difficult to degrade and reuse, and have extremely profound social significance and economic value.

Owner:NANKAI UNIV

Woven fabric with sound insulation and warm keeping properties and manufacturing method thereof

InactiveCN104652017AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberLophatherum

The invention discloses a woven fabric with sound insulation and warm keeping properties. The woven fabric is formed by weaving warp yarns and weft yarns through an air jet loom; the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30-34 parts of isotatic polypropylene, 1-3 parts of hargil, 3-7 parts of rock wool, 20-25 parts of modal fibers, 22-26 parts of fireproof fiber cotton, 25-28 parts of waste down feather fibers, 16-19 parts of bambusa texlitis pulp, 0.6-0.9 part of sodium hexametaphosphate, 8-10 parts of methyl methacrylate, 2-4 parts of eucalyptus oil, 12-15 parts of butyl glycidyl ether, 1-3 parts of jasmine, 2-5 parts of herba cepbalanoplosis segeti, 3-4 parts of lophatherum gracile, 85-95 parts of 1-butyl-3-methyl imidazole acetate, 95-110 parts of 1-allyl-3-methyl imidazole chlorine salt, proper amount of water and 5-8 parts of an auxiliary agent. The woven fabric has the sound insulation and warm keeping properties, and antibacterial and mould-proof, and inflaming retarding properties, is applied to automotive trims, and has the properties of low cost, high cost performance and good shape keeping performance and the like; the prospect is wide.

Owner:章云

Mothproof down feather composite fiber and preparation method thereof

InactiveCN104264277AAntibacterial and mothproofLightweight and high strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureAluminium silicateGluconates

The invention discloses a mothproof down feather composite fiber. The mothproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of duck's down, 15-19 parts of chicken feather, 11-13 parts of mercerized wool fibers, 12-14 parts of mercerization cotton fibers, 4-7 parts of copper ammonia fibers, 15-19 parts of straw stalk, 4-6 parts of closed cell perlite powder, 1-3 parts of angelica sinensis, 2-4 parts of gastrodia elata, 2-3 parts of ligusticum wallichii, 0.2-0.4 part of zinc gluconate, 0.3-0.6 part of aluminium silicate, 100-105 parts of 1-butyl-3-methyl imidazole acetate, 110-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. The down feather composite fiber prepared by the invention has the advantages of sterilization, moth prevention, light weight, high intensity, thermal preservation, flame retardance and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

Skin-relieving vegetable fiber fabric and preparation method thereof

ActiveCN103966685ABacteriostaticBreathableMonocomponent cellulose artificial filamentArtifical filament manufactureJojoba oilVegetable fibers

The invention relates to a skin-relieving vegetable fiber fabric and a preparation method thereof. The skin-relieving vegetable fiber fabric is prepared from the following raw materials by weight: 100-120 parts of 1-ethyl-3-methyl imidazole acetate, 4-5 parts of nanometer chitin, 1-2 parts of jojoba oil, 8-10 parts of water, 7-10 parts of plastic starch, 2-4 parts of polycaprolactone, 1-2 parts of whiting oil, 1-2 parts of vitamin E, 3-4 parts of lavender, 4-6 parts of rosemary, 10-14 parts of natural silk fiber, 54-58 parts of ramie, 25-27 parts of banana fiber, and 0.4-0.8 part of spinning auxiliaries. The skin-relieving vegetable fiber fabric adopts ramie as a raw material, so that the fabric has the performances of bacteriostasis, ventilation, cool, corrosion protection, mould prevention and sweat absorption; through the adoption of banana fiber and natural silk fiber, the gloss and softness of the fiber fabric are enhanced; through the adoption of vitamin, lavender and rosemary, the fiber fabric can be skin-relieving, the secretion of grease can be balanced, acne can be controlled, and inflammation can be eliminated; moreover, through the adoption of the spinning auxiliaries, spinning melt can be favorable in spinning property, the fiber fabric is fuzziness-free, is dyed uniformly, is excellent in the color and luster, and touches soft.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Waterproof down feather composite fiber and preparation method thereof

InactiveCN104264275AWaterproofAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureEpoxyFiber

The invention discloses a waterproof down feather composite fiber. The waterproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of duck's down, 16-21 parts of rabbit hair, 15-17 parts of merino super fine wool, 8-10 parts of gabardine fibers, 3-5 parts of acetate fibers, 0.1-0.3 part of zinc oxide, 0.4-0.8 part of methyl sodium silicate, 2-4 parts of kieselguhr, 1.2-2.3 parts of polystyrene foam particles, 1-3 parts of gastrodia elata, 0.6-0.9 part of prunella vulgaris, 0.8-1.3 parts of mint, 3-5 parts of melon vine, 4-7 parts of epoxy butyl oleate, 100-115 parts of 1-butyl-3-methyl imidazole acetate, 105-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. Polystyrene foam particles, methyl sodium, gastrodia elata, prunella vulgaris, mint and other ingredients are added; the technology is simple, convenient and feasible, and is low in production cost; the prepared down feather composite fiber has the advantages of water prevention, bacteria resistance, bacteriostasis, mildew and moth prevention and the like, so that the down feather composite fiber has no odor in using, and is clean and sanitary.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

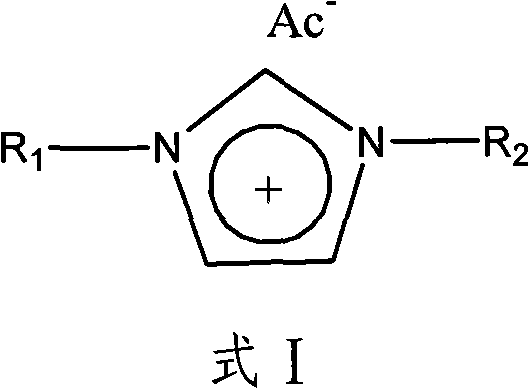

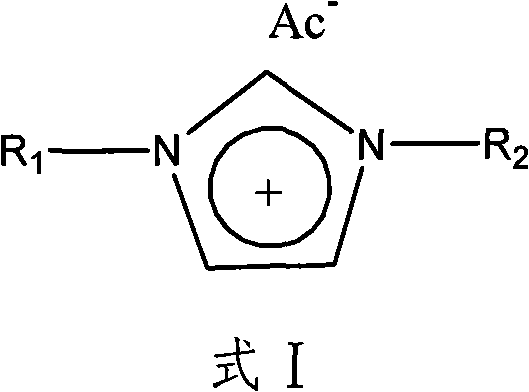

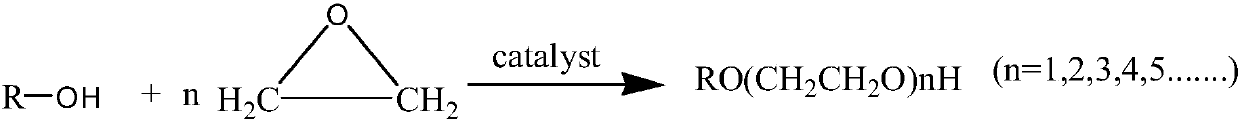

Method for preparing imidazole acetate ionic liquid

The invention discloses a method for preparing imidazole acetate ionic liquid, which comprises the following steps of: mixing organic alcoholic solution of imidazole halid salt and organic alcoholic solution of acetate, and reacting at preset temperature; evaporating to remove partial organic alcohol in a reaction system in the reaction process; and filtering reaction mixed liquor and removing organic alcohol from filtrate to obtain the imidazole acetate ionic liquid. In the method for preparing the imidazole acetate ionic liquid, the partial organic alcohol is evaporated and removed in the reaction process, so distillation can be performed by means of reaction temperature, the load of evaporating and removing a solvent after filtration is reduced, the cost is reduced, the solvent amount in the filtrate is small, and the inorganic salt amount remained in the solvent is small; therefore, the purity of the imidazole acetate ionic liquid subjected to solvent evaporation and removal is improved.

Owner:CHINESE TEXTILE ACAD

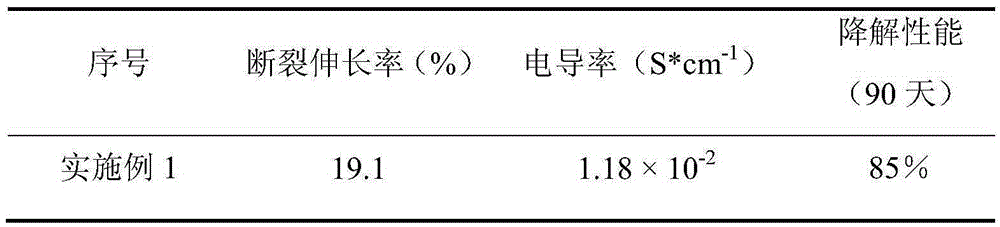

Starch-based conductive composite film built on basis of ionic liquid enhanced starch phase change, method and application

The invention discloses a starch-based conductive composite film built on the basis of ionic liquid enhanced starch phase change, a method and application. The preparation method includes the following steps that firstly, a 1-ethyl-3-methyl imidazole acetate ionic liquid aqueous solution is prepared, the molar ratio of ionic liquid to water ranges from 0.15:1 to 0.20:1, starch is added, the mass of dry basis starch accounts for 70-150% of the ionic liquid aqueous solution, and colloidal starch subjected to phase change is obtained after 1-3 hours of reinforcing; secondly, the colloidal starch obtained in the first step is placed on a mould and subjected to forming processing for 0.5-1.5 hours at the pressure of 6-10 MPa through a pressure forming machine, and the starch-based conductive composite film is obtained after balance is performed in the 33-75% humidity environment. According to the material, on one hand, conductivity is good and plasticizer is not needed; on the other hand, building temperature is low, and the composite film is applicable to the fields of biosensors and other biomedical materials.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method for modified cellulose membrane material based on ionic liquid

InactiveCN103588883AControl substitutionRealize high value utilizationSocial benefitsAcetic anhydride

The invention discloses a manufacturing method for a modified cellulose membrane material based on ionic liquid. The manufacturing method comprises the following steps: adding cellulose into 1-allyl-3-ethyl imidazole acetate ionic liquid to obtain a cellulose / ionic liquid system; adding the cellulose / ionic liquid system into an acetic anhydride and iodine oil bath for modification reaction for 60-100 min to obtain reaction liquid; allowing a glass plate to be uniformly coated with the reaction liquid, spraying an ethanol solution onto a thin film separated out by the cellulose until the thin film is colorless, and drying the thin film in vacuum to obtain the modified cellulose membrane material. The manufacturing method has the advantages that the preparation method is easy to operate, high in reaction speed, low in energy consumption and cost, safe and reliable; the substitution degree of the acetylized cellulose can be effectively controlled by controlling the reaction time; cyclic utilization can be realized through high-efficiency recycling of the ionized liquid; due to the implementation of the method, high utilization value of biomass can be realized, and outstanding economical and social benefits can be achieved.

Owner:NANKAI UNIV +1

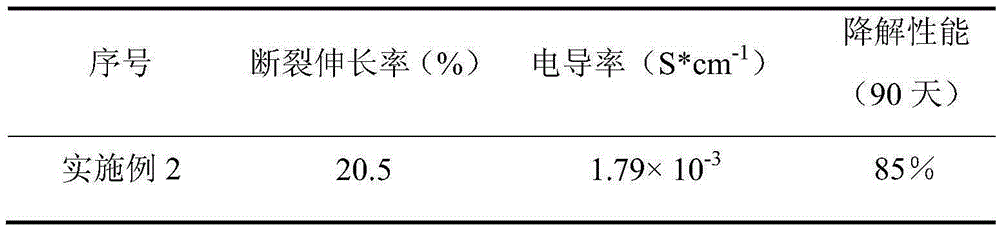

Catalyst for ethylene oxide ring-opening reaction and preparation method for oxethyl compound

InactiveCN107661778AHybrid configuration is easyImprove catalytic reaction efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesLiquid stateEthylene oxide

The invention provides a catalyst for ethylene oxide ring-opening reaction and a preparation method for an oxethyl compound. The catalyst comprises one or more of imidazole acetate, quaternary ammonium acetate and pyridine acetate. The catalyst in the execution mode of the invention is ionic liquid; the ionic liquid is under a liquid state, so that the catalyst is easily mixed with an initiator ofthe ring-opening reaction; besides, the catalytic reaction efficiency is higher under the synergistic effect of alkaline group of ionic liquid and hydrogen bond.

Owner:辽宁奥克药业股份有限公司

Phosphorus-free corrosion and scale inhibitor and preparation method thereof

InactiveCN110818097AFast film formationGood corrosion inhibition effectSpecific water treatment objectivesScale removal and water softeningCitrate saltEngineering

The invention discloses a phosphorus-free corrosion and scale inhibitor and a preparation method thereof, and belongs to the technical field of water treatment. The phosphorus-free corrosion and scaleinhibitor is prepared by mixing and complexing the components in parts by weight: 10-30 parts of a polyepoxysuccinic acid aqueous solution, 4-8 parts of citric acid and / or a citrate, 1-3 parts of 1H-benzotriazole, 5-15 parts of a zinc salt, 3-6 parts of imidazolinamide acetate, 5-10 parts of a maleic acid-acrylic acid-styrene sulfonic acid terpolymer and the balance deionized water. The phosphorus-free corrosion and scale inhibitor can be applied to water bodies with lower hardness, and the effect of corrosion and scale inhibition in water with water hardness as low as 150 mg / L (calculated based on calcium carbonate) is good.

Owner:PETROCHINA CO LTD

Compound warm down feather composite fiber and producing method thereof

InactiveCN104831407AGood warmth retentionImprove flame retardant performanceConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberPhosphate

The invention discloses compound warm down feather composite fiber which is characterized by comprising the following raw materials: 14-17 parts of duck down, 16-19 parts of chicken feather fragments, 8-12 parts of jute pulp fiber, 9-11 parts of black bamboo charcoal fiber, 4-6 parts of nano seaweed powder, 2-4 parts of konjac gum, 2-3 parts of expanded vermiculite, 3-4 parts of chlorinated paraffin, 1.1-2.1 parts of costustoot, 0.7-1.2 parts of honeysuckle, 0.8-1.4 parts of semen cassiae torae, 8-11 parts of waxberry bark, 10-14 parts of dry flos sophorae, 100-110 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 105-120 parts of 1-butyl 3-methyl imidazole acetate, 3-5 parts of an additive and a moderate amount of water; by effective compounding of the components, the prepared compound warm down feather composite fiber has good warmth retention property, flame retardant effect, green environmental protection, spinnability and tailorability, and enormous market demand potential.

Owner:ANHUI SANSEN TEXTILE

Preparation method and product of chitosan antibacterial film

The invention relates to the field of food packaging, in particular to a preparation method and product of a chitosan antibacterial film. The preparation method of the chitosan antibacterial film, provided by the invention, comprises the following steps: dipping the chitosan with tartaric acid and then washing with absolute ethyl alcohol; mixing the tartaric acid with 1-ethyl-3methyl imidazole acetate series and adding the washed chitosan; then adding chitinase and cooling the temperature until coating liquid is obtained; performing strickling on the obtained coating liquid and putting into asolvent for carrying out phase transfer to obtain a film and drying to obtain the chitosan antibacterial film. The obtained chitosan antibacterial film disclosed by the invention has good antibacterial effects and high film strength.

Owner:QINGDAO UNIV OF SCI & TECH

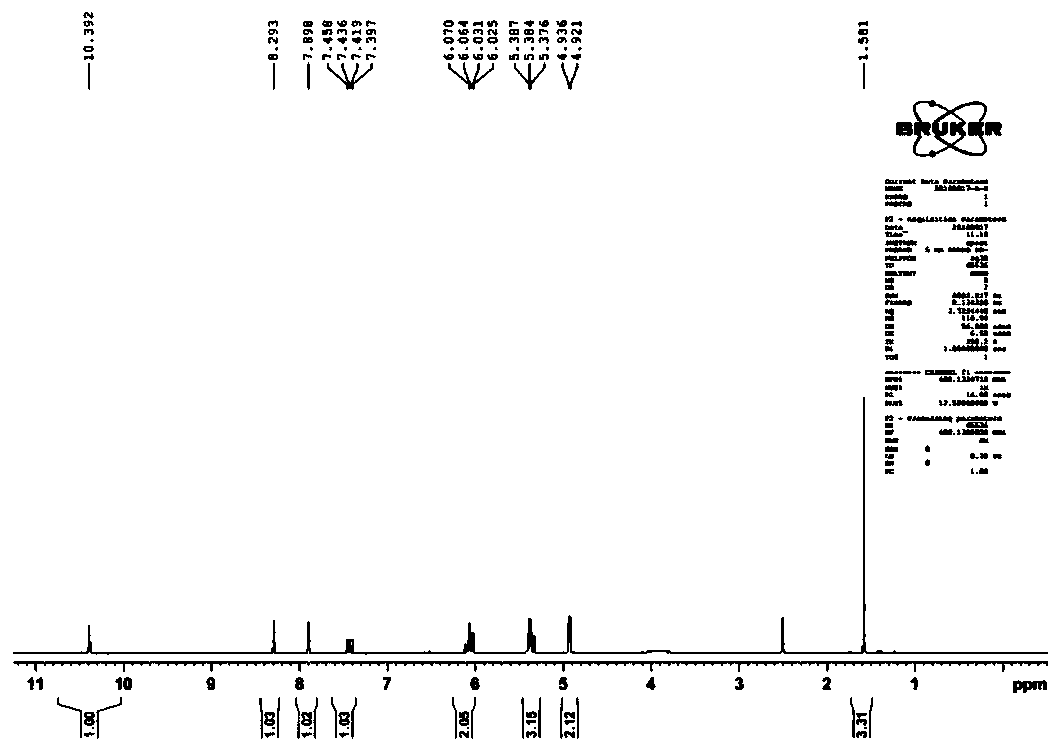

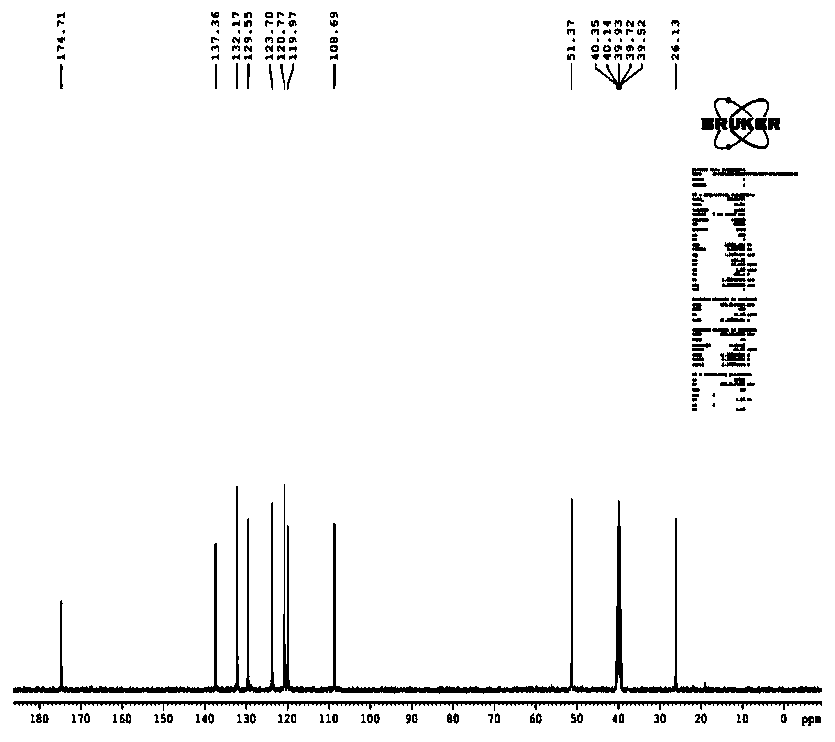

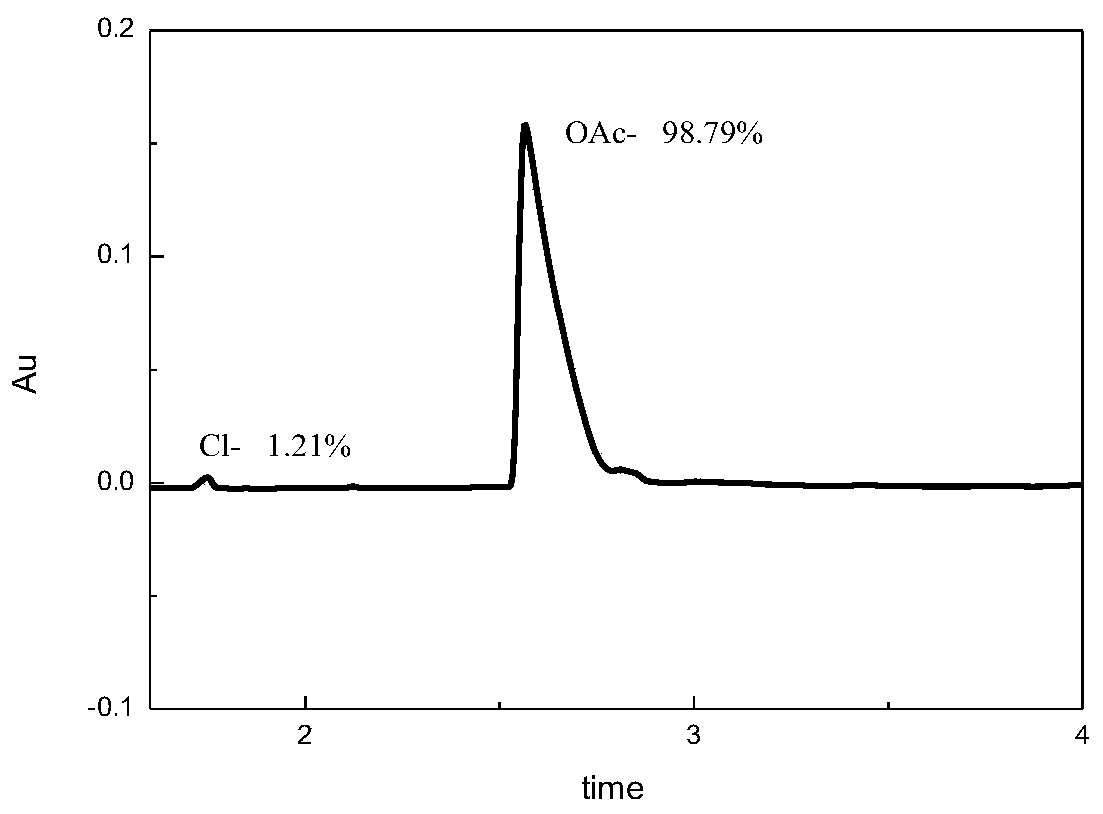

Preparing method of high-purity imidazole acetate ionic liquid

ActiveCN110294712AAdvantages and Notable ImprovementsSignificant progressOrganic chemistryHalogenPotassium acetate

The invention belongs to the technical field of ionic liquid synthesis, and particularly relates to a preparing method of high-purity imidazole acetate ionic liquid. The method includes the steps of making a 1-alkyl-3-methylimidazole halogenated product react with lithium perchlorate to obtain a high-purity 1-alkyl-3-methylimidazole perchlorate ionic liquid intermediate, and then conducting replacement reaction on the intermediate and potassium acetate or ammonium acetate to obtain the 1-alkyl-3-methylimidazole acetate ionic liquid. The raw materials are low in price and easy to obtain, the raw materials or middle byproducts are free of heavy metals or other pollutions, reaction is thorough, the reaction yield is 90.0% or above, the product purity is 99.0% or above, the content of halogenresidues in the product is smaller than or equal to 5 ppm, and the content of K ions or ammonium radicals in the product is 200 ppm or below.

Owner:SHANDONG UNIV OF SCI & TECH

Waterproof breathable down feather composite fiber and producing method thereof

InactiveCN104831406AImprove insulation effectImprove waterproof performanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyesterPhosphate

The invention discloses waterproof breathable down feather composite fiber which is characterized by comprising the following raw materials by weight: 12-16 parts of duck down, 13-15 parts of rex rabbit hair, 20-25 parts of chicken feather, 8-10 parts of nylon fiber, 6-9 parts of polyaniline conductive polyester fiber, 10-13 parts of rabbit hair keratin powder, 8-11 parts of transgenic cotton fiber, 7-10 parts of china-hemp fiber, 1-2 parts of silicon carbide powder, 0.3-0.6 part of sodium laureth sulfate, 2-5 parts of coconut shell activated carbon powder, 1.1-2.4 parts of belvedere fruit, 1.3-2.5 parts of selfheal, 2.1-3.1 parts of semen boitae, 4-7 parts of rhizoma phragmitis, 2-3 parts of tremolite powder, 100-110 parts of 1 - butyl-3-methyl imidazole dimethyl phosphate, 115-120 parts of 1-butyl 3-methyl imidazole acetate, 2-4 parts of an additive and moderate amount of water; the waterproof breathable down feather composite fiber is added with the rex rabbit hair, chicken feather and nylon fiber, has good heat preservation and air permeability good waterproof effect, and is also added with some Chinese herbal medicines, and the prepared waterproof breathable down feather composite fiber is antibacterial and mouldproof.

Owner:ANHUI SANSEN TEXTILE

High fluffy down feather composite fiber and producing method thereof

InactiveCN104831414AGuaranteed whitenessGuaranteed Odor LevelConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberCellulose

The present invention discloses a high fluffy down feather composite fiber which is characterized by comprising the following raw materials by weight: 12-16 parts of goose down, 15-17 parts of goose feather, 14-18 parts of cashmere, 13-15 parts of mohair, 8-10 parts of cellulose ester fiber, 11-13 parts of chenille yarn fiber, 0.3-0.6 part of nano zinc oxide, 0.5-0.9 part of poly diallyl dimethyl ammonium chloride, 1.3-2.5 parts of emulsion paraffin, 1-3 parts of fructus liquidambaris, 2-4 parts of gentian, 3-5 parts of clove oil, 2-5 parts of montmorillonite, 0.4-0.8 part of 1, 6-hexanediol diacrylate, 100-110 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 105-110 parts of 1-butyl-3-methyl imidazole acetate, 2-5 parts of an additive and proper amount of water; the goose down, goose feather and the cashmere, after modification, are added into the raw material, the prepared product can ensure that the feather whiteness, odor level, cleanliness and oxygen consumption are not affected, and can obviously improve the feather fluffy degree, meanwhile other effective components are added, and the prepared high fluffy down feather composite fiber has antibacterial, bacteria-resistant, mildew-resistant, washable, anti-static and other excellent characteristics.

Owner:ANHUI SANSEN TEXTILE

Antimicrobial self-cleaning type down feather composite fiber and producing method thereof

InactiveCN104831412AAntibacterialAnti-miteConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPhosphateFlax fiber

The present invention discloses antibacterial self-cleaning type down feather composite fiber characterized by comprising the following raw materials by weight: 13-16 parts of goose down, 24-28 parts of chicken feather stalk, 15-18 parts of flax fiber, 8-10 parts of aramid fiber, 11-14 parts of Shengma fiber, 4-7 parts of polyethylene fiber, 0.2-0.4 part of ascorbic acid, 2-4 parts of metakaolin, 4-6 parts of paraffin oil, 1.2-2.3 parts of garden burnet, 1.1-2.5 parts of folium isatidis, 6-9 parts of camphor tree bark, 1-3 parts of ramie root, 2.1-3.5 parts of triethyl citrate, 110-120 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 100-130 parts of 1-butyl-3-methyl imidazole acetate, 3-5 parts of an additive and proper amount of water; after treatment, the garden burnet, the folium isatidis, the camphor tree bark, the ramie root and the triethyl citrate are added into the raw materials, the materials are simple and environmentally friendly, the prepared down feather composite fiber has antibacterial, anti mite, anti fungal, anti allergic, and anti odor functions, meets the development trend of modern down products, meets the healthy environmentally friendly consumption mode advocated by the modern down products, and has wide application prospect.

Owner:ANHUI SANSEN TEXTILE

Warm down feather composite fiber and producing method thereof

InactiveCN104831408AGood warmth retentionImprove antibacterial propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPhosphateAntibacterial property

The invention discloses a warm down feather composite fiber which is characterized by comprising the following raw materials by weight: 12-14 parts of goose down, 19-24 parts of goose feather, 13-16 parts of dog hairs, 10-13 parts of cypress fiber, 12-14 parts of bamboo pulp fiber, 7-9 parts of short acrylic fiber, 0.4-0.8 parts of butyl acrylate, 0.2-0.4 parts of butyl acrylate, 2.1-3.4 parts of expanded and vitrified small ball, 2-3 parts of peanut shell, 3-5 parts of bamboo leaf, 1-2 parts of lobelia, 2-4 parts of wild chrysanthemum, 0.4-0.8 parts of rhizoma anemarrhenae, 3-6 parts of fungacetin, 100-110 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 105-115 parts of 1-butyl 3-methyl imidazole acetate, 3-5 parts of an auxiliary, and proper amount of water; the prepared warm down feather composite fiber has good heat preservation effect, does not stimulate the skin, and is safe, environmentally-friendly, excellent in antibacterial properties and washable.

Owner:ANHUI SANSEN TEXTILE

Method for preparing imidazole acetate ionic liquid

The invention discloses a method for preparing imidazole acetate ionic liquid, which comprises the following steps of: mixing organic alcoholic solution of imidazole halid salt and organic alcoholic solution of acetate, and reacting at preset temperature; evaporating to remove partial organic alcohol in a reaction system in the reaction process; and filtering reaction mixed liquor and removing organic alcohol from filtrate to obtain the imidazole acetate ionic liquid. In the method for preparing the imidazole acetate ionic liquid, the partial organic alcohol is evaporated and removed in the reaction process, so distillation can be performed by means of reaction temperature, the load of evaporating and removing a solvent after filtration is reduced, the cost is reduced, the solvent amount in the filtrate is small, and the inorganic salt amount remained in the solvent is small; therefore, the purity of the imidazole acetate ionic liquid subjected to solvent evaporation and removal is improved.

Owner:CHINESE TEXTILE ACAD

Creatine kinase isozyme assay kit

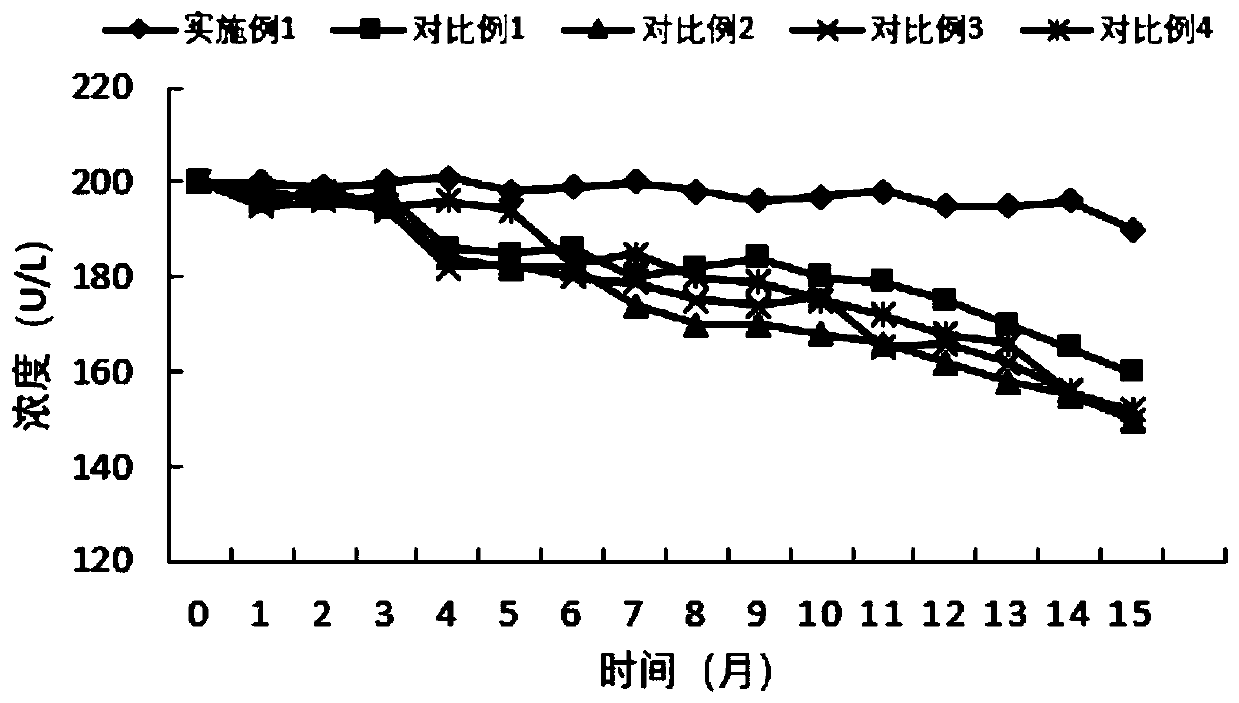

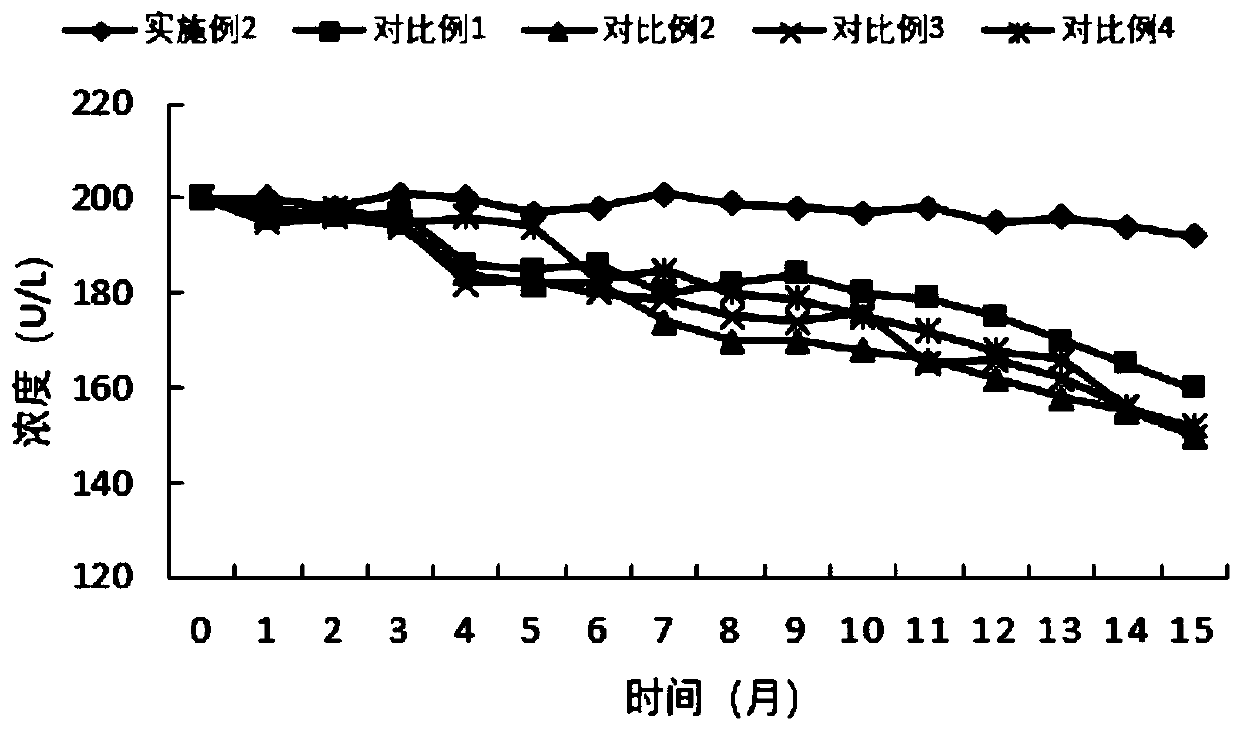

PendingCN111057746AImprove accuracyImprove precisionMicrobiological testing/measurementBiological material analysisAntiendomysial antibodiesIsozyme

The invention discloses a creatine kinase isozyme assay kit, belonging to the technical field of biological detection. The kit comprises a reagent R1 and a reagent R2 which are independent of each other. The reagent R1 comprises the following components: imidazole acetate, D-glucose, magnesium acetate L, hexokinase, N-acetylcysteine, adenosine diphosphate (ADP), an oxidized coenzyme II (NADP+), sodium azide, ethylenediamine tetraacetic acid (EDTA), glucose-6-phosphate dehydrogenase, adenosine 5'-disodium monophosphate (AMP), and diadenosine pentaphosphate (P1P5-diAP). The reagent R2 comprisesthe following components: creatine phosphate, sodium azide, and an anti-human CK-M antibody. In the implementation process, the stability, accuracy and precision of the kit are obviously improved by controlling the concentration ratio of all the components within a range disclosed by the invention, and the kit is simple to operate, low in preparation cost and suitable for promotion and application.

Owner:浙江夸克生物科技有限公司

Anti-impact polypropylene material and preparation method thereof

InactiveCN108192215AHigh impact strengthMake up for the defect of low impact strengthPolyesterButanediol

The invention relates to an anti-impact polypropylene material, which is prepared from the following raw material ingredients including modified polypropylene, titanium dioxide quantum dots, antioxidants 1076 and calcium stearate, wherein the modified polypropylene is prepared from polypropylene, 1-butyl-3-methyl imidazole stearate, stearic acid and polyurethane resin through reaction. The 1-butyl-3-methyl imidazole stearate is prepared from stearic acid, 1-butyl-3-methyl imidazole acetate, 1-butyl-3-methyl imidazole chlorine salt and ethyl alcohol through reaction; the polyurethane resin is prepared from diphenylmethane diisocyanate, glycol, 1,4-butanediol, polycarbonate diol, polytetrahydrofuran ether diol, polyester polyol CM-580 and dibutyl tin laurate through reaction; the titanium dioxide quantum dots are prepared from tetrabutyl titanate, stearic acid, ethanol, KH-560 couplin agents and Tween 60 through reaction. The anti-impact polypropylene material has excellent impact intensity.

Owner:杭州鼎友五金机械制造有限公司

New down feather composite fiber and producing method thereof

InactiveCN104831405AImprove loftImprove antibacterial propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses a new down feather composite fiber characterized by comprising the following raw materials by weight: 13-16 parts of duck down, 20-24 parts of duck feather, 7-10 parts of polyester short fiber, 1.1-2.3 parts of viscose chitin fiber, 8-10 parts of cane pulp fiber, 0.1-0.3 part of sodium lignosulphonate, 0.2-0.4 part of calcium alginate, 2.1-4.2 parts of sericite, 8-10 part of rice husk, 1-3 part of lycopodium clavatum, 1.2-3.1 part of phryma leptostachya, 2-4 part of dandelion, 0.7-1.2 part of sculellaria barbata, 100-110 part of 1-butyl 3-methyl imidazole dimethyl phosphate, 110-120 part of 1-butyl-3-methyl imidazole acetate, 3-6 part of an additive and moderate amount of water; The present invention reveals a new feather composite fiber, the feather has good bulking intensity and antibacterial mouldproof effect, the feather used as down jacket and down quilt packing can effectively improve human body blood circulation, and improve human immunity, and a variety of functions allow the product to be widely used.

Owner:ANHUI SANSEN TEXTILE

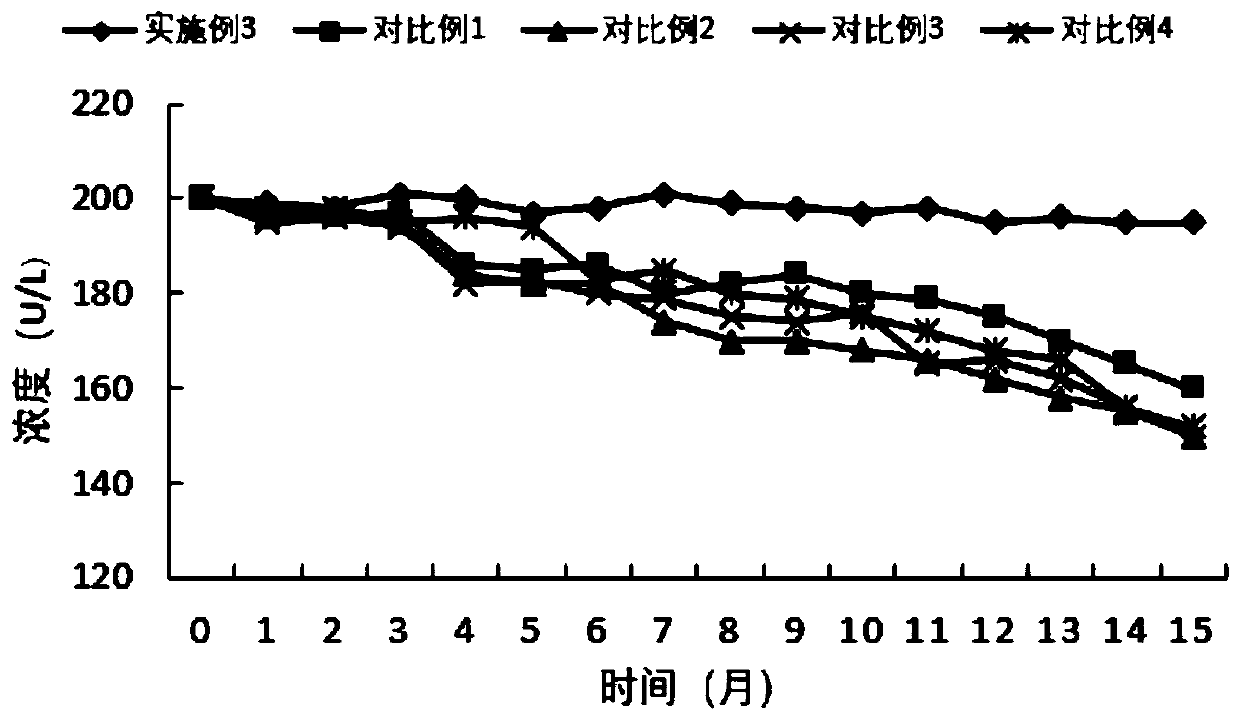

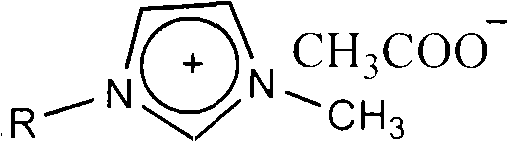

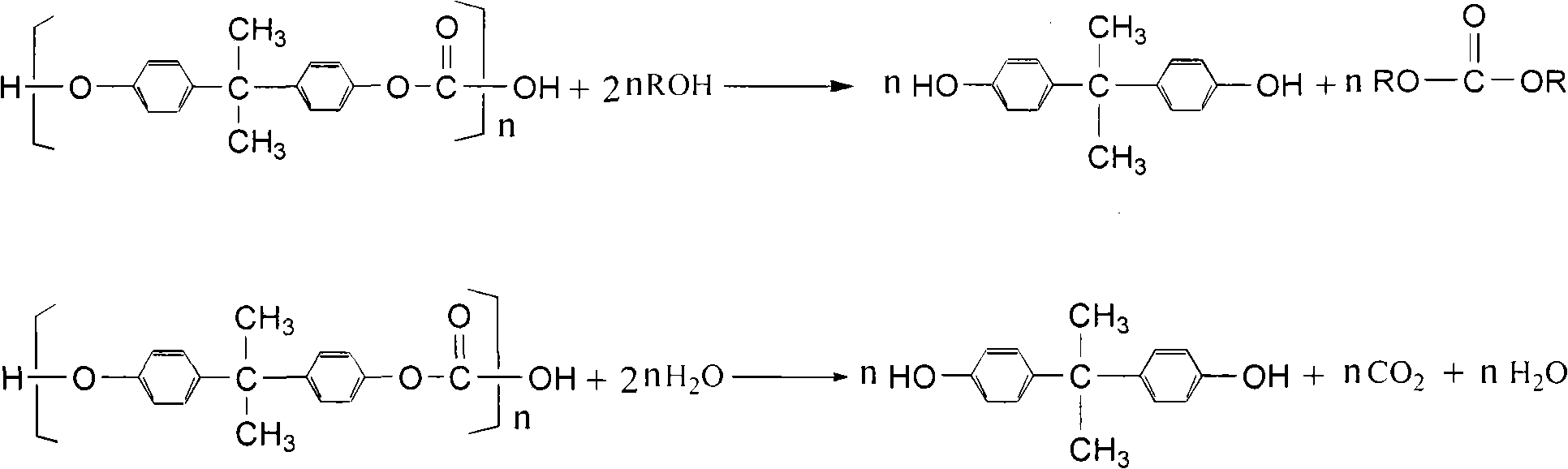

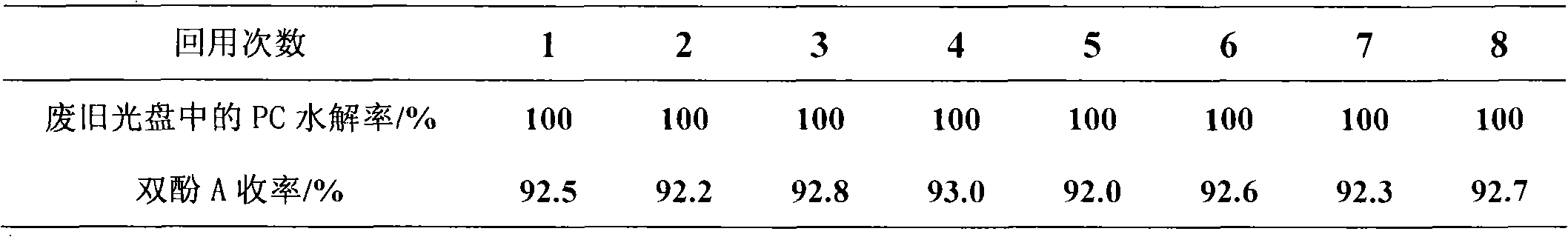

Chemical depolymerization recovery method for waste compact disks

ActiveCN102633605AOrganic compound preparationPreparation from organic carbonatesSolubilityHigh concentration

The invention relates to a novel method of chemically depolymerizing waste compact disks to generate bisphenol A and carbonic acid dialkyl ester to realize chemical recycling of the waste compact disks. The method is characterized in that 1-R-3-methyl imidazole acetate ionic liquid (the R can be ethyl, propyl or butyl) which is easy in recycling is used as a reaction medium and catalyst for hydrolysis or alcoholysis reaction at 90-140 DEG C, and a bisphenol A product (as for the alcoholysis reaction, carbonic acid dialkyl ester is further obtained) is obtained through operations of filtering, extracting, distilling and the like after the reaction is completed. The yield of each of the bisphenol A and the carbonic acid dialkyl ester is higher than 90%. Compared with the prior art, the novel method has the advantages that firstly, high-concentration organic strong acid or strong base in the background art is not needed, so that the problems of equipment corrosion and environment pollution are evidently improved; and secondly, the ionic liquid having a certain dissolubility to the waste compact disks is used as the reaction medium and catalyst, on one hand, reaction conditions are mild, and on the other hand, the problem that the catalyst in the background art cannot be recycled is solved as the ionic liquid is reusable.

Owner:QINGDAO UNIV OF SCI & TECH

High efficient composite inoculant for producing ethanol from straws, preparation and application thereof

The invention discloses a high efficient composite inoculant for producing ethanol from straws. The inoculant is composed of an inoculant I and an inoculant II; wherein the inoculant I is composed of one or more components selected from trichoderma, blue mould, aspergillus, and actinomycetes according to any ratio, the inoculant II is composed of one or more components selected from beer yeast, hansenula, and candida according to any ratio, and the inoculant I accounts for 50 to 70% of the total weight of the composite inoculant. The composite inoculant can be used to ethanol production through straw fermentation. The invention has the advantages that: (1) the straw powder is processed by being soaked in imidazole acetate so as to improve the cellulose dissolving performance, and thus the cellulose is easier to absorb; (2) the composite inoculant is used to co-ferment the straw to produce ethanol, during the degradation process, different microorganisms secrete complementary enzymes to completely degrade the substrate through metabolism, and thus the fermentation efficiency is improved; (3) the equipment and the technology is simple, the technology is environment-friendly, and the biomass resource utilization rate is improved.

Owner:NANKAI UNIV +1

Washable down feather composite fiber added with titanium dioxide and producing method thereof

InactiveCN104831409AIncrease profitImprove washing resistanceConjugated cellulose/protein artificial filamentsArtifical filament manufacturePhosphateResource development

The invention discloses washable down feather composite fiber added with titanium dioxide and a producing method thereof, the washable down feather composite fiber is characterized by comprising the following raw materials by weight 13-15 parts of duck down, 17-19 parts of rabbit hair, 10-13 parts of alpaca hair, 15-18 parts of rabbit wool fiber, 12-14 parts of mercerizing australasian wool, 0.03-0.06 part of nano selenium, 0.1-0.3 part of poly (tetramethyleneether) glycol, 2-4 parts of nano attapulgite, 4-7 parts of perilla leaf, 1.1-2.4 parts of titanium dioxide, 1-3 parts of hedyotis diffusa, 0.4-0.7 part of hippocampus, 3-5 parts of fennel oil, 100-120 parts of 1 - butyl-3-methyl imidazole dimethyl phosphate, 110-130 parts of 1-butyl-3-methyl imidazole acetate, 2-4 parts of an additive and a moderate amount of water; by use of the technology of the present invention, the utilization rate of feathers can be can greatly improved, the washable down feather composite fiber has obvious social and economic benefits for resource development and utilization and sustainable development, at the same time, the washable down feather composite fiber is added with titanium dioxide and other components, washable, antibacterial, mouldproof, anti-oxidation, immunity-improving and other functions of the down feather can be improved.

Owner:ANHUI SANSEN TEXTILE

Imidazole ionic liquid and synthesis method and application thereof

ActiveCN109912507AImprove solubilityLess impuritiesCarboxylic acid salt preparationCelluloseSynthesis methods

The invention provides a synthesis method of imidazole ionic liquid 1-allyl-3-vinylimidazole acetate. The synthesis method comprises the following steps: carrying out one-step reaction on N-vinylimidazole and allyl chloride to obtain an ionic liquid intermediate 1-allyl-3-vinylimidazole chloride salt at first, and then carrying out anion exchange on the intermediate and potassium acetate to obtain1-allyl-3-vinylimidazole acetate ([AVIM] [OAc]). The ionic liquid 1-allyl-3-vinyl imidazole acetate can be used as a solvent and can be used for dissolving biological macromolecules such as starch and cellulose.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

New down feather composite fiber helping sleep and producing method thereof

InactiveCN104831410AGood warmth retentionGood flexibilityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsMohairPhosphate

The invention discloses a new down feather composite fiber helping sleep, the new down feather composite fiber helping sleep is characterized by comprising the following raw materials by weight: 15-20 parts of duck down, 20-24 parts of mohair, 10-13 parts of milk protein fiber, 9-12 parts of carbon copper fiber, 13-15 parts of tribute silk fiber, 1.2-3.5 parts of chitosan, 0.2-0.5 part of borax, 7-9 parts of polyethylene fiber, 1-3 parts of peach gum, 10-12 parts of chestnut shell, 1-3 parts of folium artemisiae argyi, 6-8 parts of grapefruit leaves, 1.1-2.1 parts of tuber fleeceflower stem, 2-4 parts of epoxy soybean oil, 100-110 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 110-130 parts of 1-butyl-3-methyl imidazole acetate, 3-5 parts of an assistant and the proper amount of water; the new down feather composite fiber adopts the duck down, the mohair and the polyethylene fiber composite for mutual compound, the heat retention property is far better than that of pure duck down, by addition of the folium artemisiae argyi, the grapefruit leaves, the tuber fleeceflower stem and the like, the prepared new down feather composite fiber product has the characteristics of mildew resistance, good softness, good hygroscopicity and strong wear resistance.

Owner:ANHUI SANSEN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com