A kind of process of calcium carbide producing pvc

A calcium carbide and process technology, applied in the field of polymer material science and engineering, can solve the problems of heat waste, water waste, environmental impact, etc., and achieve the effect of improving utilization rate, avoiding pollution, and avoiding excessive evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

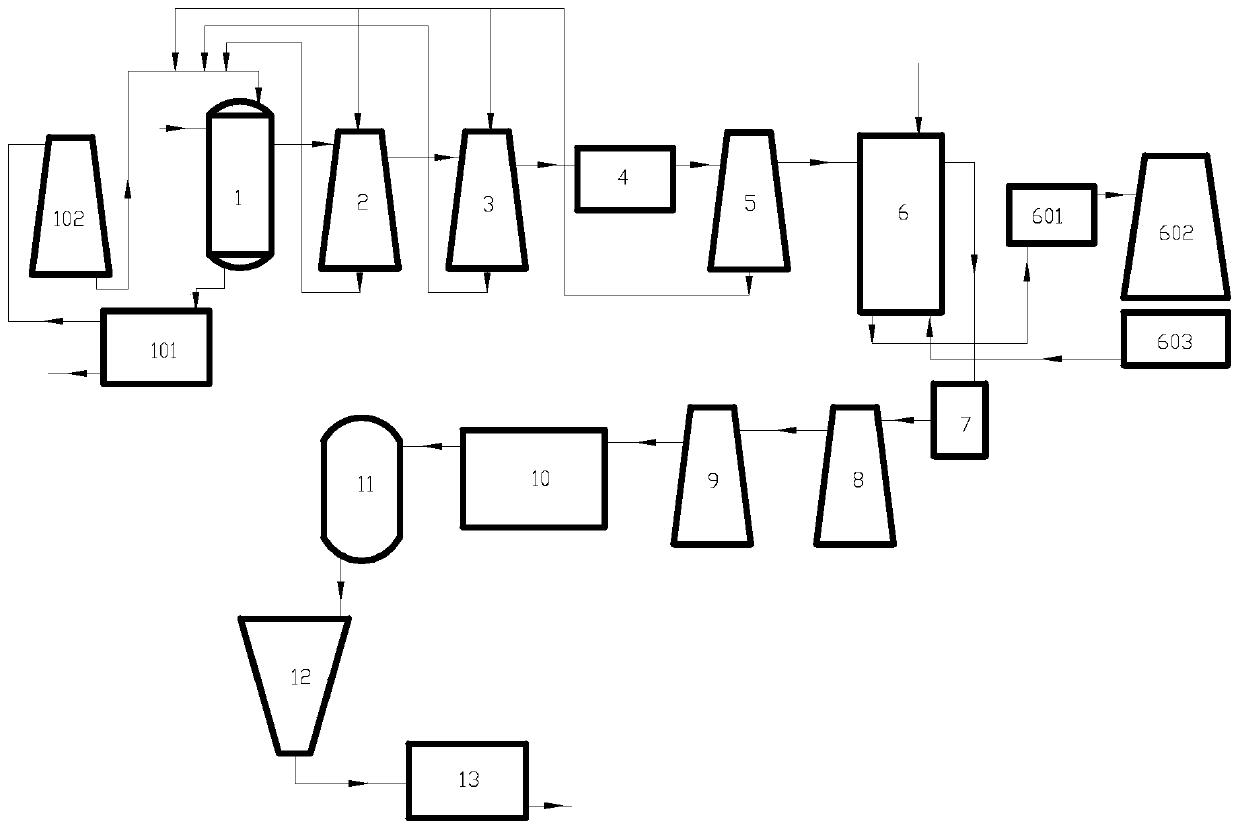

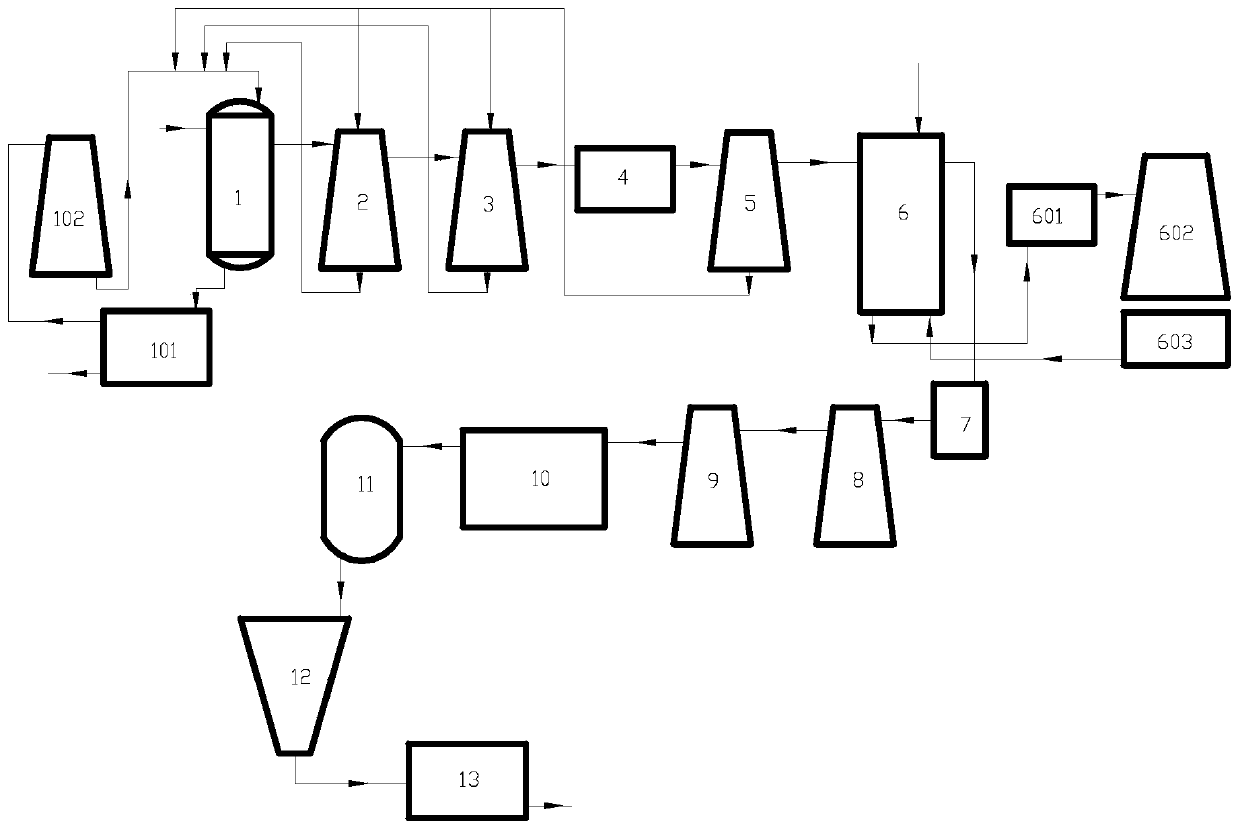

[0018] The invention provides a process for producing PVC from calcium carbide, see figure 1 Calcium carbide and water react in the acetylene generator 1 to generate acetylene gas, and the acetylene gas passes through the dedusting cooling tower 2, the desulfurization tower 3, the gas cabinet 4, and the cleaning tower 5 in sequence, and then enters the converter 6 to react with hydrogen chloride gas to generate crude gas. Vinyl chloride gas, crude vinyl chloride gas is demercurized by mercury remover 7, acid is recovered by water washing tower 8, alkali washing by alkali washing tower 9 and rectified by rectification device 10 to obtain refined vinyl chloride gas, and then refined vinyl chloride gas enters polymerization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com