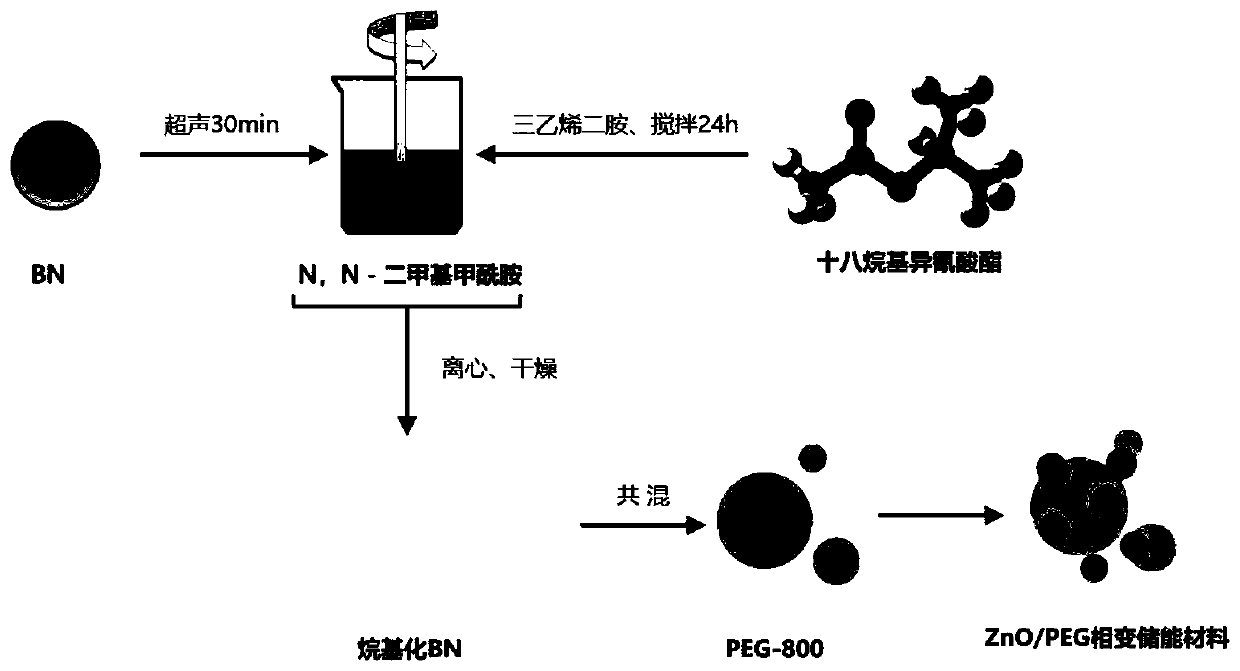

Energy storage wood material using alkylated boron nitride as filler

A boron nitride and alkylation technology, used in wood treatment, wood impregnation, wood impregnation, etc., can solve problems such as poor encapsulation, low thermal conductivity, etc., and achieve improved service life, mild reaction conditions, and high operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An energy storage wood using alkylated boron nitride as a filler, comprising the following steps:

[0024] (1) Delignified wood: select fast-growing poplar, select mature sapwood above breast height, the specification is 20mm long x 20mm wide x 20mm thick, free from defects such as cracking, decay and discoloration. After weighing, place the wood specimen in deionized water and vacuumize (-0.1MPa, 1h) to discharge the air inside the wood. Pour 500ml deionized water into the beaker, then add 40gNaOH and 63gNa 2 SO 3 , after heating to 95°C, place the wood in the mixture and cook for 24 hours (the mixture is replaced 3-4 times during the process), and ensure that the wood is submerged in the solution during this period. Finally, place the cooked wood in ethanol boiling liquid at 78°C for 1 hour to replace the moisture in the wood. The prepared wood was kept in absolute ethanol. .

[0025] (2) Organic solvent: ①Put glycidyl methacrylate through the oxidation pot and p...

Embodiment 2

[0030] An energy storage wood using alkylated boron nitride as a filler, comprising the following steps:

[0031] (1) Delignified wood: Paulownia wood is selected, and mature sapwood above breast height is selected. The specifications are 30mm long x 30mm wide x 20mm thick, without cracking, decay and discoloration. After weighing, place the wood specimen in deionized water and vacuumize (-0.1MPa, 1h) to discharge the air inside the wood. Pour 500ml deionized water into the beaker, then add 5gNaOH and 2.5gNa 2 SO 3 , after heating to 95°C, place the wood in the mixture and cook for 24 hours (the mixture is replaced 3-4 times during the process), and ensure that the wood is submerged in the solution during this period. Finally, place the cooked wood in ethanol boiling liquid at 78°C for 1 hour to replace the moisture in the wood. The prepared wood was kept in absolute ethanol.

[0032] (2) Organic solvent: ①Put glycidyl methacrylate through the oxidation pot to get purified g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com