Multi-element composite solid-solid phase-change material and preparation method thereof

A phase-change material and multi-component compounding technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of rare application, difficult packaging, high cost, etc., and achieve simple process, low production cost, and alleviate phase change performance The effect of the decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 2.7g PEGA, 0.3g NMA, 4.5g PEG4000 in 18ml deionized water, fully disperse and mix evenly in ultrasonic dispersion, add 0.06g N-N, methylenebisacrylamide, 0.045g ammonium persulfate, and raise the system temperature to 75°C , reacted for 3.5 hours to form a hydrogel with a cross-linked network structure, and freeze-dried for 48 hours to obtain a copolymer blended gel phase change material PEGA-NMA / PEG.

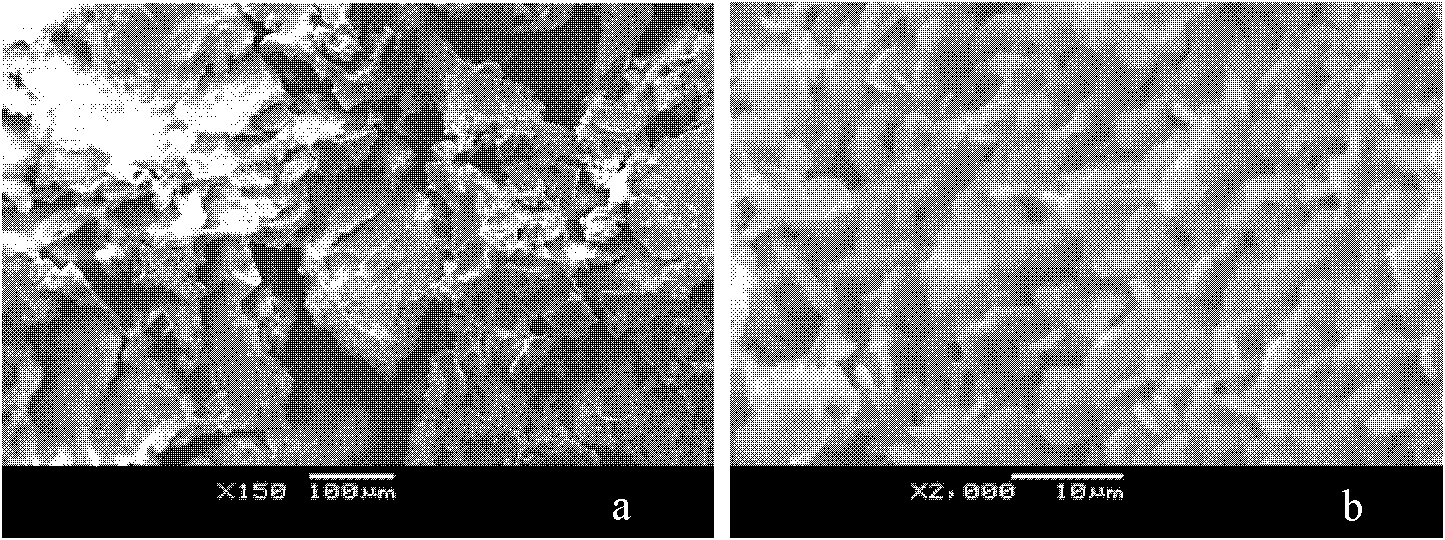

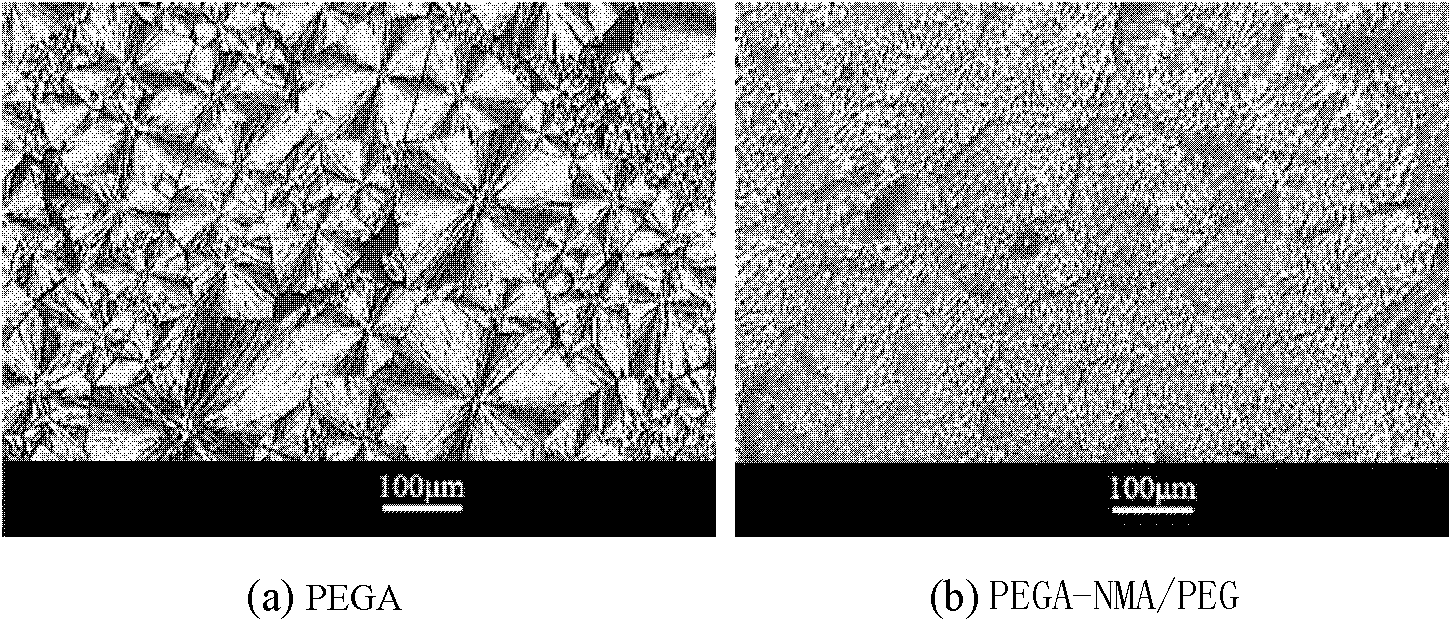

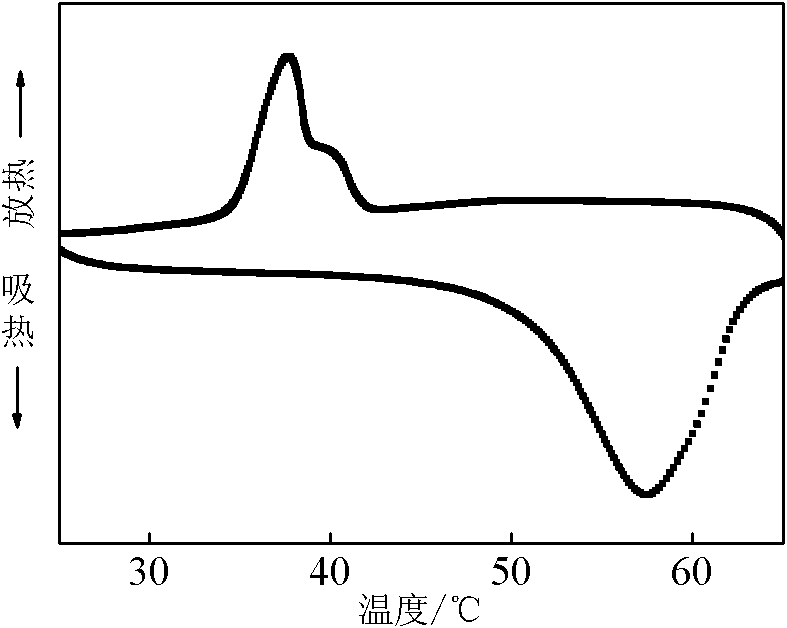

[0033] Carry out SEM analysis to the section of above-mentioned phase change material [see figure 1 ], the two-phase structure of the composite material prepared by this method is uniformly dispersed, and no obvious phase separation can be seen. It can also be seen from the figure that the freeze-drying has preserved the three-dimensional network structure obtained by the composite material to the greatest extent, and the composite material is uniformly dispersed. With pores ranging in diameter from one micron to several microns, the copolymerization and blendi...

Embodiment 2

[0038] Dissolve 2.1g of PEGA, 0.9g of NMA, and 2g of PEG4000 in 18ml of deionized water, disperse and mix well in ultrasonic dispersion, add 0.06g of N-N, methylenebisacrylamide, and 0.045g of ammonium persulfate, and raise the temperature of the system to 75°C. After reacting for 2 hours, a hydrogel with a cross-linked network structure was formed, and freeze-dried for 48 hours to obtain a copolymer blended gel phase change material.

Embodiment 3

[0040] Dissolve 2.4g of PEGA, 0.6g of NMA, and 2g of PEG4000 in 24ml of deionized water, disperse and mix well in ultrasonic dispersion, add 0.09g of N-N, methylenebisacrylamide, 0.045g of ammonium persulfate, and raise the temperature of the system to 75°C. After reacting for 3 hours, a hydrogel with a cross-linked network structure was formed, and dried by blowing for 48 hours to obtain a copolymer blended gel phase change material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com