Extinguishment preventing garbage processing device

A garbage disposal device and garbage technology, which are applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems that garbage in the furnace cannot be dried normally, cannot be continuously burned, and the combustion layer is extinguished, and achieve the effect of accelerating reduction and carbonization. , speed up the drying effect, avoid the effect of flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

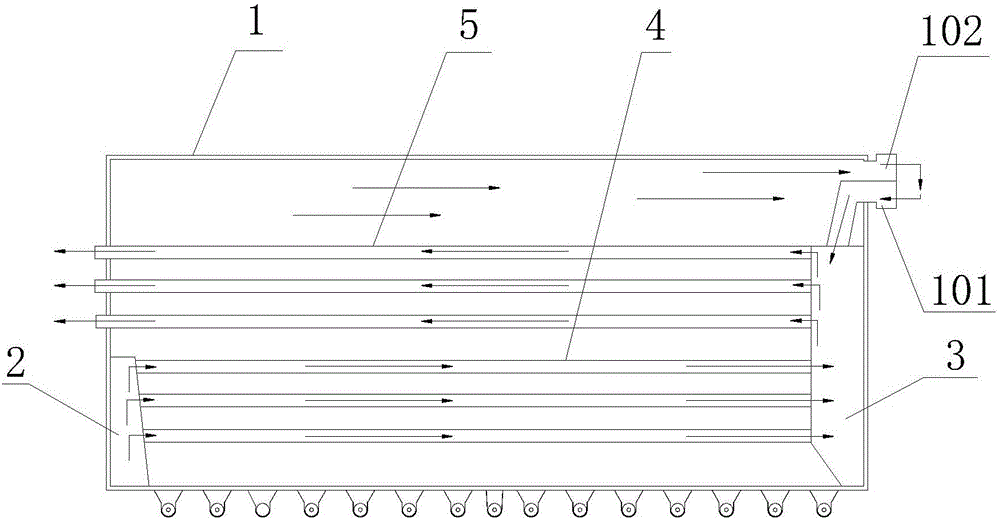

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an anti-extinguishing garbage disposal device proposed by the present invention.

[0019] refer to figure 1 , an anti-extinguishing garbage treatment device proposed in the embodiment of the present invention, comprising: a furnace body 1 for treating garbage, wherein:

[0020] The inner cavity of the body of furnace 1 has a length direction and a width direction, and its width direction is smaller than its length direction; in the inner cavity of the body of furnace 1 and located on both sides near its bottom, a heating chamber 2 and a drainage chamber 3 are respectively provided. The heating chamber 2 has an inlet communicating with the outside world for introducing a high-temperature medium; an energy balancer is provided in the inner cavity of the furnace body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com