Auxiliary heat garbage disposal equipment

A waste treatment equipment and auxiliary heating technology, applied in lighting and heating equipment, combustion types, combustion methods, etc., can solve problems such as difficult to ignite, heat, and affect the effect of waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the technical solution of the present invention will be described in detail through specific examples.

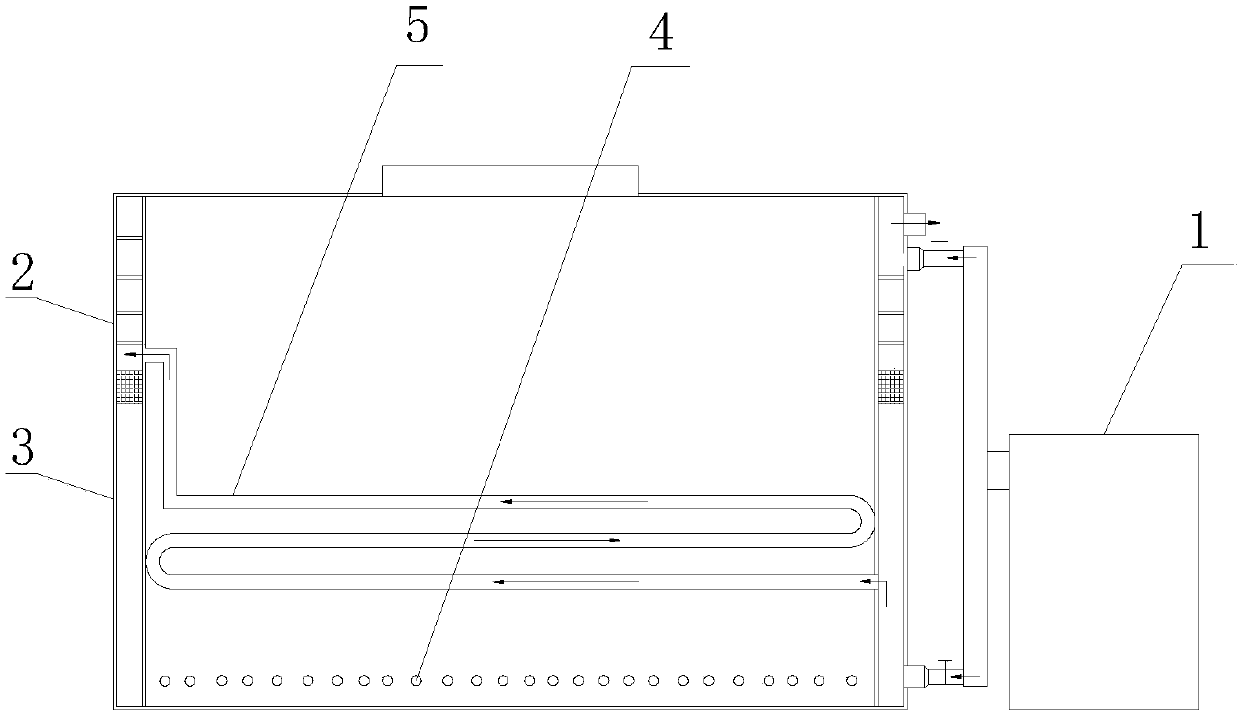

[0017] like figure 1 as shown, figure 1 It is a schematic structural diagram of an auxiliary heating garbage disposal equipment proposed by the present invention.

[0018] refer to figure 1 , a kind of auxiliary heating garbage treatment equipment proposed by the embodiment of the present invention, comprising: a furnace body and a heating device 1, the furnace body includes an upper furnace body 2 and a lower furnace body 3 arranged up and down, and the heating device 1 Used to transport high temperature gas, among which:

[0019] The furnace chambers of the upper furnace body 2 and the lower furnace body 3 are connected, and an upper clamping cavity arranged circularly around the furnace cavity of the upper furnace body 2 is provided between the inner and outer walls of the upper furnace body 2, and the upper clamping cavity is provided with a row communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com