Oxygen supply device of high-temperature pyrolysis gasification furnace

An oxygen supply device and high-temperature pyrolysis technology, applied in incinerators, indirect carbon dioxide emission reduction, non-flammable liquid/gas transportation, etc., can solve the problems of no blocking device and blockage at the oxygen supply port, and achieve the reduction of flue gas, Effects of cost reduction and sufficient waste incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

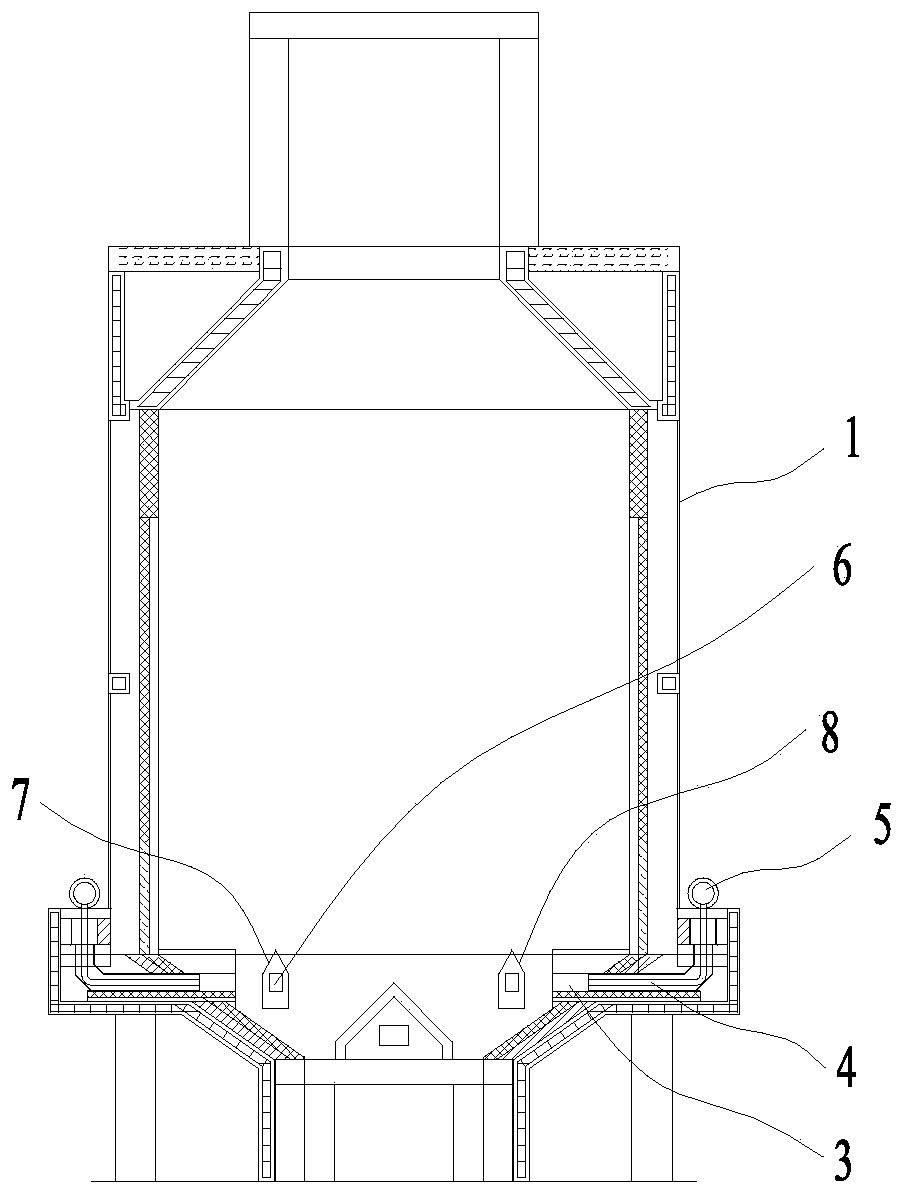

[0022] See also figure 1 with figure 2 , The embodiment of the present invention provides an oxygen supply device for a high-temperature cracking gasifier, which is installed in the cracking furnace 1, and includes an air duct 2 arranged on the inner wall of the cracking furnace 1, and the air duct 2 is provided with an inlet toward the side of the inner wall of the cracking furnace 1. The tuyere 3 and the air inlet 3 are connected to the outside of the cracking furnace 1 through the air inlet pipe 4. A fan 5 is provided on the air inlet pipe 4. The side of the air duct 2 facing away from the air inlet 3 is provided with an air outlet 6, and a shielding device 7 is provided above the air outlet 6.

[0023] When the oxygen supply device of the high-temperature pyrolysis gasifier of the present invention is in use, the fan 5 introduces fresh air into the air inlet pipe 4, and then into the air duct 2 from the air inlet 3, and finally through the air outlet 6 of the air duct 2 Oxy...

Embodiment 2

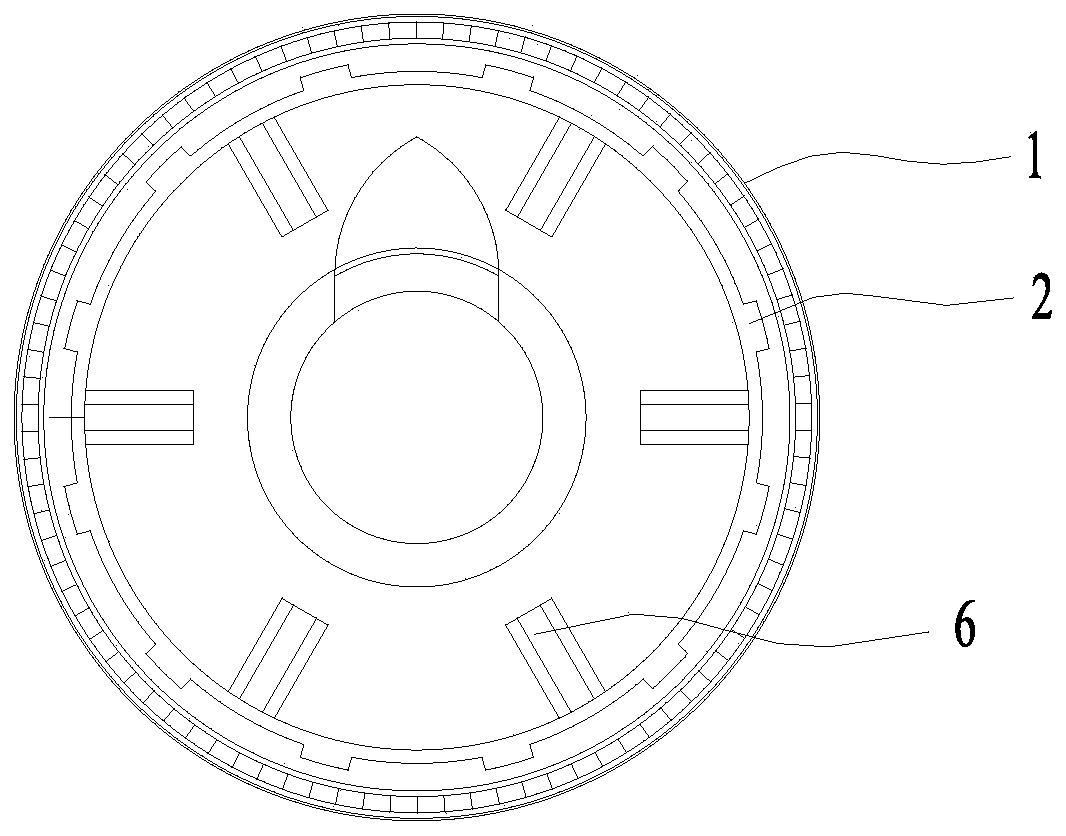

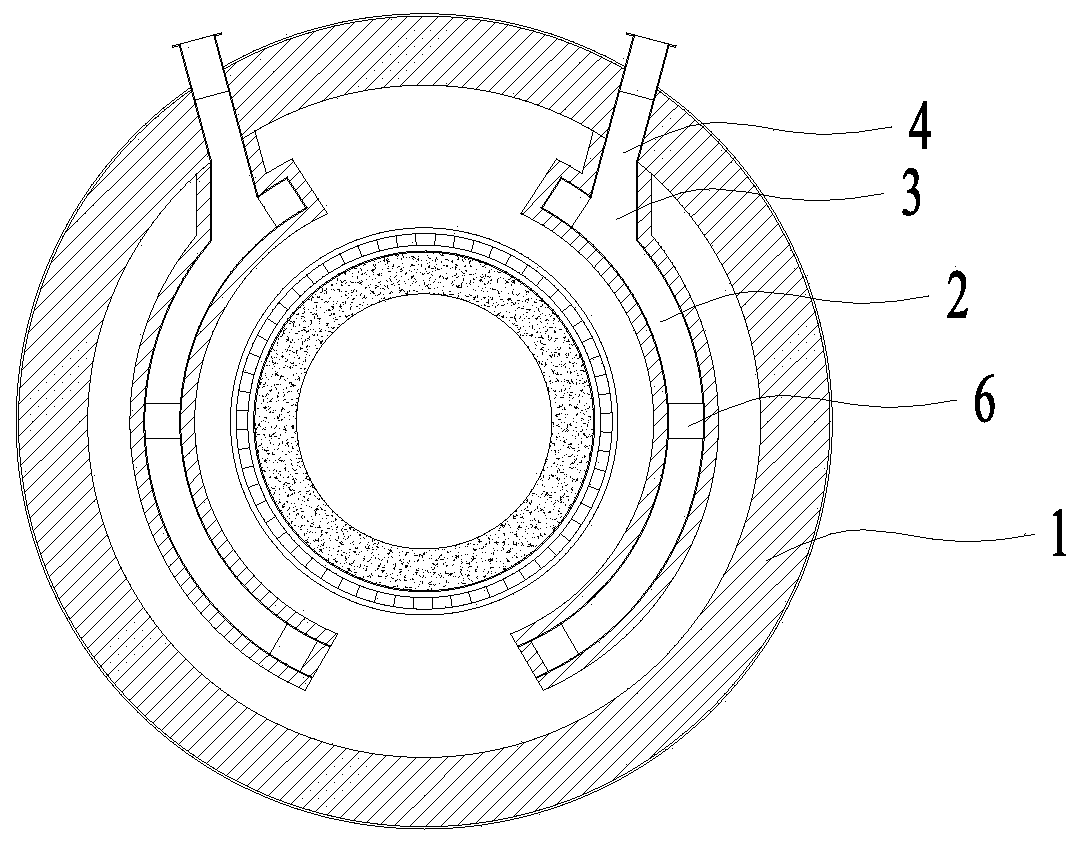

[0028] See image 3 In this embodiment, except that the structure of the air duct 2 is different, everything else is the same as the embodiment 1.

[0029] In this embodiment, two air ducts 2 are provided, and each air duct 2 is arc-shaped. Each air duct 2 is provided with an air inlet 3 on the side facing the inner wall of the cracking furnace 1, and the air inlet 3 is connected to the outside of the cracking furnace 1 through an air inlet pipe 4. A fan 5 is provided on the air inlet pipe 4. Three air outlets 6 are evenly provided on the side of each air duct 2 facing away from the air inlet 3.

[0030] When in use, the fan 5 introduces fresh air into the air inlet pipe 4, and then enters the air duct 2 from the air inlet 3, and finally supplies oxygen to the cracking furnace 1 through the air outlet 6 of the air duct 2, so that the material is in the cracking furnace Fully burn within 1

Embodiment 3

[0032] See Figure 4 In this embodiment, except that the structure of the shielding device 7 is different, everything else is the same as the first embodiment.

[0033] In this embodiment, the shielding device 7 is an arc-shaped baffle 9, and the arc-shaped baffle 9 protrudes upward. When the rubbish falls down, it continues to slide down along the arc edge of the curved baffle 9, thereby avoiding the rubbish blocking the air outlet 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com