A flame spray head, a combustion tank and the use of the combustion tank in processing fuel

A technology of flame spray head and combustion tank, which is applied in the field of combustion tank and combustion tank to process fuel and flame spray head. It can solve the problems of prolonging the construction period, inconvenient operation, and cumbersome operation, so as to save manpower and material resources, reduce production costs, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Oil test and discharge experiment

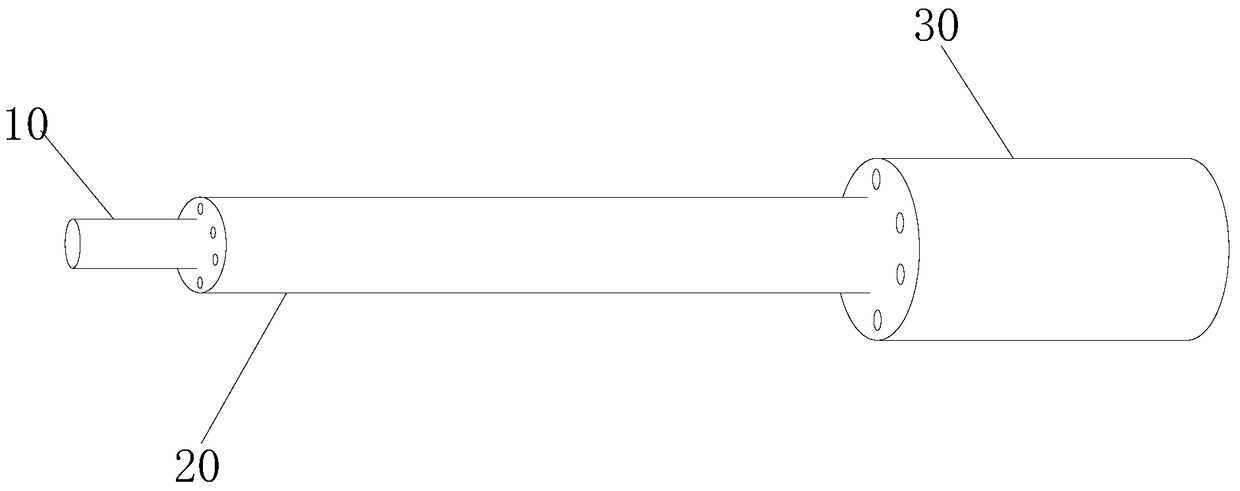

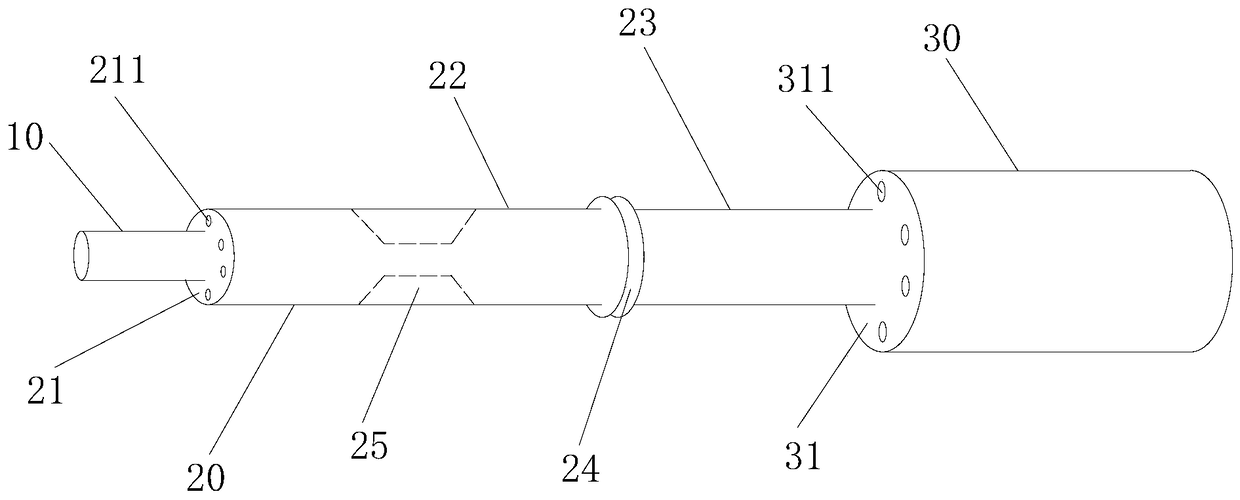

[0052] Such as figure 1 As shown, the feed pipe 10 is connected to the oil pipeline of the oil well. The oil enters from the feed pipe 10, enters the first pipe 20 through the feed pipe 10, and then enters the second pipe 30 through the first pipe 20. The outlet of the second pipe 30 is ignited to start processing fuel.

[0053] As a result, the fuel is fully burned, no black smoke and noxious gases are generated, and under the same task amount, compared with the existing fire nozzles such as duckbills, the service life of the existing fire nozzles is 3-8 hours, and The flame spray head of the embodiment of the present invention can be used for more than 1000 hours, and the service life is extended by more than hundreds of times; the existing operation requires the cooperation of at least 3 workers to complete, while the embodiment of the present invention only requires 1 worker to operate. Cost saving more than two-thirds and s...

Embodiment 2

[0076] Example 2 Oil test and discharge experiment

[0077] Such as Figure 4 As shown, there is no need to dig pits, lay plastic sheets, and lay bricks. Just connect the flame nozzle directly with the oil pipeline of the oil well, and the oil enters the flame nozzle in the cavity 41 and ignites at the outlet of the flame nozzle. The oil is processed in the cavity 41.

[0078] As a result, the fuel is fully burned, no black smoke and noxious gases are generated, and under the same task amount, compared with the existing technical means for processing fuel, the existing technology requires a large number of fields to dig pits, and a large amount of plastic cloth and Bricks and other materials, while the combustion can in the embodiment of the present invention can be used directly, hardly occupying the field, and does not require materials such as plastic cloth and bricks, which greatly reduces the production cost; the existing preparation time is more than 48 hours, and the implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com