Method for preparing composite phase-changing material

A composite phase change material and organic phase technology, applied in the field of preparation of phase change materials, can solve the problems of reducing the thermal conductivity of materials, achieve low cost, expand the application range, and improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Synthesis of copper nanowires: Take 12 mL of 0.1 M copper nitrate solution, mix with 360 mL of sodium hydroxide aqueous solution (7 M), then add 6 mL of 99% ethylenediamine, and mix well. Add 0.36mL of 50% (V / V) hydrazine hydrate, mix well and put it in a water bath at 60°C, take it out and cool it after 2 hours. Filter to obtain copper nanowires. Repeat several times to obtain sufficient copper nanowires.

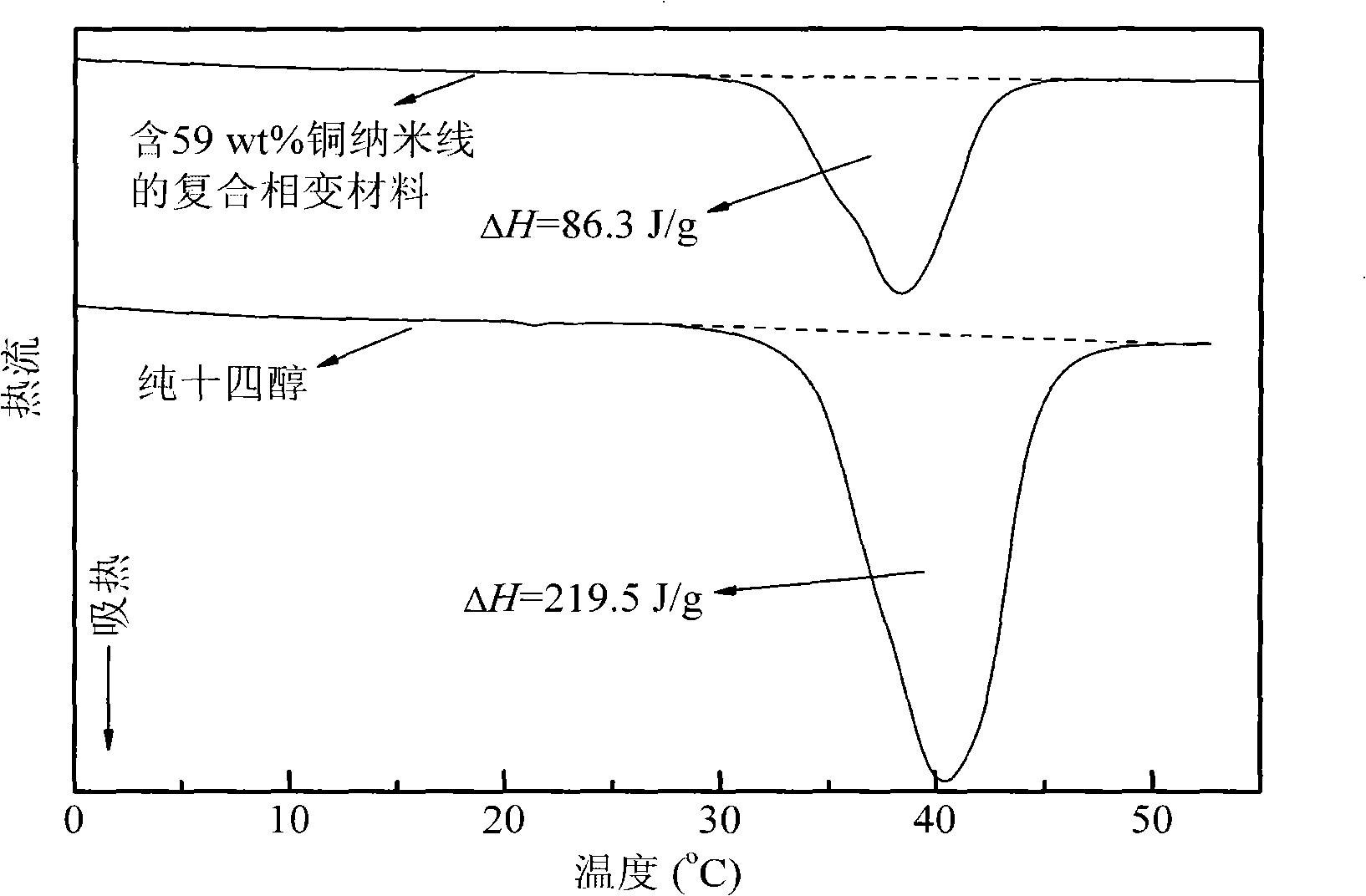

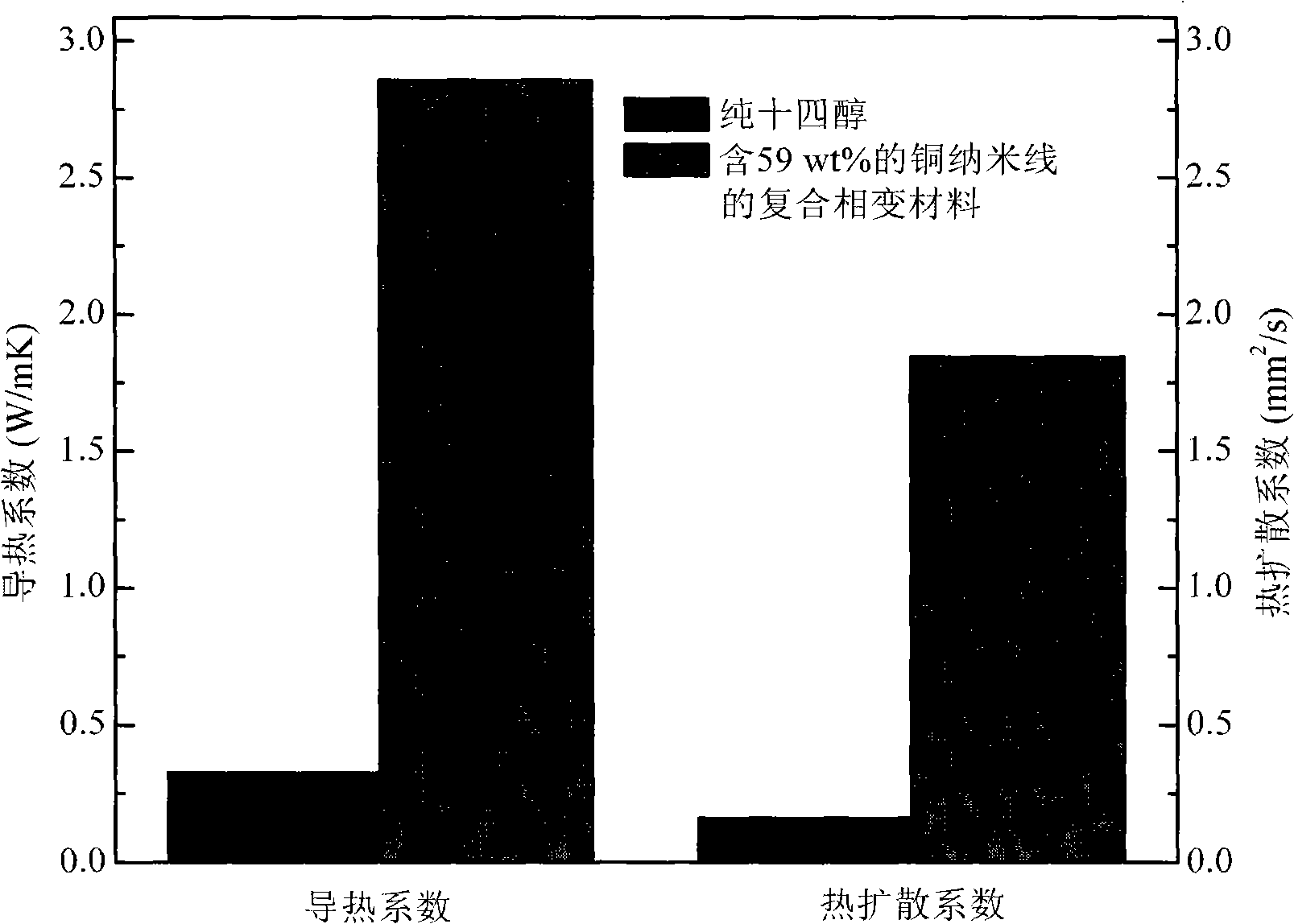

[0031] 2) Preparation of copper nanowire / tetradecyl alcohol composite phase change material: take 0.86g of copper nanowire, add 15mL of acetone, stir magnetically for 1.5 hours, disperse by ultrasonic wave for 0.5 hour, then volatilize the acetone to the remaining 1.5mL, then add 0.60g of ten Tetrol, the above mixture is placed in a 50-degree water bath for ultrasonic dispersion until the acetone is completely volatilized, taken out and cooled to obtain a copper nanowire / tetradecyl alcohol composite phase change material. Which contains copper nanowires 59wt% ...

Embodiment 2

[0046] 1) Synthesis of copper nanowires: Take 12 mL of 0.1 M copper nitrate solution, mix with 360 mL of sodium hydroxide aqueous solution (7 M), then add 6 mL of 99% ethylenediamine, and mix well. Add 0.36mL of 50% (V / V) hydrazine hydrate, mix well and put it in a water bath at 60°C, take it out and cool it after 2 hours. Filter to obtain copper nanowires. Repeat several times to get enough copper nanowires.

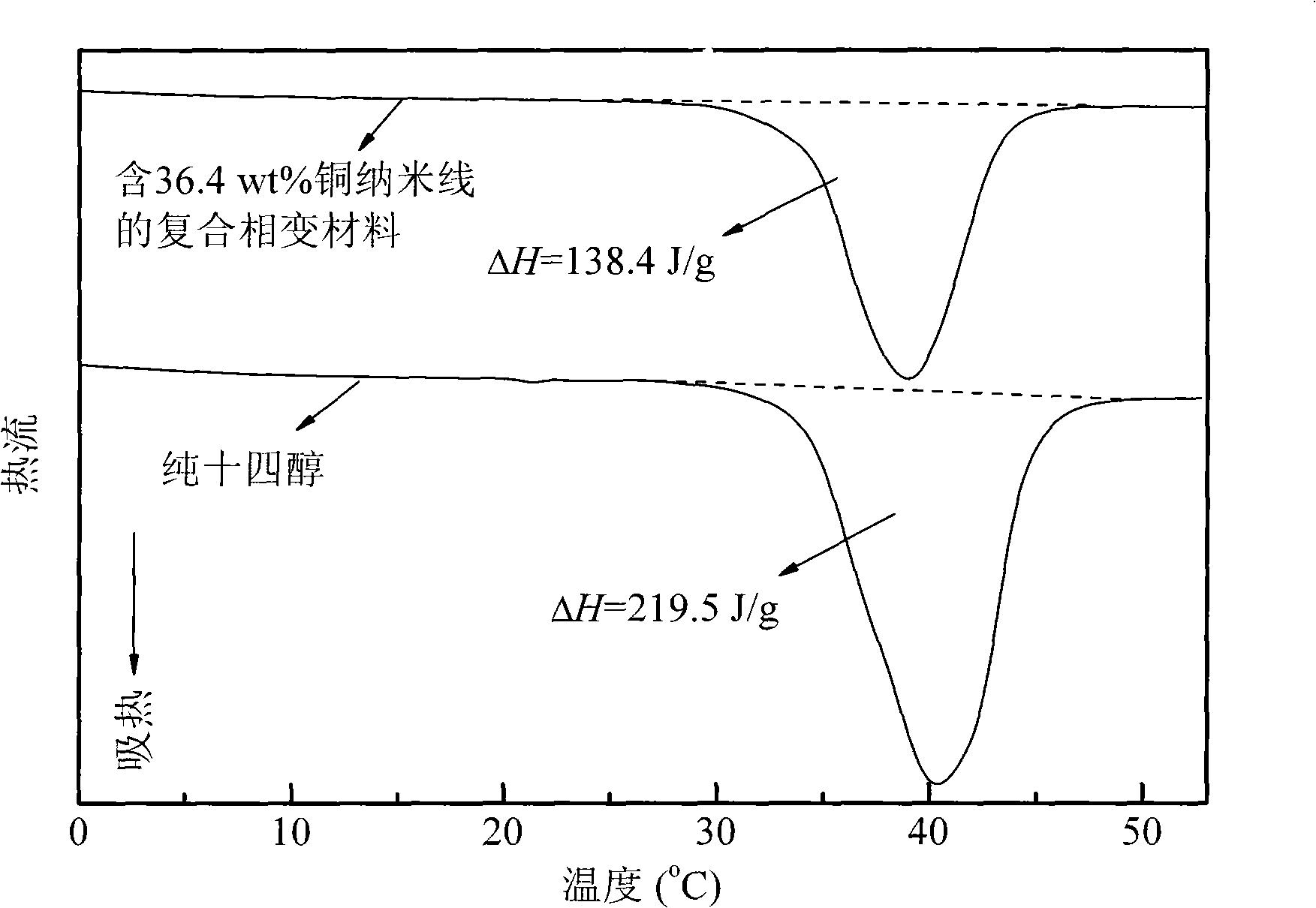

[0047] 2) Preparation of copper nanowire / tetradecyl alcohol composite phase change material: take 0.53g of copper nanowire, add 15mL of acetone, magnetically stir for 1.5 hours, ultrasonically disperse for 0.5 hour, then volatilize the acetone to the remaining 1.5mL, then add 1.00g of ten Tetrol, the above mixture is placed in a 50-degree water bath for ultrasonic dispersion until the acetone is completely volatilized, taken out and cooled to obtain a copper nanowire / tetradecyl alcohol composite phase change material. Which contains copper nanowires 34.6wt%

[0048] ...

Embodiment 3

[0051] 1) Synthesis of silver nanowires:

[0052] 1) Dissolve 2.50g of polyvinylpyrrolidone in 62mL of ethylene glycol to obtain a solution with a concentration of 0.36M. The solution was vigorously stirred and refluxed in an oil bath at 160°C for 2 hours.

[0053] 2) Dissolve 0.62g AgNO3 in 30mL ethylene glycol, and add this solution dropwise at a rate of 0.5mL / min to the aforementioned solution while vigorously stirring. After the dropwise addition, it was stirred and refluxed for 1 hour, and then cooled to room temperature.

[0054] 3) Add 10 times the volume of acetone to the above reaction product mixture, let it stand for 24 hours, and discard the upper yellow clear liquid. The lower precipitate was filtered to obtain silver nanowires.

[0055] 2) Preparation of silver nanowire / tetradecyl alcohol composite phase change material: take 1.00g of silver nanowire, add 15mL of acetone, magnetically stir for 1.5 hours, ultrasonically disperse for 0.5 hour, then volatilize th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com