Polyether-based composite phase change energy storage material and preparation method thereof

A technology of composite phase change and energy storage materials, applied in the field of polyether-based composite phase change energy storage materials and their preparation, can solve problems such as affecting use, and achieve the effects of strong practicability, simple synthesis process and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

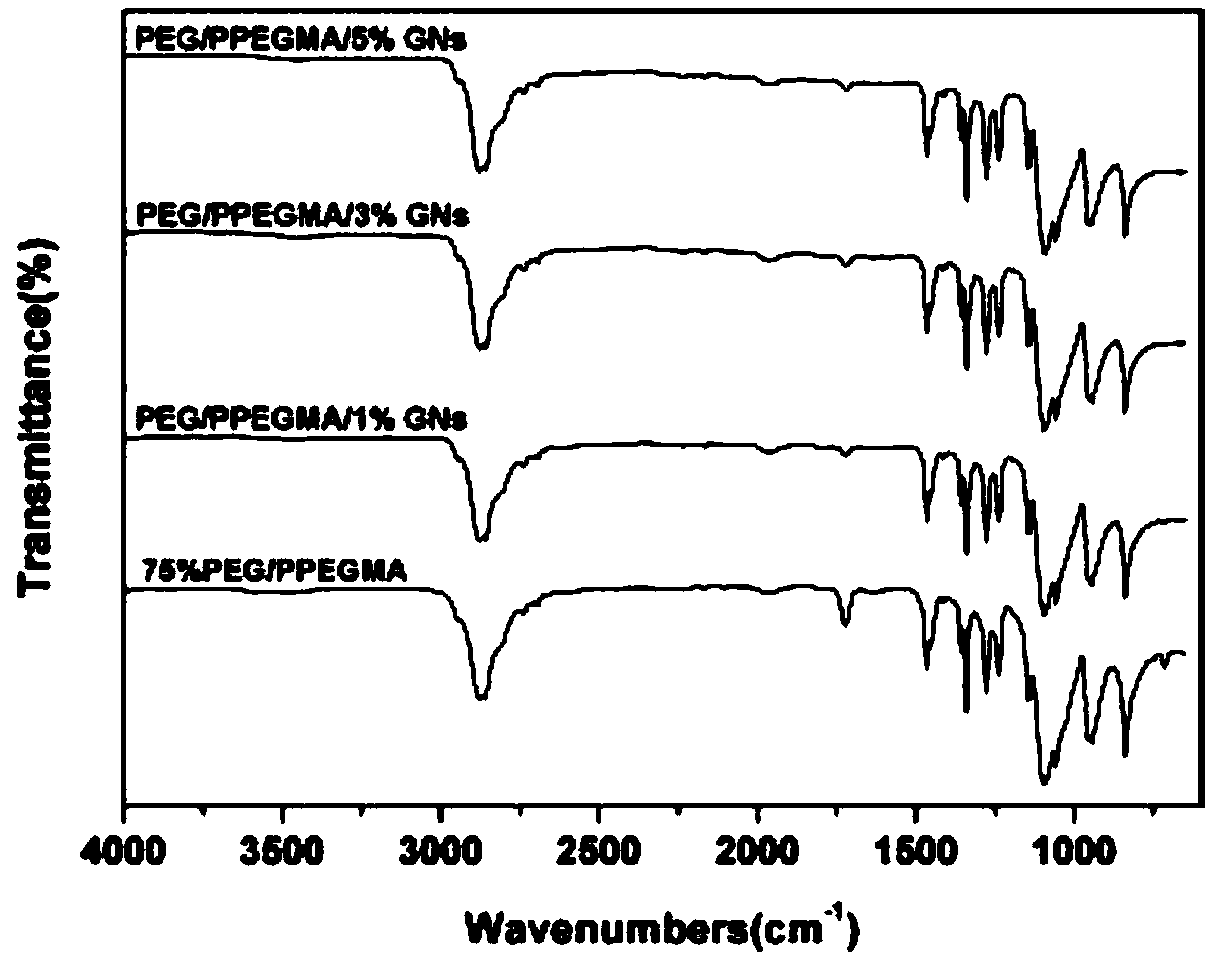

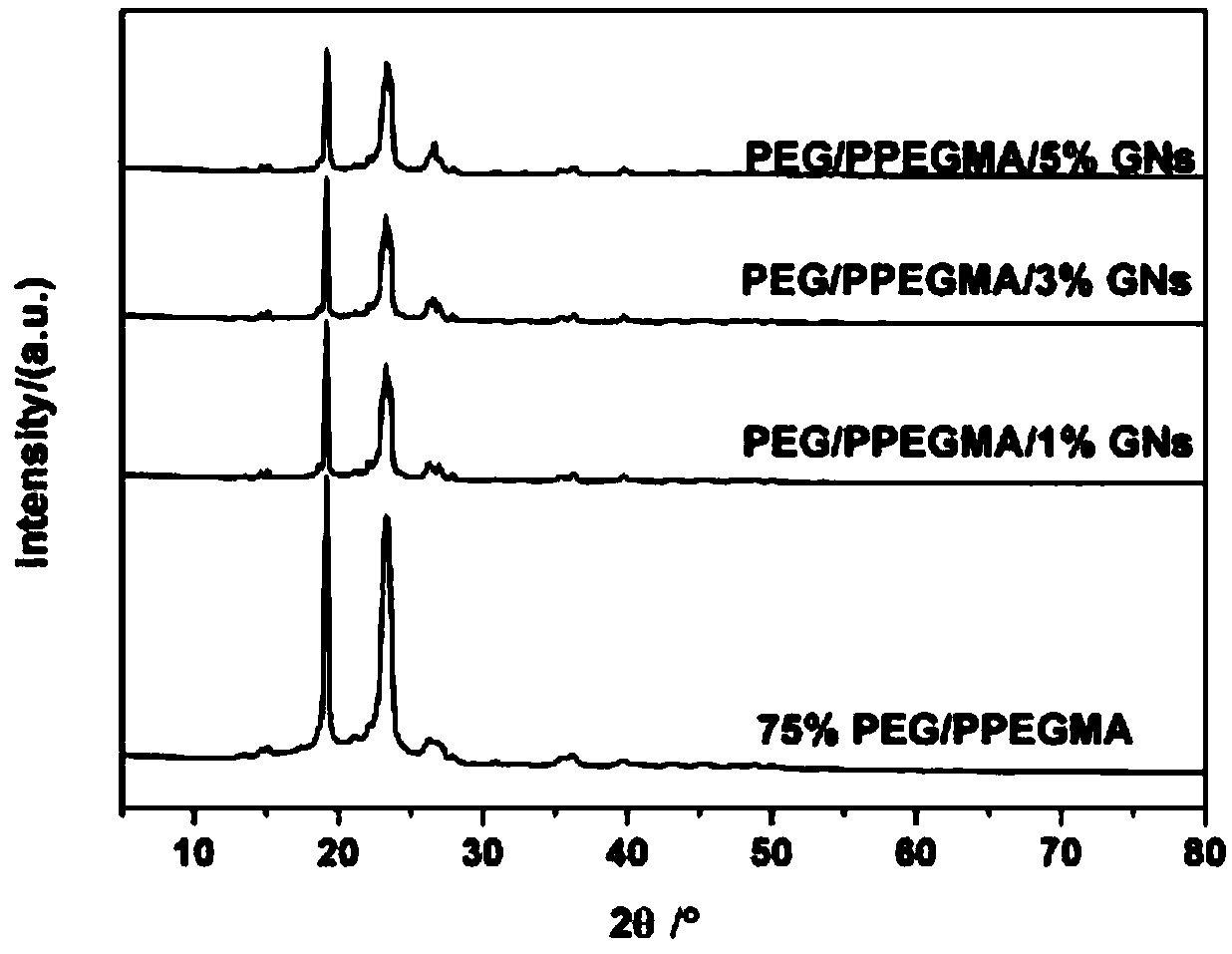

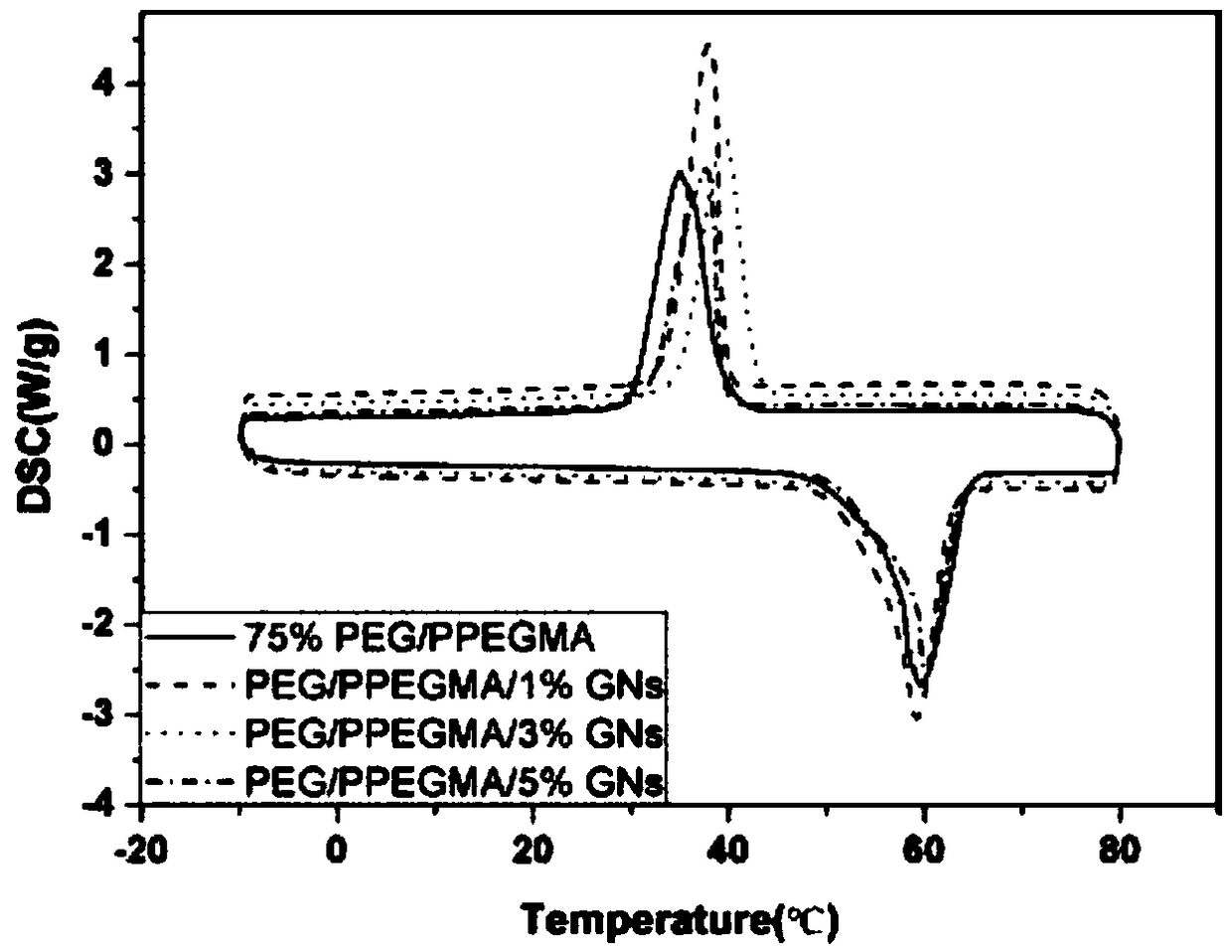

Method used

Image

Examples

Embodiment 1

[0072] (1) Polyethylene glycol with an average molecular weight of 6000 and methoxypolyethylene glycol methacrylate with an average molecular weight of 2000 are mixed in the reactor according to a mass ratio of 3:7, and the N 2 , mechanically stirred, the reactor was heated in an 80°C oil bath, and stirred at a constant temperature for 0.5h.

[0073] Wherein, the mass percent concentration of methoxypolyethylene glycol methacrylate with an average molecular weight of 2000 is 50%.

[0074] (2) Initiator BPO is added in the reactor, initiator and methoxypolyethylene glycol methacrylate are added according to mass ratio 18:1000 ratio, pass N 2 , stirring, after 20min, when the inside of the reactor is under N 2 environment, stop passing N 2 , and continue stirring for 2h to obtain a phase change material.

[0075] (3) During this reaction, the graphene is dispersed in the solvent, the solvent is water, mixed according to the ratio of mass ratio 1:20, ultrasonically stirred, af...

Embodiment 2-6

[0081] It is 300,500,950,1500,4000 that the methoxy polyethylene glycol methacrylate that the average molecular weight is 2000 is replaced by the methoxy polyethylene glycol methacrylate of 300,500,950,1500,4000, and initiator and average molecular weight are 300 , 500, 950, 1500, 4000 of methoxypolyethylene glycol methacrylate in a mass ratio of 9:1000, compounded to obtain a PEG / PPEGMA composite phase change energy storage material, and other conditions are consistent with Example 1. The phase change enthalpy of the obtained composite shape-setting phase change material is still about 170 J / g, and has the same high thermal stability as that of Example 1.

Embodiment 7-11

[0083] In Example 1, the polyethylene glycol with an average molecular weight of 6000 was replaced with polyethylene glycol with an average molecular weight of 1000, 2000, 4000, 8000, and 10000, and other conditions were consistent with those in Example 1. The phase transition temperature of the obtained material changes, and different molecular weight polyethylene glycols can be selected for compounding according to the different requirements of the use environment. The obtained material has excellent shape stability, energy storage density and thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| latent heat | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com