Medium-temperature phase-change heat storage material and preparation method thereof

A technology of phase change heat storage and medium temperature, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of complex process, high cost, difficulty in large-scale application, etc., and achieve high phase change latent heat and short production cycle , to overcome the effect of leakage of liquid phase substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material components and mass ratio of the phase change heat storage material for medium temperature are: 80% adipic acid, 10% rare earth oxide (cerium oxide), 10% graphene, and a binder, the quality of which is 3% of the total mass of diacid, rare earth oxide and graphene, wherein the binder used is an aqueous solution of sodium carboxymethyl cellulose with a concentration of 3wt%.

[0026] Grind adipic acid powder through a 100-mesh sieve and mechanically mix it with rare earth materials (cerium oxide) and graphene. After mixing evenly, put it into a crucible, put it in a vacuum drying oven, and melt and adsorb it at a temperature of 150-160°C for 6 hours. , and then mixed with the binder CMC for tablet molding, the pressure is 10-15 MPa, the pressure is stabilized for 60 seconds, and the mold is demoulded to obtain the phase change heat storage material for medium temperature.

[0027] After testing, the phase transition temperature of the medium-temperature p...

Embodiment 2

[0029] The raw material components and mass ratio of the phase change thermal storage material for medium temperature are: 82% adipic acid, 10% rare earth oxide (praseodymium oxide), 8% graphene, and a binder, the quality of which is 3% of the total mass of diacid, rare earth oxide and graphene, wherein the binder used is an aqueous solution of sodium carboxymethyl cellulose with a concentration of 3wt%.

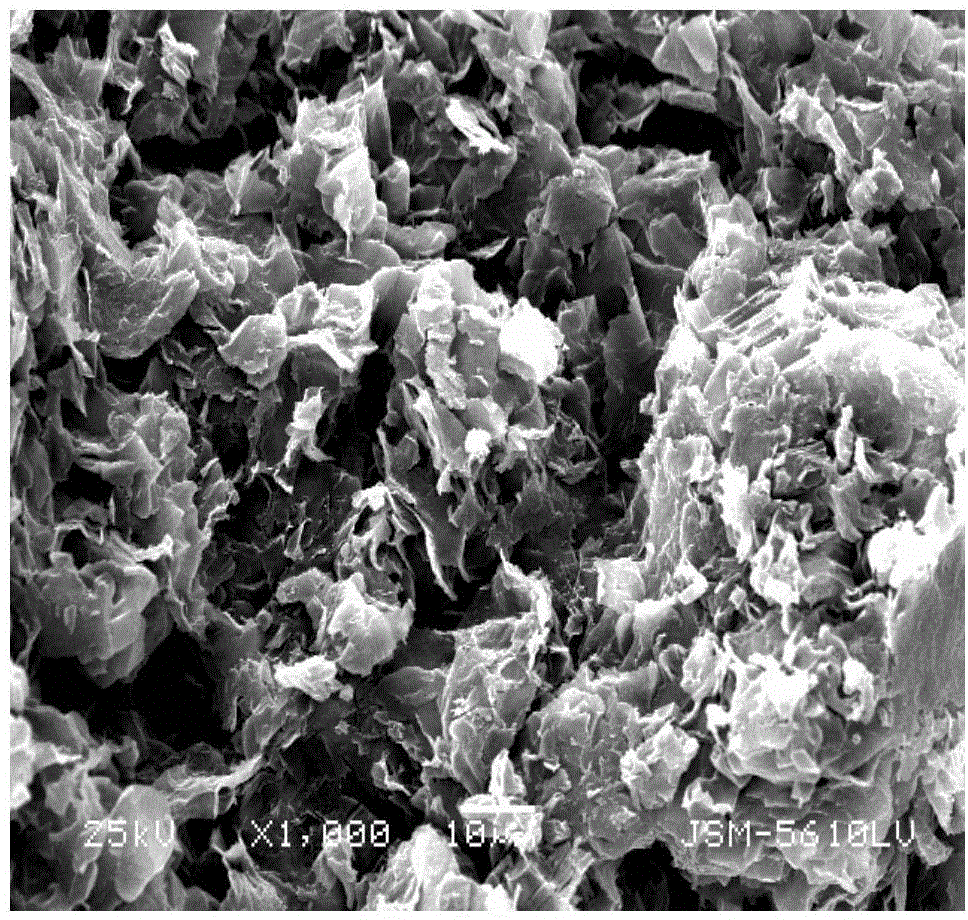

[0030] Grind adipic acid powder through a 100-mesh sieve and mechanically mix it with rare earth material (praseodymium oxide) and graphene. After mixing evenly, put it into a crucible, put it in a vacuum drying oven, and melt and adsorb it at a temperature of 150-160°C for 6 hours. , and then mixed with the binder CMC for tablet molding, the pressure is 10-15 MPa, the pressure is stabilized for 60 seconds, and the mold is demoulded to obtain the phase change heat storage material for medium temperature. Its scanning electron microscope pictures are as figure 1 As shown in ...

Embodiment 3

[0033] The raw material components and mass ratio of the phase change thermal storage material for medium temperature are: 84% adipic acid, 9% rare earth oxide (europium oxide), 7% graphene, and a binder, the quality of which is 3% of the total mass of diacid, rare earth oxide and graphene, wherein the binder used is an aqueous solution of sodium carboxymethyl cellulose with a concentration of 3wt%.

[0034] Grind adipic acid powder through a 100-mesh sieve and mechanically mix it with rare earth material (europium oxide) and graphene. After mixing evenly, put it into a crucible, put it in a vacuum drying oven, and melt and adsorb it at a temperature of 150-160°C for 6 hours. , and then mixed with the binder CMC for tablet molding, the pressure is 10-15 MPa, the pressure is stabilized for 60 seconds, and the mold is demoulded to obtain the phase change heat storage material for medium temperature.

[0035] The medium-temperature phase change heat storage material prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com