Method for preparing phase-change materials from Fischer-Tropsch (F-T) synthesis product

A phase-change material and a synthesis technology, applied in heat exchange materials, chemical instruments and methods, petroleum industry, etc., can solve problems affecting the performance of phase-change materials, high production costs, complexity, etc., and achieve continuous phase-change temperature Adjustable, the effect of high latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

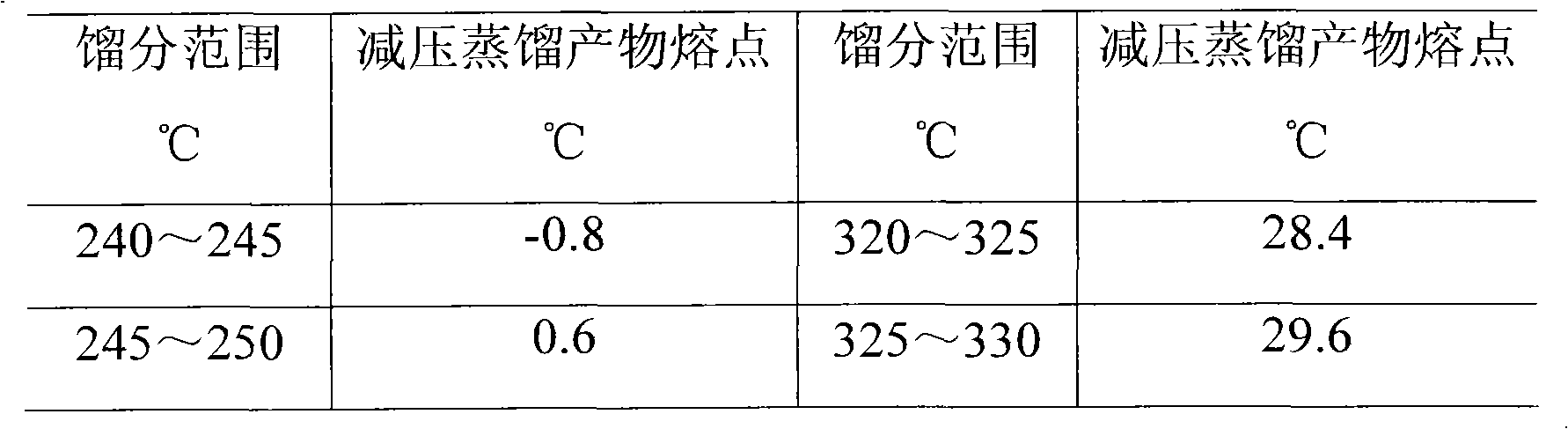

[0021] (1) Using the product of the low-temperature F-T synthesis experimental device of China Petroleum & Chemical Corporation as the raw material, the fraction with a boiling point of 220°C to 420°C was prepared by vacuum distillation in a distillation apparatus with 17 theoretical plates. The weight content of n-alkanes in this fraction is 95%, the weight content of olefins is 2%, and the weight content of oxygen-containing compounds is 3%.

[0022] (2) the above-mentioned cuts obtained in the FHJ-2 catalyst (a kind of Ni / Al 2 o 3 Commercial catalyst, developed and produced by Fushun Petrochemical Research Institute, the content of active metal nickel in terms of oxides is 40%, and the catalyst is subjected to conventional reduction treatment before use) under the conditions of 5MPa, 200°C, 1.0LHSV and hydrogen-to-liquid ratio of 500 Hydroconversion is used to convert olefins and oxygen-containing compounds therein, and the weight content of normal paraffins in the hydroge...

Embodiment 2

[0030] (1) with embodiment 1;

[0031] (2) Under the action of FHJ-2 catalyst, the fraction obtained above is subjected to hydrogenation conversion under the conditions of 5MPa, 220°C, 0.5LHSV and hydrogen-to-liquid ratio of 500 to convert the olefins and oxygenated compounds therein, and the weight of normal alkanes in the hydrogenation product The content is close to 100%.

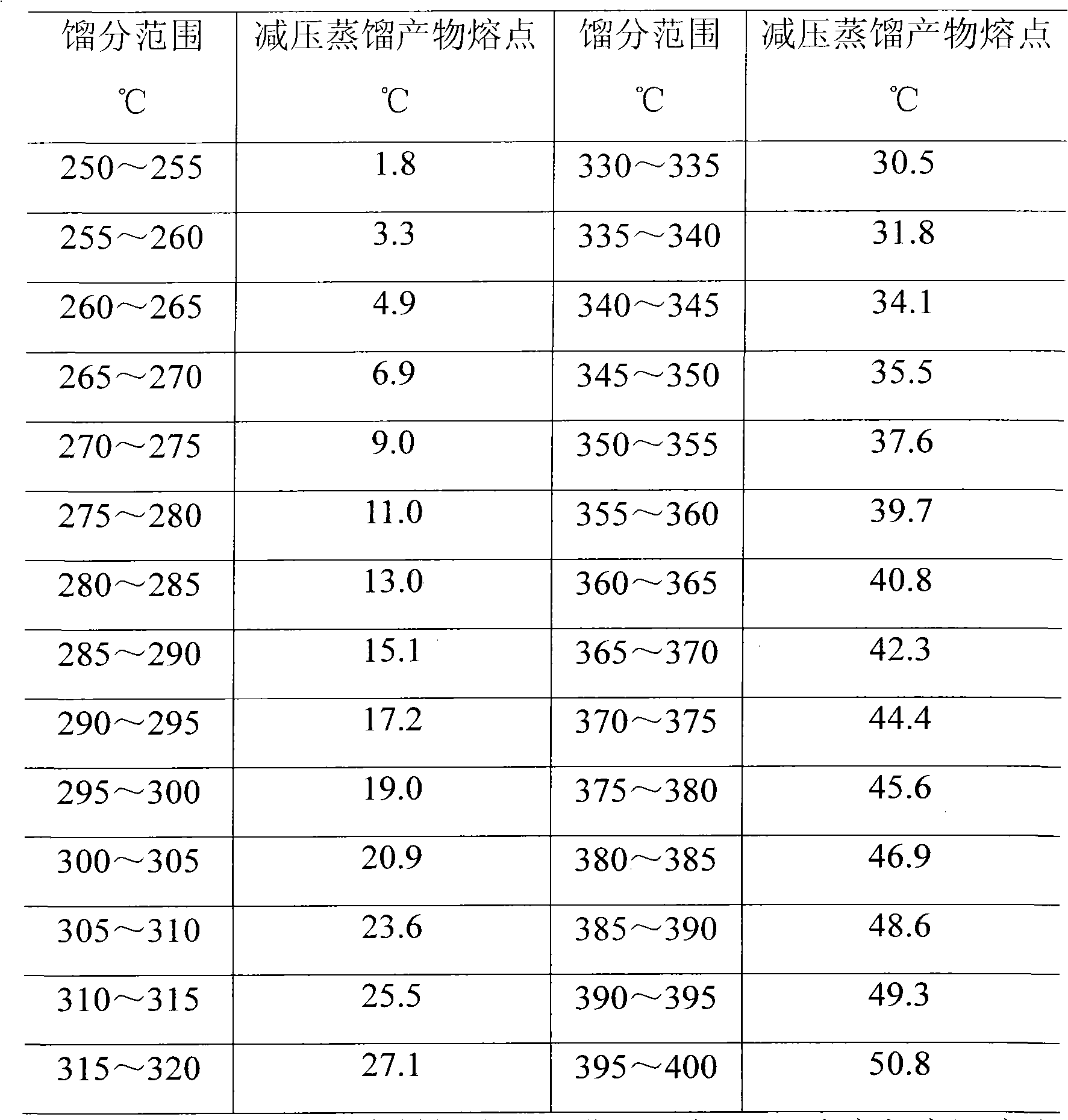

[0032] (3) the above-mentioned product obtained through hydrogenation conversion is in a distillation unit with 17 theoretical plates, at 1.33 × 10 3 Under Pa pressure, distillates at 240-400°C were prepared at intervals of 10°C. The melting points of the fraction products in each section are shown in Table 2, and each fraction can be used as a phase change material with a corresponding phase transition temperature.

[0033] Each underpressure distillation product melting point of table 2 embodiment 2

[0034]

[0035](4) Mix the above n-alkane phase change materials in proportion to produce a seri...

Embodiment 3

[0041] (1) Using the product of the low-temperature F-T synthesis experimental device of China Petroleum and Chemical Corporation as raw material, in a distillation device with 17 theoretical plates, a fraction with a boiling point of 220°C to 420°C is prepared through vacuum distillation, and the weight of normal alkanes in this fraction is The content is 90%, the olefin weight content is 5%, and the oxygen-containing compound weight content is 3%.

[0042] (2) Put the above-mentioned cuts on FV-10 catalyst (a kind of W-Mo-Ni / Al 2 o 3 Type commercial catalyst, developed and produced by Fushun Petrochemical Research Institute, the catalyst is subjected to conventional sulfurization treatment before use) under the action of 6MPa, 280°C, 1.0LHSV and hydrogen-to-liquid ratio of 300 for hydrogenation conversion to convert olefins and oxygen-containing compound, the weight content of n-alkanes in the hydrogenation product is 97%.

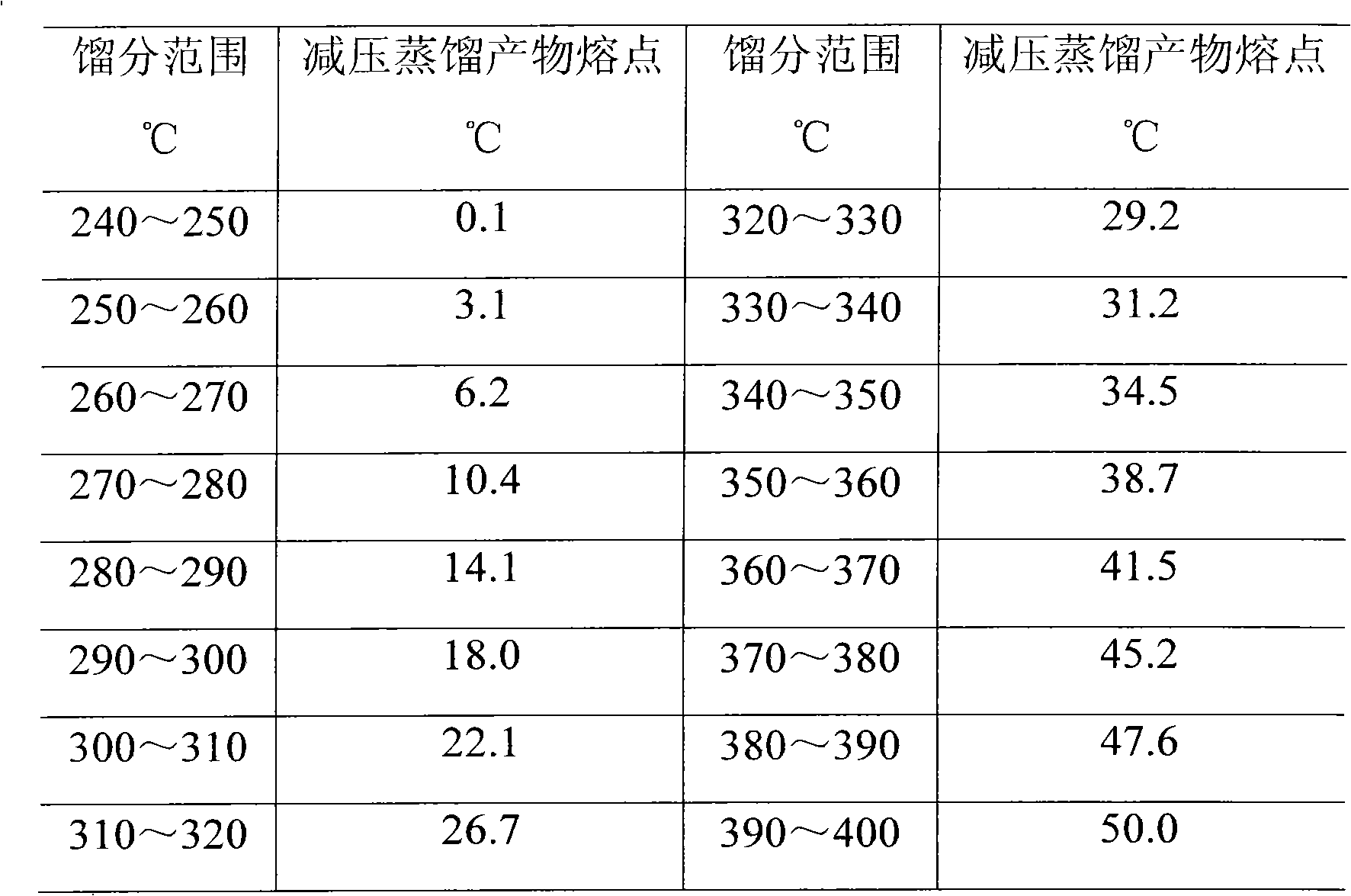

[0043] (3) the above-mentioned product obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com