Method for enhancing thermal conductivity of phase-change energy-storage superfine composite polyamide fiber and method for producing phase-change energy-storage superfine composite polyamide fiber

A technology of nylon fiber and reinforced phase, which is applied in the field of phase change energy storage ultrafine composite nylon fiber membrane, can solve the problems of composite uniformity and heat transfer effect, increase the total weight of the system, and low overall efficiency, and achieve thermal cycle Good stability, simple and easy-to-control preparation process, and the effect of expanding the applicable field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

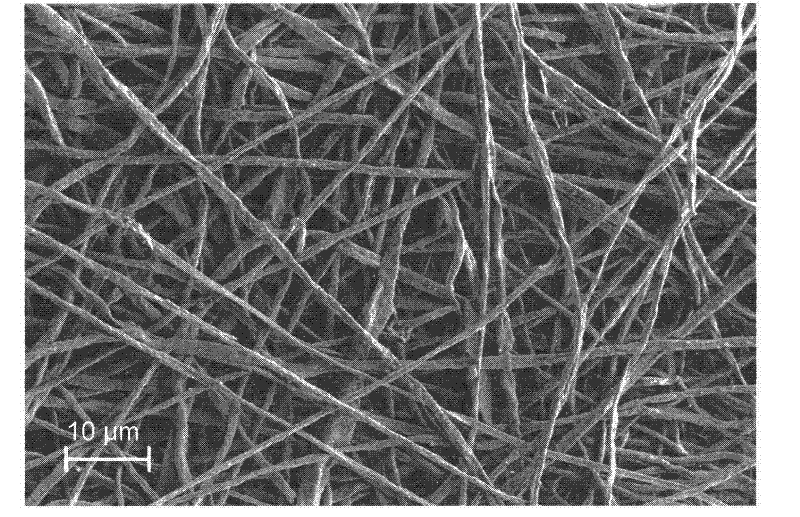

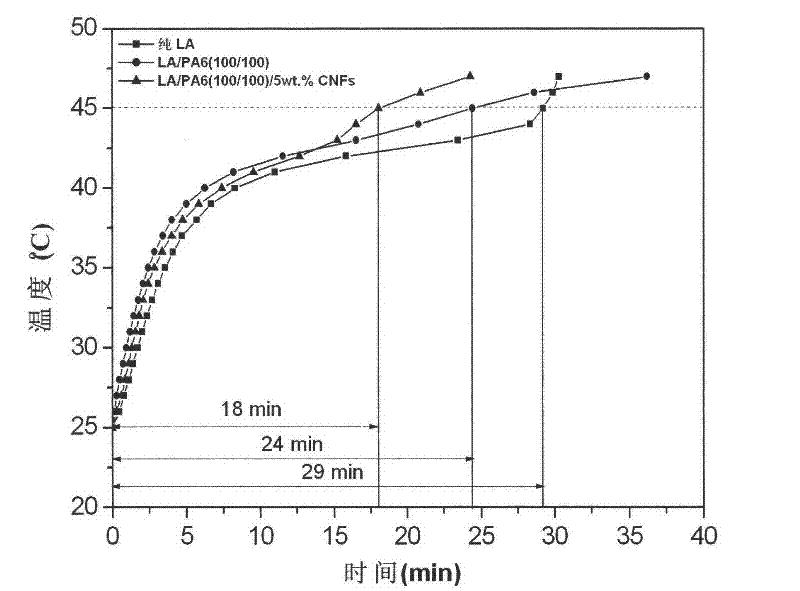

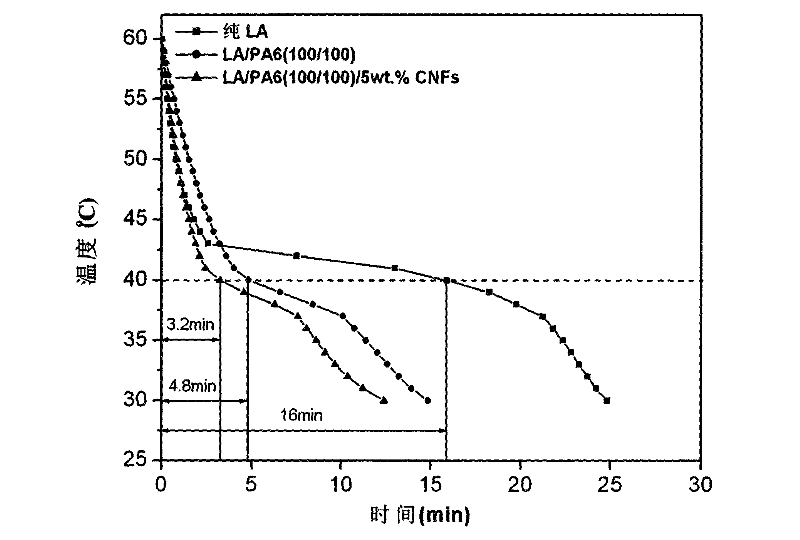

[0022] Add 0.2g of carbon nanofibers (CNFs) into a 50ml round bottom flask filled with 20g of concentrated nitric acid solution, stir magnetically for 2 hours, and oscillate ultrasonically for 30 minutes to make the CNFs evenly dispersed, heat and reflux for 2 hours, cool naturally to room temperature, add distilled water to dilute and, washing, filtering, and then placed in a vacuum oven at 80°C, dried for 12 hours, and ground to obtain modified CNFs powder. Weigh 1g of polyamide 6 (PA6) slices and dissolve them in a 50ml Erlenmeyer flask containing 11.5g of hexafluoroisopropanol (HFIP), and stir at a constant speed for 10h at room temperature to obtain a homogeneous solution A (8wt% PA6 solution). Then add 1 g of lauric acid (LA) to dissolve in the above solution A, and magnetically stir until LA is completely dissolved to obtain a uniform mixed solution B (mass ratio: LA / PA6=100 / 100). Finally, 0.020g, 0.062g and 0.105g of modified CNFs were weighed, respectively added to 3 ...

Embodiment 2

[0025]Add 0.2g of carbon nanotubes (CNTs) into a 50ml round-bottomed flask filled with 20g of concentrated sulfuric acid solution, stir magnetically for 3 hours, and oscillate ultrasonically for 1 hour to make the CNTs evenly dispersed, heat and reflux for 3 hours, cool naturally to room temperature, and add distilled water to dilute and, washing, filtering, and then placed in a vacuum oven at 90° C., dried for 10 hours, and ground to obtain modified CNTs powder. Weigh 1g of PA6 slices and dissolve them in a 50ml Erlenmeyer flask filled with 11.5g of hexafluoroisopropanol (HFIP), and stir at a constant speed for 10h at room temperature to obtain a homogeneous solution A (8wt% PA6 solution). Then add 1 g of LA to dissolve in the above solution A, and magnetically stir until the LA is completely dissolved to obtain a uniform mixed solution B (mass ratio: LA / PA6=100 / 100). Finally, 0.020g, 0.062g, 0.105g and 0.222g of modified CNTs were weighed, added to 4 parts of solution B resp...

Embodiment 3

[0028] Add 0.2g CNFs into a 50ml round bottom flask containing 20g concentrated nitric acid solution, stir magnetically for 2 hours, and oscillate ultrasonically for 30 minutes to make the CNFs evenly dispersed, heat and reflux for 2 hours, cool to room temperature naturally, add distilled water to dilute, neutralize, wash and filter , then placed in a vacuum oven at 80°C, dried for 12 hours, and ground to obtain modified CNFs powder. Weigh 1g of PA6 slices and dissolve them in a 50ml Erlenmeyer flask filled with 9g of HFIP, and stir at a constant speed for 10h at room temperature to obtain a homogeneous solution A (10wt% PA6 solution). Then add 1.5 g of myristic acid (MA) to dissolve in the above solution A, and magnetically stir until MA is completely dissolved to obtain a uniform mixed solution B (mass ratio: MA / PA6=150 / 100). Finally, 0.025g, 0.077g and 0.132g of modified CNFs were weighed, respectively added to 3 parts of solution B, stirred at room temperature for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com