Low temperature step phase change heat storage and cold storage device

A cold storage device and phase change heat storage technology, which is applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of slow development of heat storage and cold storage products, limited heat storage capacity of concrete, limited heat storage capacity, etc. problems, to achieve the effect of prolonging the heat storage and heat release time, suitable phase transition temperature, and large heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

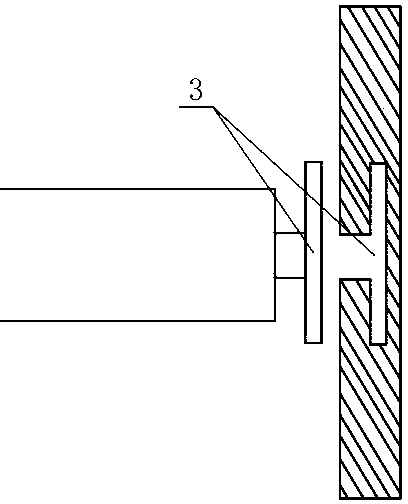

[0010] Embodiment 1, a low-temperature stepped phase change heat storage and cold storage device, comprising: a black plastic pipe body (1), a long fixed plate (2), characterized in that: the two ends of the black plastic pipe body (1) pass through The connecting piece is fixed or directly adhered to the elongated fixing plate (2), and the black plastic pipes (1) are placed in parallel with intervals; the black plastic pipes (1) are provided with A material Or B material, the black plastic pipe body (1) with material A added is added with material B in the adjacent black plastic pipe body (1), and the black plastic pipe body (1) with material B added is adjacent to the black plastic pipe body (1). A material is added to the plastic pipe body (1), and the A material is composed of 84% Na2SO410H2O, 3% borax, 2% sodium carboxymethyl cellulose, 6% white carbon black, 4% NaCl, 1% sodium hexametaphosphate Composition, the B material is composed of 91% CaCl2 6H2O, 3% barium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com