Shape-stabilized phase-change heat-storage cooling pavement material suitable for high-temperature area

A technology of shape-setting phase change and pavement materials, which is applied to cohesive pavement paved on site, roads, roads, etc., and can solve the problem of unexplained dynamic stability, strength and other road performance of asphalt mixtures, which affect phase change asphalt mixtures. Work performance, not suitable for large-scale production and application, etc., to solve the problem of high temperature rutting, reduce temperature sensitivity, and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

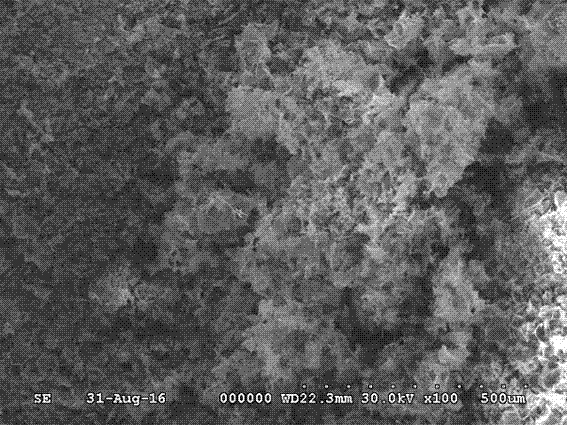

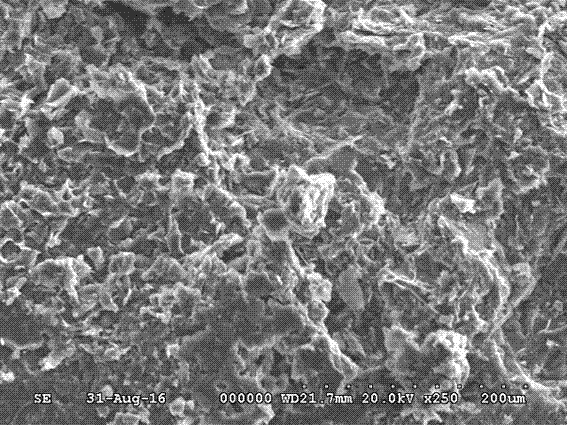

Image

Examples

Embodiment 1

[0030] The shape-setting phase-change thermal insulation and cooling material is composed of the following materials: coarse aggregate 70%, fine aggregate 10%, mineral powder 9%, binary shape-setting composite phase change material 5.7%, asphalt 4.9%, fiber 0.4%

[0031] The coarse aggregate and the fine aggregate are limestone, the binary shape-setting composite phase change material is stearic acid+palmitic acid / expanded perlite, the asphalt is 70# matrix asphalt, the mineral powder is limestone powder, and the fiber is Basalt fiber

[0032] The preparation method of the binary shape-setting composite phase-change material is as follows: the expanded perlite is placed in a drying box to dry for 5 hours, and the phase-change material, the mineral-based Put it into an Erlenmeyer flask, place it in a magnetic stirring pot, and keep stirring in a water bath at 90°C. After 30 minutes, the circulating water vacuum pump was turned on, and the pressure in the Erlenmeyer flask was e...

Embodiment 2

[0037] The shape-setting phase change heat insulation and cooling material is composed of the following materials: 70% coarse aggregate, 9% fine aggregate, 9% mineral powder, 6.7% binary shape-setting composite phase change material, 4.9% asphalt, and 0.4% fiber

[0038] Coarse aggregate and fine aggregate are limestone: the binary shape-setting composite phase change material is stearic acid+palmitic acid / expanded perlite, the asphalt is 70# matrix asphalt, the mineral powder is limestone powder, and the fiber is Basalt fiber

[0039] The preparation method of the binary shape-setting composite phase-change material is as follows: the expanded perlite is placed in a drying box to dry for 5 hours, and the phase-change material, the mineral-based Put it into an Erlenmeyer flask, place it in a magnetic stirring pot, and keep stirring in a water bath at 90°C. After 30 minutes, the circulating water vacuum pump was turned on, and the pressure in the Erlenmeyer flask was evacuated...

Embodiment 3

[0045] The shape-setting phase-change thermal insulation and cooling material is composed of the following materials: coarse aggregate 70%, fine aggregate 9%, mineral powder 8.5%, binary shape-setting composite phase change material 7.2%, asphalt 4.9%, fiber 0.4%

[0046] Coarse aggregate and fine aggregate are limestone: the binary shape-setting composite phase change material is stearic acid+palmitic acid / expanded perlite, the asphalt is 70# matrix asphalt, the mineral powder is limestone powder, and the fiber is Basalt fiber

[0047] The preparation method of the binary shape-setting composite phase-change material is as follows: the expanded perlite is placed in a drying box to dry for 5 hours, and the phase-change material, the mineral-based Put it into an Erlenmeyer flask, place it in a magnetic stirring pot, and keep stirring in a water bath at 90°C. After 30 minutes, the circulating water vacuum pump was turned on, and the pressure in the Erlenmeyer flask was evacuated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com