Phase change cold accumulating device

A phase change cold storage and phase change material technology, applied in the field of heat exchange management, can solve problems such as unseen applications, achieve a wide range of applications, highlight substantial characteristics, and increase the effect of total heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

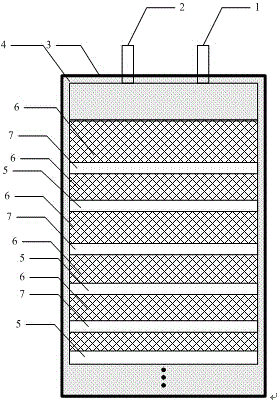

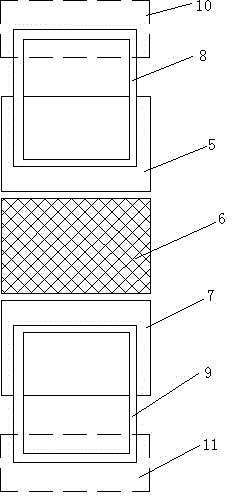

[0024] The invention includes a heat-taking cold plate, a heat-releasing cold plate, a skeleton material, a phase-change material, and a thermal insulation material arranged in a package casing; a skeleton material is arranged between the heat-taking cold plate and the heat-releasing cold plate; the skeleton material and The heat-releasing cold plate and the heat-taking cold plate are stacked and staggered in layers; the skeleton material is filled with phase-change materials; the inner wall of the package shell is provided with heat-insulating materials; A heat releasing circuit is arranged in the cold plate; a heat-taking refrigerant is arranged in the heat-taking circuit; a heat-releasing refrigerant is arranged in the heat-releasing circuit; an exhaust hole and a phase-change material filling port are arranged on the top of the packaging shell.

[0025] After absorbing the heat from the heat source, the heat-absorbing refrigerant enters the heat-extracting cold plate throug...

Embodiment 2

[0034] It is basically the same as Example 1, except that the size of the skeleton material is 135mm×270mm×40mm, and the number of layers is 2 layers.

[0035] Take the hot and cold plate as a copper plate, the number of layers is 1 layer, the section of the hot loop is circular, the inner diameter is 6mm, and the center distance of the hot loop is 38mm, and the hot and cold plate is connected to the hot loop through the interface pipe.

[0036] The heat release cold plate is a copper plate with 1 layer, the heat release circuit cross section is circular, the inner diameter is 6mm, and the center distance of the heat release circuit is 40mm. The heat release cold plate is connected to the heat release circuit through the interface pipe.

[0037] The phase change material is n-tetradecane, the filling volume is 2.0L, the expansion space accounts for 18% of the total effective volume of the regenerator, and the single cold storage capacity is 400kJ.

[0038] The phase change mat...

Embodiment 3

[0041] It is basically the same as Example 1, except that the skeleton material is HTC foamed graphite, the interlayer thermal conductivity is 245w / m K, the open porosity is 61%, the effective porosity is 95%, and the size is 152mm×194mm×25mm , the number of layers is 4 layers.

[0042] Take the hot and cold plate as an aluminum plate, the number of layers is 2 layers, the cross section of the hot circuit is circular, the inner diameter is 6mm, and the center distance of the hot circuit is 38mm, and the hot and cold plate is connected to the hot circuit through the interface pipe.

[0043] The heat release cold plate is an aluminum plate with 2 layers. The heat release circuit has a circular cross-section with an inner diameter of 6mm. The center distance of the heat release circuit is 40mm. The heat release cold plate is connected to the heat release circuit through an interface pipe.

[0044] The phase change material is n-hexadecane, the filling volume is 1.5L, the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com