Zirconium corundum refractory ball

A zirconium corundum-based refractory ball technology, applied in the field of metallurgy, can solve the problems of high porosity, shutdown, ball replacement, and low volume density of refractory balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

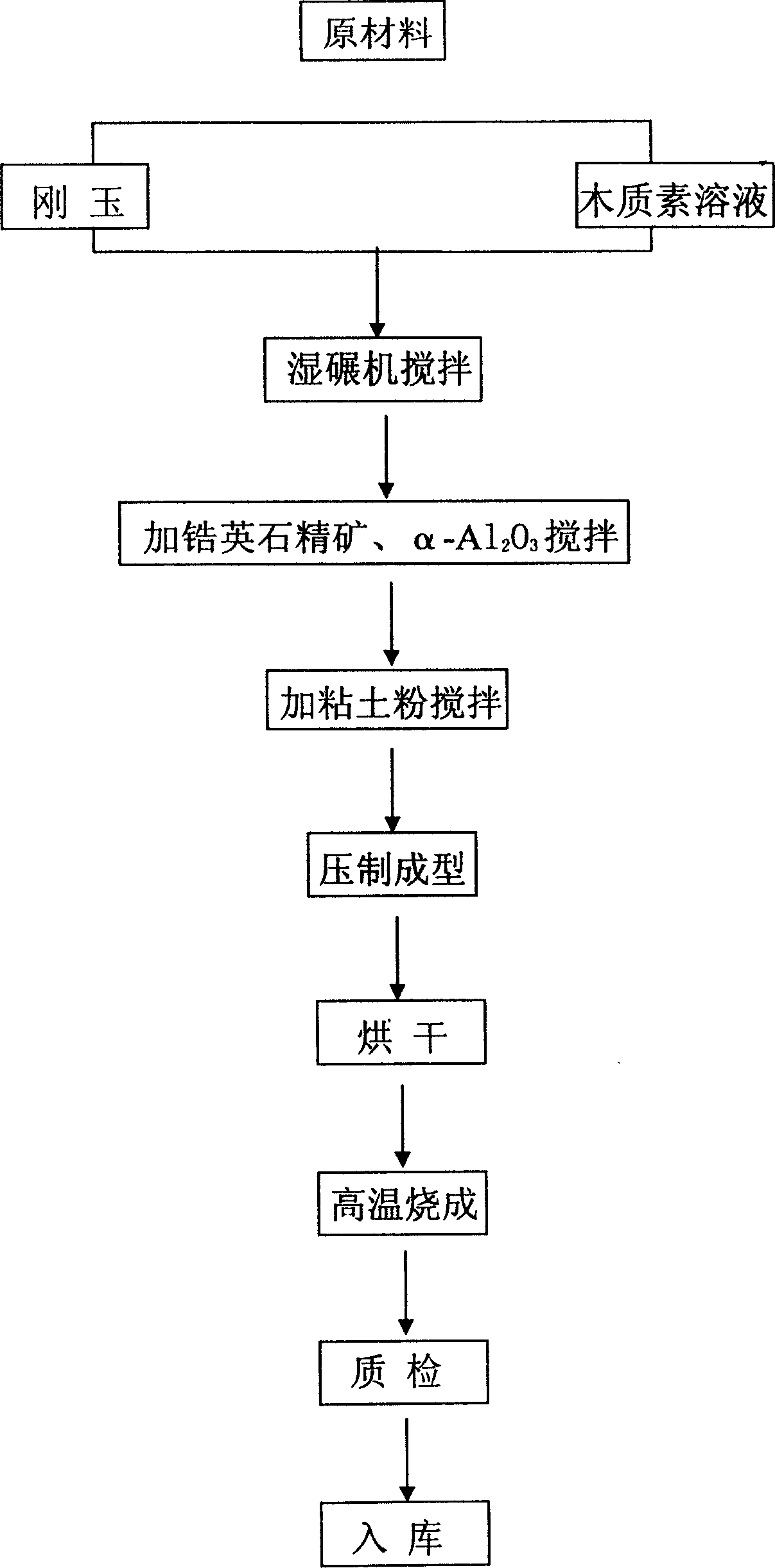

[0005] The specific implementation of the present invention will be described in detail below in conjunction with specific conditions and process flow diagrams.

[0006] Provided by the technical scheme and process flow chart, the refractory ball of the present invention is composed of: corundum 75-85%, α-Al 2 o 3 5-10%, zircon concentrate 8-15%, clay powder (bonding agent) 5-8%, and the above-mentioned corundum, α-Al 2 o 3 It is made of lignin solution with 3-5% of the total weight of zircon concentrate and clay powder, among which corundum, α-Al 2 o 3 After wet milling and stirring with lignin solution, zircon concentrate, α-Al 2 o 3 , after stirring, add clay powder and grind evenly (the above is generally called mixed rolling), after being pressed into a spherical shape by a molding machine, it is dried in a drying furnace (residual water content 2 o 3 80-85% and ZrO 2 5-10%, refractoriness greater than 1790°C, load softening start temperature above 1550°C, densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com