Patents

Literature

42results about How to "Small heat storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

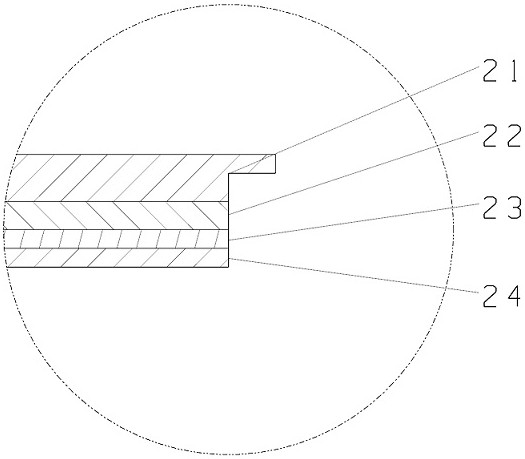

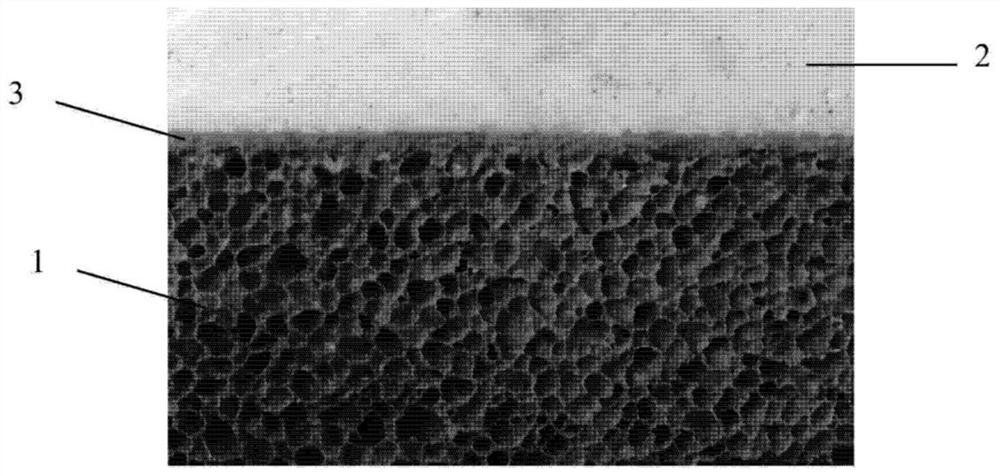

Electrothermal insulation and decoration integrated wall and floor tiles and preparation method thereof

ActiveCN109053136ARealize transmissionReduce heat lossCovering/liningsCeramic shaping apparatusFoaming agentBrick

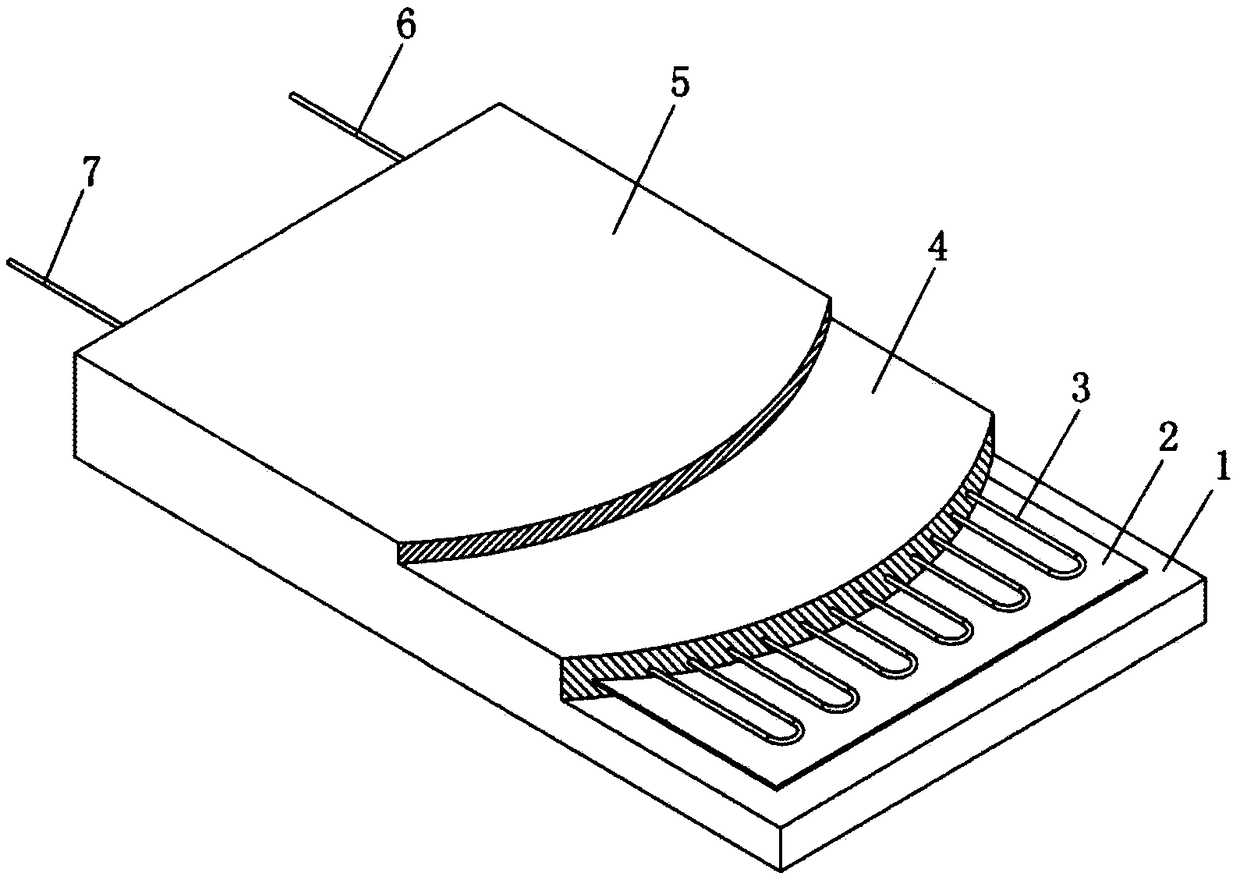

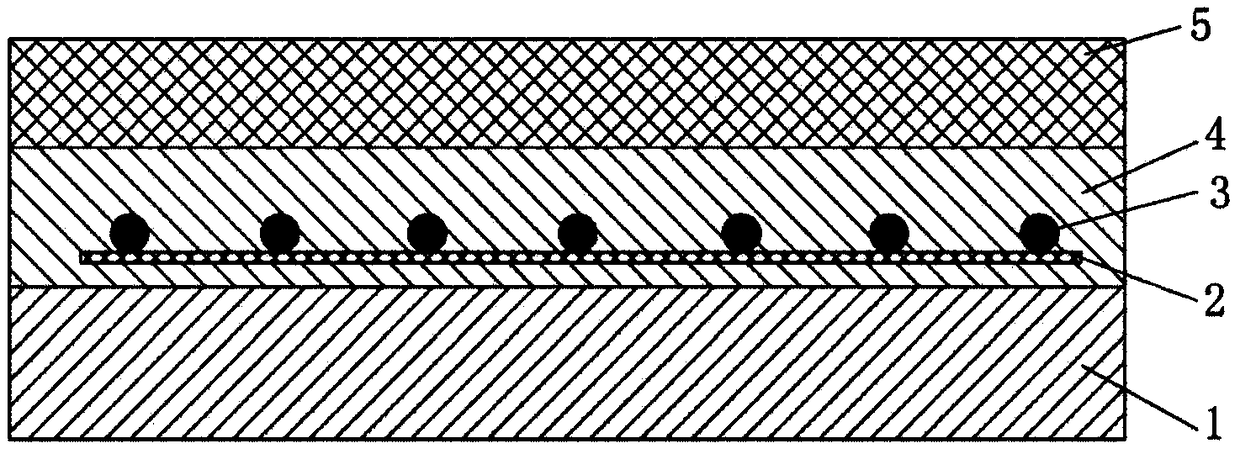

The invention discloses electrothermal insulation and decoration integrated wall and floor tiles and a preparation method thereof. The method comprises the steps of sequentially distributing a tile matrix layer mixture (prepared from the following components: clay, quartz, feldspar and pigment), a non-metallic conductive layer mixture (prepared from the following components: a carbonaceous material, clay, an iron material and feldspar), and a foamed ceramic insulating layer mixture (prepared from the following components: solid wastes, feldspar, clay and a foaming agent); pressing into green bodies by using a press, drying the green bodies, and then firing the dried green bodies in a kiln at the high temperature. The wall and floor tiles have the advantages of being low in thermal loss energy consumption, having an electrothermal efficiency reaching up to 99%, and being convenient in construction, and can lower the construction and use costs to a certain extent.

Owner:山东晟世达科技有限公司

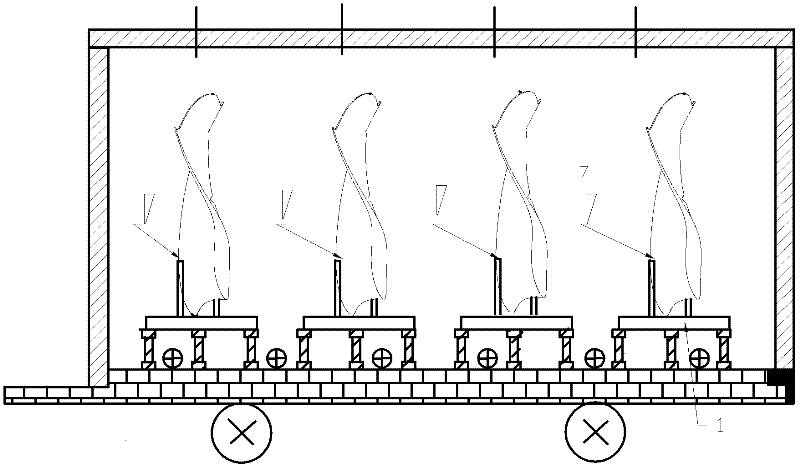

High and medium-temperature heat treatment deformation preventing device for large turbine blades

ActiveCN102560053AUnique structureWon't fallFurnace typesHeat treatment furnacesWater turbineTurbine blade

The invention relates to a deformation preventing device, in particular to a high and medium-temperature heat treatment deformation preventing device for large turbine blades. The device is characterized by being formed by assembling a casting support frame and supporting cushion blocks for supporting the casting support frame; the casting support frame is formed by assembling a U-shaped groove in the middle, groove walls on two sides of the U-shaped groove and a triangular side support which is fixed at each of two ends of the outer side of each groove wall; three cross beams with arc-shapedtops and different heights are fixed in the U-shaped groove at intervals; and two groove columns are fixed at each edge of the U-shaped groove. The device can make up the defects of the conventional blade heat treatment technology and prevent deformation of the blades in the heat treatment process according to the conventional heat treatment process mode, the characteristics of a trolley furnace and the overall dimension of the blades of different types.

Owner:KOCEL EQUIP

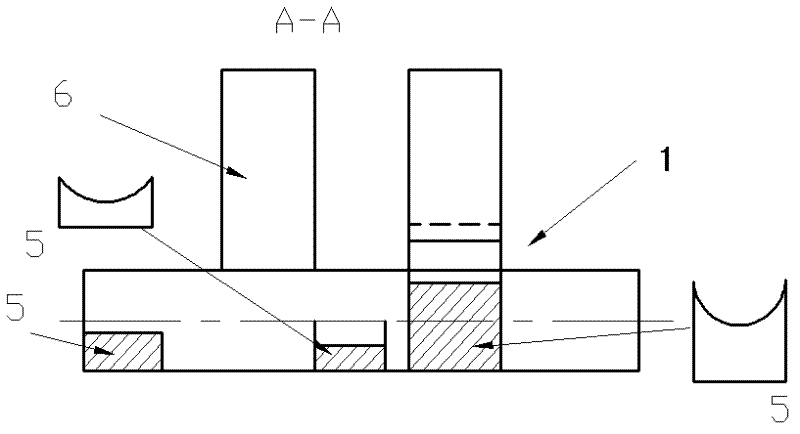

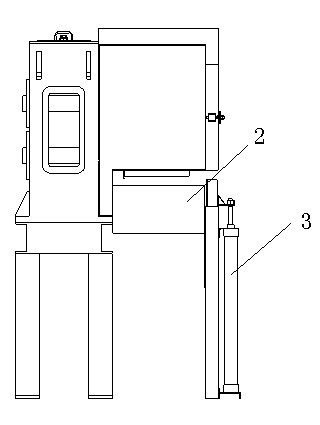

Heat holding furnace for drafting machine

The invention discloses a heat holding furnace for a drafting machine. The heat holding furnace comprises a shell, a furnace door, a furnace door lifting mechanism, a furnace lining, heat elements and a hot wind circulating system, wherein the furnace door is arranged on the shell and connected with the furnace door lifting mechanism; the furnace lining is fixed on the shell; a heat insulating layer is arranged on the furnace lining; the heat elements are arranged in the shell and positioned at two sides of a hearth; and the hot wind circulating system comprises a circulating fan and an air flue in the furnace, and the circulating fan blows the heat of the heat elements to a work area through the air flue in the furnace. The heat holding furnace has good heat and insulation effect, safety, reliability and long service life.

Owner:南京际华三五二一环保科技有限公司

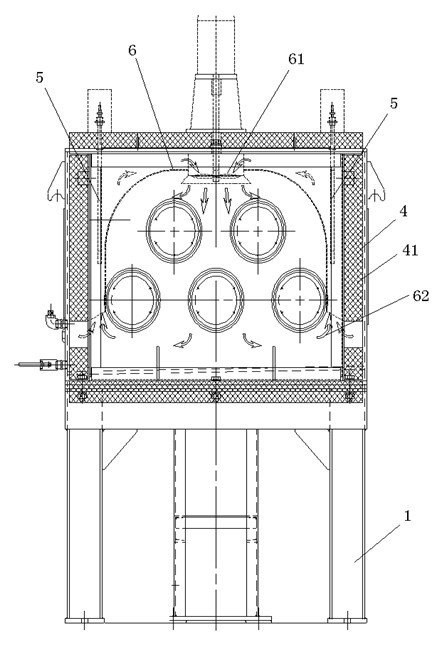

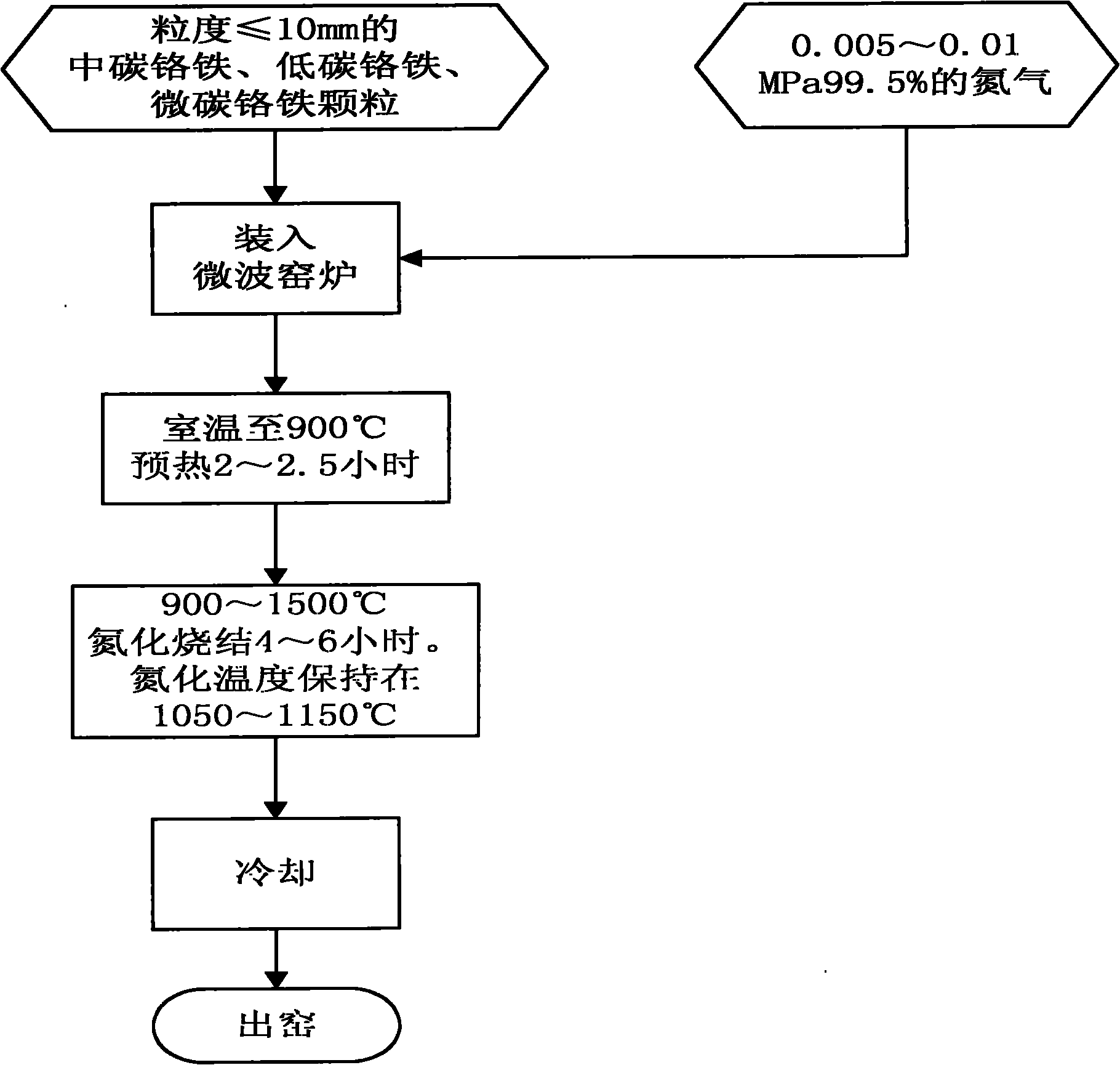

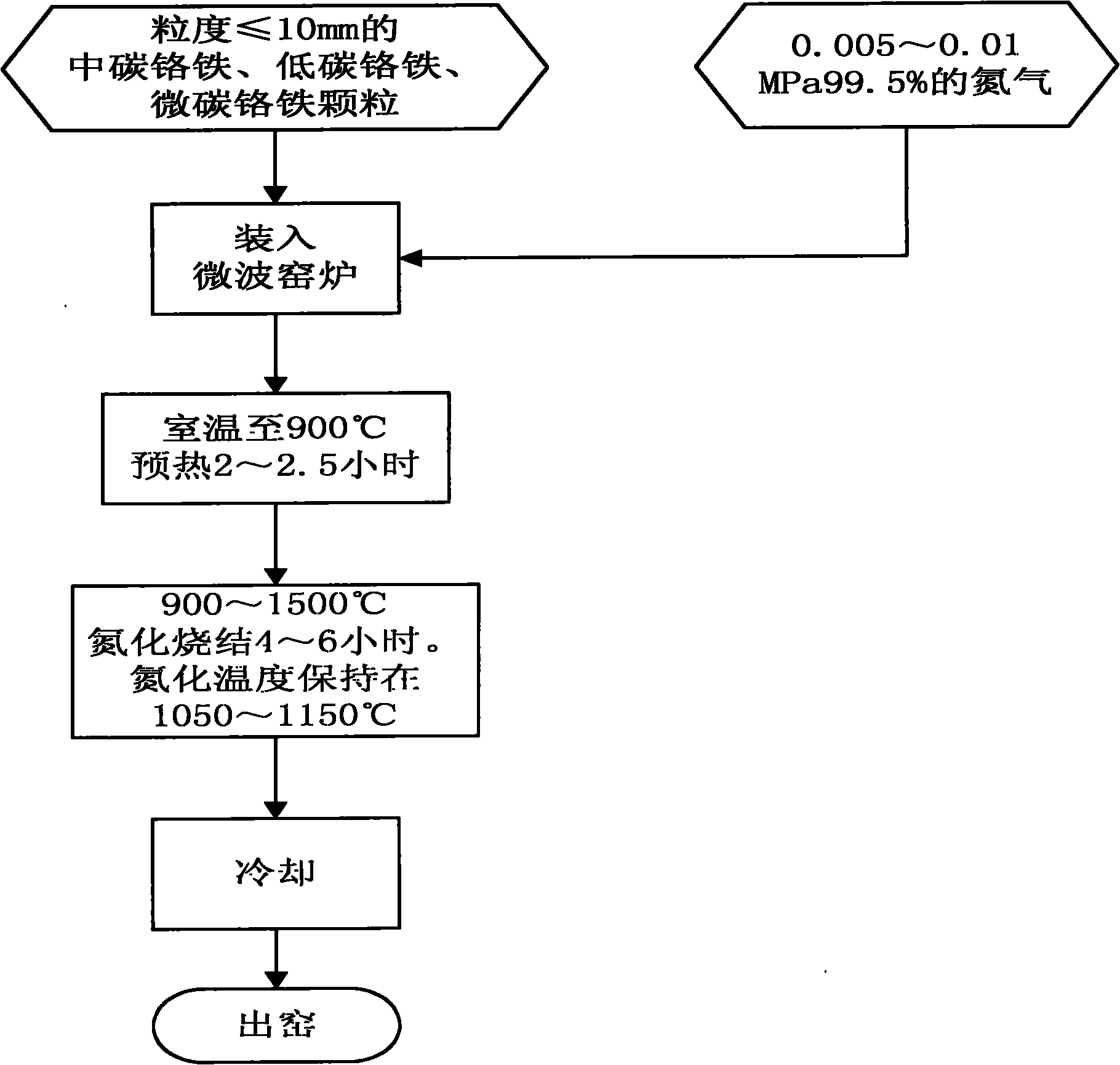

Method for producing ferrochrome nitride with microwave as heat source

InactiveCN101994083AHeating evenlySmall heat storageSolid state diffusion coatingMicrowaveGranularity

The invention discloses a method for producing ferrochrome nitride with microwave as a heat source, wherein 2.45GHz microwave is used as a heat source. The method comprises the steps of: preheating medium carbon ferrochrome particles, low carbon ferrochrome particles and micro carbon ferrochrome particles, with the granularity not larger than 10mm, for 2-2.5h in an atmosphere of 0.005-0.01MPa nitrogen to raise the room temperature to 900 DEG C, then keeping the temperature to be 900-1500 DEG C for nitriding reaction and sintering densification for 4-6h, and cooling to obtain the ferrochrome nitride with the content of 3-6wt%. The microwave nitrification method for synthesizing the ferrochrome nitride favorably solves the problems of high power consumption, long smelting time, uneven material temperature field, poor product appearance quality and the like in the traditional method for smelting the ferrochrome nitride.

Owner:SINOSTEEL JILIN FERROALLOYS

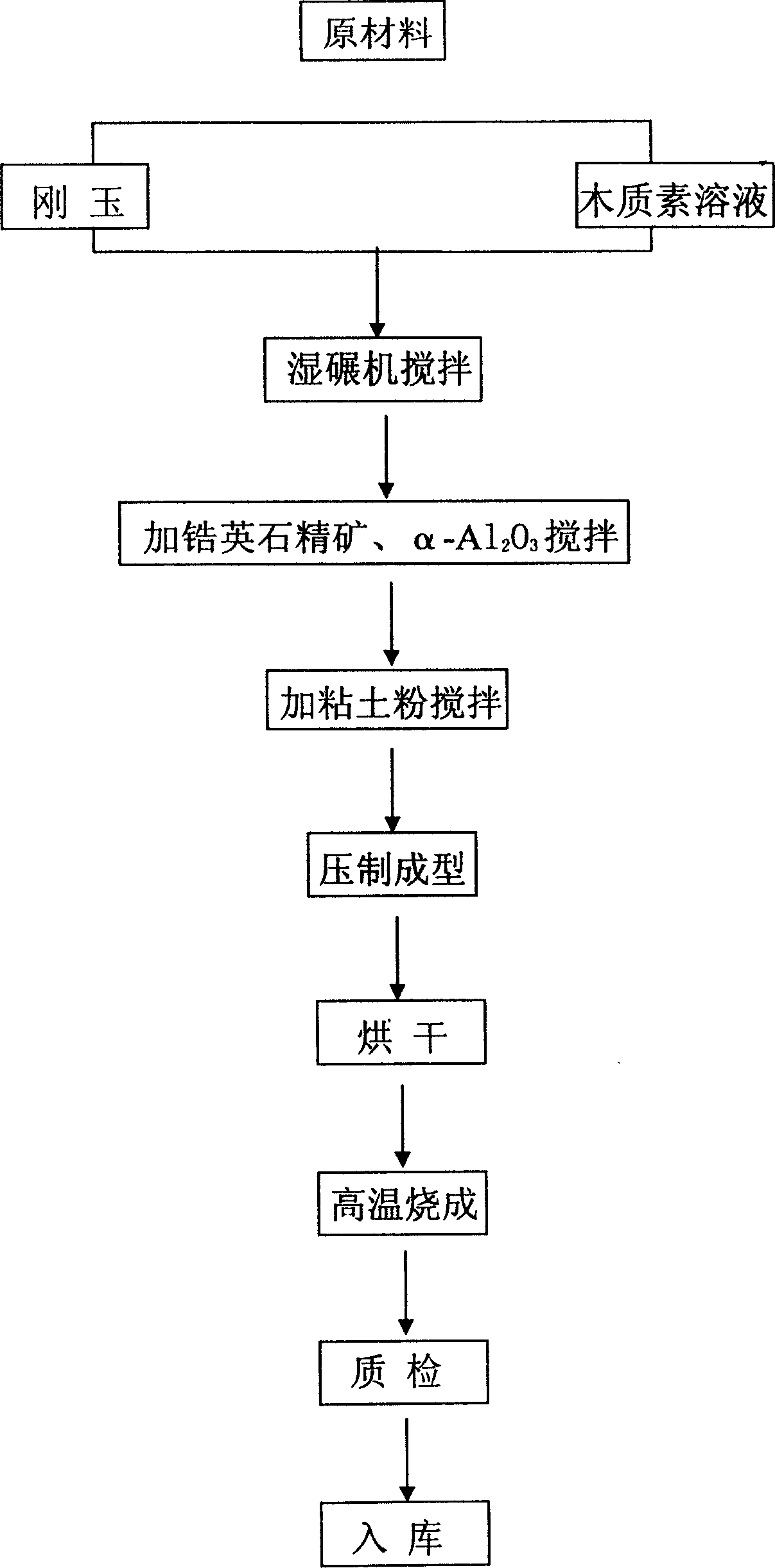

Zirconium corundum refractory ball

A refractory zirconium corundum sphere for the air heater of blast furnace is proportionally prepared from conundum, alpha-Al2O3, zircon concentrate, clay powder and lignin solution through mixing, grinding, baking and sintering.

Owner:郑州豫兴氮氧结合耐火材料有限公司

Refractory castable for incinerator

The invention discloses a refractory castable for an incinerator, which comprises the following raw materials in percentage by weight: 40-50% of silicon carbide particles and fine powder, 5-10% of corundum particles and fine powder, 3-7% of aluminate cement, 2-4% of silicon micro powder, 1-5% of silicon nitride, 1-5% of boron carbide, 15-20% of magnesium-containing material, 5-10% of alumina micro powder and 0.1-0.2% of organic fiber. The refractory castable disclosed by the invention has the beneficial effects of high strength and good abrasion resistance, good volume stability and acid-base resistance, good thermal shock stability and good erosion resistance.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Microwave synthesis method of Si-Mn-N alloy

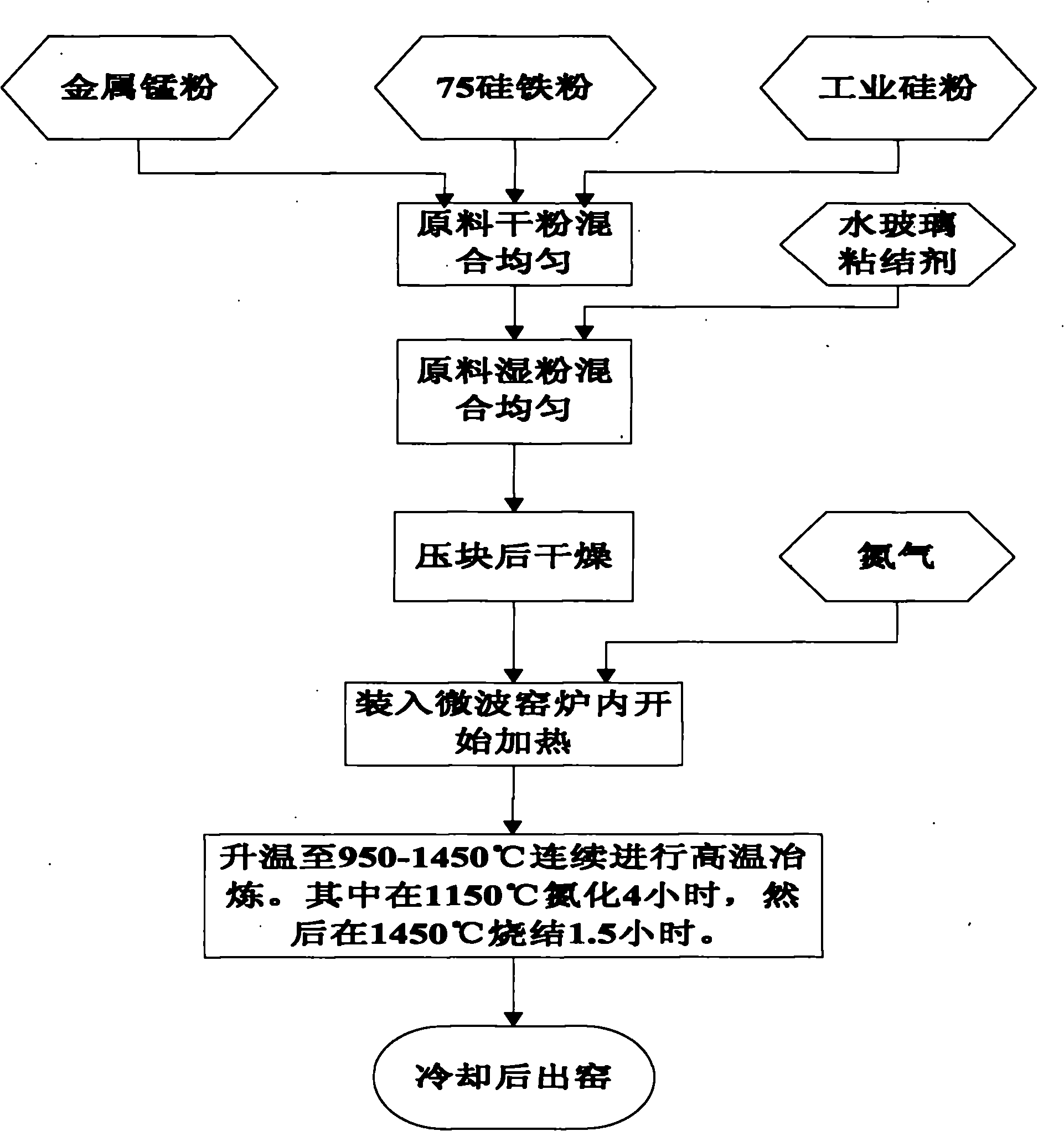

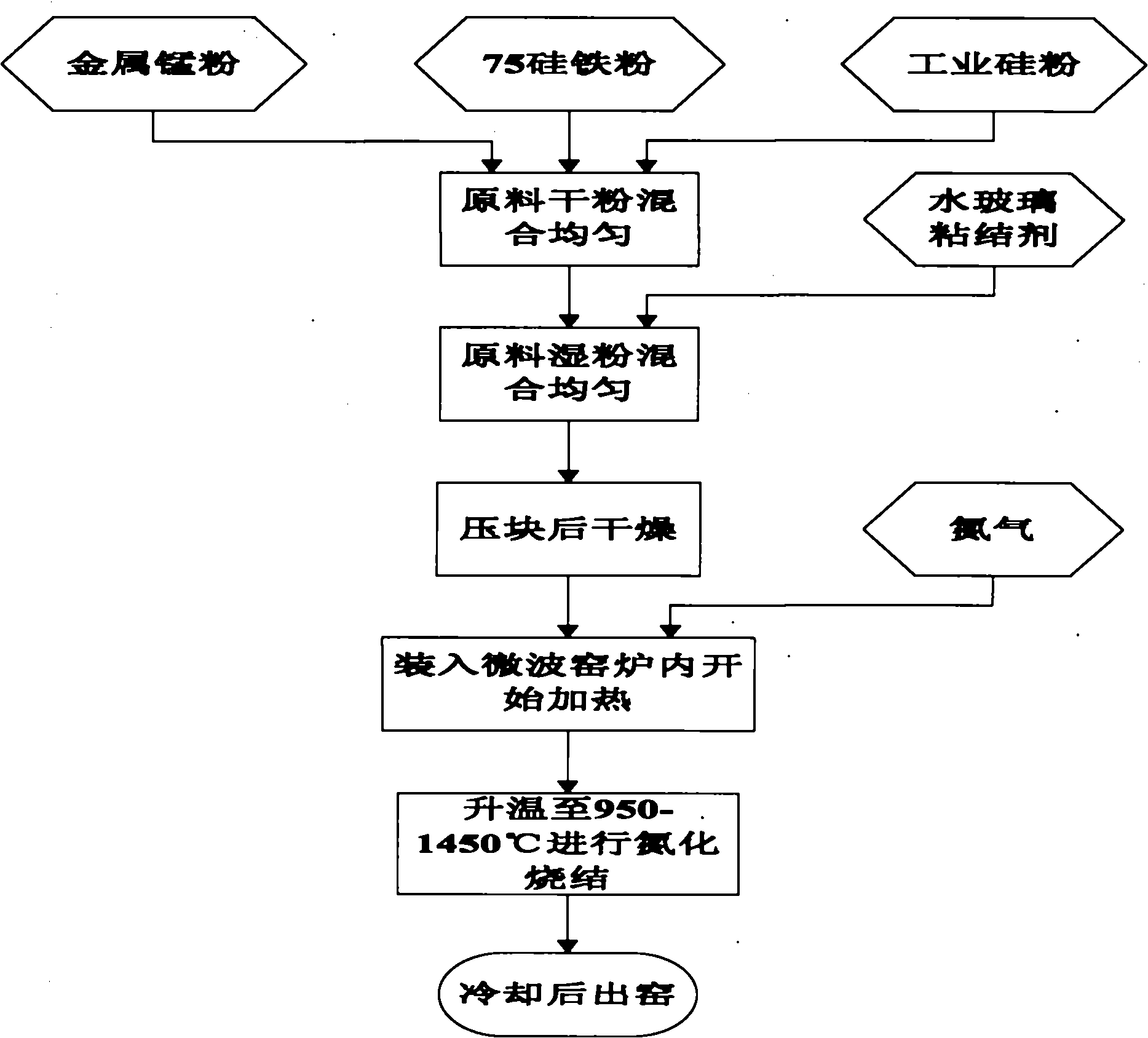

The invention relates to a microwave synthesis method of a Si-Mn-N alloy. In the method, 2.45GHz microwave is used as a heat source, and silicoferrite, manganese metal and industrial silicon are used as raw materials; if the mass sum of the dry raw materials is 100 74 parts of silicon content 75-77% of silicoferrite, 19 parts of manganese conten 97.9% of manganese metaland 7 parts of silicon conten 99.8% of industrial silicon, and the granularity is not more than 80 meshes. The method comprises the steps of: mixing the raw materials in a dry mode; adding sodium silicate solution which accounts for 2-3% of the total amount of the raw materials and blending in a wet mode; pressing the mixture into blocks of 100mm*230mm*100mm, placing the blocks on a slip car, and drying in a dry kiln; after drying, placing the blocks on a push plate used for a microwave tunnel kiln; pushing the push plate into the microwave tunnel kiln at a speed of 4.5m / h continuously, and introducing pure nitrogen into the kiln at a pressure of 0.01Mpa-0.02Mpa; and after preheating in a nitrogen atmosphere, continuously nitrogenizing the blocks at a high temperature of 950-1450 DEG C, sintering, cooling and taking out from the kiln to obtain the qualified Si-Mn-N alloy.

Owner:SINOSTEEL JILIN FERROALLOYS

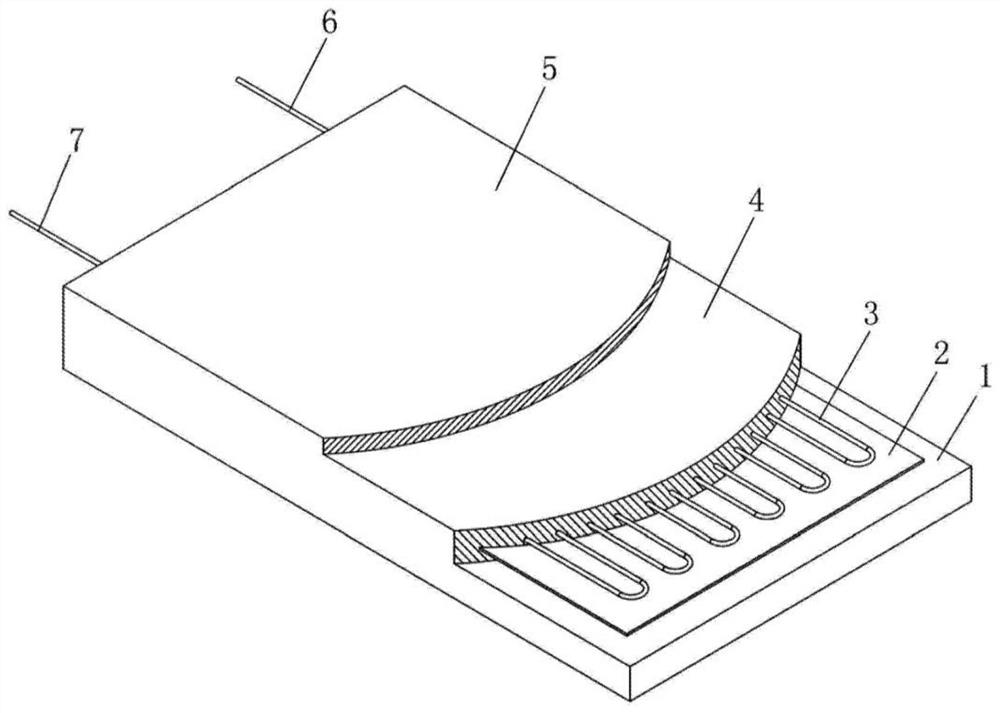

Construction method for anti-icing road face

InactiveCN105178137ALow thermal conductivityImprove temperature resistancePaving detailsInsulation layerRoad surface

The invention belongs to the field of road construction and particularly relates to a construction method for an antifreeze road body. The construction method comprises the following steps that 1, power-on test is conducted on heating cables to be laid before the heating cables to be laid enter a field, whether the heating cables work normally is detected, and the road face base layer is leveled and cleaned; 2, a damp-proof layer is laid; 3, a heat insulation layer and a reflection layer are laid; 4, a heat dissipation layer is laid; 5, a heating cable layer is laid; 6, a temperature sensing probe is arranged; 7, a road face cushion layer is laid; and 8, a road surface layer is laid. The problem of road face freezing is solved thoroughly, the road face is heated before the road face freezes, the performance of the road body is improved while it is ensured that the road face does not freeze, and the situation that the road face freezes to affect the performance of the road body and shorten the service life of the road body is prevented. The service life of the road body can be prolonged through the design of the road body, and safety of the road face is improved.

Owner:浙江佳中木业有限公司

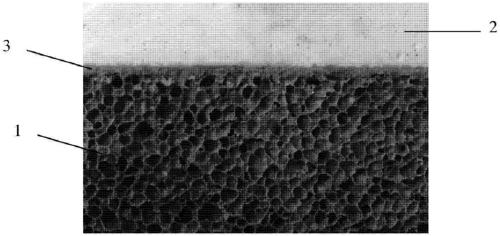

Impregnation method for manufacturing carbon fiber hard composite felt

The invention discloses an impregnation method for manufacturing carbon fiber hard composite felt. The method comprises the following steps: preparing an impregnating agent, completely soaking a carbon fiber soft felt into the impregnating agent, and drying the impregnated carbon fiber soft felt by an industrial spin-drying machine. According to the method provided by the invention, the carbon fiber soft felt is completely soaked by the appropriate impregnating agent, so that resin can fully penetrate into the soft felt, and the overall strength and mechanical processing performance of a finished product are obviously improved. According to the carbon fiber hard composite felt prepared by adopting the process, resin in large pores is thrown out by the spin-drying machine, and the resin only adheres to carbon fiber filaments and in small pores, so that the density of the finished product is uniform. The process provided by the invention is very simple, the product quality can be obviously improved by skillfully combining resin solution impregnation and a spin-drying process, and after spin-drying with the industrial spin-drying machine, excess resin can be recycled, and the cost canbe effectively reduced.

Owner:HUNAN JIUHUA CARBON HI TECH

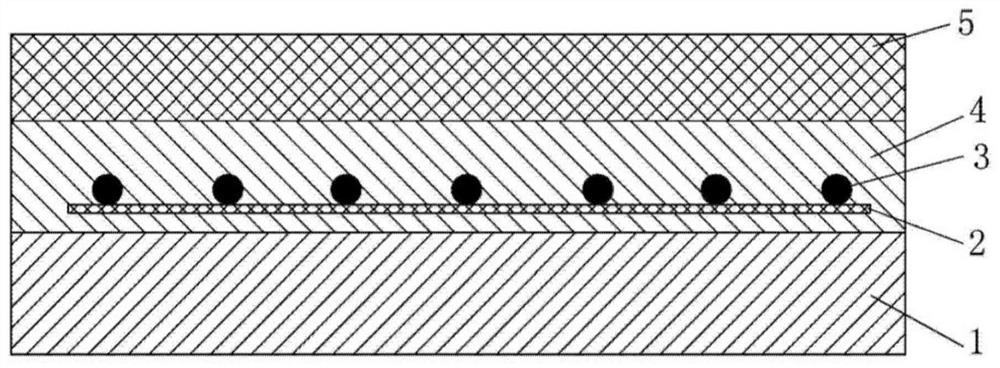

Valley electricity application control device and method based on phase change energy storage

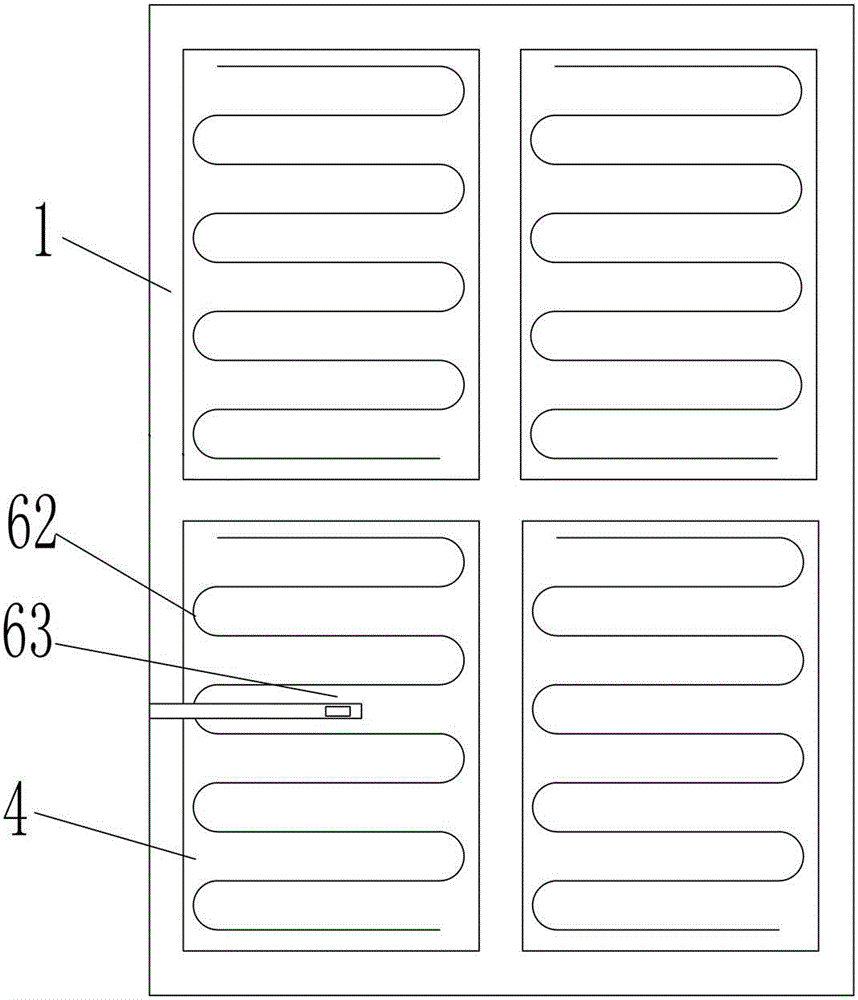

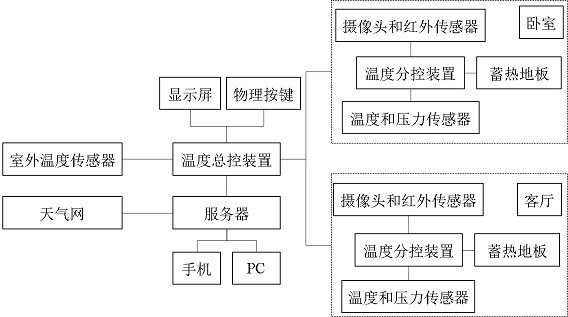

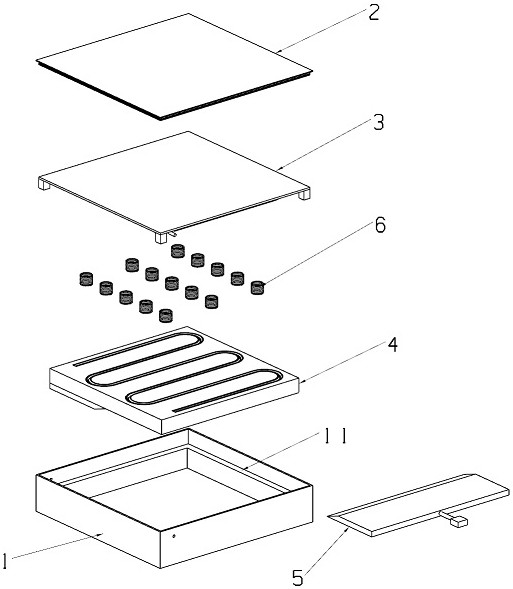

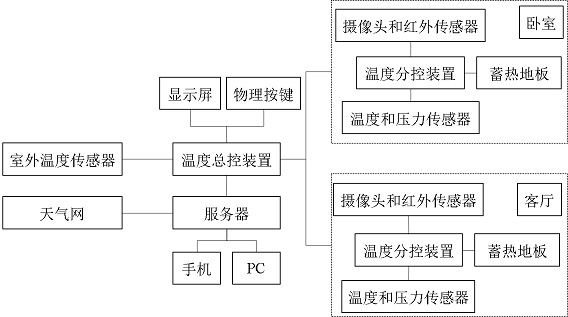

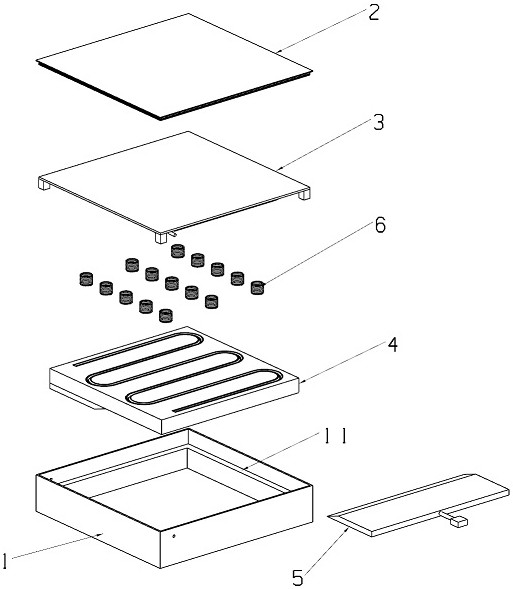

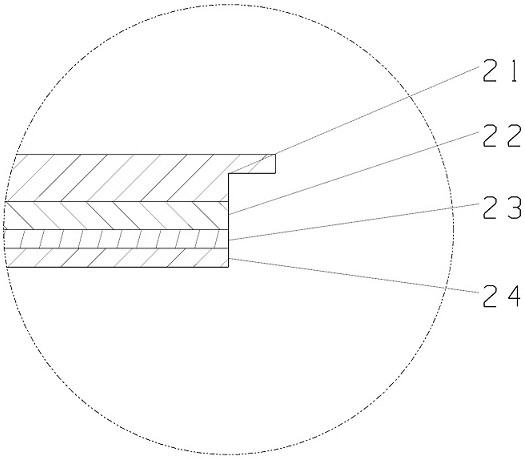

ActiveCN112665007AReduce consumptionReduce heating costs in winterLighting and heating apparatusElectric heating systemFiberThermodynamics

The invention provides a valley electricity application control device and method based on phase change energy storage. More than one heat storage floor is arranged in a heat supply area, and phase change heat storage bricks and carbon fiber heating modules in the heat storage floors are arranged to be separable and combinable. A temperature master control device determines the accurate heat storage time according to infrared data, pressure data, video data and other data in the heat supply area, the phase change heat storage bricks and the carbon fiber heating modules are separated after heat storage is finished, heat storage is stopped, accurate control over the heat storage time is achieved, and the power consumption in the off-peak period of electricity utilization is reduced. In the peak period of power utilization, heat stored by the heat storage floors is used for supplying heat, the temperature master control device judges whether the heat supply area is a vacant area or an active area, and after heat storage time or heat storage capacity is reached in the vacant area, the phase change heat storage bricks and the carbon fiber heating modules are separated, heat storage is stopped, heat consumption is reduced, heat storage time is shortened, accurate control and distribution of heat storage and heat supply electric power are achieved, and electric energy is further saved.

Owner:BEIJING FINE & CLEAN ENERGY

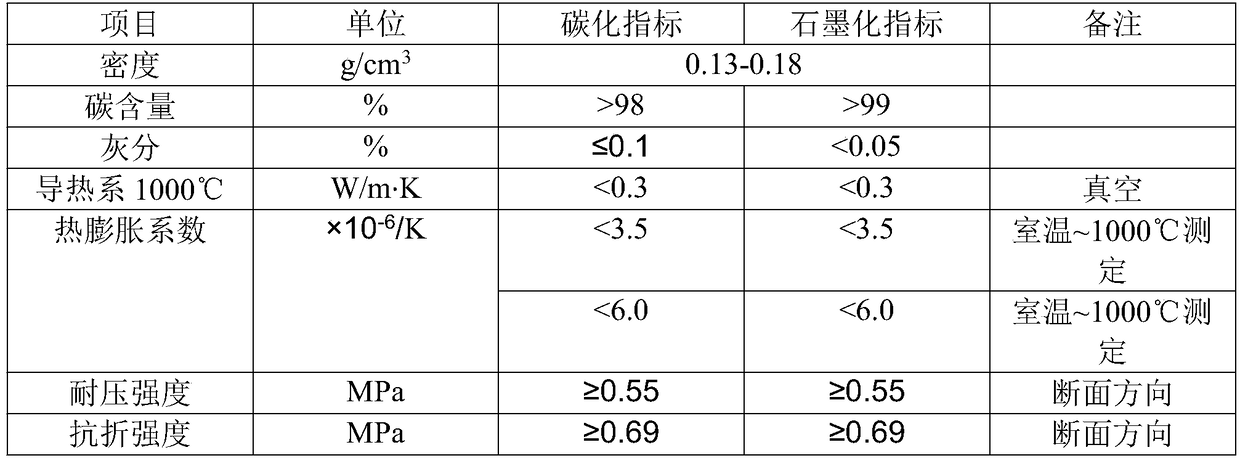

High-efficiency energy-saving cured carbon felt, and preparation method thereof

InactiveCN108625185ANo pollutionIncrease effective spaceNon-woven fabricsThermal insulationCarbon felt

The invention discloses a high-efficiency energy-saving cured carbon felt, and a preparation method thereof. The high-efficiency energy-saving cured carbon felt is prepared from, by weight, 650 to 720parts of soft felt, 30 to 40 parts of a dilluent, 50 to 100 parts of a curing agent, 200 to 300 parts of a resin, and 25 to 35 parts of an inorganic filing material. The preparation method comprisesfollowing steps: 1, felt cutting; 2, rubber preparation; 3, rubber coating; 4, manufacturing and moulding; 5, high temperature oven drying; 6, machining; 7, coating; 8 high temperature calcining; and9, detection. The high-efficiency energy-saving cured carbon felt is low in thermal conductivity, excellent in thermal insulation performance, uniform in density, low in heat storage capacity, quick in degassing, low in outgassing amount in vacuum, possesses heat impact resistance; product pollution or hearth pollution is not caused; furnace body effective space is enlarged; installation and maintenance are convenient; thermal insulation requirements of various monocrystalline growth furnaces and polysilicon ingot furnaces are satisfied. The preparation method is simple, is suitable for largescale industrialized production, and is promising in application prospect.

Owner:NINGJIN JINGXING ELECTRONICS MATERIAL

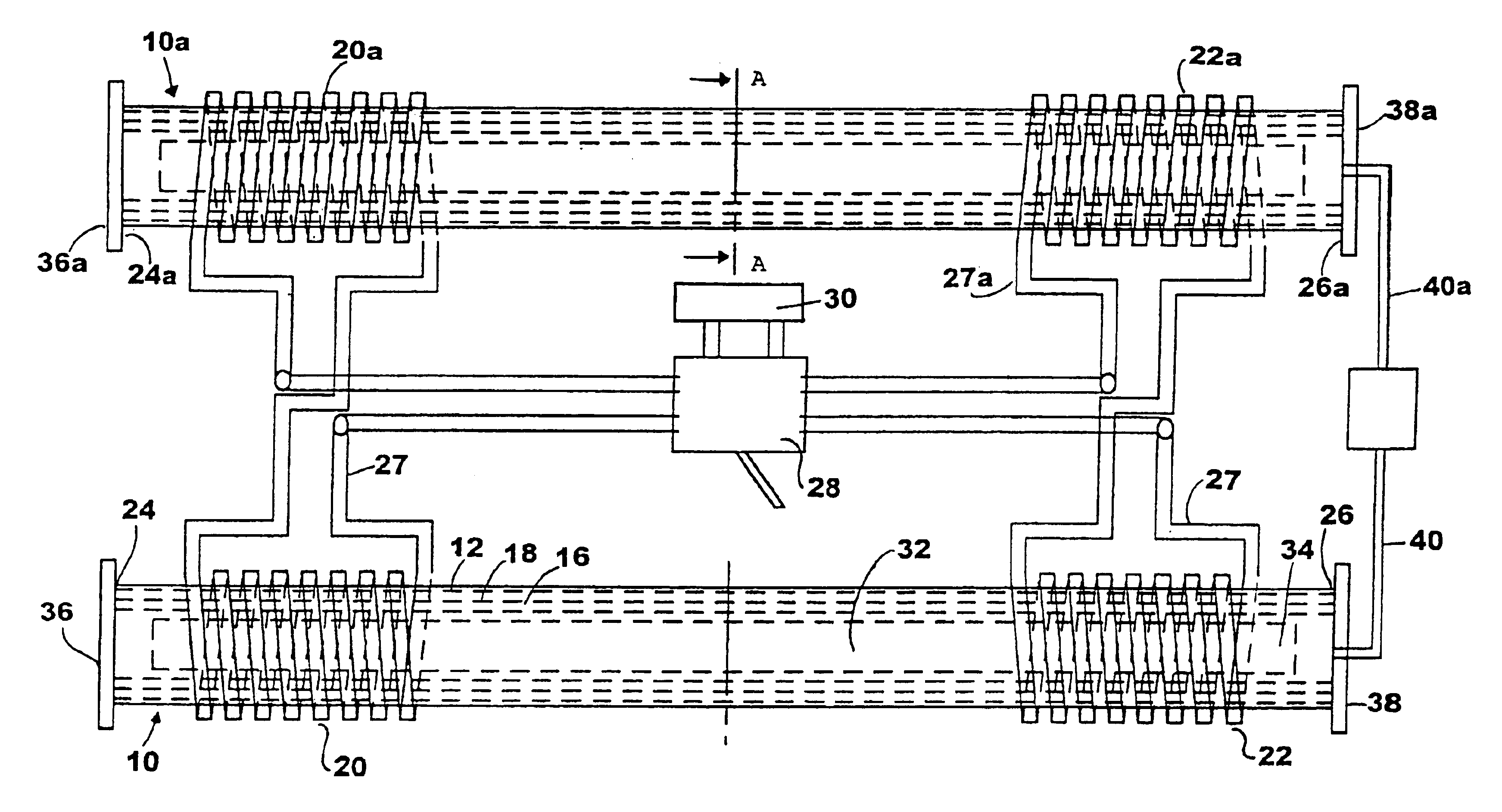

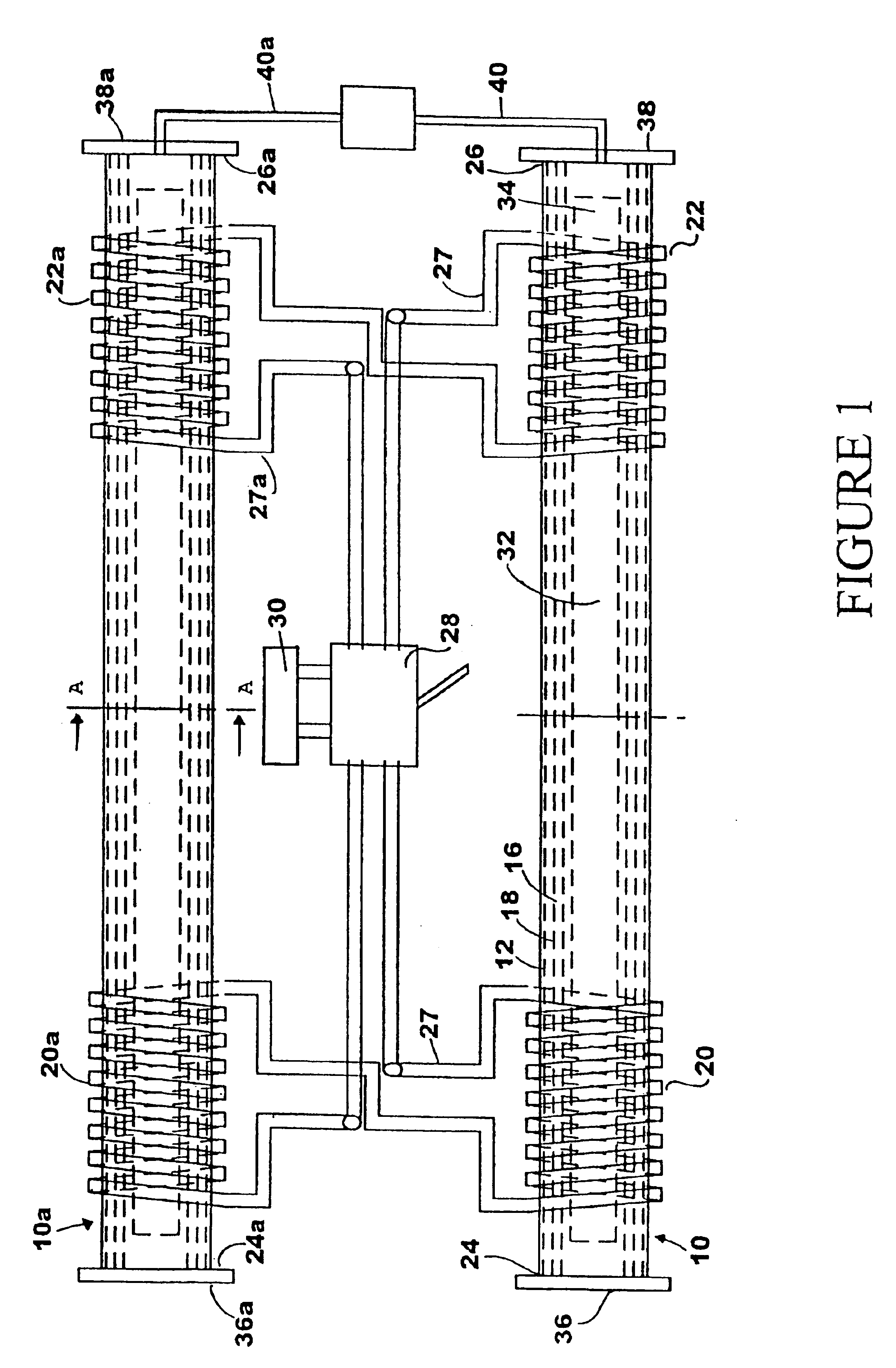

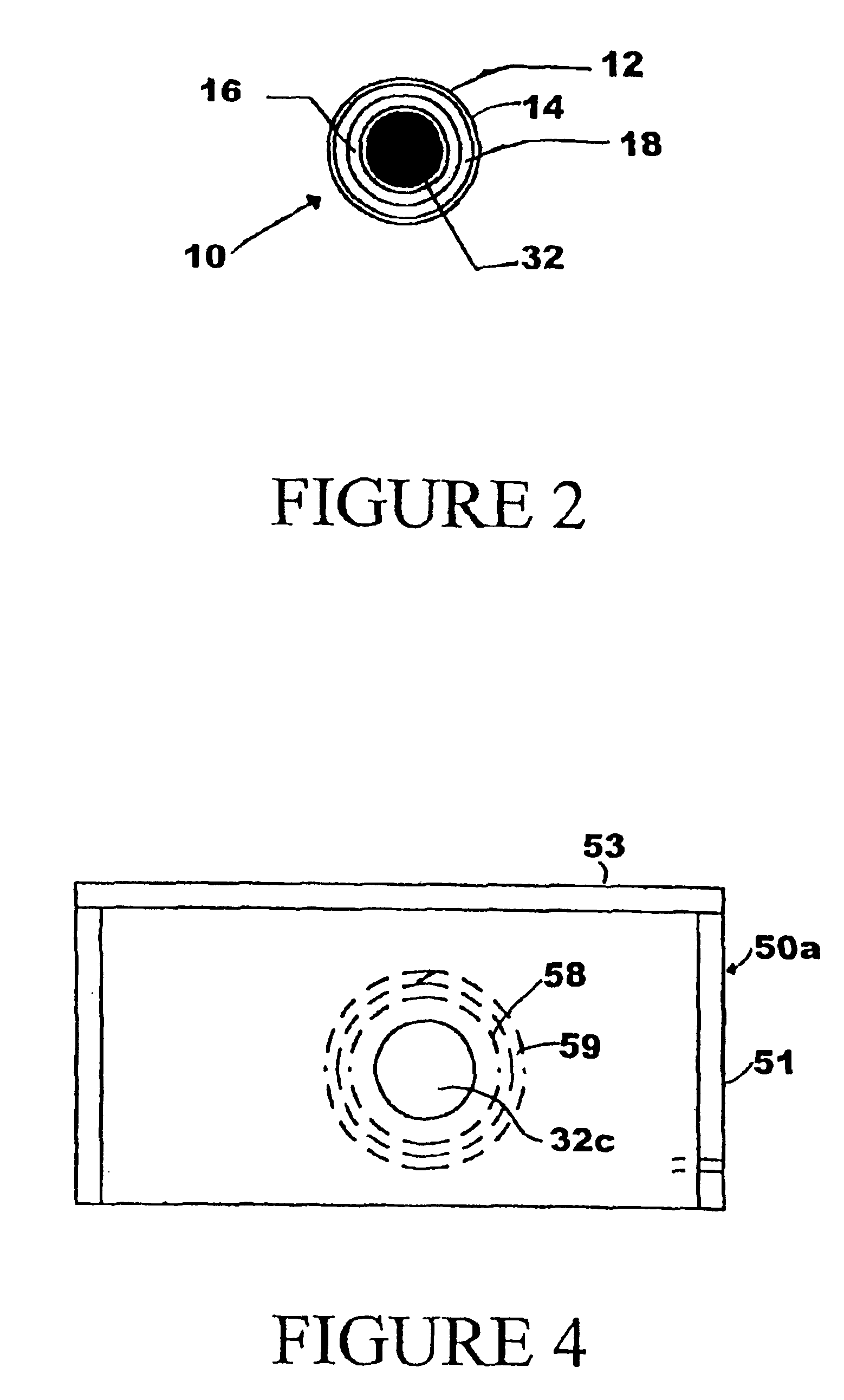

Method for making a silicon carbide resistor with silicon/silicon carbide contacts by induction heating

InactiveUS6887421B2Little be loseLess volumeLayered productsCeramic shaping apparatusElectrically conductiveMetal

A method for bonding an electrically conductive silicon carbide structure to an electrically conductive siliconized silicon carbide structure by temporarily securing the siliconized silicon carbide structure to the silicon carbide structure; placing the silicon carbide structure with secured siliconized silicon carbide structure into an induction heating furnace having an induction coil which heats electrically conductive material in the furnace when sufficient electrical power at a frequency of from about 300 to about 1000 KC is passed through the coil; and causing sufficient electrical power at a frequency of from about 300 to about 1000 KC to be passed through the coil to raise the temperature of the siliconized silicon carbide structure and silicon carbide structure to a temperature above about 1500° C. at the region of temporary attachment to release the attachment and cause silicon metal to flow from the siliconized silicon carbide structure into the silicon carbide structure to form a siliconized silicon carbide bond between the silicon carbide structure and siliconized silicon carbide structure.

Owner:REDUNNDANT MATERIALS

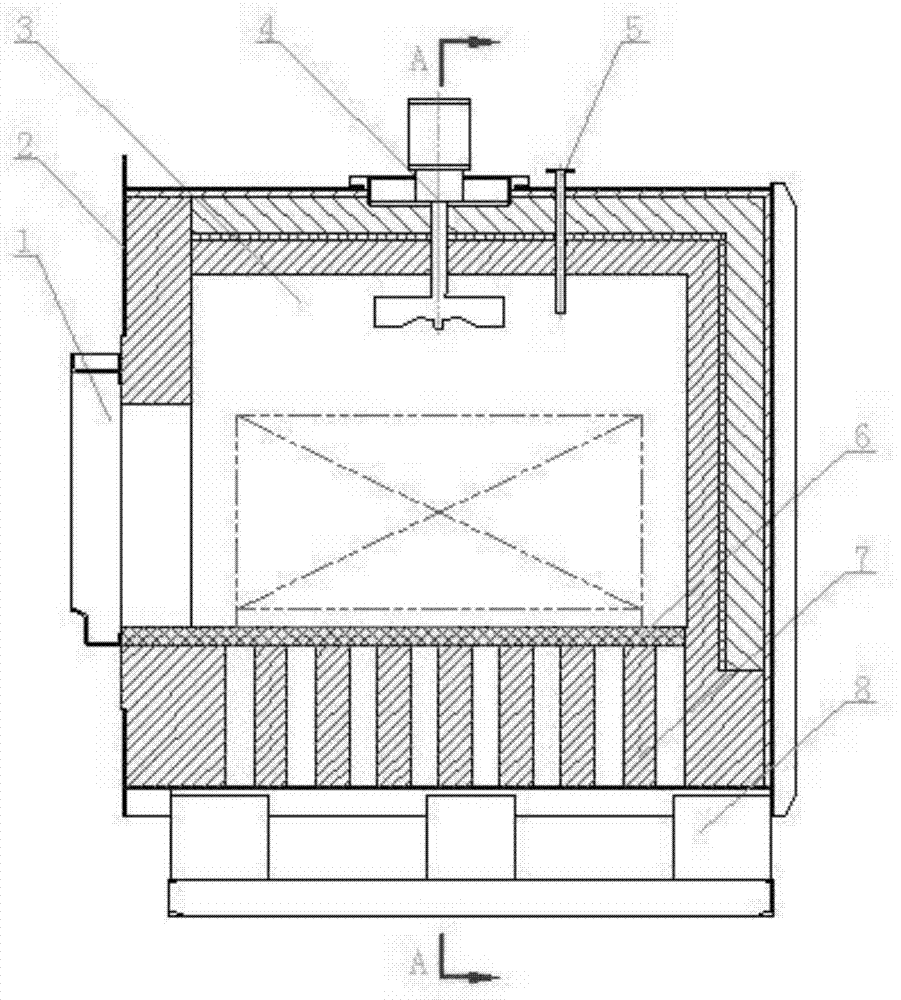

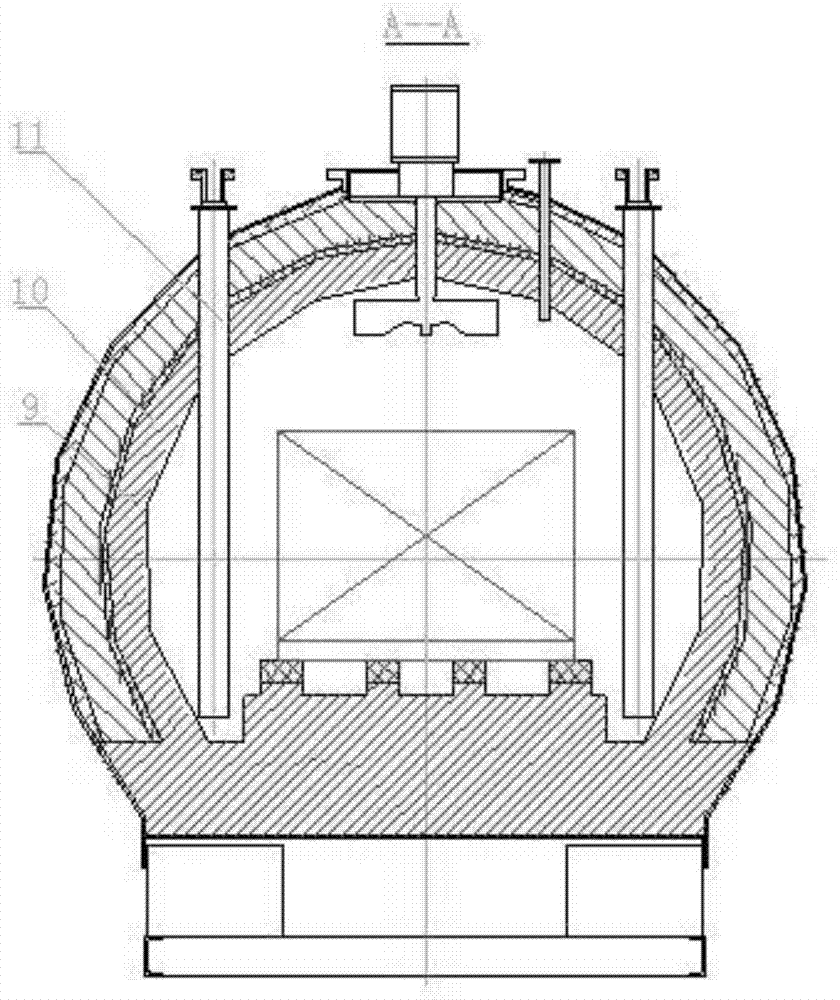

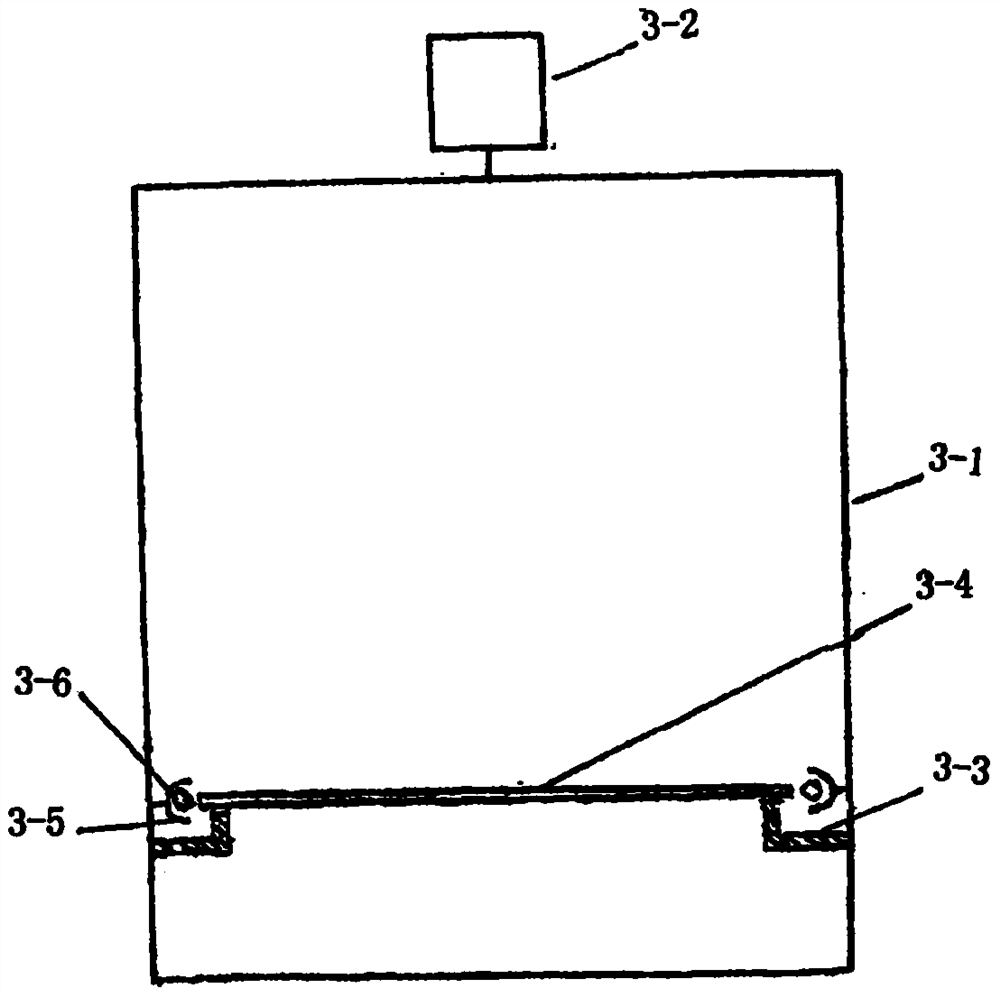

High-temperature carburizing multi-purpose furnace by adopting composite furnace liner structure

The invention discloses a high-temperature carburizing multi-purpose furnace by adopting a composite furnace liner structure. The high-temperature carburizing multi-purpose furnace comprises a furnace door, a furnace shell, a hearth, a shell seat, a furnace interior guide rail and furnace bottom supporting bricks, wherein the furnace door is arranged on one side of the hearth; the hollow hearth is encircled by the furnace shell; the furnace shell is supported by the shell seat; the furnace interior guide rail is arranged above the furnace bottom supporting bricks. The high-temperature carburizing multi-purpose furnace also comprises a high-temperature fan, an air inlet pipe, an impervious brick and refractory fiber layer and a heating element, wherein the high-temperature fan is arranged above the furnace shell and extends into the hearth; the air inlet pipe penetrates through the furnace shell, and outside air can be introduced to balance the air pressure in the furnace; the impervious brick and refractory fiber layer is formed in a built hearth in a circular structure; the heating element penetrates through the furnace shell and extends to the bottom of the hearth. According to the high-temperature carburizing multi-purpose furnace, the heat storage capacity of equipment is reduced, the thermal load of equipment is reduced, the service life of the equipment is prolonged, and the thermal efficiency of the equipment is improved.

Owner:江苏益科热处理设备有限公司

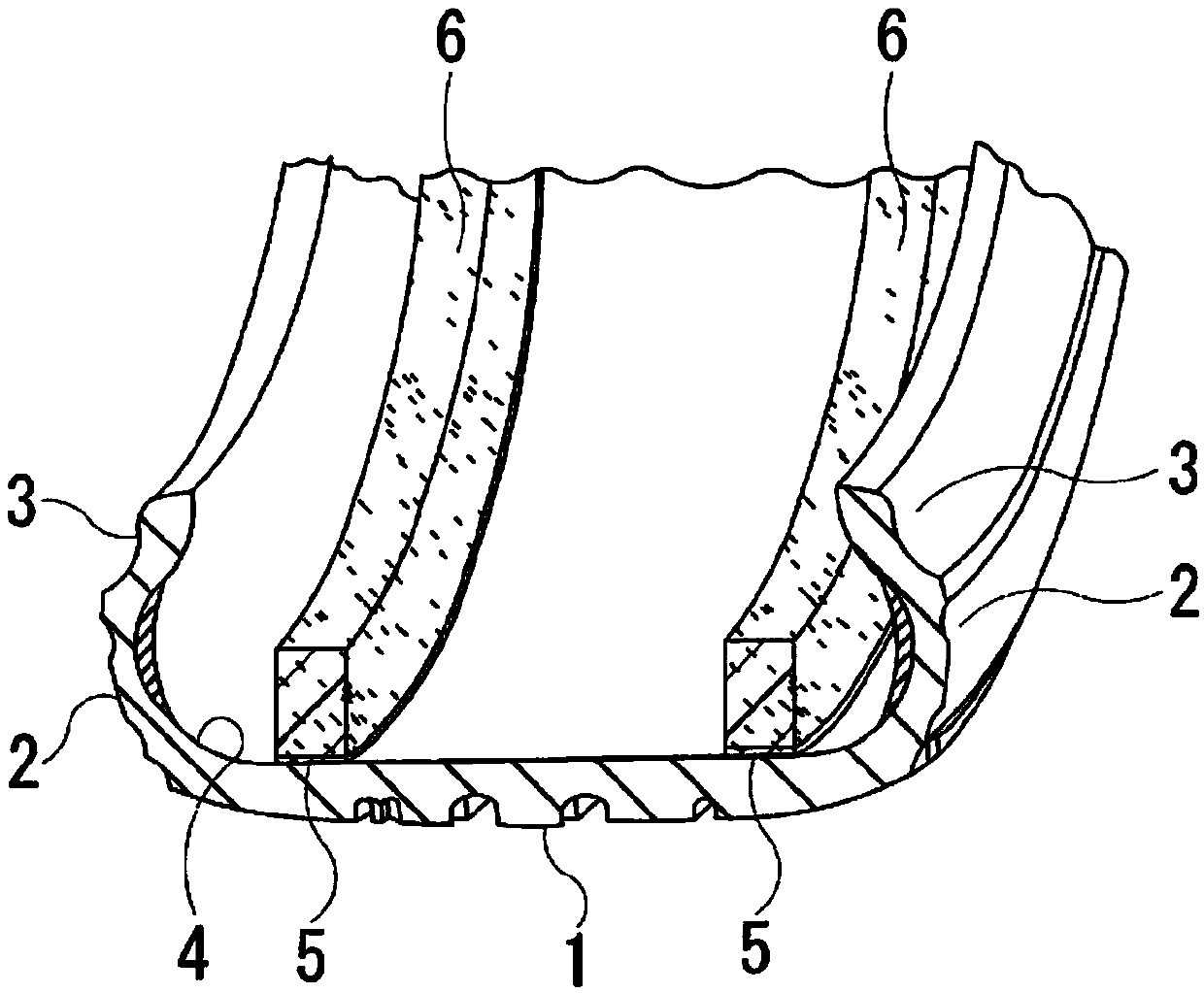

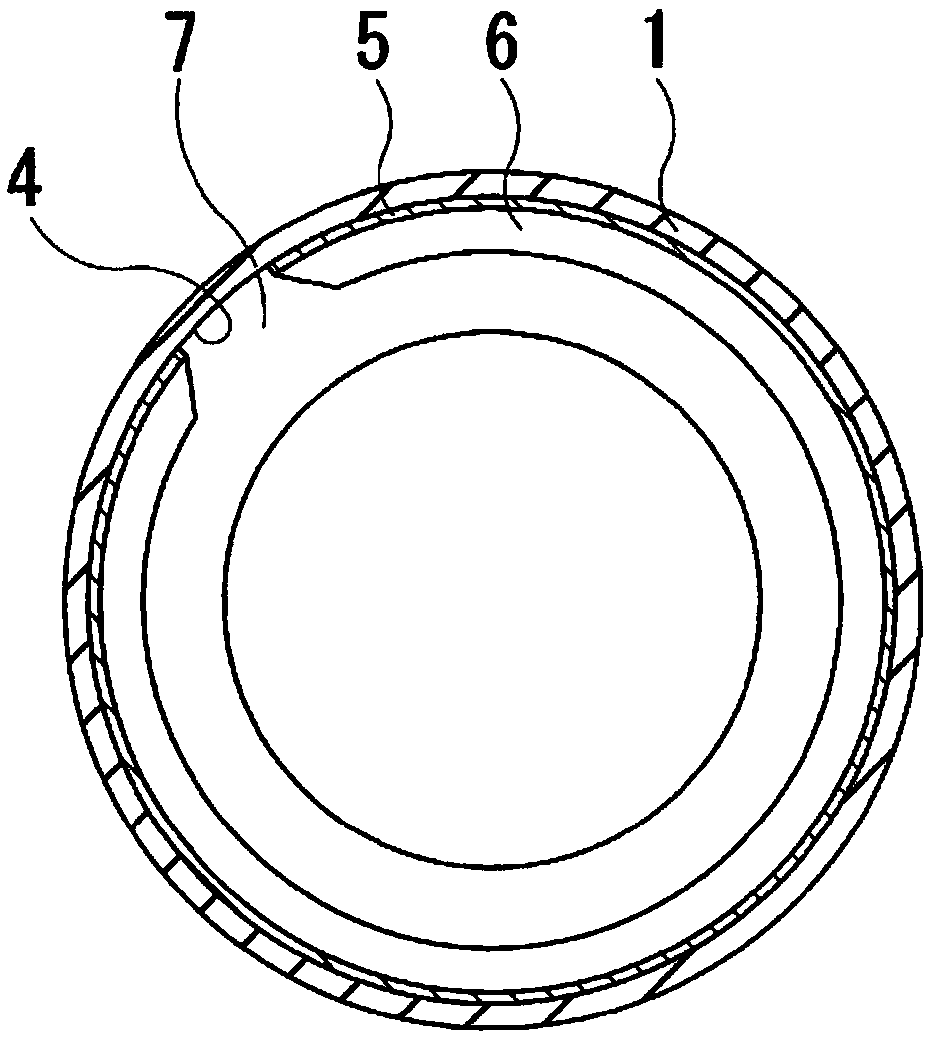

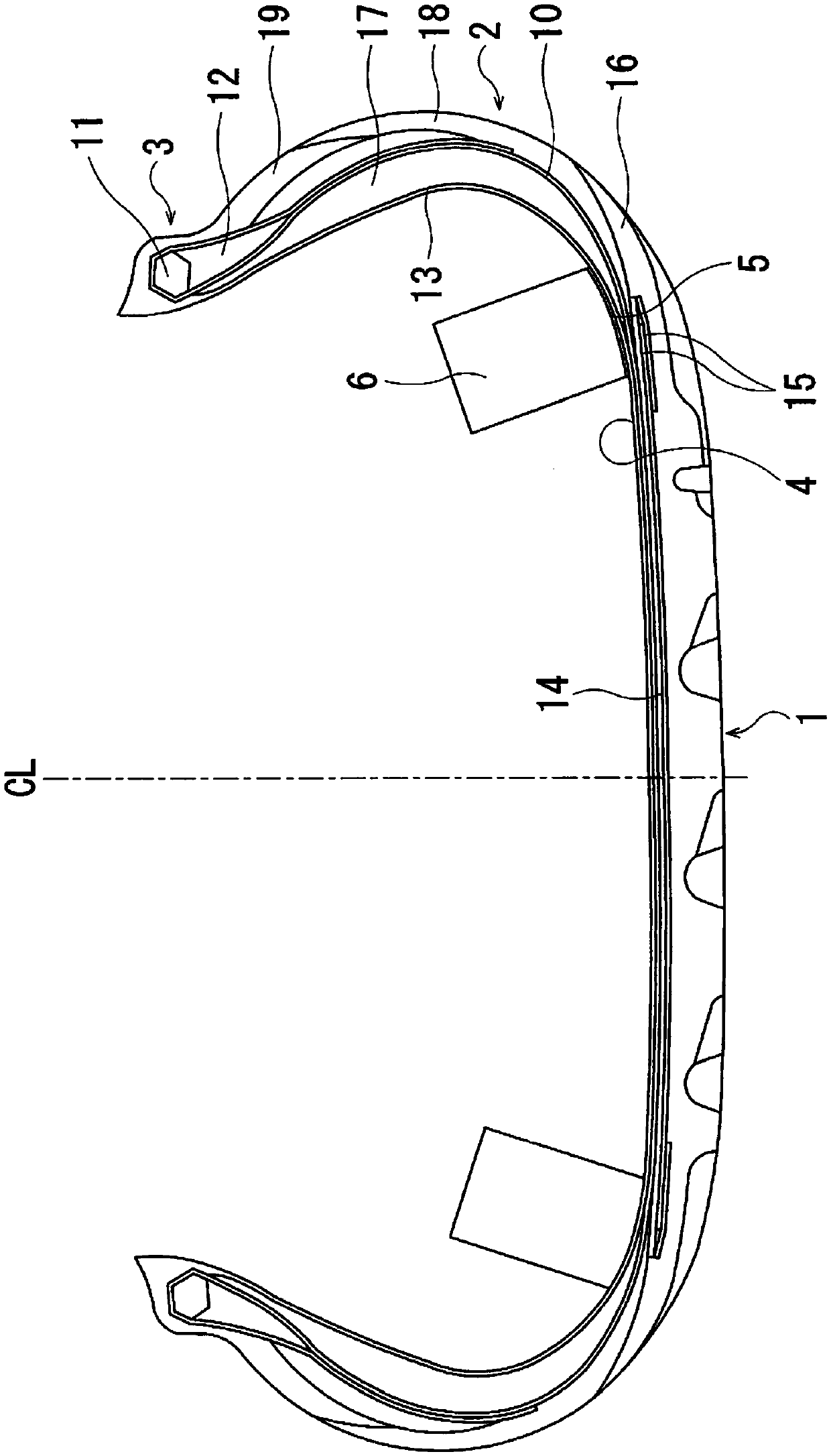

Run-flat tire

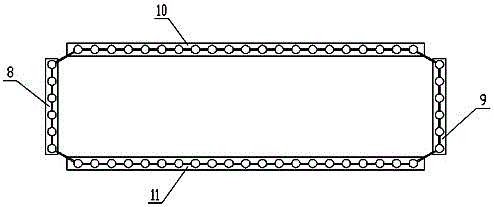

ActiveCN109562645ASmall heat storageSuppresses deterioration of high-speed durabilityInflatable tyresTire beadShoulder region

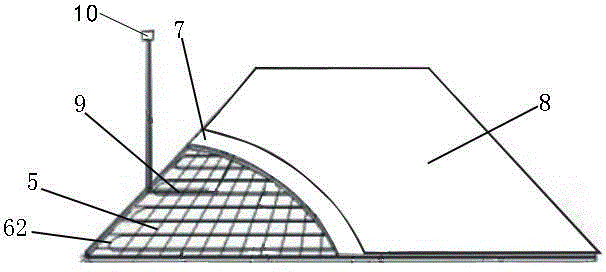

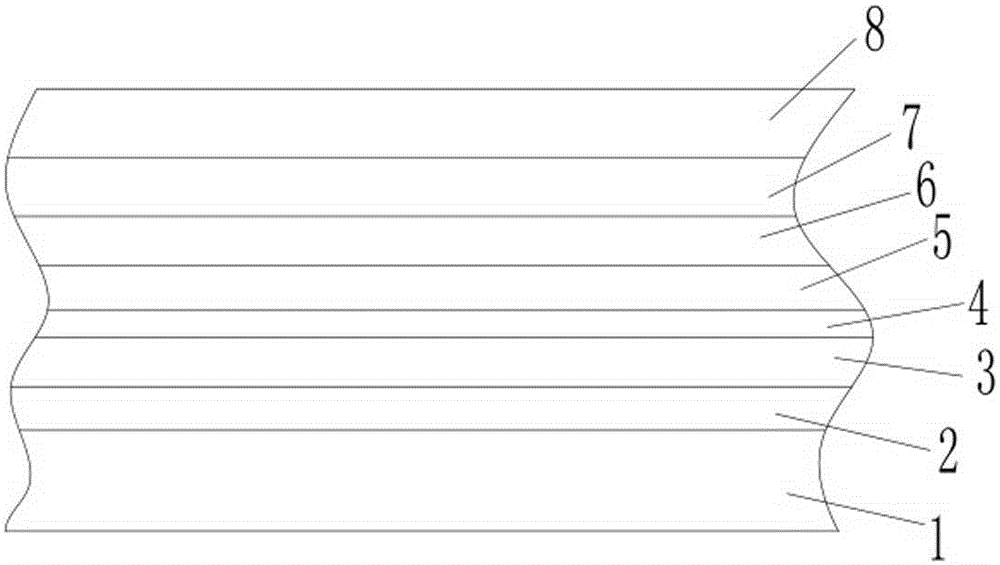

Provided is a run-flat tire in which run-flat durability is improved by the arrangement position and shape of a band-shaped sound-absorbing member bonded to the tire inner surface, and the deterioration of high-speed durability can be suppressed. A run-flat tire provided with a carcass layer 10 mounted between a pair of bead sections 3, and a cross-sectionally crescent-shaped run-flat reinforcement layer 17 on the inner side of the carcass layer 10 in the sidewall sections 2 in the tire width direction, the band-shaped sound-absorbing member 6, which extends in the tire circumferential direction, being bonded in a region of the tire inner surface corresponding to a tread section 1, wherein the band-shaped sound-absorbing member 6 is disposed locally in at least one shoulder region among the regions corresponding to the tread section 1.

Owner:THE YOKOHAMA RUBBER CO LTD

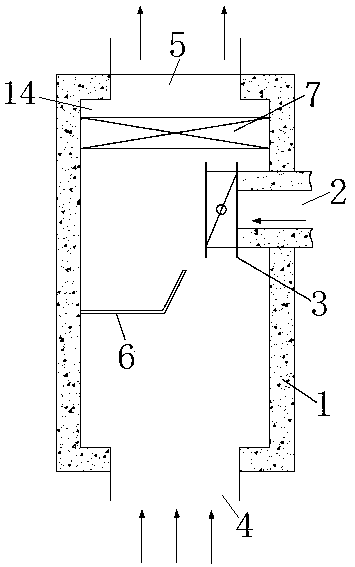

Rapid combustion chamber temperature adjusting device

PendingCN108426466AFacilitated releaseAvoid high temperature oxidationDirect contact heat exchangersHeat exchanger casingsTemperature controlCombustion chamber

The invention relates to a rapid combustion chamber temperature adjusting device which comprise a shell, wherein a high-temperature flue gas inlet is formed in the shell; a high-temperature flue gas adjusting valve is arranged at the inner end of the high-temperature flue gas inlet; a low-temperature flue gas inlet is formed in the shell beside the high-temperature flue gas inlet; a mixed flue gasoutlet is formed in the shell beside the high-temperature flue gas inlet; a uniform low-temperature flue gas distributor is arranged on the shell between the low-temperature flue gas inlet and the high-temperature flue gas adjusting valve; a guide mechanism is arranged inside the shell between the mixed flue gas outlet and the high-temperature flue gas adjusting valve; and a temperature controller is arranged outside the shell. By adopting the device, heat of a combustion chamber can be rapidly released, metals can be effectively prevented from high-temperature oxidation, the energy consumption can be reduced, and the service life can be prolonged.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

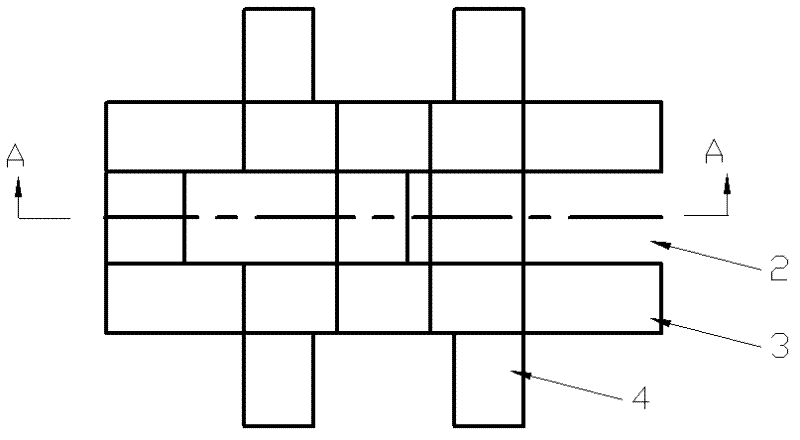

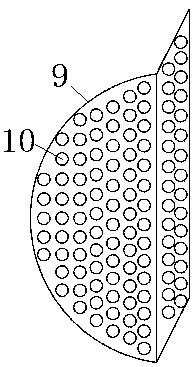

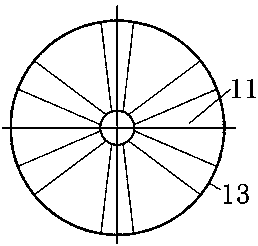

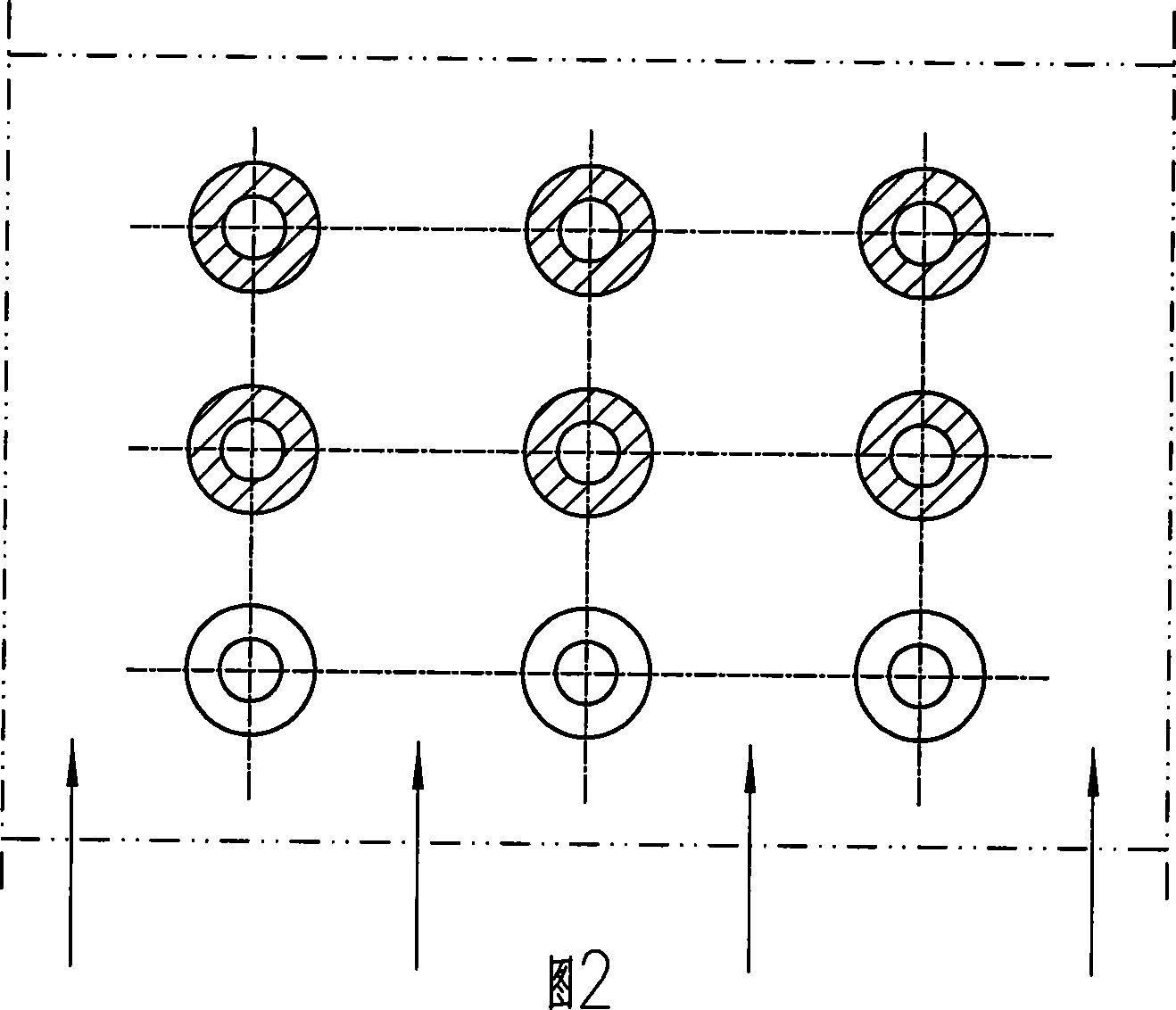

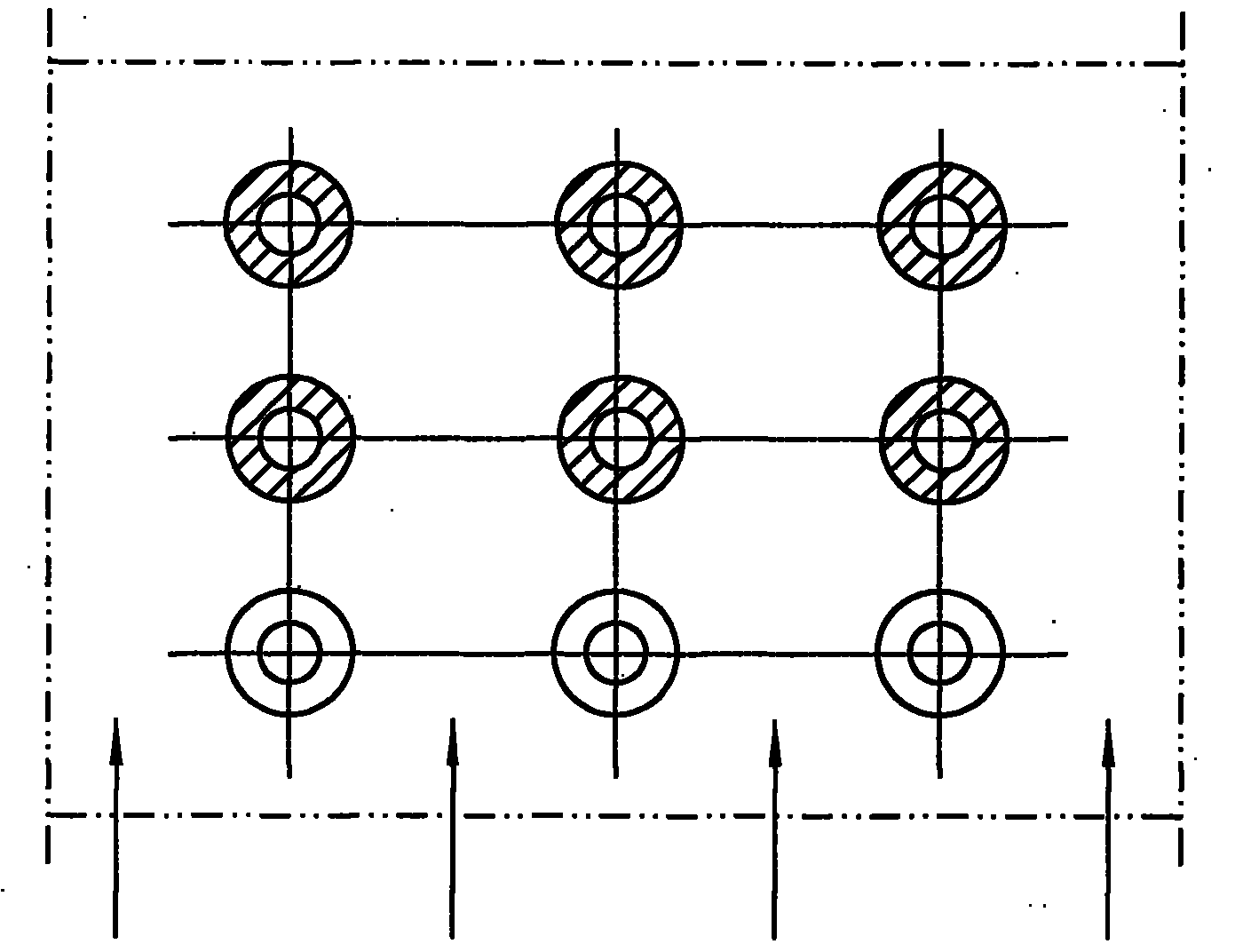

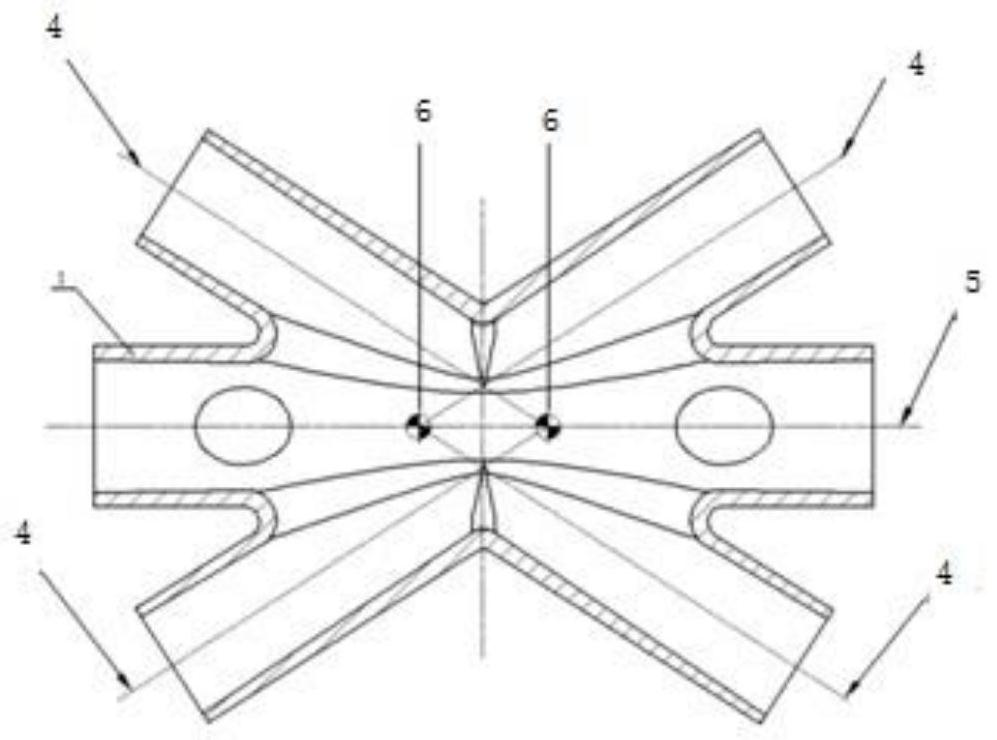

Bottom flue gas passage structure of electrode calcination furnace with cap

InactiveCN101398259AReduce local drag lossIncrease the circulation areaMaintainance of heating chambersWaste heat treatmentBrickGraphite electrode

The invention discloses an electrode roasting furnace with a lid in the field of graphite electrode production, particularly relates to a furnace floor flue gas channel structure of the electrode roasting furnace with the lid. The furnace floor flue gas channel structure is realized by the following steps: an ondol pier is arranged between a furnace floor masonry and ondol surface bricks and is composed of an upper ondol pier brick section and a lower ondol pier brick section. The calandria arrangement in the furnace floor flue gas channel that is formed by the ondol pier bricks with circular sections greatly lowers the local resistance loss of flue gas. As the furnace is a running system consisting of a plurality of furnace chambers, the accumulated reduction value of local resistance loss is very remarkable. As section size of the ondol pier bricks is reduced and the calandria flue gas channel structure is additionally arranged, the flue gas circulation area in the channel is increased, and the friction resistance loss in the flue gas circulation process is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Preparation method of natural far infrared functional mattress capable of resisting bacteria and removing mites

InactiveCN110680115AImprove immunityDisease prevention and health care has a long historyStuffed mattressesSpring mattressesBiotechnologyCollodion Cotton

The invention relates to a preparation method of a natural far infrared functional mattress capable of resisting bacteria and removing mites, and relates to the technical field of living appliances. The invention aims to solve the problems that the energy consumption is high and the environment is not favorable in the manufacturing process of the traditional mattress, the material running phenomenon of the mattress is easy to occur, the mattress is easy to mildew or breed bacteria, mites and peculiar smell, and the body health of people is influenced. The method comprises the following steps of pretreating the Wula sedge raw grass to obtain Wula sedge fine fibers; mixing the fine Wula sedge fine fibers with the collodion cotton fibers and the ES fibers to obtain mixed fibers; lapping and forming the mixed fiber, and forming a mattress core by hot-pressing and forming; and covering the composite industrial hemp fiber cloth quilted with the activated carbon fiber cloth on the surface ofthe mattress core body, and cutting and sewing to obtain the natural far infrared functional mattress capable of resisting bacteria and removing mites. The invention can obtain the preparation methodof the natural far infrared functional mattress capable of resisting bacteria and removing mites

Owner:黑龙江壹善汉麻生物科技有限公司

Heat-reflection-and-heat-resistance-combined road cooling material

The invention discloses a heat-reflection-and-heat-resistance-combined road cooling material. The heat-reflection-and-heat-resistance-combined road cooling material is prepared from porous asphalt, color fillings, aggregate, porous fly ash microspheres, light calcium carbonate, talcum powder, organic bentonite, pure acrylic emulsion, silicone acrylic emulsion and the like; a preparing method of the porous fly ash microspheres includes the following steps that dried fly ash and concentrated sulphuric acid are mixed according to the molar ratio of the concentrated sulphuric acid to metal oxide in the fly ash of 0.2-1.6, then the mixture is roasted for 80 min to 120 min at the temperature of 180 DEG C to 280 DEG C, soluble salt in the mixture is dissolved out with the water bath method, and solid-liquid separation is carried out, wherein the water-bath temperature is 45 DEG C to 80 DEG C, and water-bath time is 0.5 h to 1.0 h; the over-high pavement temperature is 'actively' reduced withheat reflection and heat resistance technological means, the working temperature of a pavement structure is reduced, the temperature reduction amplitude can be 15 DEG C to 20 DEG C, the heat storage capacity of a road body can also be reduced, rutting damage of an asphalt concrete pavement is reduced accordingly, the thermal physics characteristic of urban paving is improved, and the increasingly-serious urban heat island effect can be effectively relieved.

Owner:重庆奥思德仪器设备有限公司

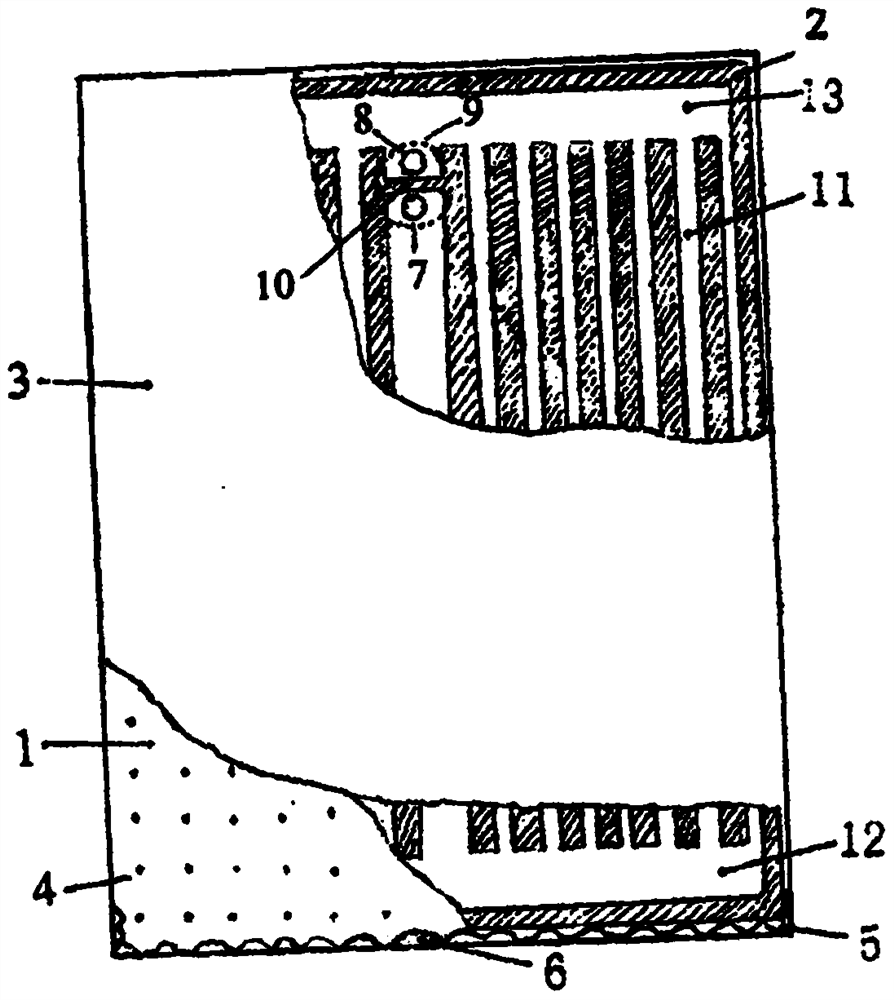

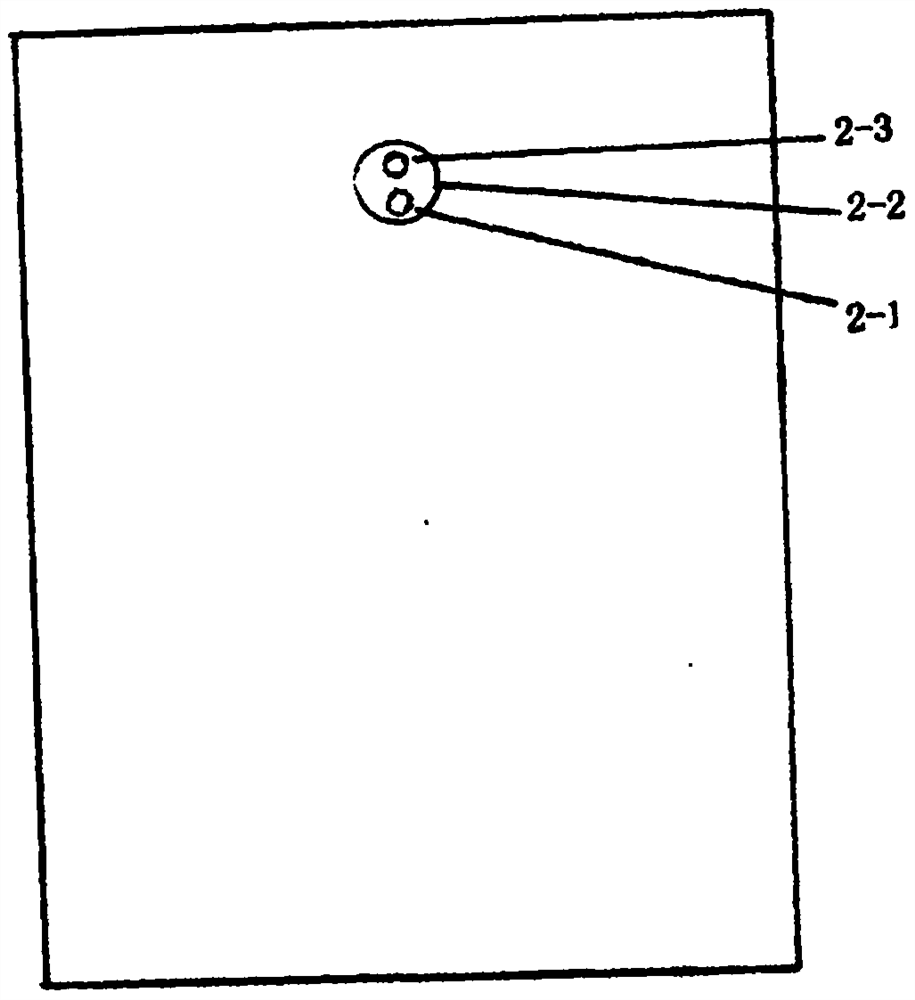

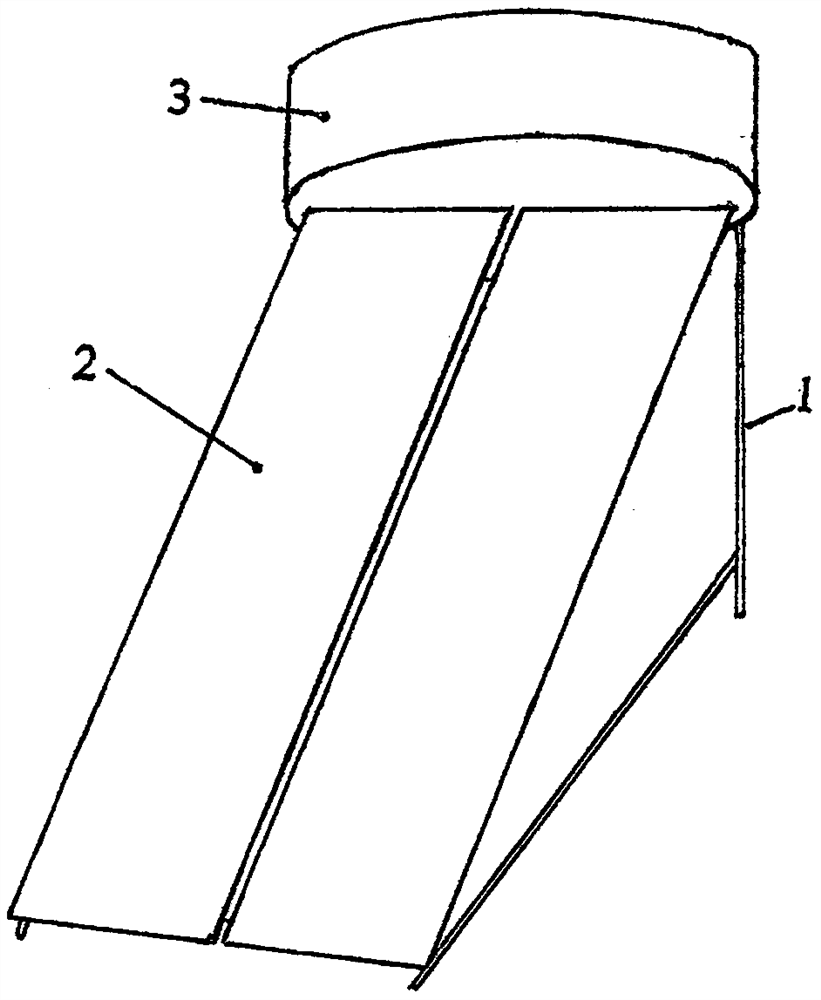

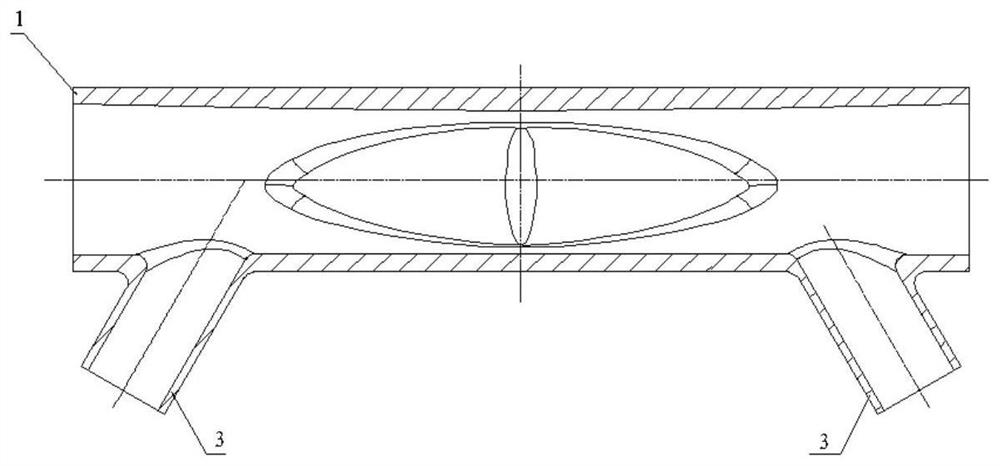

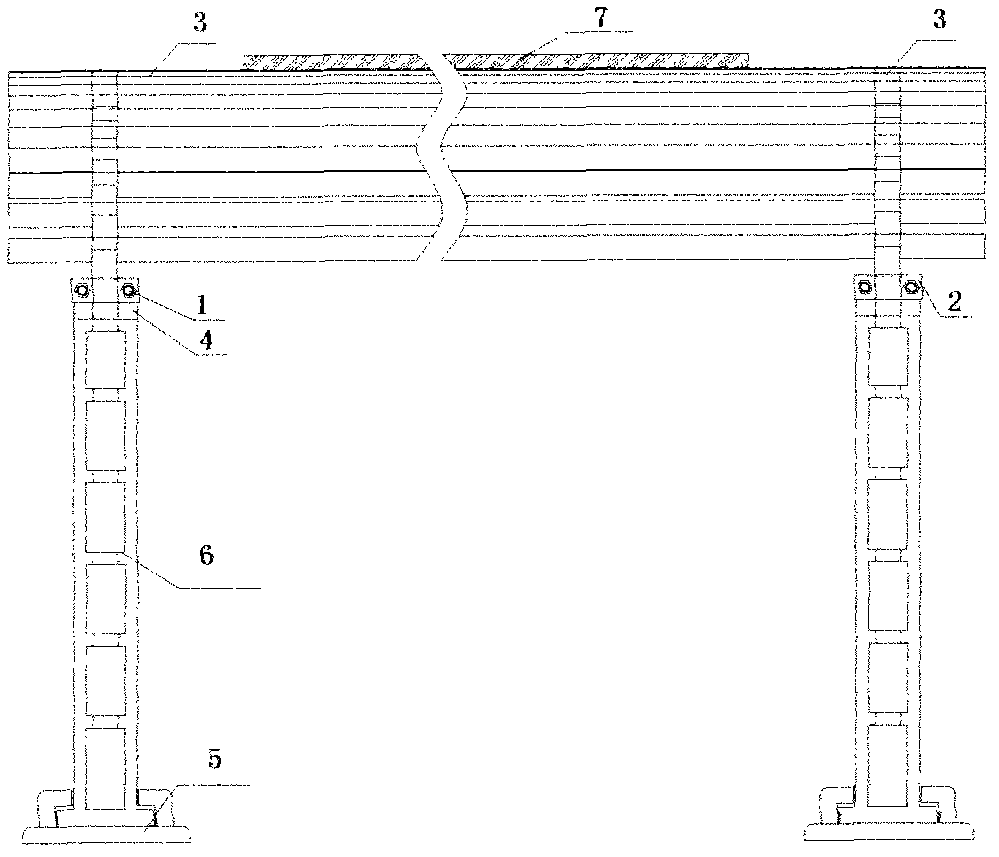

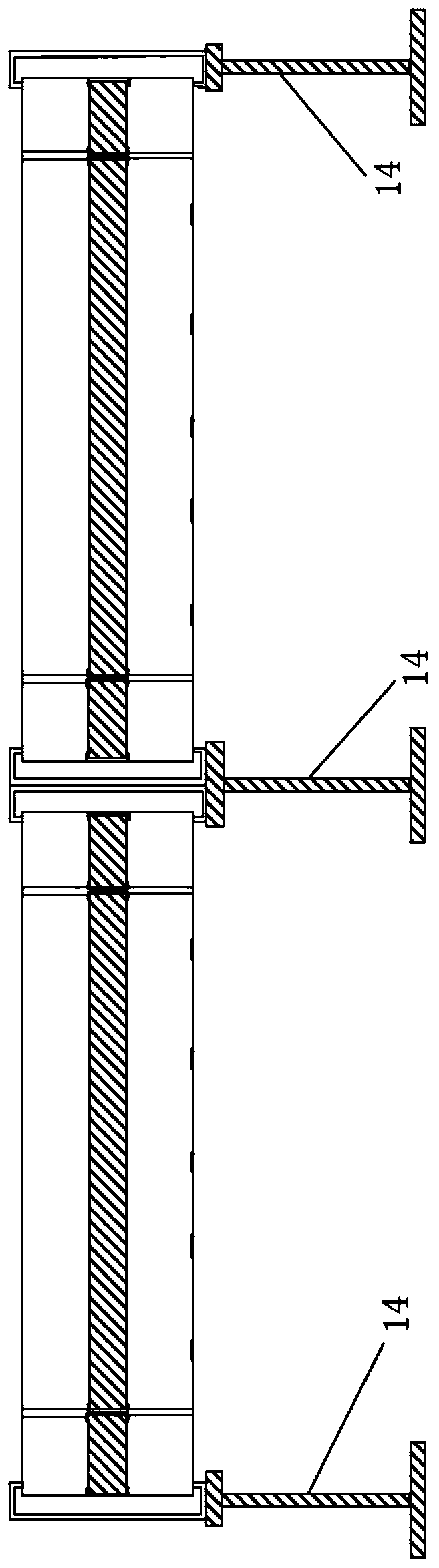

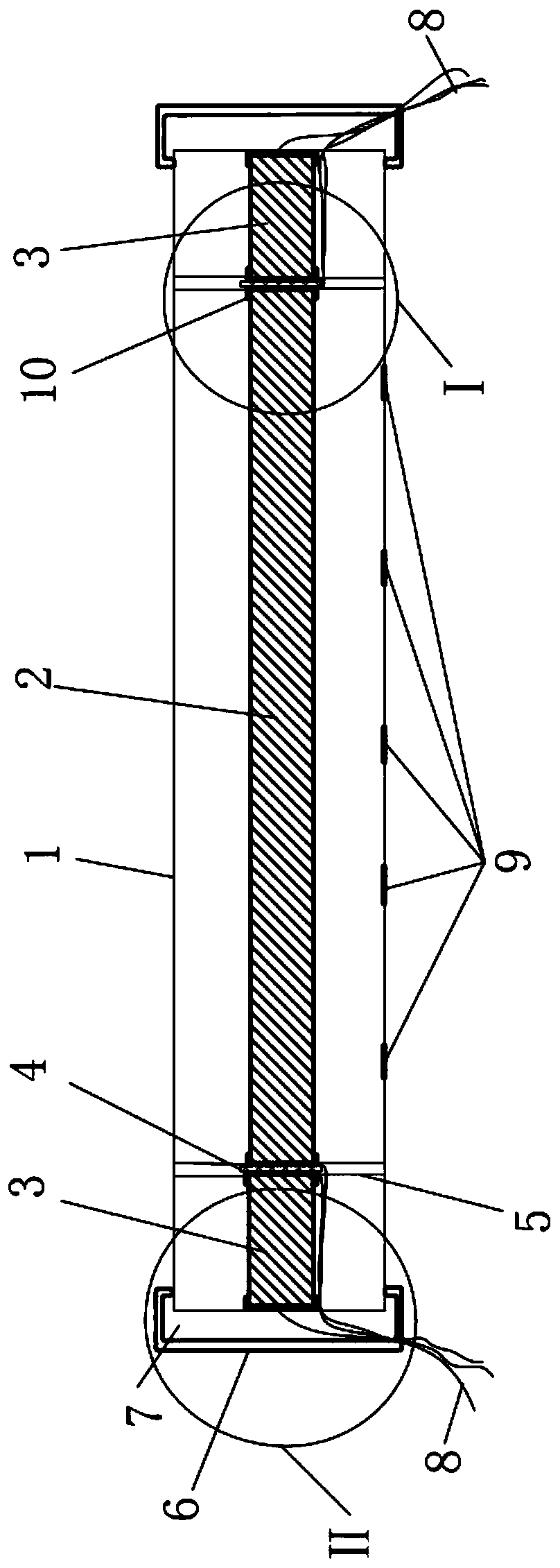

Vacuum flat plate heat collector and manufacturing method and equipment thereof

PendingCN111947323AHigh mechanical strengthImprove thermal shock resistanceSolar heating energySolar heat storageThermodynamicsBuilding energy

The invention discloses a vacuum flat plate heat collector and a manufacturing method and equipment thereof, and belongs to the field of solar energy application. The popularization of a vacuum pipe heat collector enables a flat plate heat collector to be marginalized, so that people know the importance of vacuum heat preservation in solar low-temperature heat collection application. A blow-up type plate core is arranged in the middle of a vacuum glass flat box, supporting columns are arranged between the plate core and the glass box, a heat absorption coating is manufactured on the front faceof the plate core, an inlet pipe nozzle and an outlet pipe nozzle are adjacent on the center line of the back face of the plate core and are vertically led out of a round hole of the same glass backplate, and the problems of heat stress and sealing are well solved. The heat collector in which the ultra-thin plate core is arranged in the vacuum glass box with the homogeneous integrated supportingcolumns is small in heat storage amount, fast in starting and high in heat collection efficiency, and is combined with a building and mounted on a steel structure to form a solar wall which saves energy and generates energy, and the building energy consumption can be effectively reduced. The vacuum flat plate heat collector is combined with a heat pump or a medium-temperature heat collector to produce steam as solar industrial energy, so that the device has a wider application prospect.

Owner:余华阳

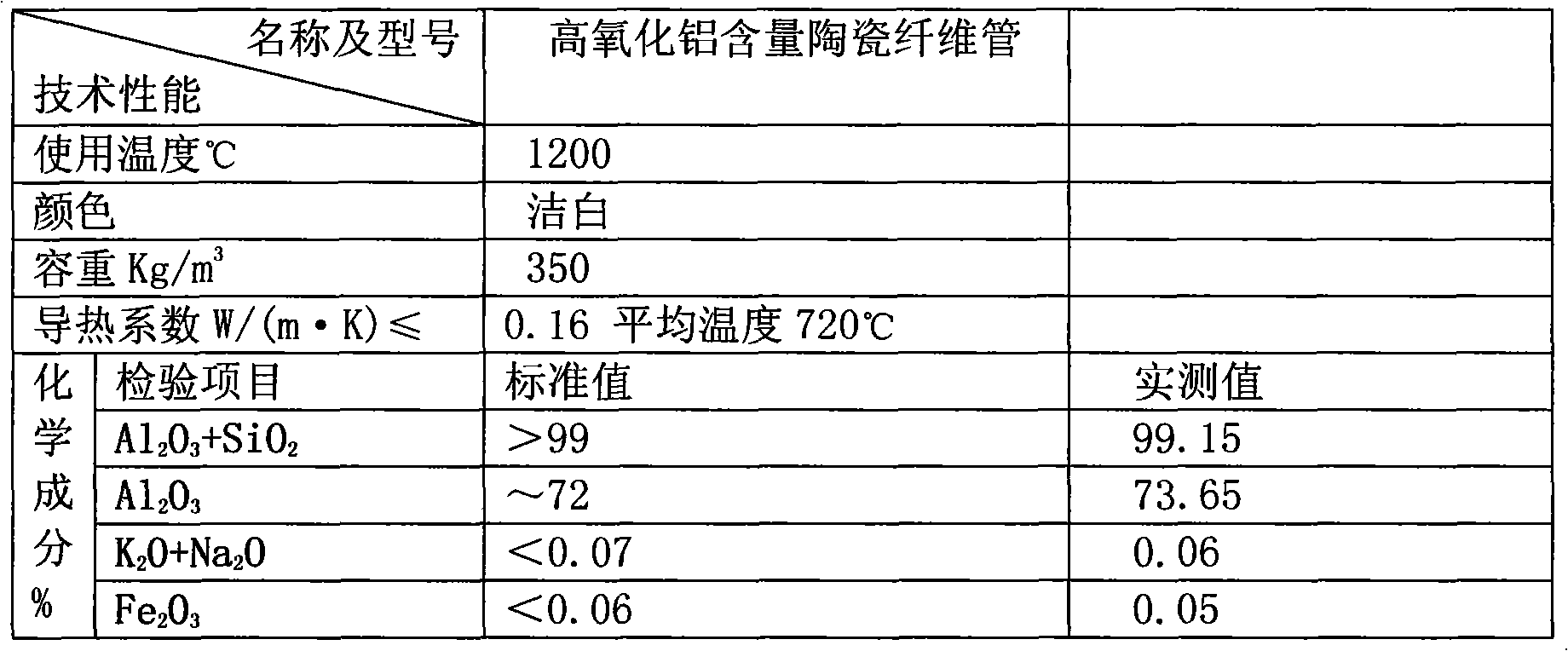

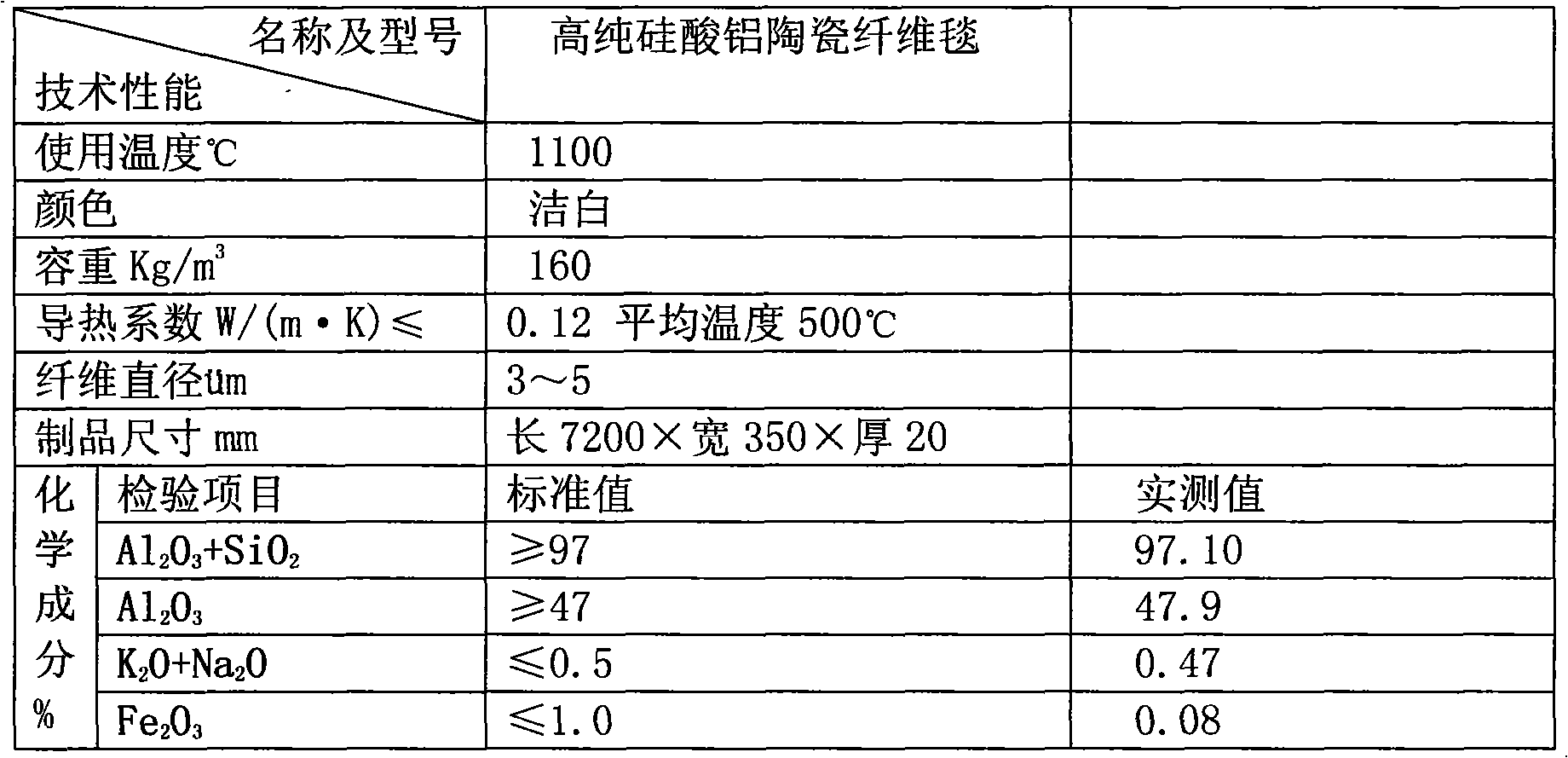

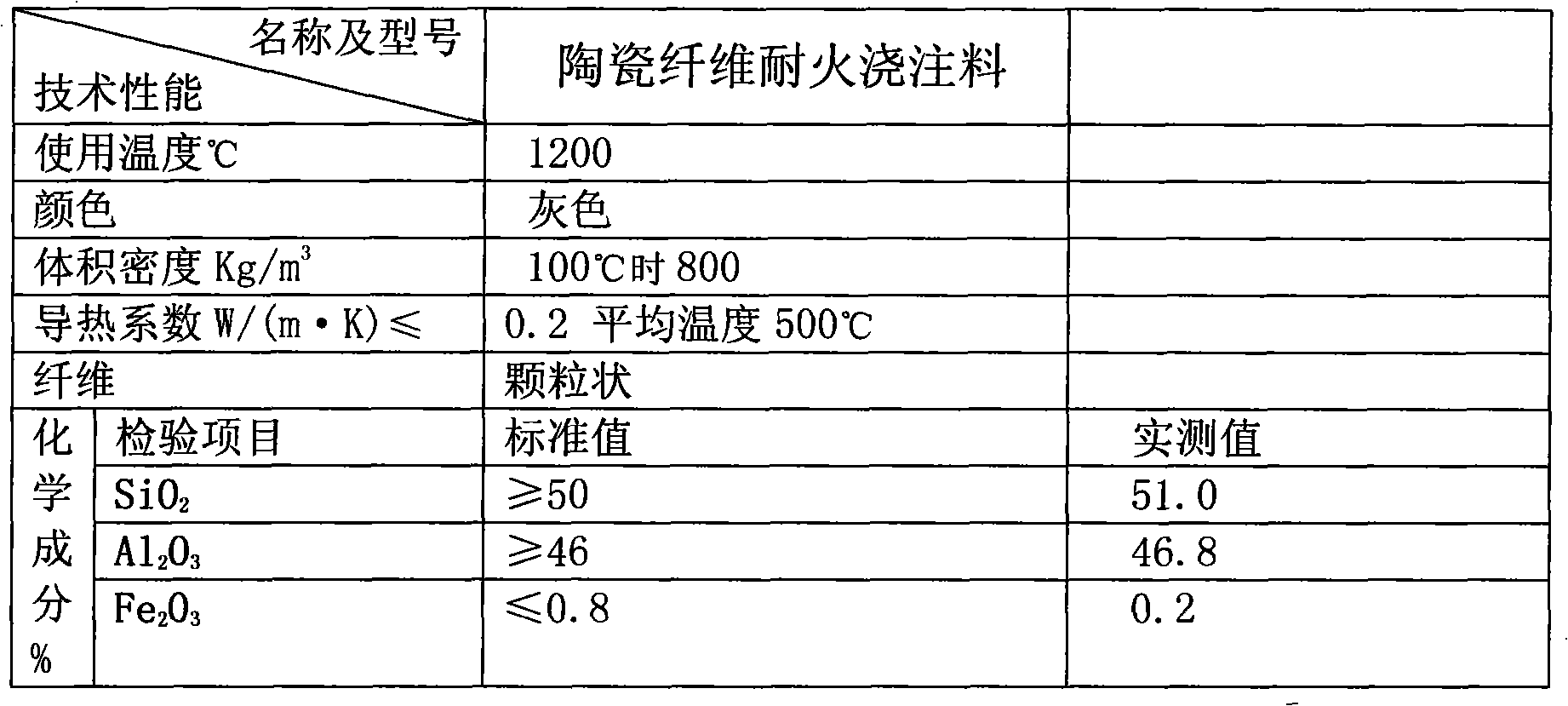

Optical-fiber temperature measuring probe and optical cable cooling method in high-temperature environment

InactiveCN101620009BReduce the burden of cold insulationStrong insulationRadiation pyrometryFibre mechanical structuresFiberOxide ceramic

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Bottom flue gas passage structure of electrode calcination furnace with cap

InactiveCN101398259BReduce local drag lossIncrease the circulation areaMaintainance of heating chambersChimneysGraphite electrodeBrick

The invention discloses an electrode roasting furnace with a lid in the field of graphite electrode production, particularly relates to a furnace floor flue gas channel structure of the electrode roasting furnace with the lid. The furnace floor flue gas channel structure is realized by the following steps: an ondol pier is arranged between a furnace floor masonry and ondol surface bricks and is composed of an upper ondol pier brick section and a lower ondol pier brick section. The calandria arrangement in the furnace floor flue gas channel that is formed by the ondol pier bricks with circularsections greatly lowers the local resistance loss of flue gas. As the furnace is a running system consisting of a plurality of furnace chambers, the accumulated reduction value of local resistance loss is very remarkable. As section size of the ondol pier bricks is reduced and the calandria flue gas channel structure is additionally arranged, the flue gas circulation area in the channel is increased, and the friction resistance loss in the flue gas circulation process is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Flat-plate vacuum tube water heater

InactiveCN111981701ASmall heat storageStart fastSolar heating energyCollector thermal insulationFlat glassCollector device

The invention discloses a flat-plate vacuum tube water heater, and belongs to the field of solar energy application. The water heater is composed of a support, a heat collector and a water tank, the heat collector is a flat-plate vacuum tube heat collector, and the water tank is a vacuum flat water tank; the heat collector comprises an outer flat plate glass flat pipe, namely an outer pipe, and aninner flat plate glass flat pipe, namely an inner pipe, and the outer surface of the inner pipe is provided with a supporting column and a heat absorption coating; the lower end of the outer pipe ismelted into an outer cylinder, the lower end of the inner pipe is melted into an inner cylinder, the inner cylinder is arranged in the outer cylinder, edge openings of the inner cylinder and the outercylinder are melted and sealed, and a hole is formed in the tail end of the outer cylinder for air exhaust and sealing to form a flat vacuum tube; the water tank comprises a vacuum barrel, an end cover and an insertion opening, wherein the vacuum barrel is an inverted flat barrel, the flat barrel is formed by rolling a stainless steel sheet into an inner barrel and an outer barrel, edge openingsof the inner barrel and the outer barrel are welded and sealed, and the space between the inner barrel and the outer barrel is vacuumized and sealed into a vacuum flat barrel; and the insertion opening on the end cover is an insertion opening of the flat vacuum tube. The water heater has the advantages that the temperature rise is fast, the efficiency is high, and the heat insulation time is long.

Owner:余华阳

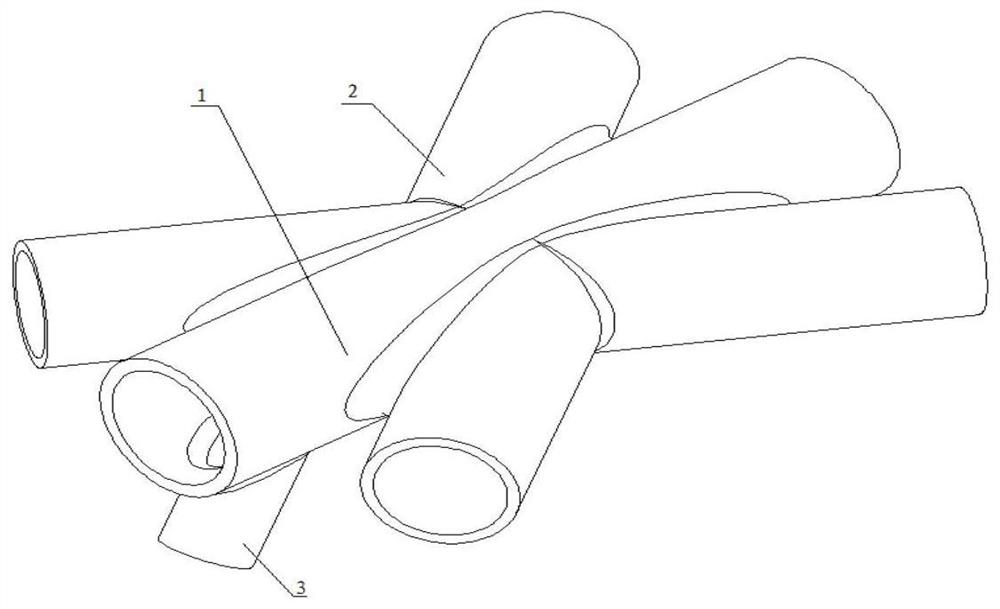

Ocean platform wall thickness gradient casting joint and preparation method thereof

ActiveCN113431014AImprove corrosion resistanceSmall heat storageArtificial islandsFurnace typesMarine engineeringPipe fitting

The invention discloses an ocean platform wall thickness gradient casting joint. The casting joint comprises a main body used for being connected with steel structure pipe fittings, wherein the main body is integrally cast steel, the main body comprises a center connecting pipe, 2-4 inclined pipes and 2-6 bottom pipes, the connecting ends of the central connecting pipe, the inclined pipes and the bottom pipes are intersected and converged at one position to form a joint core area, the central axes of all the connecting pipe fittings are intersected at two central points in the joint core area, the distance between the two central points is 250-300 mm, and a fillet is arranged between the surfaces of the inner wall and the outer wall of every two adjacent connecting pipes for transition. According to the casting joint, the overall weight is reduced, and meanwhile good welding performance is guaranteed; and the casting joint can be formed at a time, the process is simpler, and the manufacturing cost is greatly reduced.

Owner:中信金属股份有限公司 +2

Asphalt pavement heat-reflecting material

The invention discloses an asphalt pavement heat-reflecting material, comprising 30-40 parts of polypropionic acid resin, 10-20 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 10-20 parts of dibutyl maleate-vinyl acetate copolymer, 2-6 parts of 3-glycidoxypropyltrimethoxysilane, 4-9 part of silicic acid, 1-5 parts of rutile titanium dioxide, 5-10 parts of expanded perlite, 2-6 parts of indium oxide micropowder, 1-3 parts of hydroxyethyl cellulose, 5-10 parts of nano hollow glass fiber, 2-6 parts of a near-infrared reflecting material, 2-6 parts of ethylene-vinyl acetate copolymer, and 1-3 parts of a dispersant. The asphalt pavement heat-reflecting material can absorb visible light with wavelength of 400-750 nm in sunlight and reflect the visible light under reduced quantity, and can reflect most of the non-visible light with wavelength of 750-2500 nm, the effective reflection rate is up to 80-90%, cooling is achieved accordingly, temperature rise may reach 10-18 DEG C,road heat storage can be lessened so that rutting damage to an asphalt concrete pavement is reduced, the service life of the pavement is extended, driving safety is improved, and durability and anti-rutting of the pavement can be improved.

Owner:重庆渝茁科技有限公司

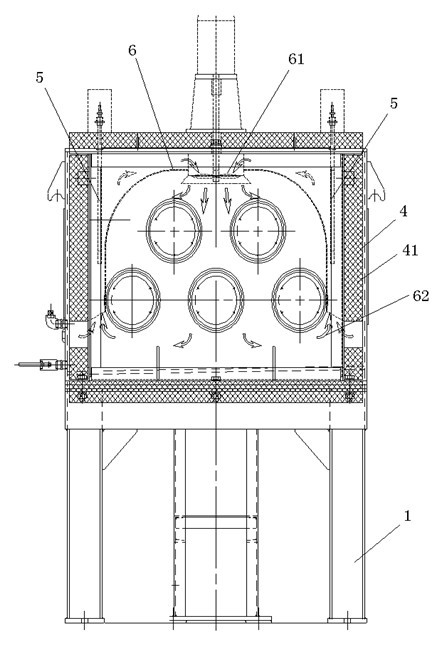

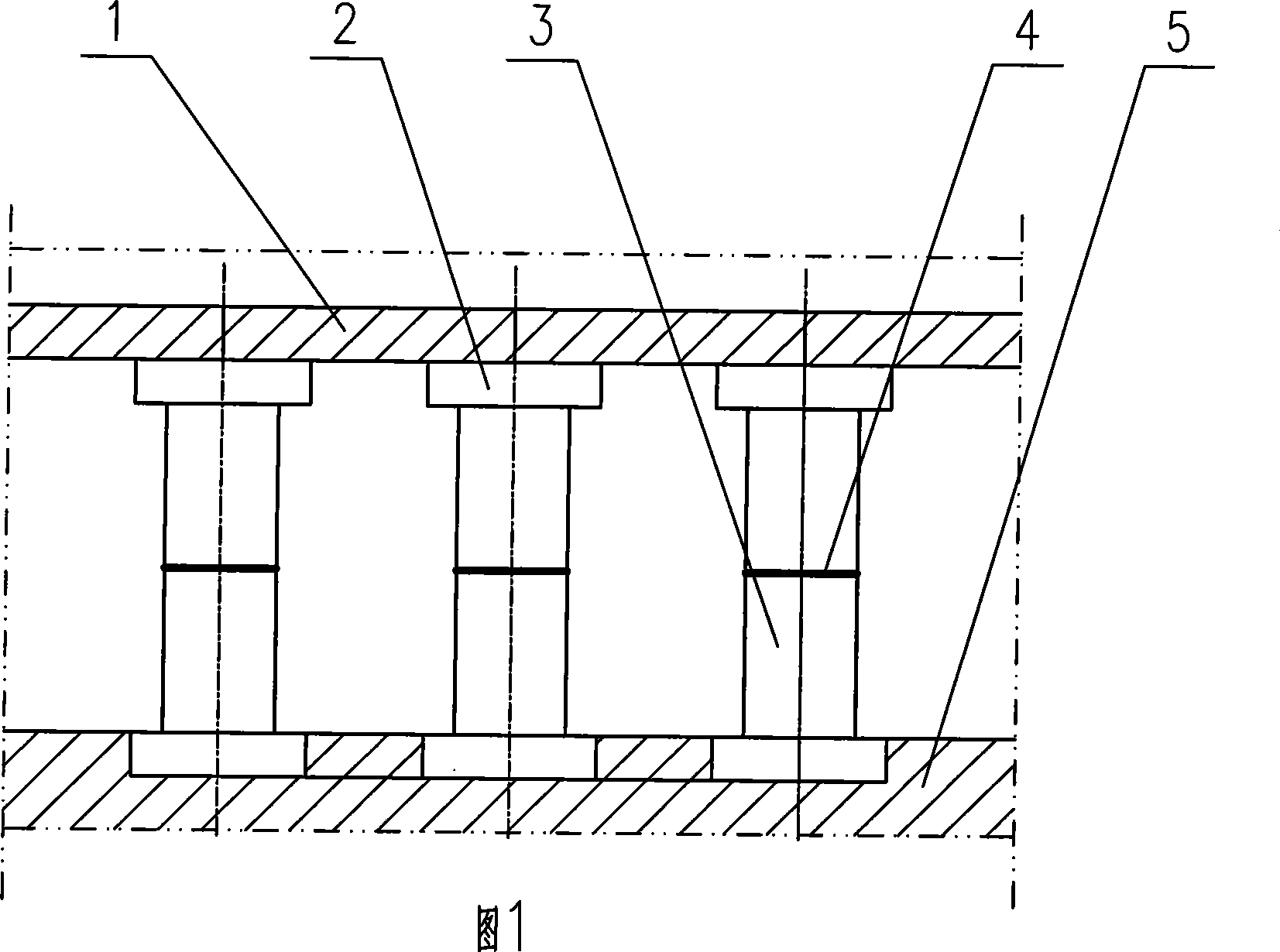

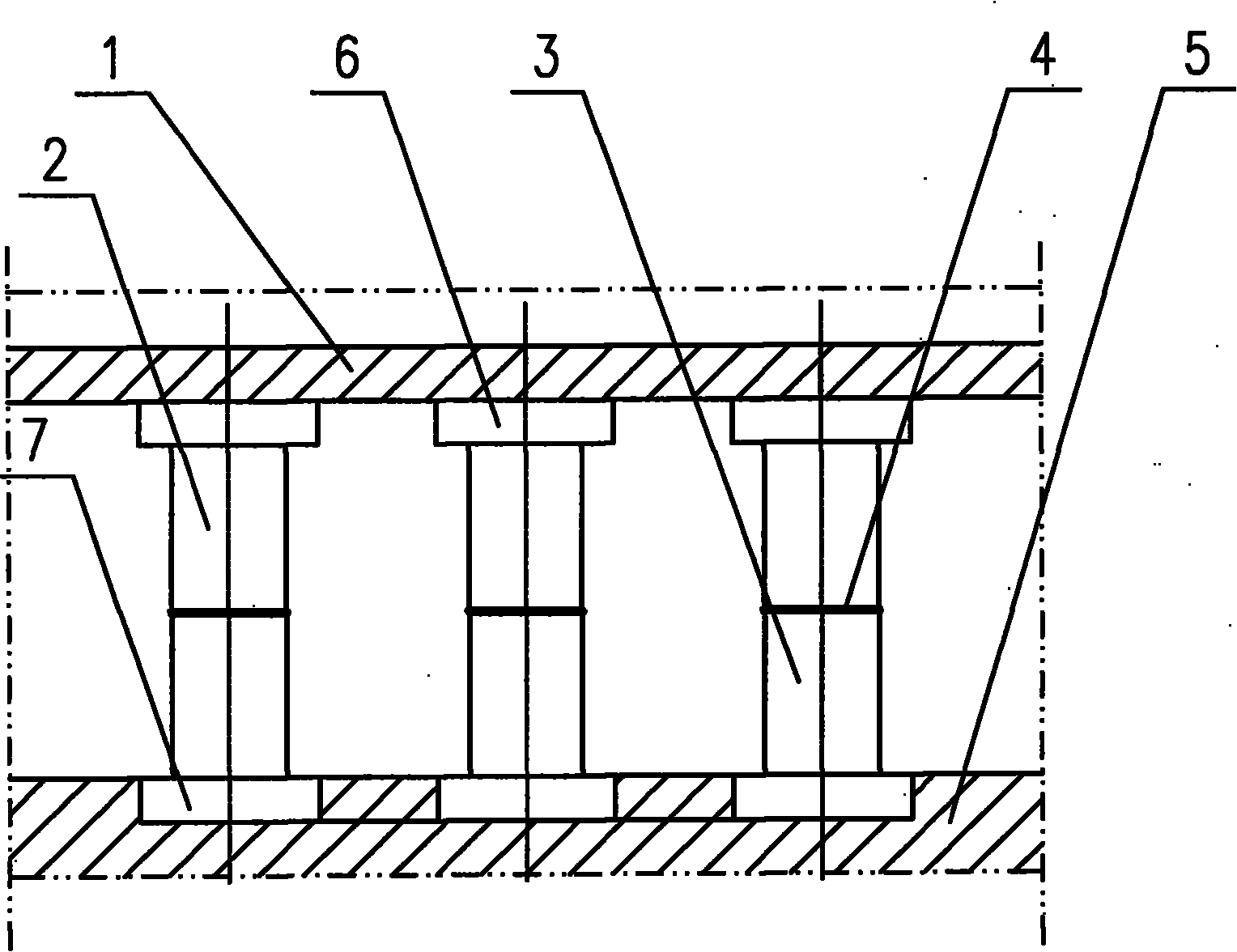

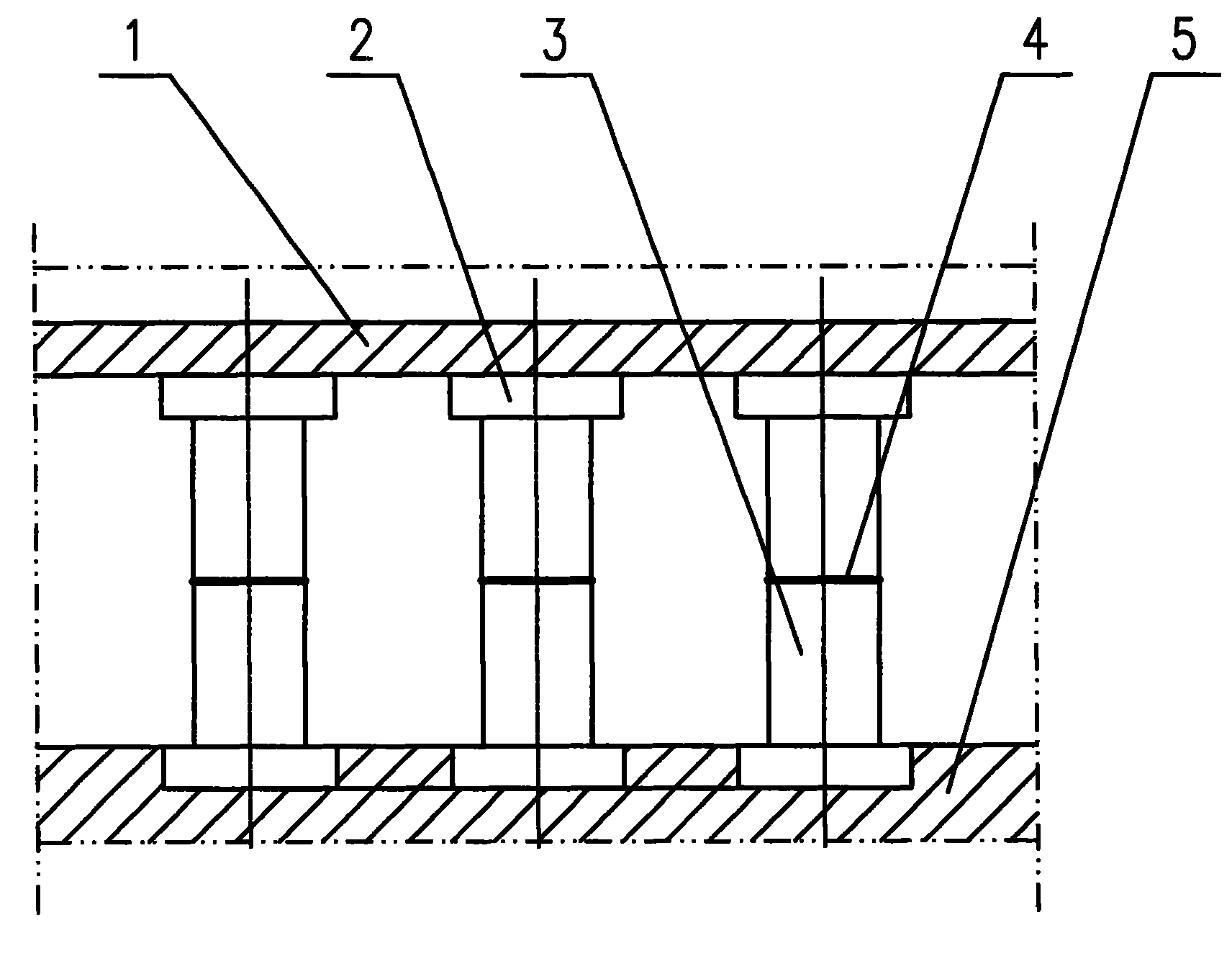

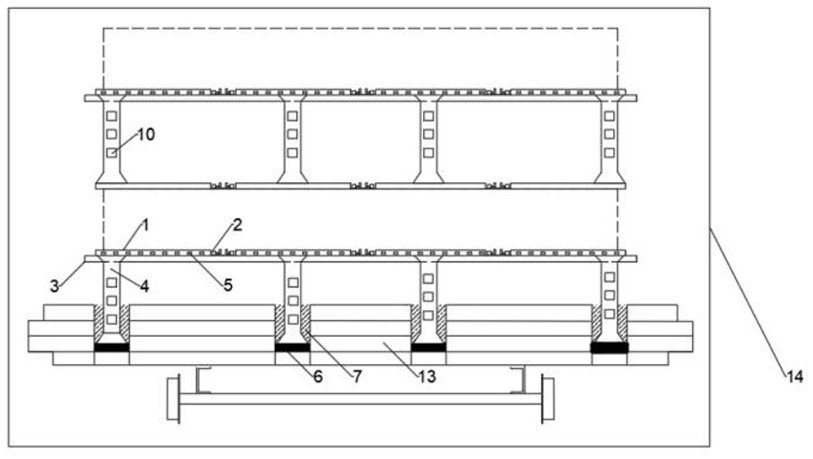

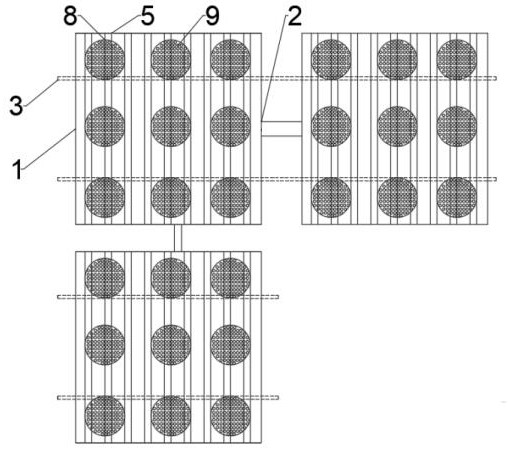

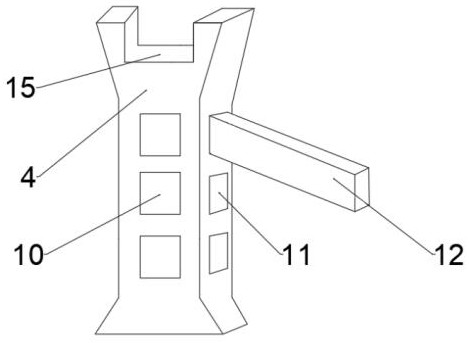

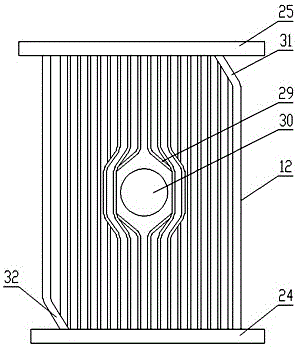

Kiln furniture structure with height-adjustable shelf board

PendingCN114739167AReduce weightSmall heat storageFurnace typesCeramic materials productionTunnel kilnFire brick

The kiln furniture structure comprises a plurality of layers of shed plates arranged in a kiln car and a shed plate supporting structure arranged below the shed plates, the shed plate supporting structure comprises stand columns and cross beams, and refractory bricks are arranged at the bottom of the kiln car. The bottoms of the stand columns of the shed plate supporting structure located below the lowermost shed plate in the multiple layers of shed plates are inserted into the refractory bricks and filled with energy-saving sand and high-purity blankets. U-shaped grooves are formed in the tops of the stand columns, a set of cross beam holes penetrating through the stand columns are formed in the front faces of the stand columns in the axial direction of the stand columns, the cross beams are arranged in the U-shaped grooves or the cross beam holes of the stand columns, the shed plates are arranged on the cross beams, and the shed plates on the same layer are connected through shed plate connectors. According to the tunnel kiln, the weight of kiln furniture is greatly reduced by fully utilizing the light weight of the shed plates, the stand columns and the cross beams, and one tunnel kiln uses more kiln furniture, so that the heat storage capacity of the kiln furniture is greatly reduced.

Owner:ZHEJIANG UNIV OF TECH

Novel microcrystalline arc plate mould

InactiveCN102848453AReduce manufacturing costImprove application efficiencyMouldsCordieritesEnergy conservation

The invention relates to a novel microcrystalline arc plate mould which mainly comprises ceramic bolts, ceramic fasteners, ceramic bars, cordierite-mullite casing plates, cordierite-mullite holders, cordierite-mullite pillars and the like. The novel microcrystalline arc plate mould is made once and durable. Radian, height, length and the like of the novel microcrystalline arc plate mould can be adjusted optionally. The novel microcrystalline arc plate mould is low in manufacturing cost, low in heat storage capacity, effective in energy conservation, accurate in size with optionally regulated radian and high in production efficiency, the cost of the novel microcrystalline arc plate mould is lowered, and the production cost of microcrystalline arc plates is lowered greatly.

Owner:淄博钰晶新型材料科技有限公司 +1

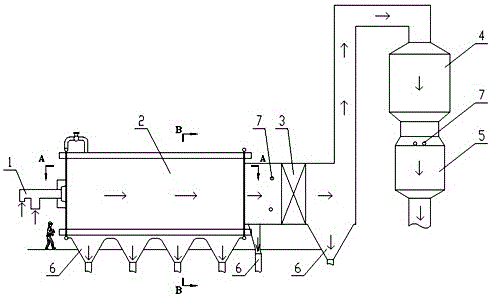

Forced circulation coal powder burning water heating boiler

InactiveCN106765293AImprove sealingHigh thermal efficiencyWater heatersCasings/liningsCombustorEngineering

A forced circulation coal powder burning water heating boiler comprises a boiler body, a mixing header and a combustor arranged at one end of the boiler body. The forced circulation coal powder burning water heating boiler is characterized in that the boiler body comprises a hearth, a water outlet header, a connecting pipe system connecting the hearth and the water outlet header, and a boiler wall; the hearth is defined by a hearth front wall, a hearth rear wall, a hearth left boiler wall, a hearth right boiler wall, a hearth top boiler wall and a hearth bottom boiler wall; the hearth left boiler wall and the hearth top boiler wall form a hearth left wall, and the hearth right boiler wall and the hearth bottom boiler wall form a hearth right wall; the hearth left wall and the hearth right wall are each an integral membrane type water wall heating surface formed by parallelly arranging a plurality of bent L-shaped smooth pipes and welding the adjacent L-shaped smooth pipes together through flat steel; the hearth left wall and the hearth right wall are oppositely arranged and welded to a hearth upper right header and a hearth lower left header to form a frame structure; and the hearth upper right header and the hearth lower left header communicate with the smooth pipes of the hearth left wall and the hearth right wall to form a water circulation channel.

Owner:TAISHAN GROUP

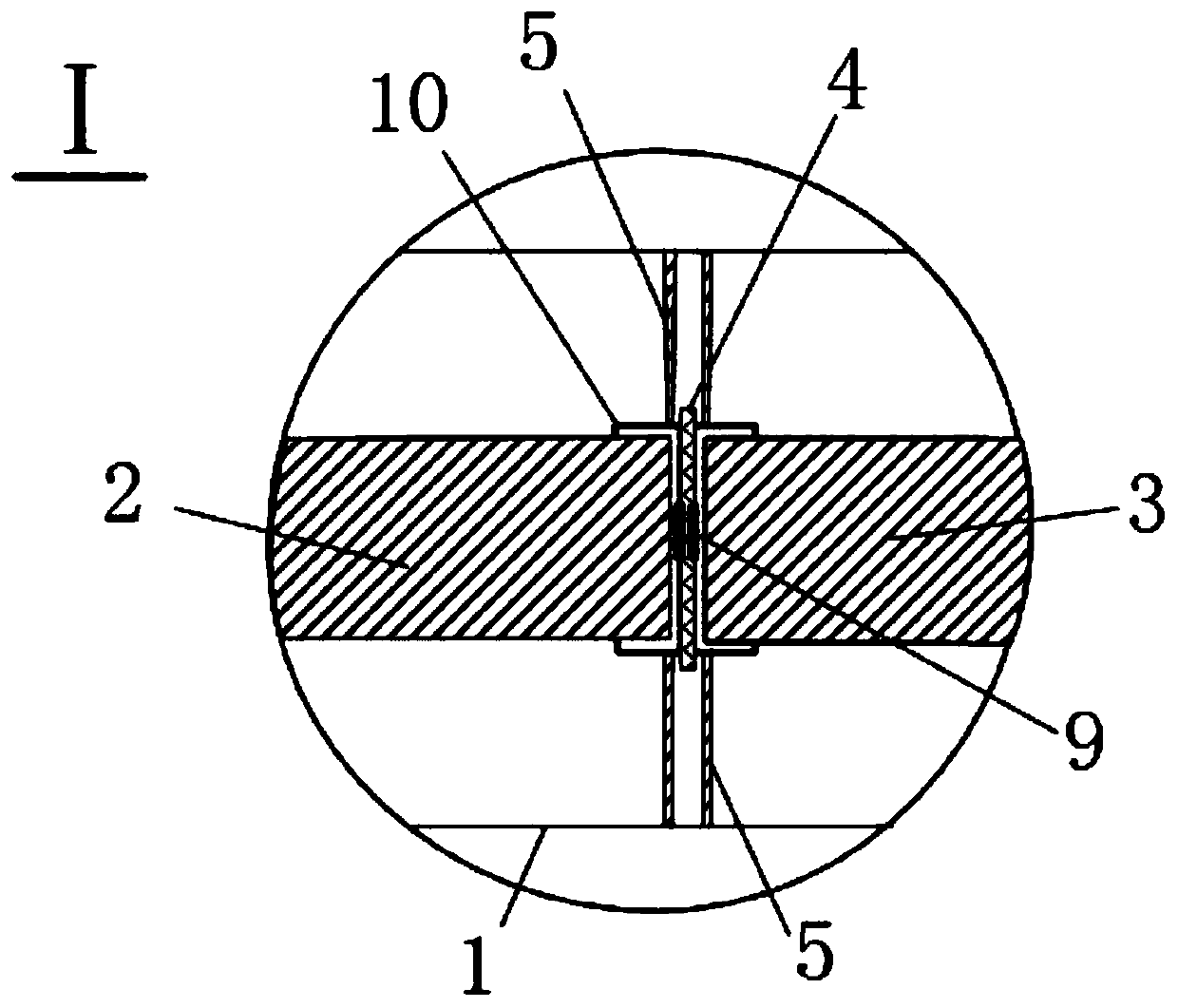

A high-efficiency and high-precision natural convection heat release coefficient measurement experimental device

ActiveCN107064209BGuaranteed calorific valueReduce axial heat lossMaterial heat developmentThin film thermocouplesEngineering

The invention provides a high-efficiency and high-precision measurement experimental device for a natural convection heat transfer coefficient. The device comprises a unit-pipe pipe wall, a primary heating rod, an auxiliary heating rod, an insulating sheet, a heat-insulation jacket, heat-isolation end covers, a film thermocouple, terminal sleeves, an A / D (Analog / Digital) converter, a computer, a control box and a bracket. The insulating sheet is inserted between the primary and auxiliary heating rods of the device to form close connection; pipe cavities at an effective experimental section and an auxiliary experimental section which are corresponding to the primary and auxiliary heating rods respectively are spaced by using the annular heat-insulation jacket; the temperatures of the adjacent terminal sleeves of the primary and auxiliary heating rods are controlled to be the same through regulating the current and the voltage of the auxiliary heating rod, so as to reduce the axial heat loss of the primary heating rod; the internal surface silvered heat-isolation end covers are sleeved at each unit-pipe port; high-temperature-resistant heat-isolation foam mats are filled in gaps among the heat-isolation end covers and unit pipes, so as to reduce the heat loss due to radiation at an auxiliary-section port; the external surfaces of the unit pipes are slivered, and the internal surfaces of the unit pipes are plated with high-radiance materials, so as to shorten an experimental time. The measurement problem of the natural convection heat transfer coefficient is solved highly efficiently and highly precisely.

Owner:XIANGTAN UNIV

An electric heat preservation and decoration integrated wall and floor tile and its preparation method

ActiveCN109053136BSmall heat storageIncrease the indoor heating rateCovering/liningsCeramic shaping apparatusBrickInsulation layer

The invention discloses an electric heat preservation and decoration integrated wall and floor tile and a preparation method thereof. It is a combination of brick base layer mixture (components: clay, quartz, feldspar and pigment), non-metallic conductive layer mixture (components: carbonaceous materials, clay, iron raw materials and feldspar) and foamed ceramic insulation. The layer mixture (components: solid waste, feldspar, clay and foaming agent) is sequentially distributed, pressed by a press to form a green body, and the green body is fired at a high temperature in a kiln after drying. The floor tile has the advantages of small heat loss, electric heating efficiency up to 99%, and simple construction, which can reduce construction and use costs to a certain extent.

Owner:山东晟世达科技有限公司

A control device and method for valley power application based on phase change energy storage

ActiveCN112665007BReduce consumptionReduce heating costs in winterLighting and heating apparatusElectric heating systemFiberPower application

Owner:BEIJING FINE & CLEAN ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com