Microwave synthesis method of Si-Mn-N alloy

A silicon-manganese nitride alloy and microwave synthesis technology is applied in the field of high-temperature synthesis of silicon-manganese nitride alloy, which can solve the problems of low production efficiency, high smelting power consumption, long nitriding time, etc., so as to improve the operation rate and save water resources. , the effect of low heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

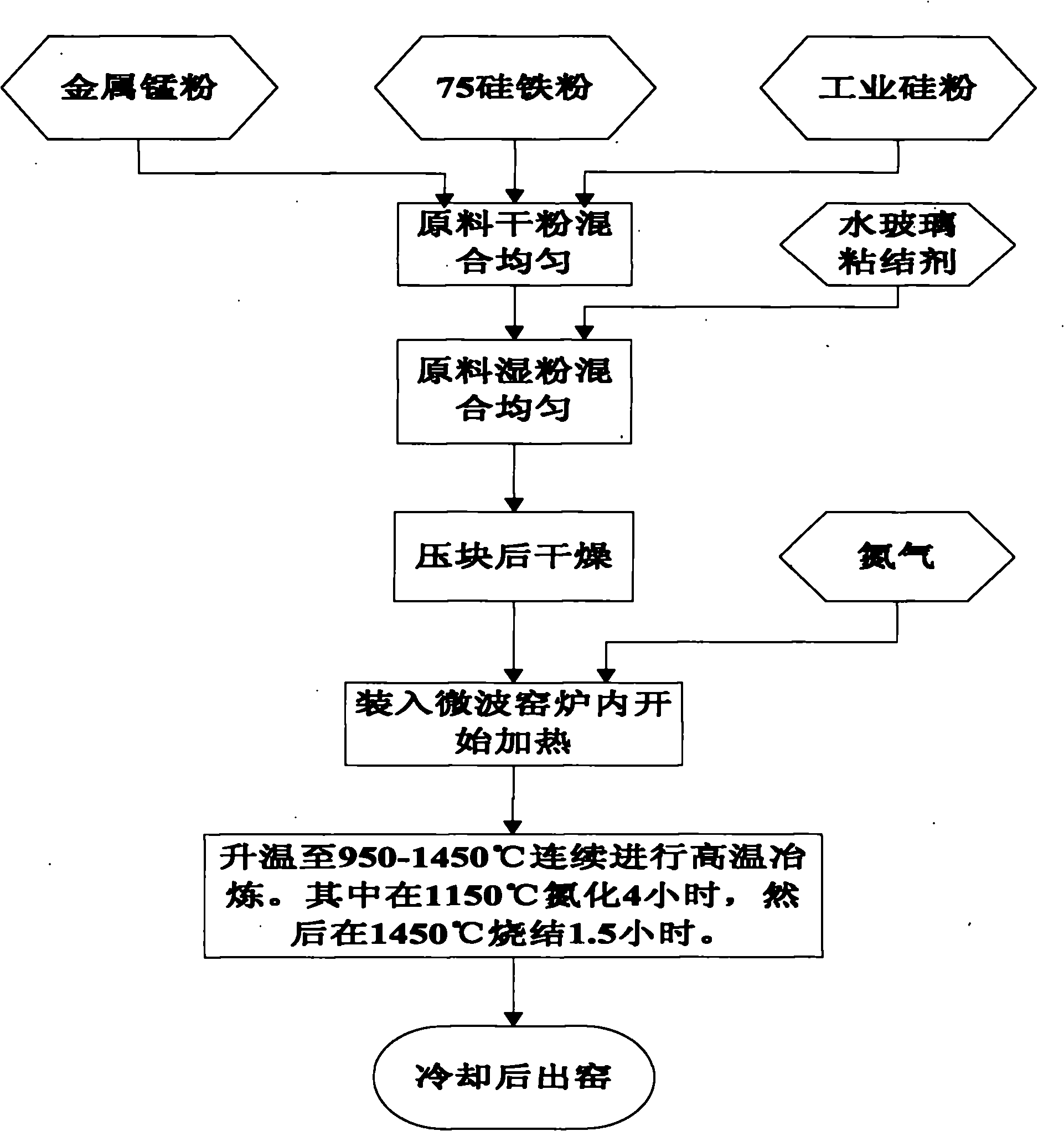

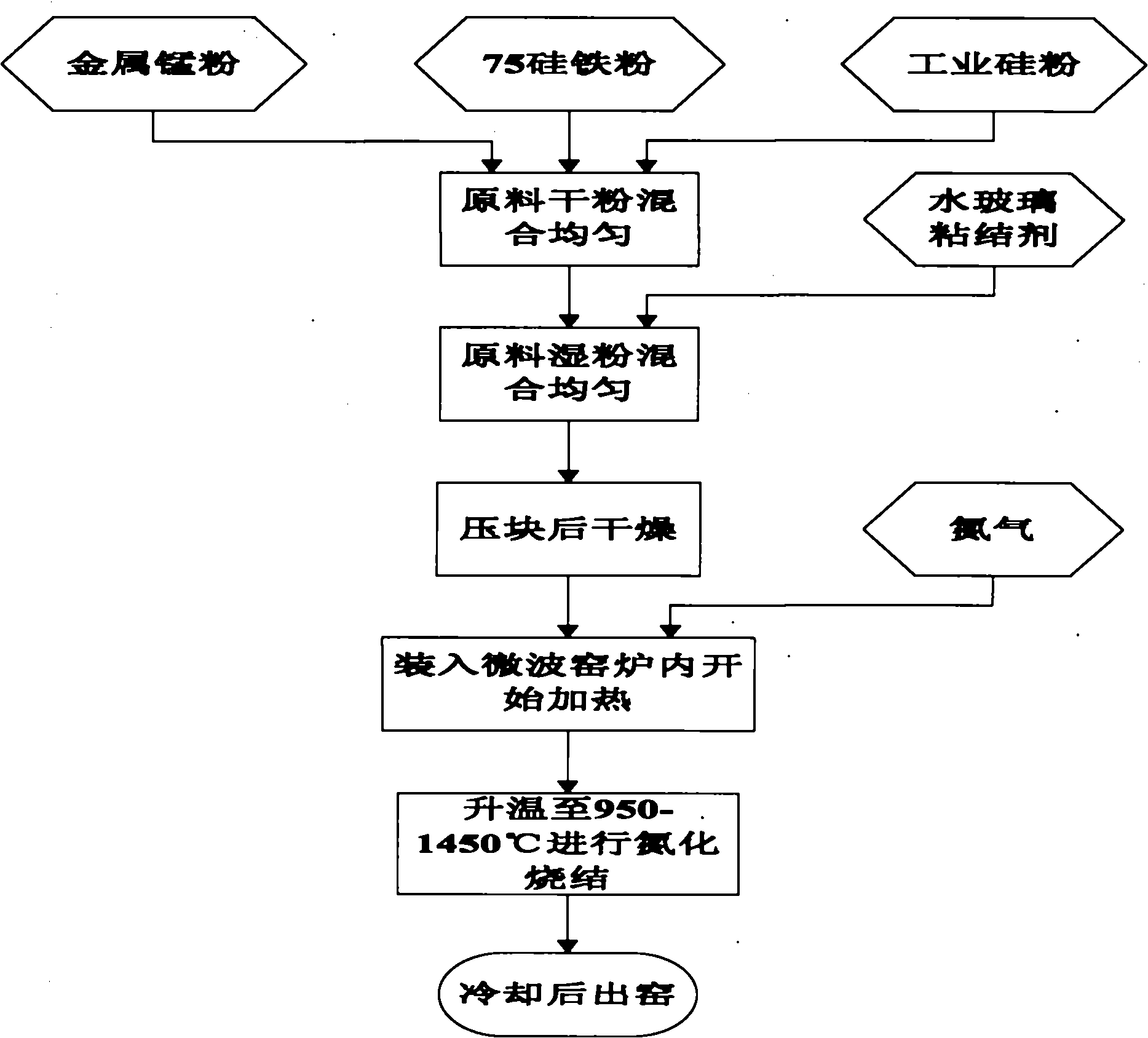

[0016] As can be seen from the accompanying drawings, the microwave synthesis method of silicon-manganese nitride alloy of the present invention is characterized in that 2.45 GHz microwave is used as heat source, with ferrosilicon, metal manganese, industrial silicon as raw materials, according to the mass of dry material, its raw material mass parts The sum is 100, wherein, 74 parts of ferrosilicon with a silicon content of 75-77% and a particle size of ≤80 mesh, 19 parts of manganese with a manganese content of 99.7% and a particle size of ≤80 mesh, and 7 parts of industrial silicon with a silicon content of 99.8% and a particle size of ≤80 mesh, the aforementioned After the raw materials are dry-mixed evenly, add 2 to 3% water glass solution of the total mass of the aforementioned total raw materials as a binder for wet mixing, press the wet-mixed uniform raw materials into a block of 100mm×230mm×100mm, and then The material block is placed on the feeding car and sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com