Ocean platform wall thickness gradient casting joint and preparation method thereof

An offshore platform and node technology, applied in the field of offshore platform equipment, can solve problems such as high stress of welded joints, endangering platform safety, node damage, etc., and achieves uniform shrinkage stress, stable filling process, and favorable effects of slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

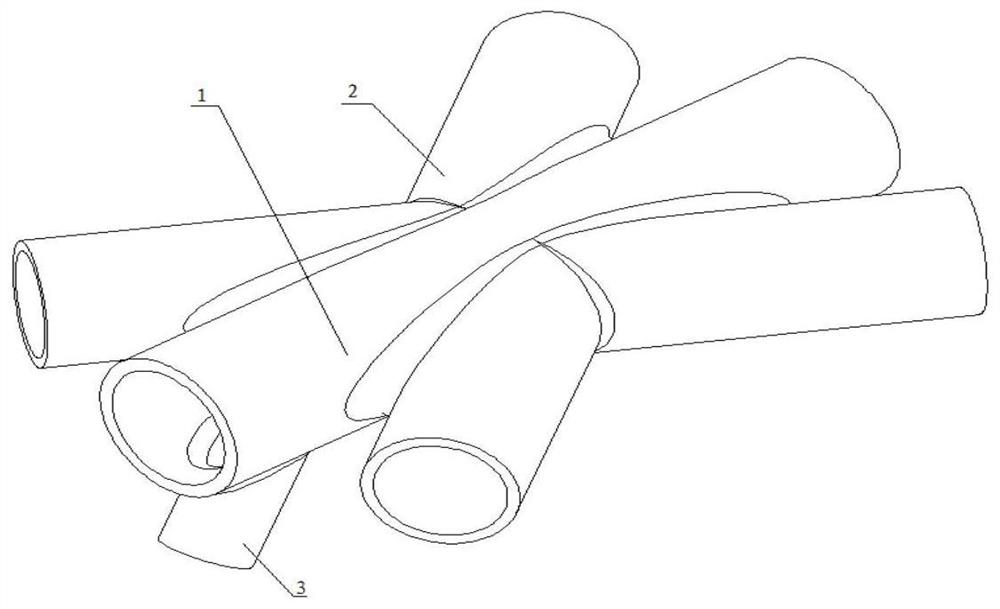

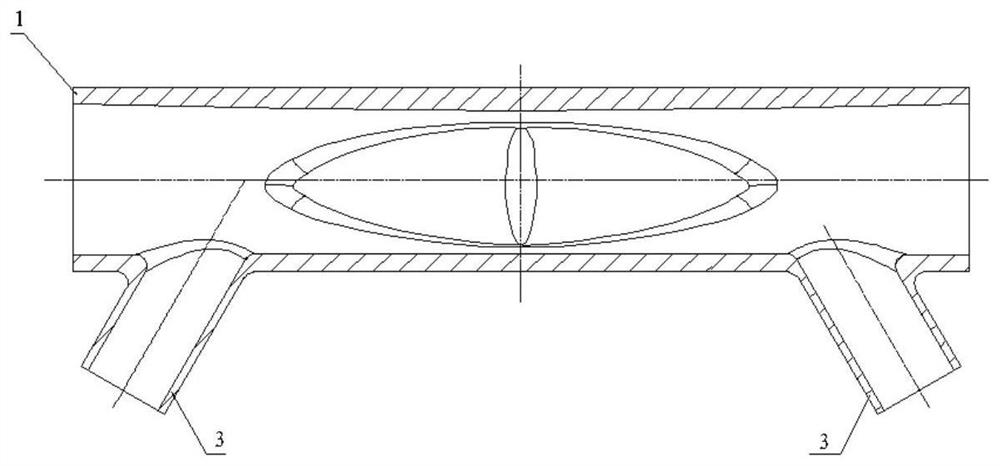

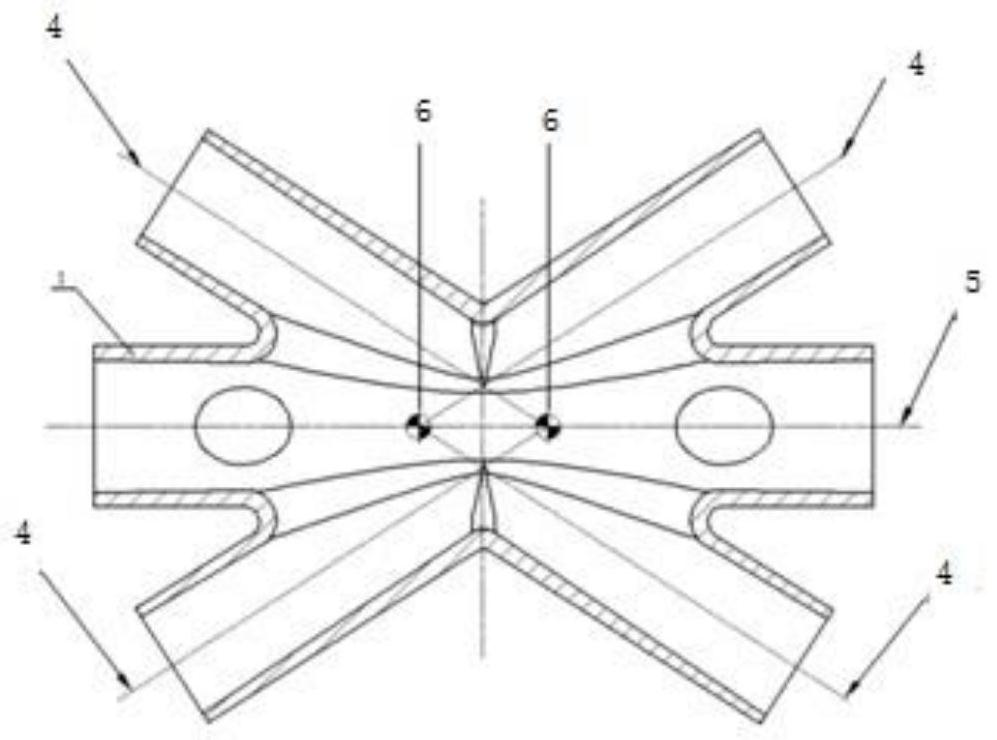

[0022] A casting node with gradual wall thickness on an offshore platform, comprising a main body for connecting steel structure pipes, the main body is a cast steel node cast integrally, the main body includes a main body for connecting steel structure pipe fittings, and the main body is integral Cast steel, the main body includes a central connecting pipe, 2 inclined pipes, and 2 bottom pipes; the connecting ends of the central connecting pipe, inclined pipes and bottom pipes are intersected in one place to form a node core area, and all connecting pipes The central axis of the joint intersects at two center points in the core area of the node, and the distance between the two center points is 250mm, and a circular arc transition is set between the inner and outer wall surfaces of two adjacent connecting pipes. The new casting node with gradual wall thickness has a gradual wall thickness at the upper part and a uniform wall thickness at the lower part; the minimum wall thic...

Embodiment 2

[0024] A casting node with gradual wall thickness on an offshore platform, comprising a main body for connecting steel structure pipes, the main body is a cast steel node cast integrally, the main body includes a main body for connecting steel structure pipe fittings, and the main body is integral Cast steel, the main body includes a central connecting pipe, 2 inclined pipes, and 2 bottom pipes; the connecting ends of the central connecting pipe, inclined pipes and bottom pipes are intersected in one place to form a node core area, and all connecting pipes The central axis of the joint intersects at two center points in the core area of the node, and the distance between the two center points is 300mm, and a circular arc transition is set between the inner and outer wall surfaces of two adjacent connecting pipes.

[0025] The new casting node with gradual wall thickness has a gradual wall thickness at the upper part and a uniform wall thickness at the lower part; the minimum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com