Vacuum flat plate heat collector and manufacturing method and equipment thereof

A flat plate heat collector and a manufacturing method technology, which are applied to solar heat collectors, lighting and heating equipment, solar heat collectors using working fluid, etc. Without application and other problems, to achieve the effect of good thermal insulation effect, less medium and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

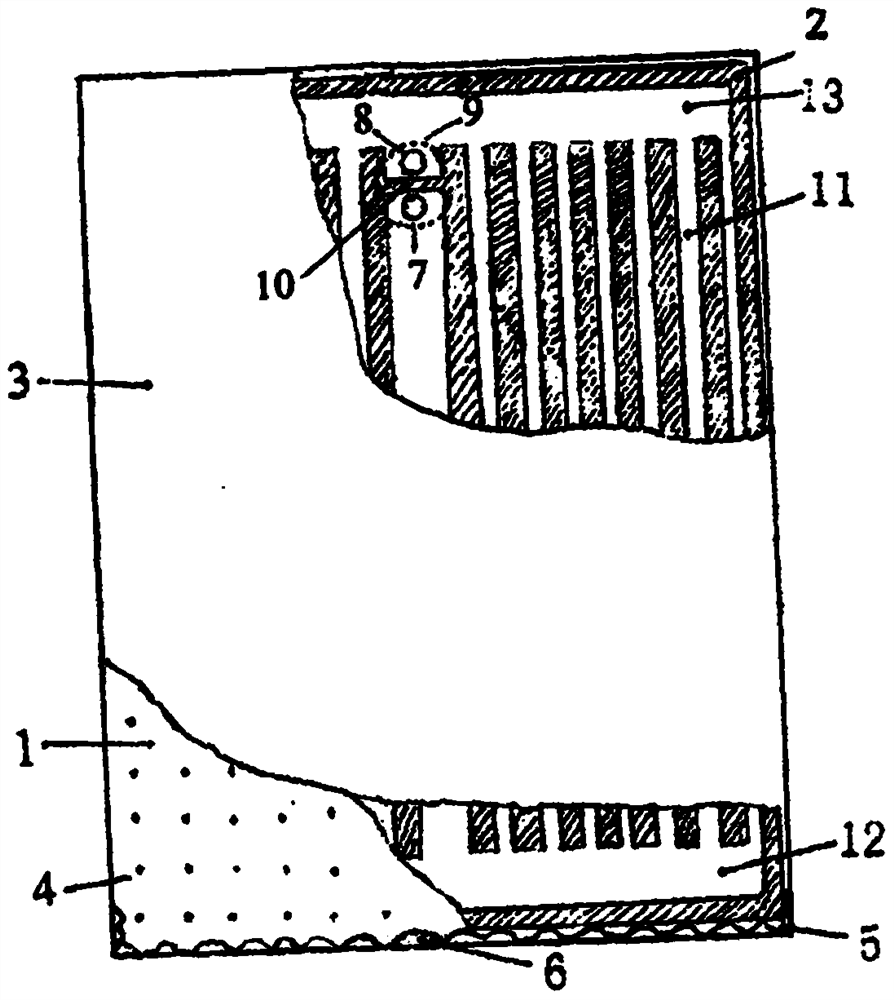

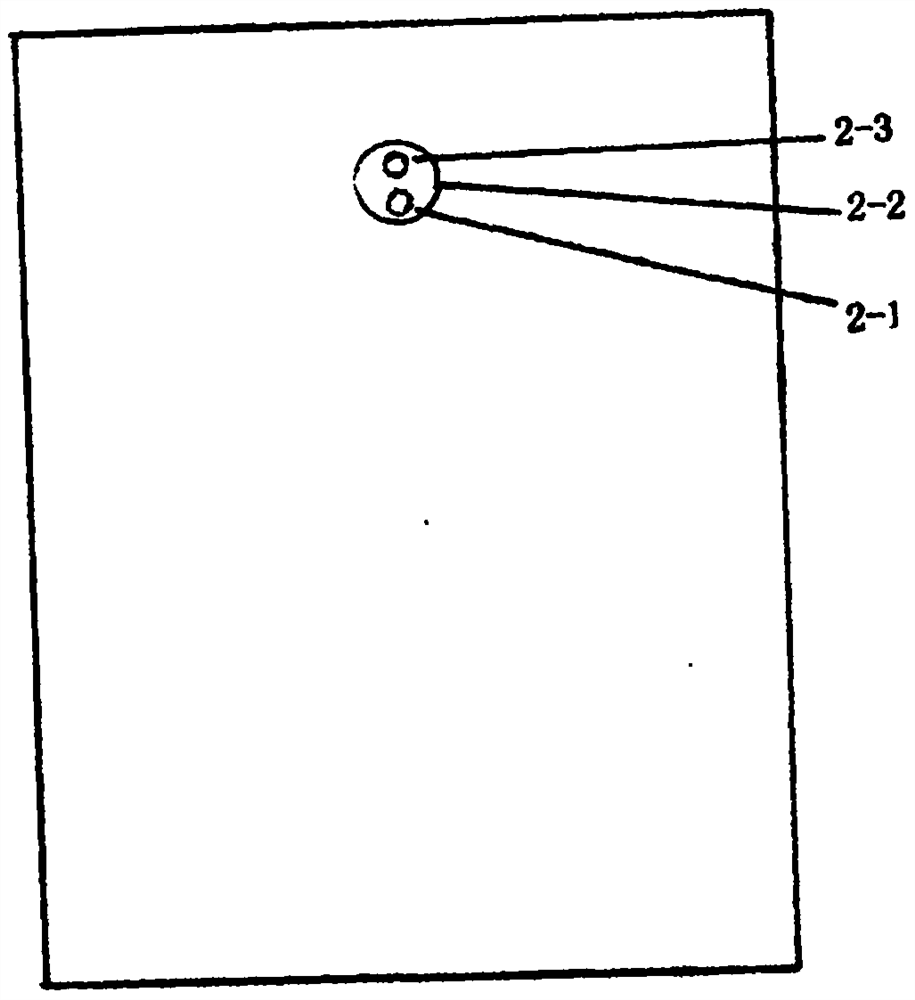

[0029] Embodiment 1, the support column is attached to the inside of the glass panel and the glass back panel; figure 1 with attached figure 2To illustrate: Cool down the hot molten glass liquid flowing out of the furnace into the calender to form the calendered glass. The calendered glass is made on the surface of a roller of the calender, and a small hole is punched at an interval of 14--25 mm horizontally and vertically. , the glass pressed into the small hole becomes the dot-shaped protrusion on the surface of the flat glass, that is, the support column 4; the flat glass extruded from the calender enters the cutting machine along the conveyor belt, and becomes the glass panel 1 after being cut; The glass backboard 3 is formed by pressing the pipe hole 2-2 on the center line of the glass panel extruded by another calender to become the glass backboard 3; the heat-absorbing plate core 2 is an inflatable metal plate core, The production of the vacuum flat plate heat collect...

Embodiment approach 2

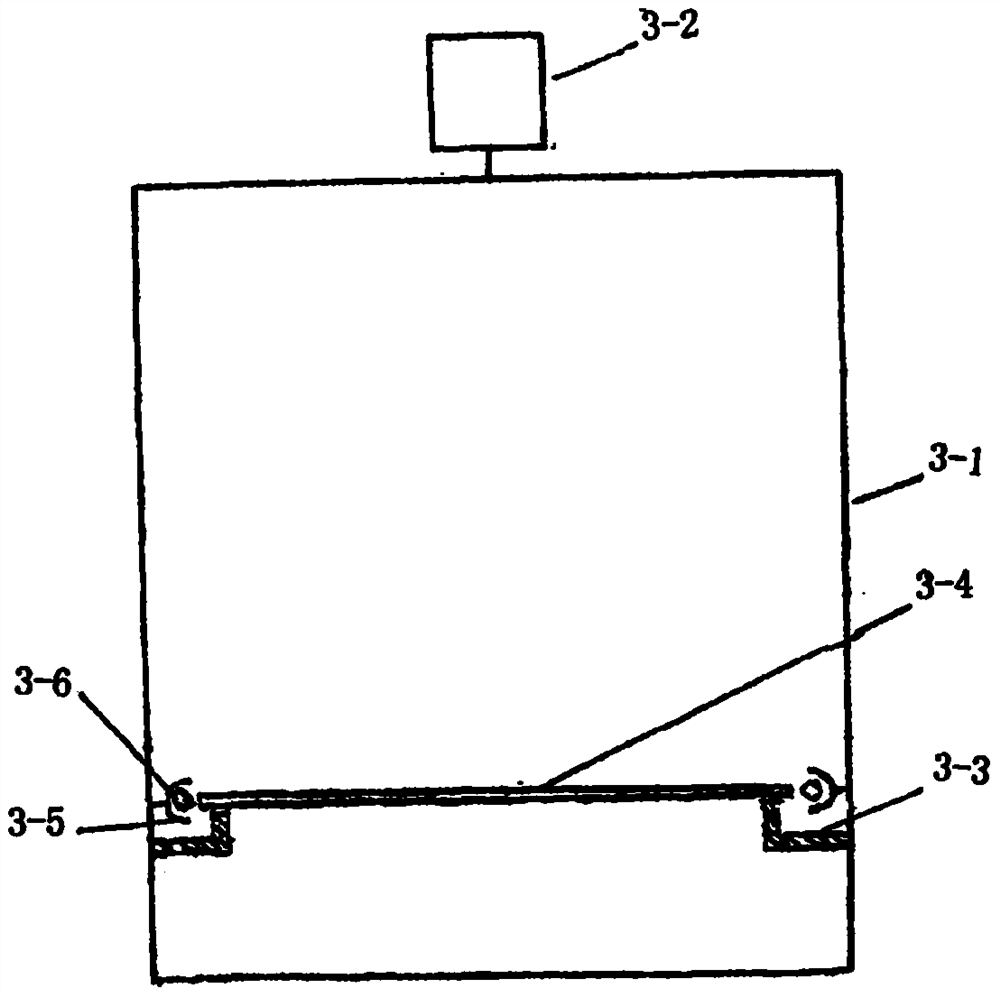

[0030] Embodiment 2: The support column is attached to the surface of the heat-absorbing plate core; figure 1 and Figure 5 To illustrate, the vacuum flat plate heat collector is composed of a vacuum glass box and a heat-absorbing plate core, and the vacuum glass box is composed of a glass panel 1 and a glass back panel 3, and the glass panel 1 and the glass back panel 3 have two sides Smooth flat glass, the flat glass is borosilicate flat glass that has been physically tempered or chemically tempered; in the middle of the two pieces of flat glass is a heat-absorbing plate core, and the heat-absorbing plate core is formed by a crimping belt 5-2 It consists of two parts, the medium flow channel, the medium flow channel includes the vertical flow channel 5-3, the lower branch flow channel 5-4 and the upper confluence horizontal channel 5-5; All have outward point-like protrusions, these point-like protrusions are the support columns 5-9 of the vacuum space, and there is a horiz...

Embodiment approach 3

[0041] Embodiment three, the support column is a glass bead; figure 1 and Figure 4 To illustrate, both the glass panel 1 and the glass back plate 3 are flat glass with smooth sides, and in the middle of the two sheets of flat glass is a heat-absorbing plate core 4-1, the heat-absorbing plate core is an inflation type, absorbing heat The board core is divided into two parts, the crimping belt 4-2 and the medium flow channel. The medium flow channel includes the vertical flow channel 4-3, the distribution channel 4-4 at the lower end of the vertical channel, and the confluence channel 4-5 at the upper end. There is an isolation belt 4-10 under the center of the confluence crossway 4-5, and all the crimping belts are evenly punched with round holes, and glass beads are arranged in the round holes, and the glass beads are the upper and lower flat glass. The vacuum support column 4-9 between; Use glass bead as support column, glass panel and glass back plate are just flat glass, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com