Patents

Literature

49results about How to "Reduce medium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

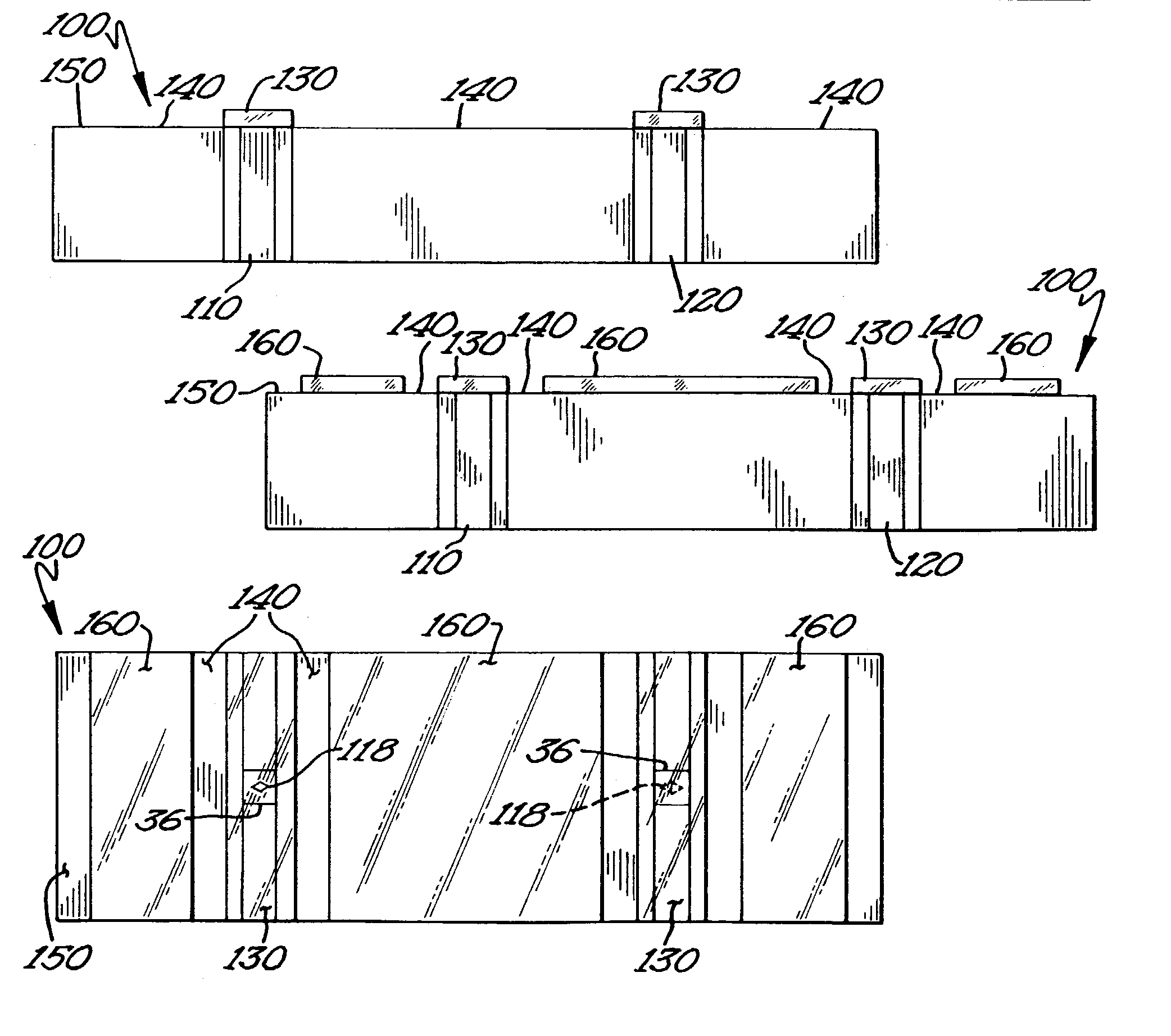

Wear pads for timing-based surface film servo heads

InactiveUS6989960B2Avoid negative effectsQuick wearElectrical transducersManufacture head surfaceEngineeringBearing surface

A thin film magnetic recording head is provided with a tape bearing surface that has magnetically isolated channels while still providing a maximum continuous surface area with which to engage the media. This can be accomplished by providing spaces in the magnetically permeable thin film that are large enough to prevent cross-talk between the channels, but small enough to prevent significant interference with the moving media. Alternatively, magnetically impermeable thin film spacers can be provided to magnetically isolate each of the channels. The spacers are generally even with the magnetically permeable thin film so as to provide a continuous media-bearing surface.

Owner:ADVANCED RES

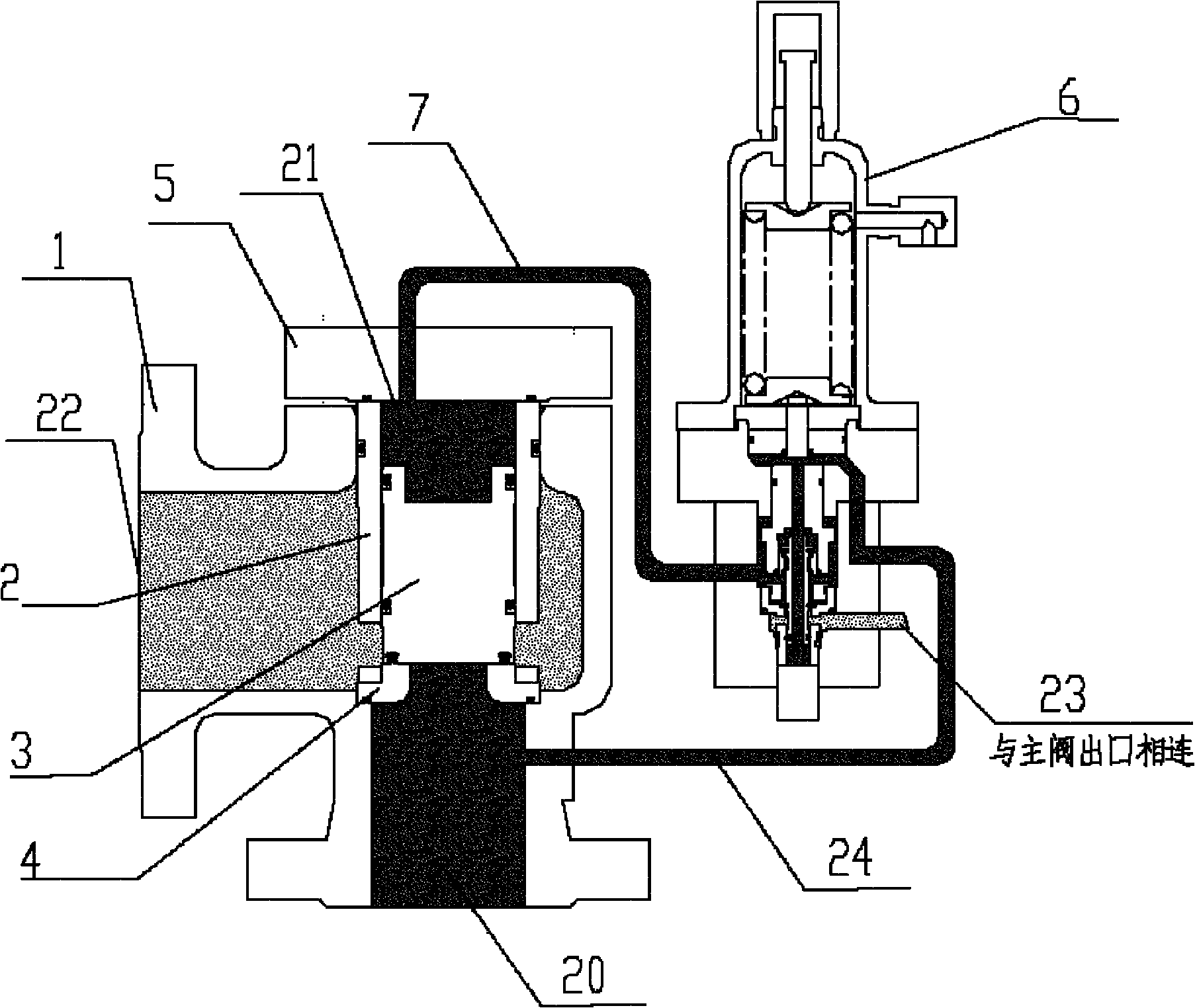

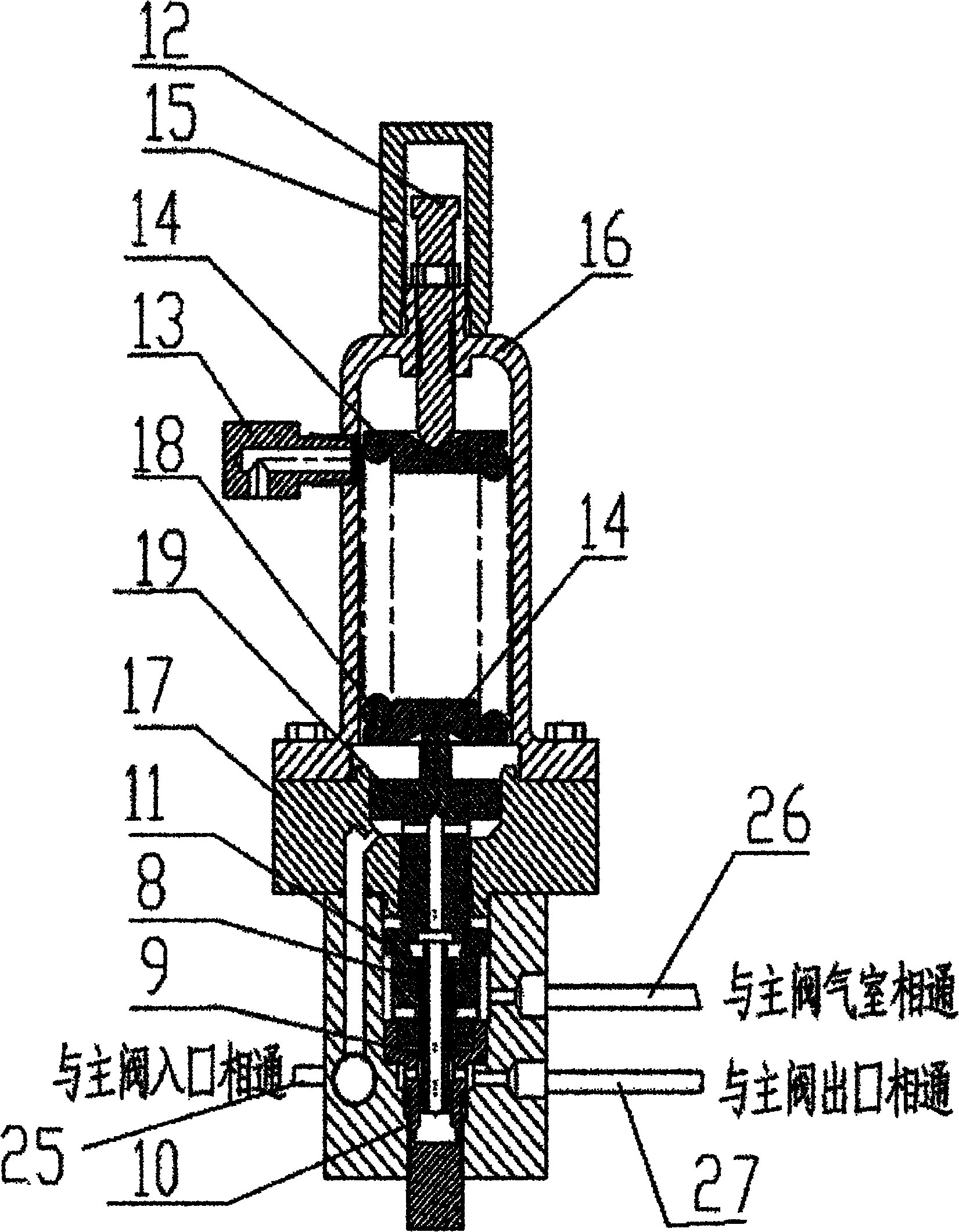

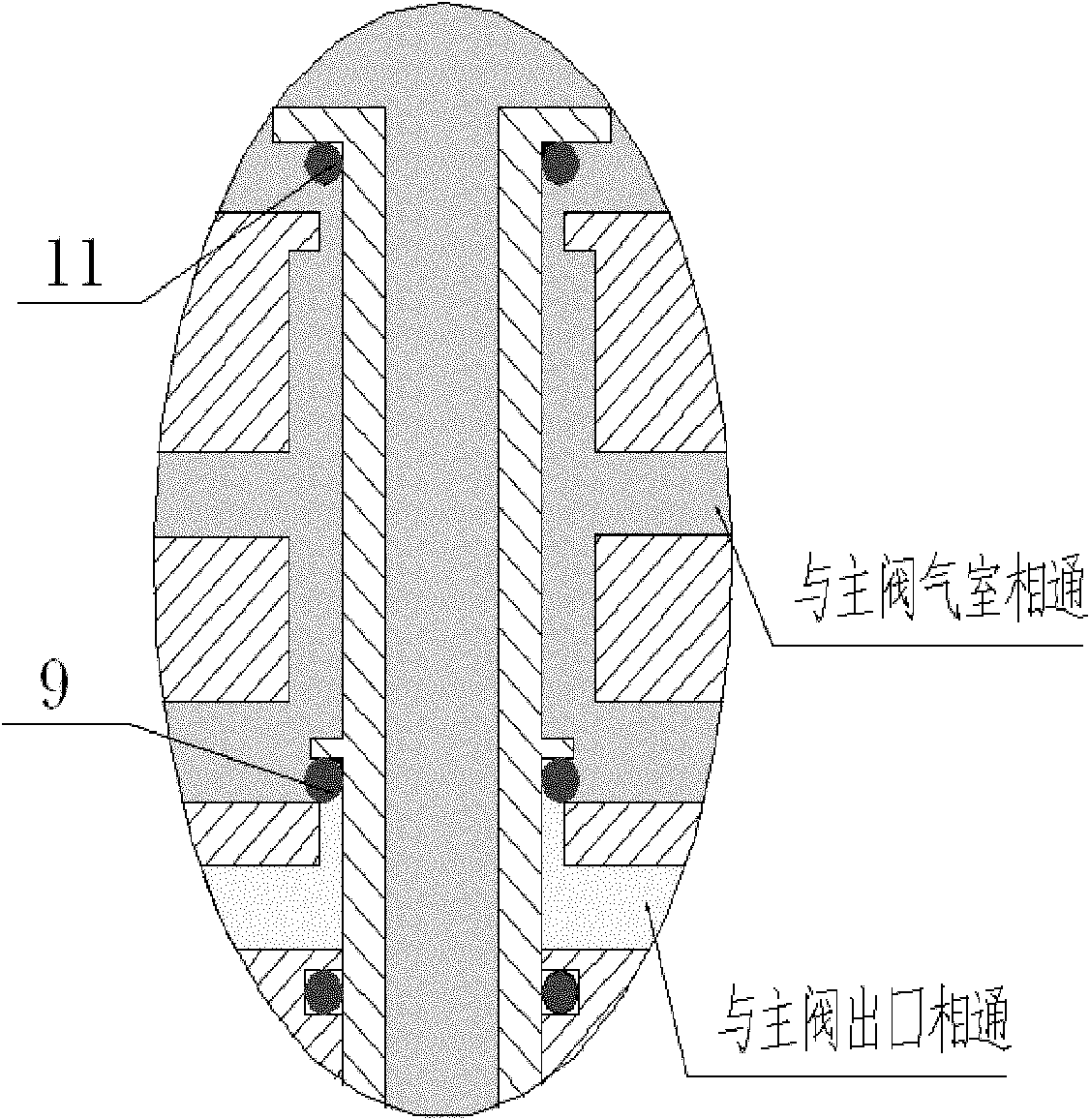

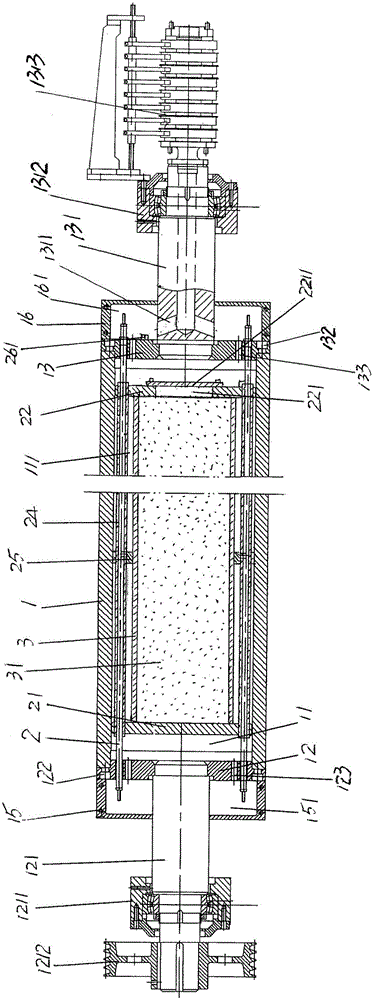

Pilot-operated safety valve with modulation characteristic

ActiveCN101963251AWith modulating propertiesChange the circulation areaEqualizing valvesSafety valvesSafety valvePiston

The invention provides a pilot-operated safety valve with modulation characteristic, which comprises a main valve and a modulation type guide valve, wherein a valve seat of the modulation type guide valve is fixed in the lower part of a cavity of a guide valve body; a guide valve piston is arranged above the cavity in the guide valve body and the valve seat of the guide valve; the middle upper part of a guide valve shaft is installed in the guide valve piston, and the lower part thereof is arranged in the valve seat of the guide valve; the connecting part between the upper part of the guide valve shaft and the guide valve piston is provided with an inlet sealing ring; and the connecting part between the lower part of the guide valve shaft and the valve seat of the guide valve is provided with an outlet sealing ring. The pilot-operated safety valve can be used for effectively controlling the pressure of an air chamber of the main valve, leads the pressure of the air chamber to be slowly reduced along with the augment of overpressure value, and ensures the opening height of the main valve to be gradually changed along with the overpressure value, thus guaranteeing the circulation area to be changed along with the demand of release quantity; and the discharge capacity can be adjusted according to the actual demand of the system for overpressure protection.

Owner:BEIJING AEROSPACE PROPULSION INST +1

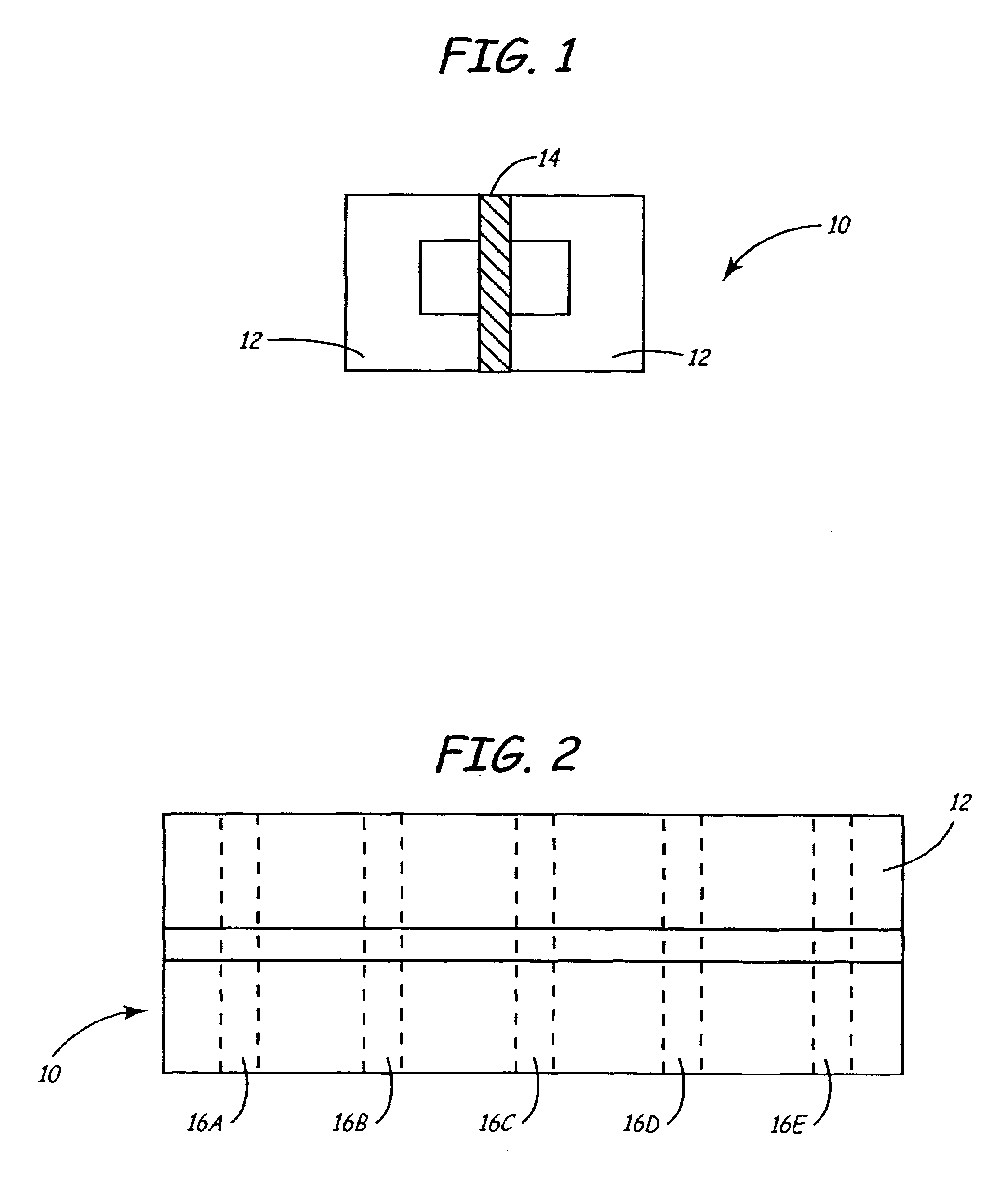

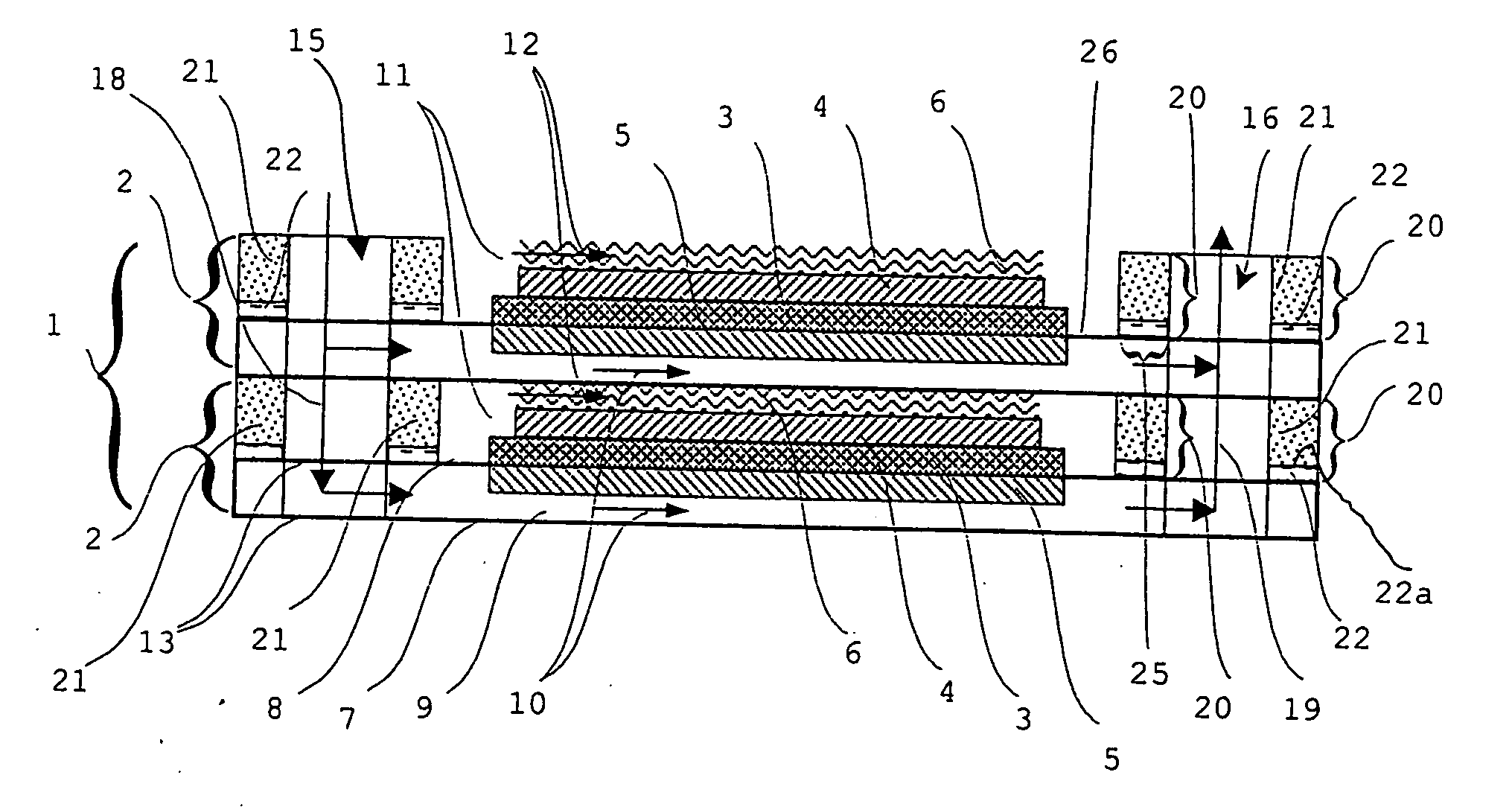

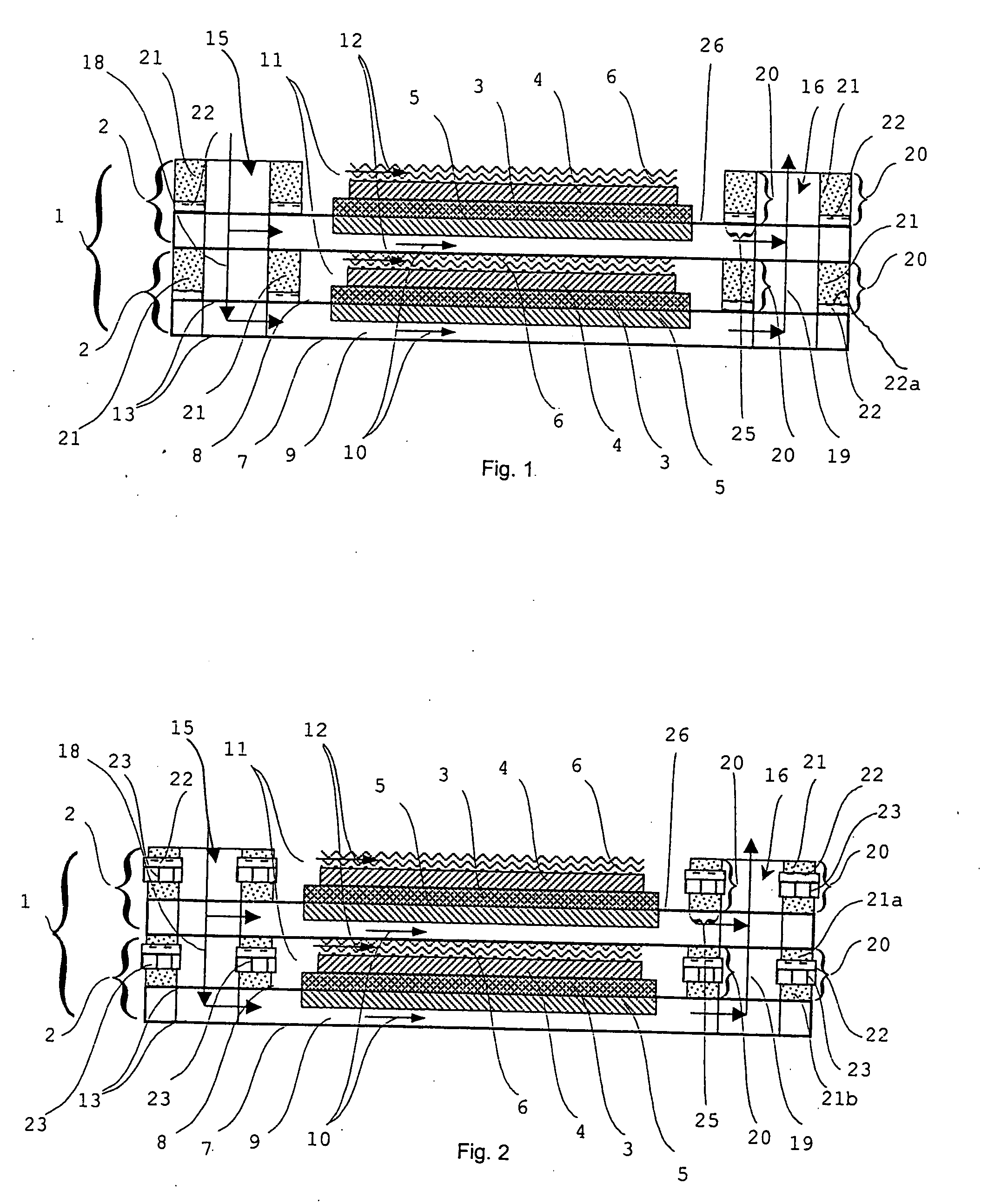

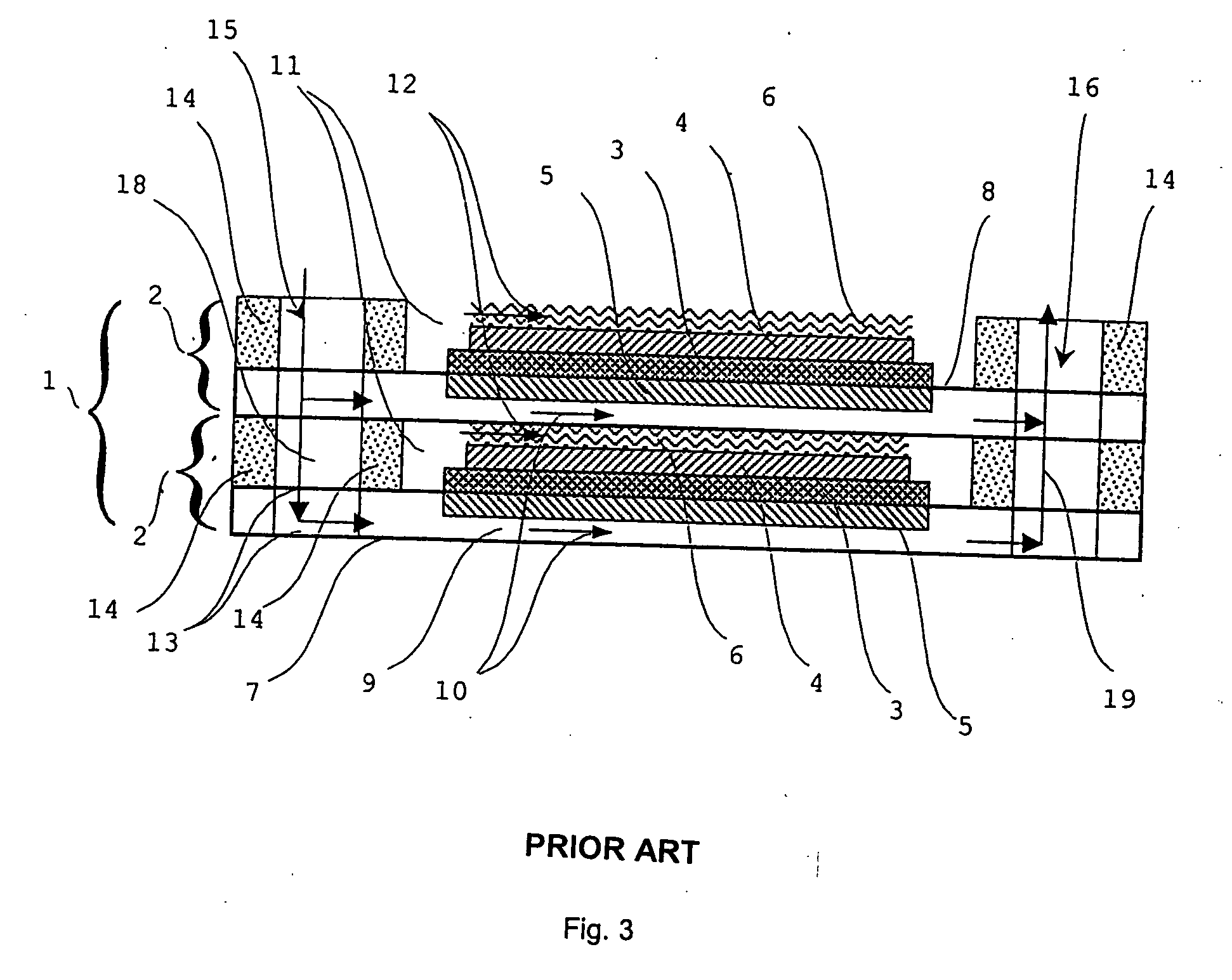

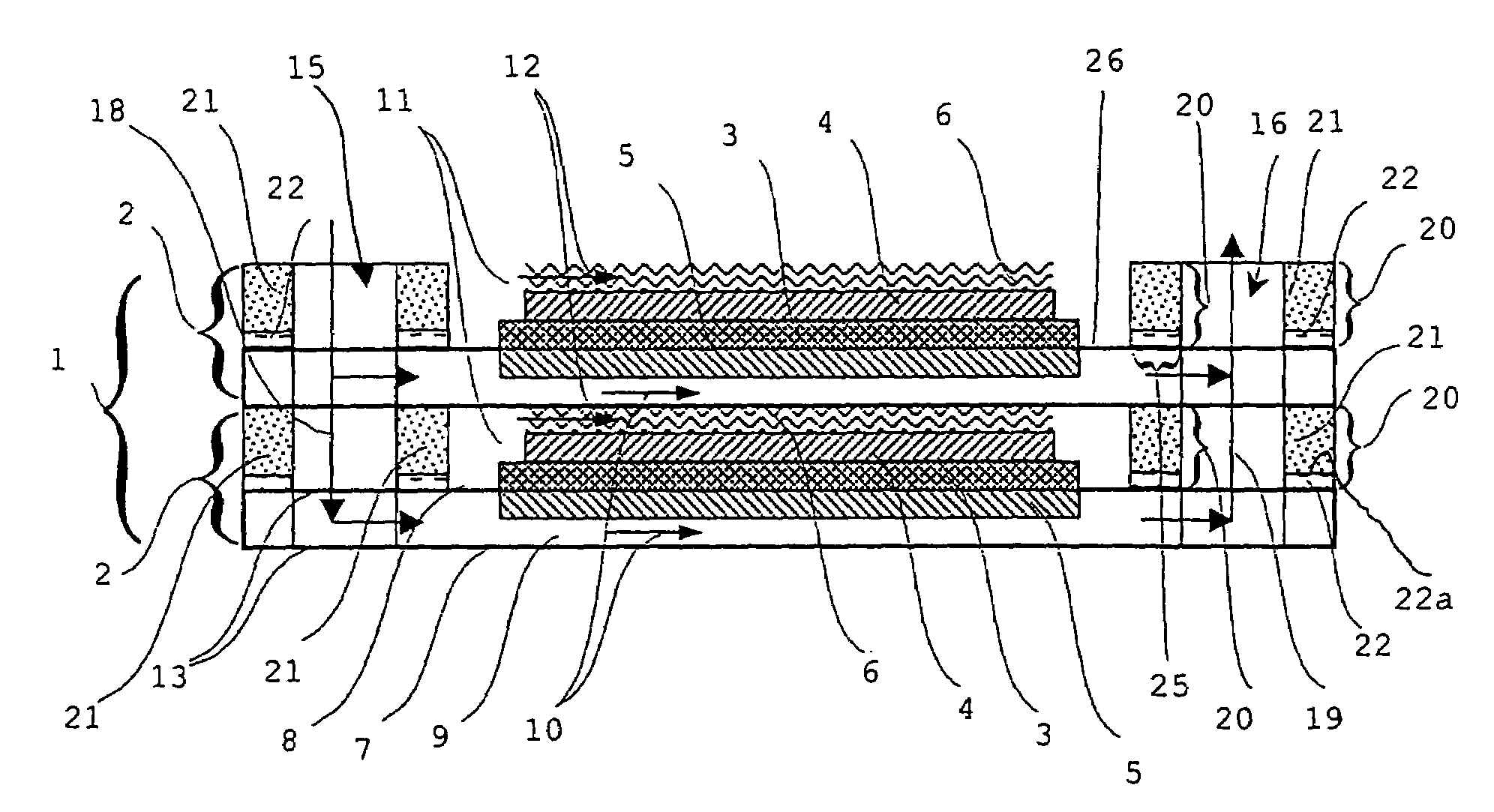

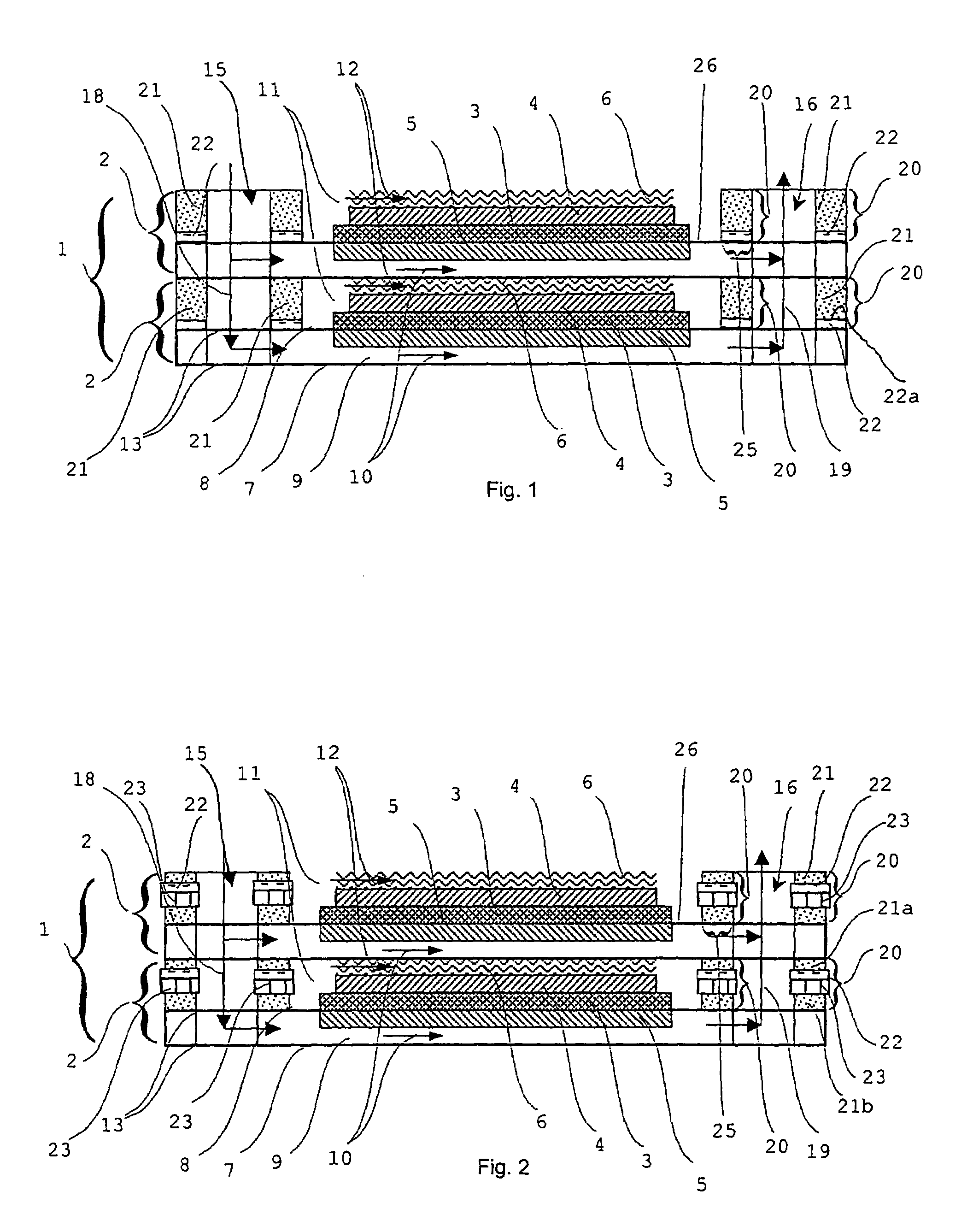

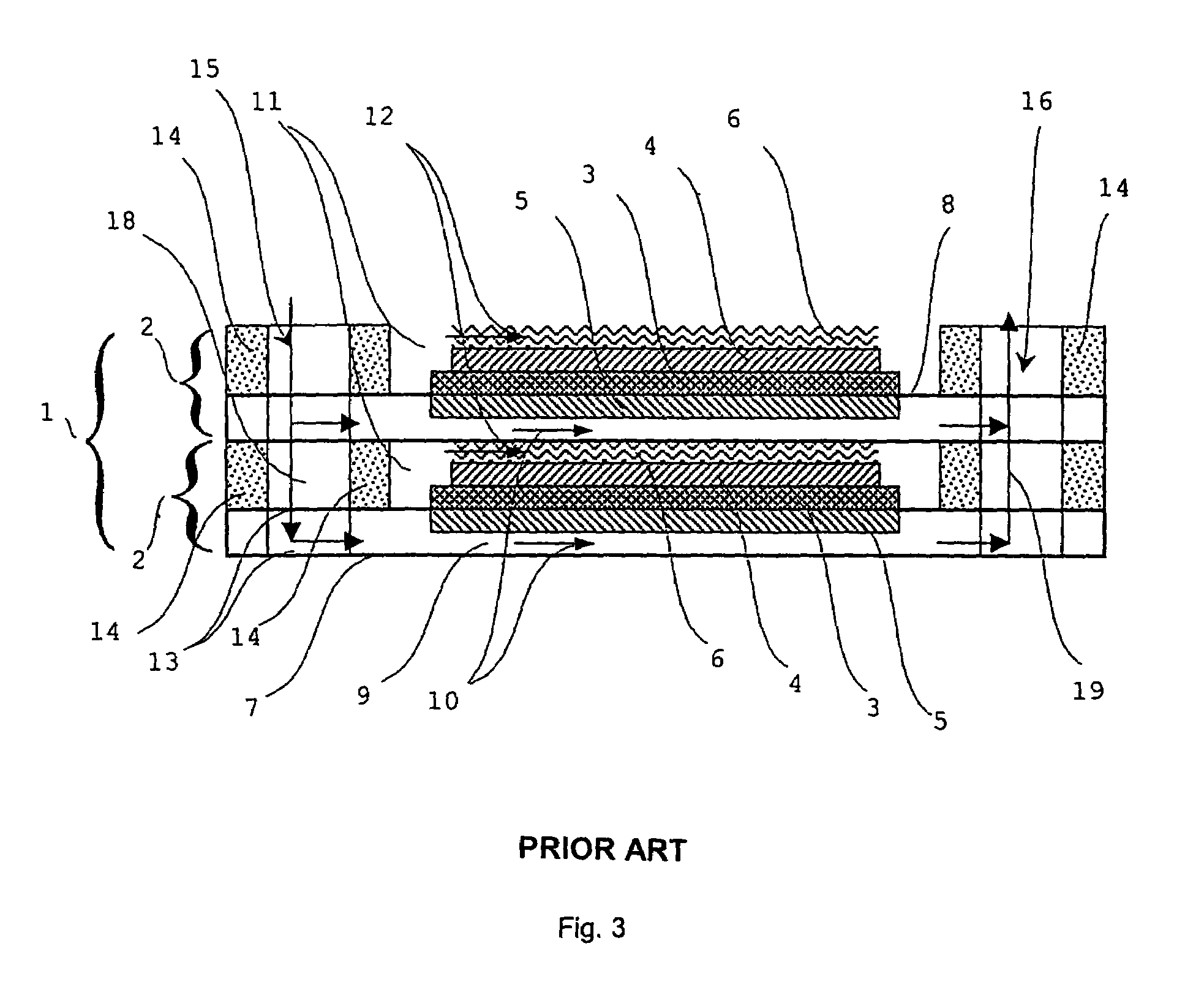

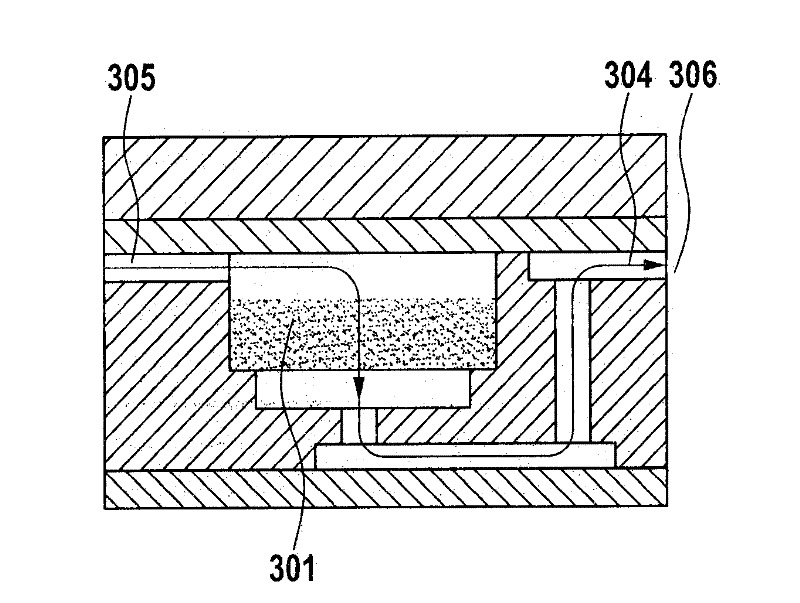

Seal construction for a fuel cell electrolyser and process for making a fuel cell with same

InactiveUS20050186463A1Facilitated and particularly more process-secure mountingSimple and cost-effectiveFuel cells groupingFinal product manufactureFuel cellsEngineering

A sealing structure in a fuel cell and / or an electrolyzer (particularly a solid-oxide fuel cell and / or a solid-oxide electrolyzer) is arranged between neighboring separator plates of a cell stack. The sealing structure is constructed in at least two layers, including at least one insulating layer and at least one sealing layer.

Owner:BAYERISCHE MOTOREN WERKE AG +1

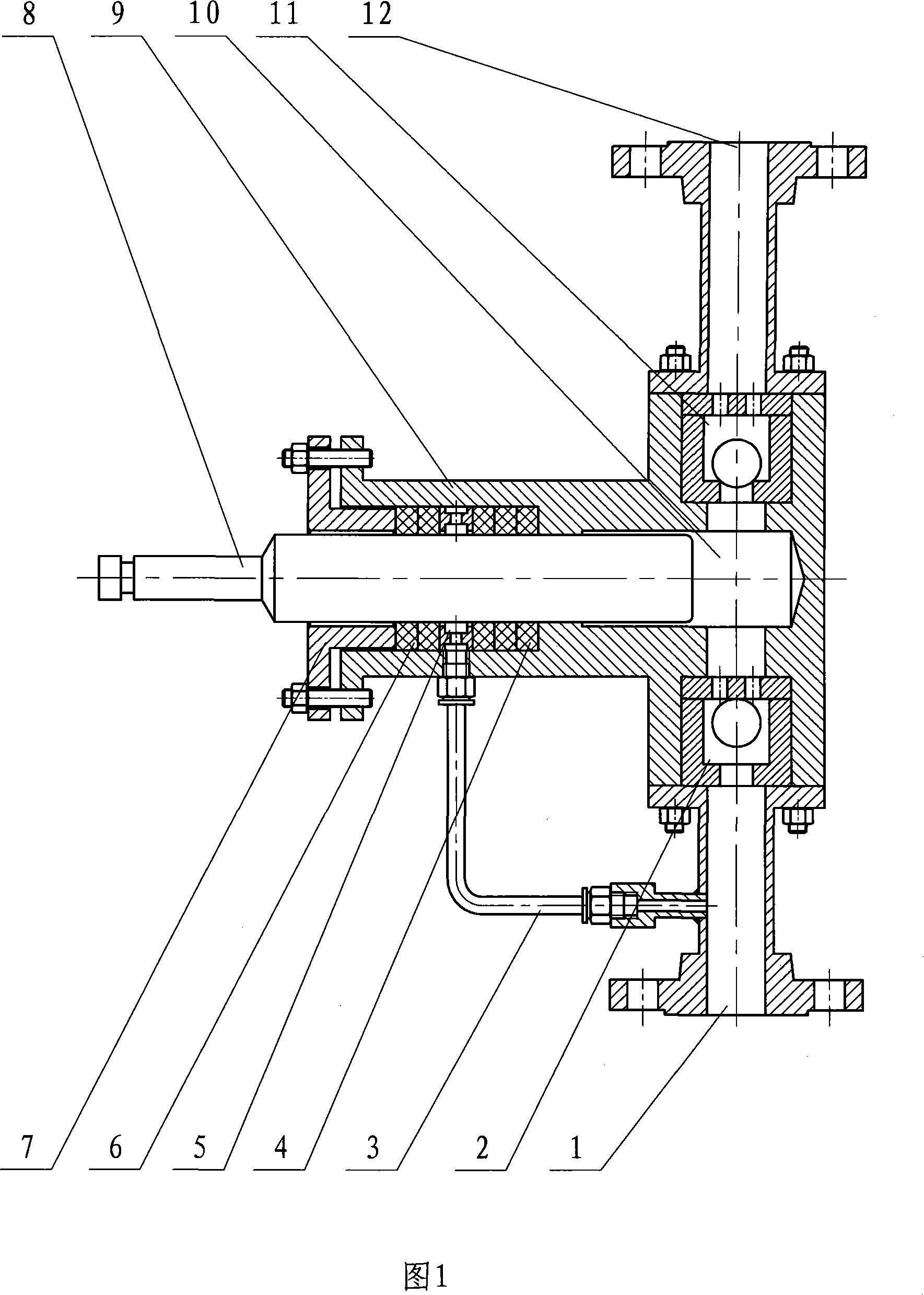

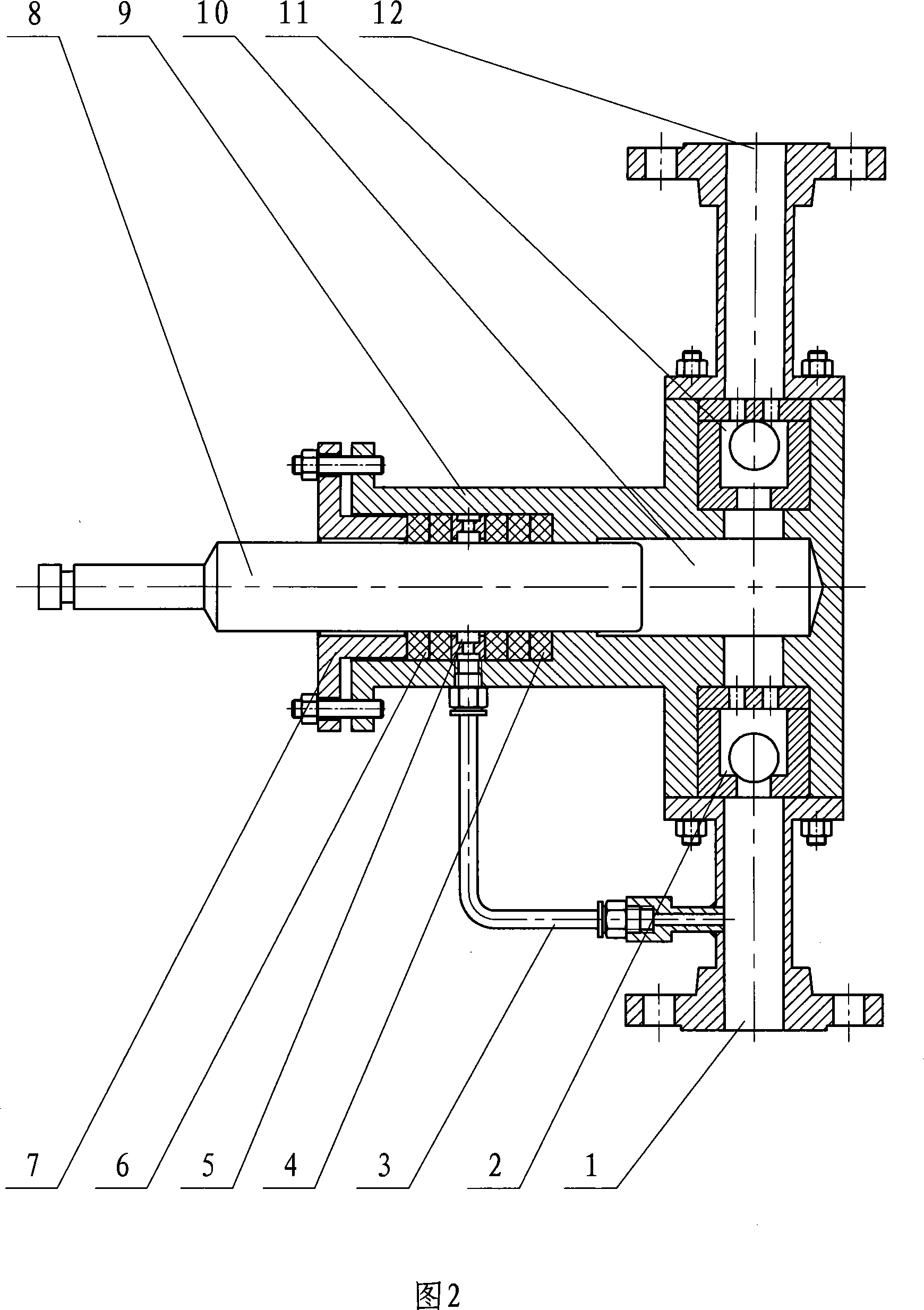

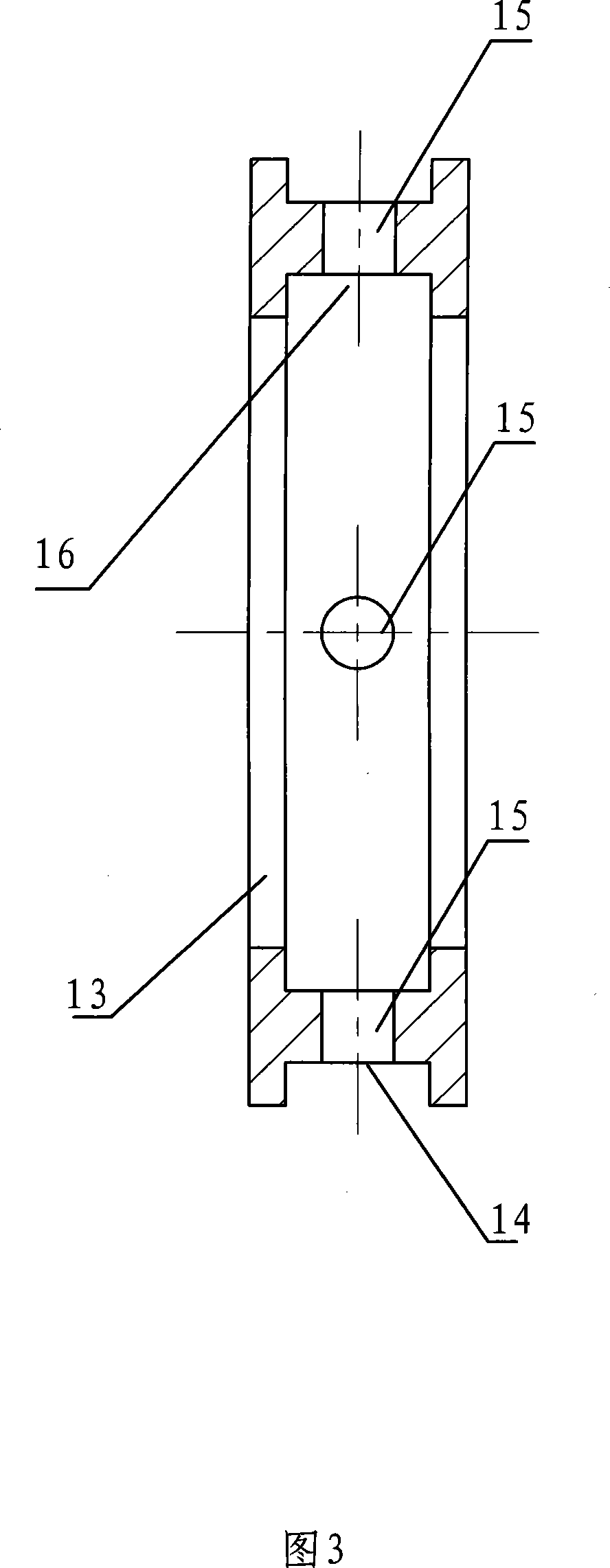

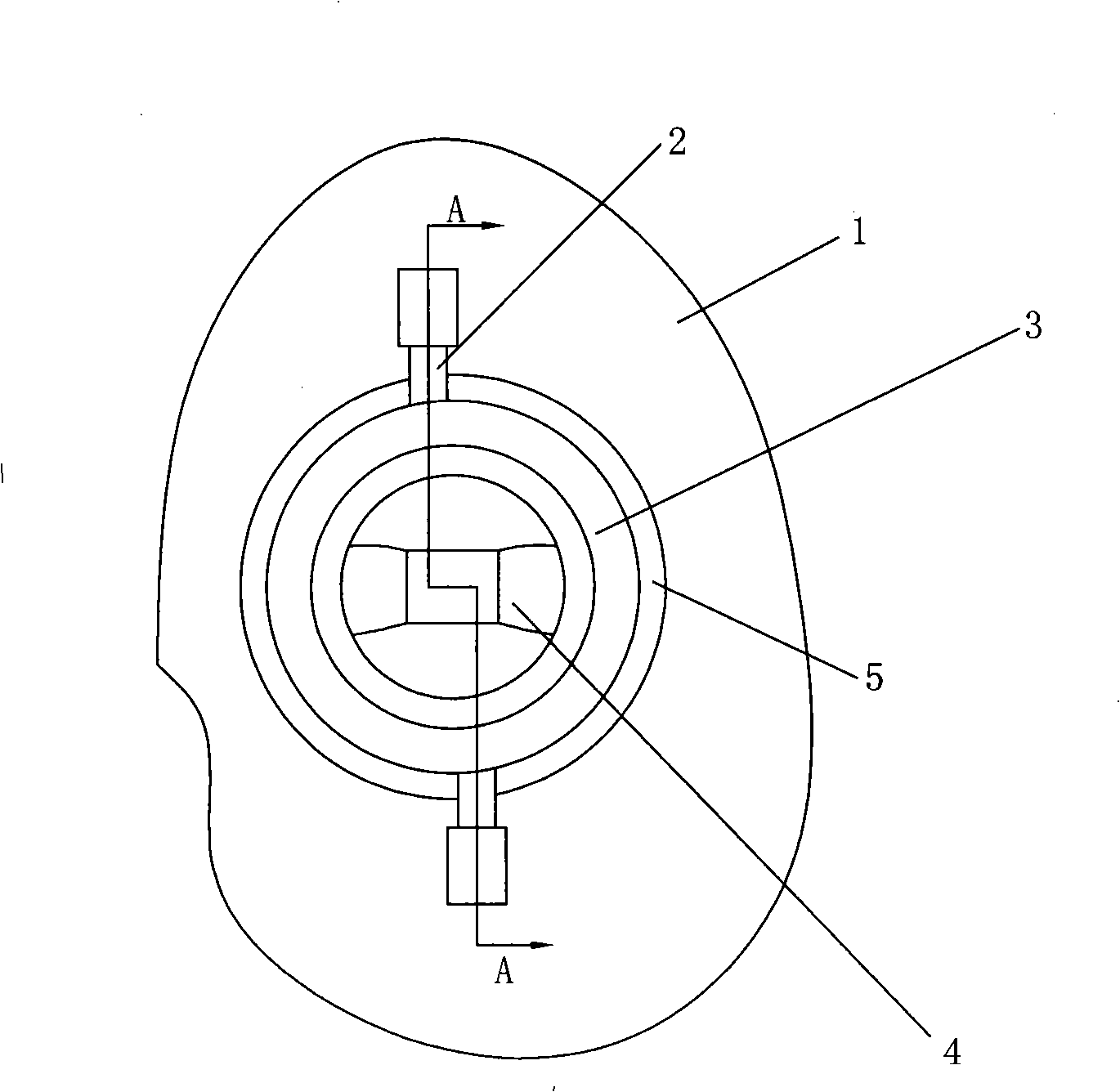

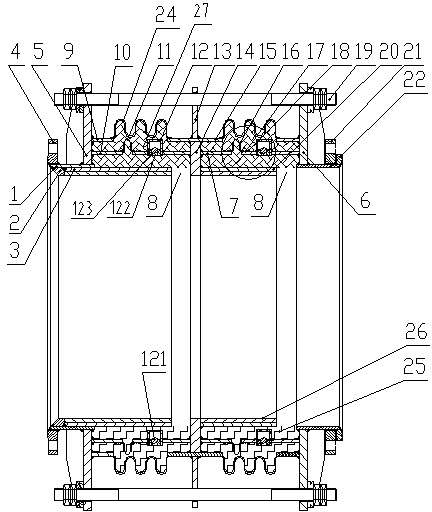

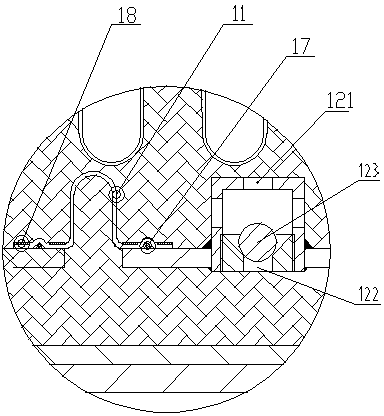

Non-leakage reversed flow type plunger pump

InactiveCN101225805AReduce mediumReduce manufacturing costPositive displacement pump componentsPiston pumpsReciprocating pumpPlunger pump

The invention relates to a leakage-free reflow piston pump as a reciprocating pump used in liquid transportation, in particular to a leakage-free reflow device used in the piston pump. The structure is that: a plurality of spacing rings are arranged between inner side packing of the piston pump and the outside packing; a groove is arranged on internal surface and external surface of the spacing ring; a plurality of round through holes are evenly distributed on the bottom of the groove; a plurality of pipe joints are arranged at both ends of a reflow pipe and are respectively connected with a pump body and an inlet pipe of the pump corresponding to the installation position of the spacing ring; leaking mediator from the inner side of the piston pump is transported to the inlet pipe of the pump by a close loop composed of a spacing ring and the reflow pipe. The leakage-free reflow piston pump as a reciprocating pump used in liquid transportation has an advantage that the mediator in the reflow pipe is inhaled into the working cavity of the piston pump when the piston pump is working, so the problem of mediator leakage outside the pump due to wear of the seal packing is effectively prevented.

Owner:DALIAN LAUREL LIQUID EQUIP

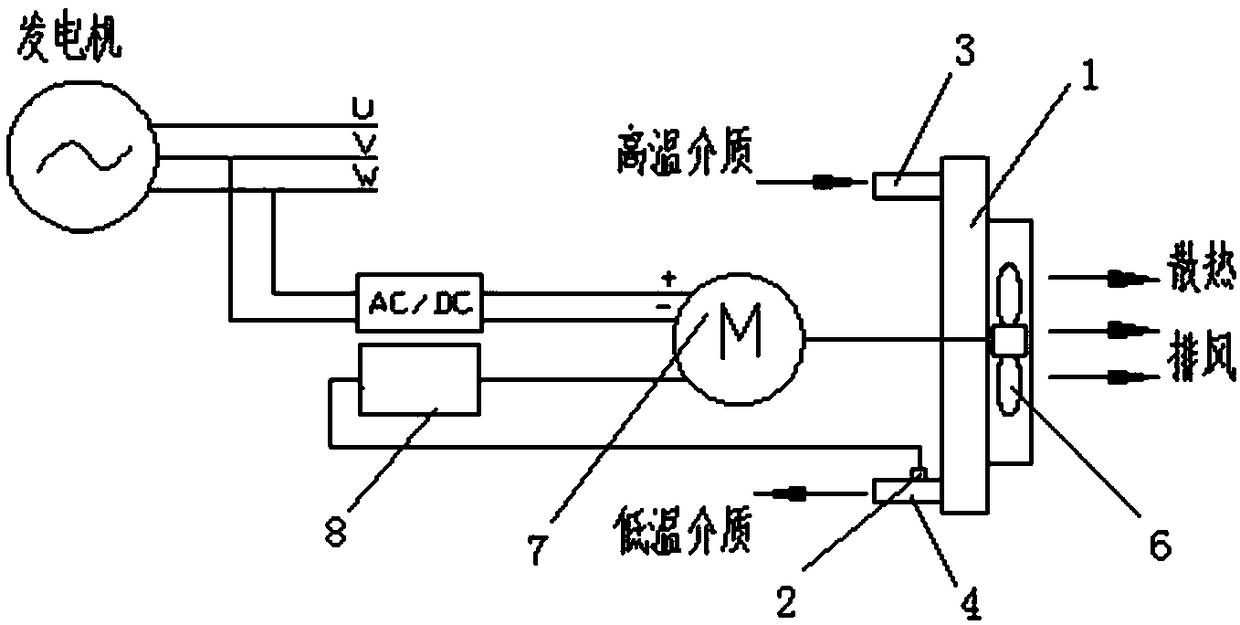

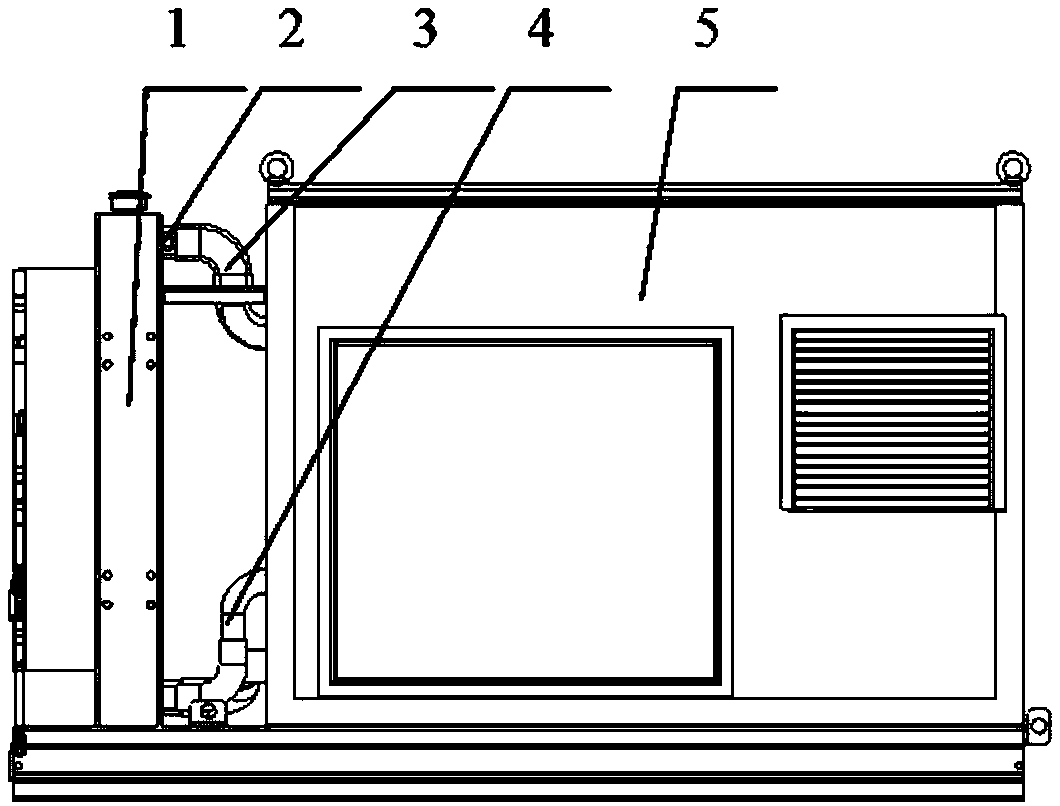

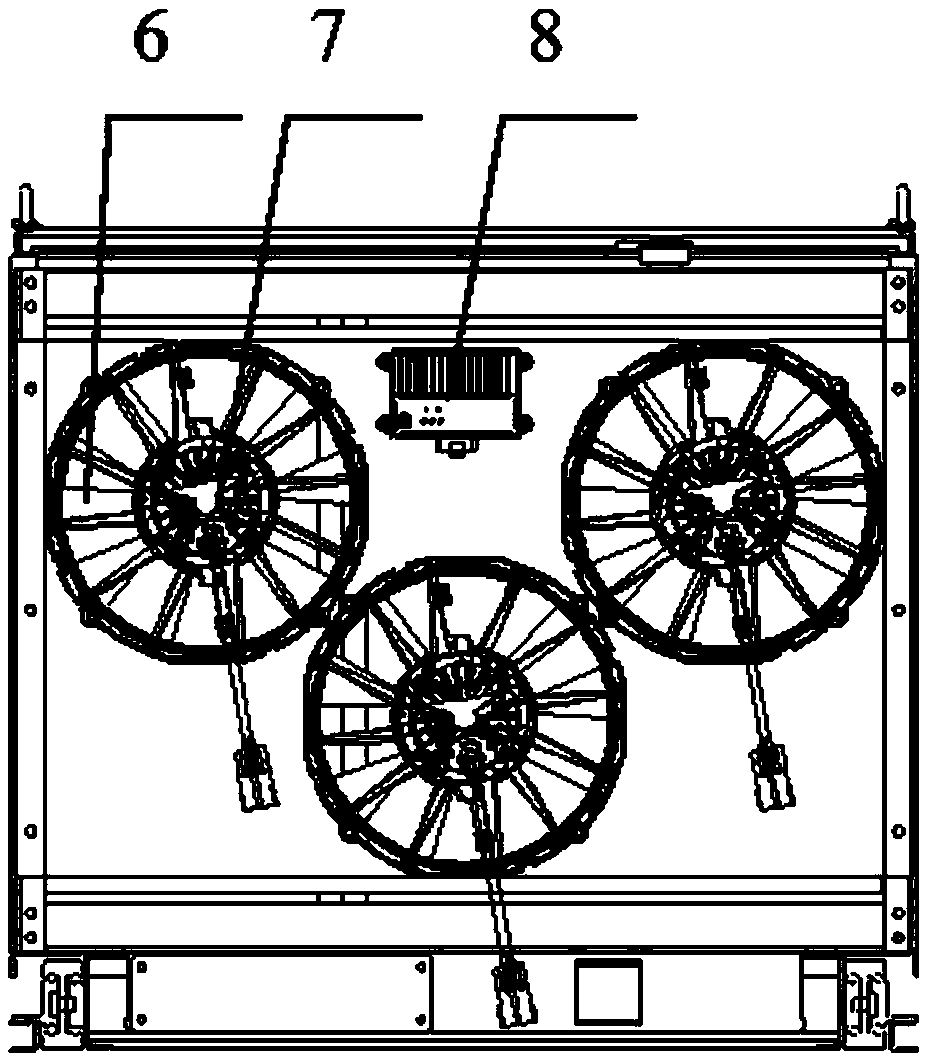

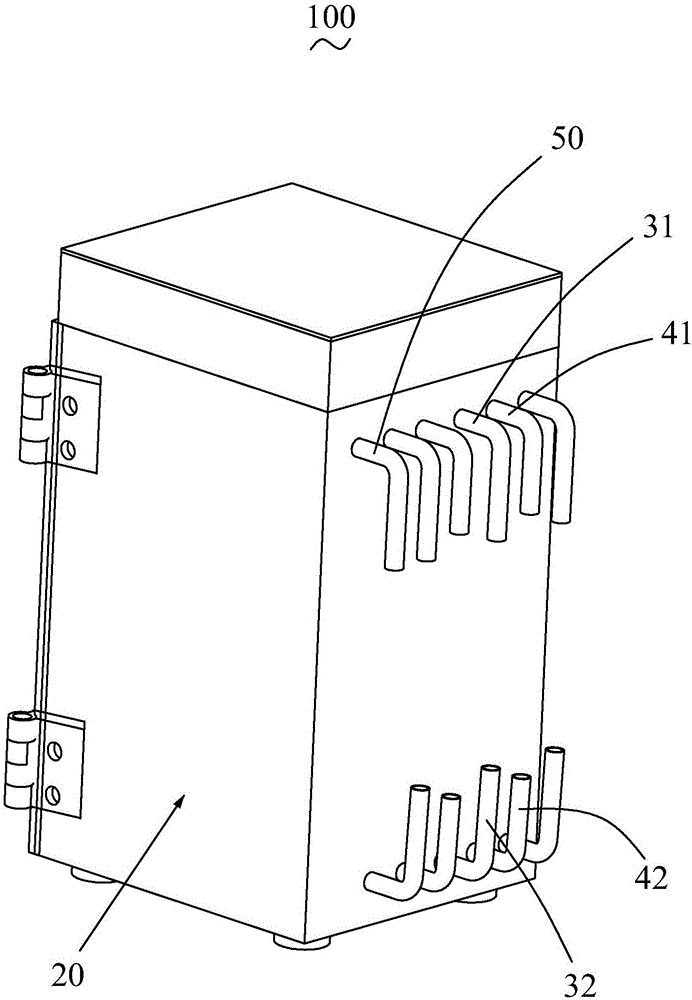

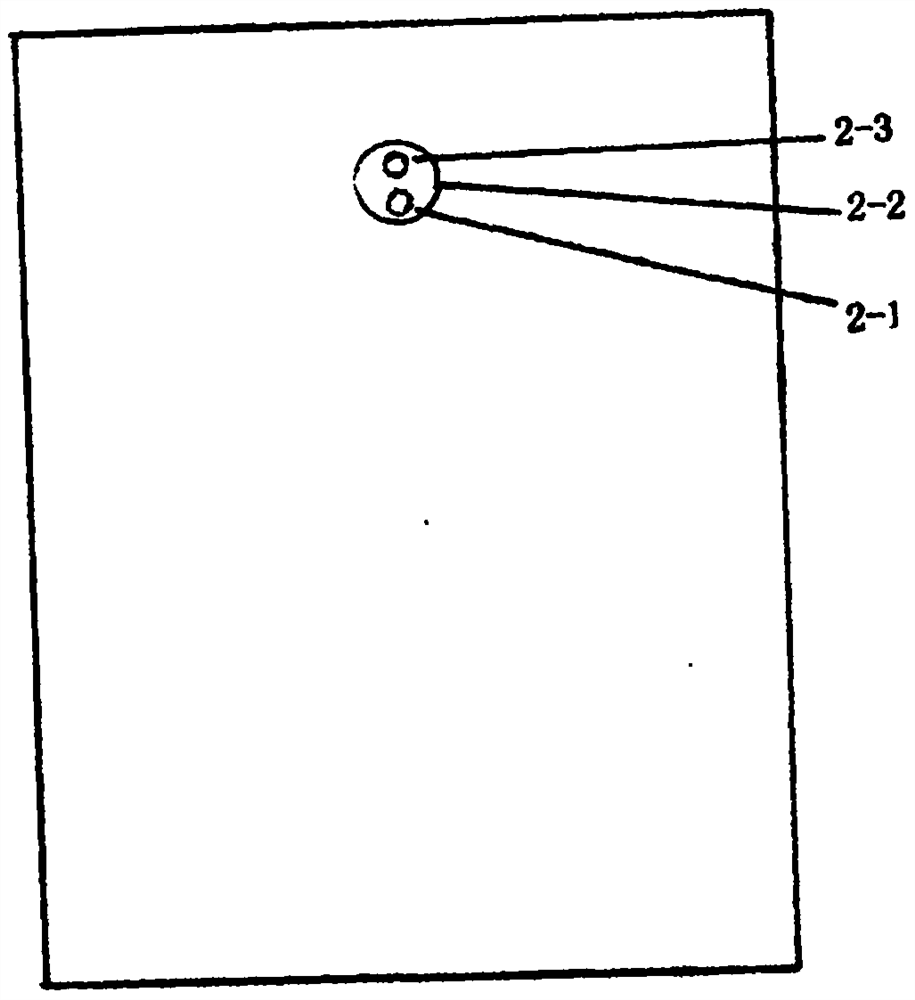

Power station silent energy-saving type heat dissipation system

PendingCN109026342AReduce mediumEasy to replaceCoolant flow controlMachines/enginesPower stationComputer fan

The invention provides a power station silent energy-saving type heat dissipation system. The power station silent energy-saving type heat dissipation system comprises a radiator, a temperature sensor, a radiator water inflow pipe, a radiator water return pipe, a box type unit, at least one heat dissipation fan, a heat dissipation draught fan and a draught fan controller. The radiator is arrangedoutside the box type unit, the radiator is connected with the box type unit through the radiator water inflow pipe and the radiator water return pie to form a circulation loop, and the circulation loop is provided with a flowing circulation cooling medium. The temperature sensor is arranged at the joint of the radiator and the radiator water inflow pipe, and the heat dissipation fans are connectedwith the heat dissipation draught fan and all arranged in the radiator. The temperature sensor and the heat dissipation draught fan are connected to the draught fan controller. The purposes of silence and energy saving of the power station heat dissipation system in normal environments are achieved, and the efficient heat dissipation requirements at high temperature are met.

Owner:JIANGXI QINGHUA TAIHAO SANBO ELECTRICAL MACHINE

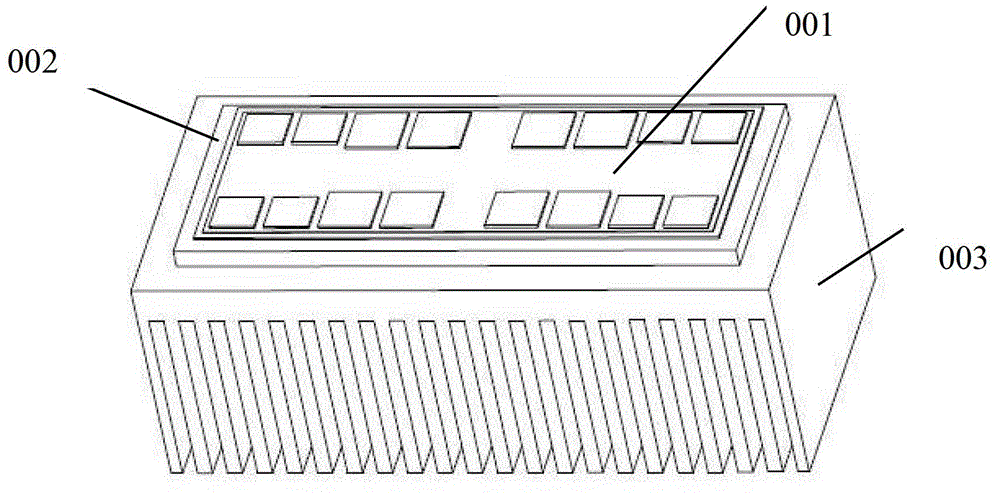

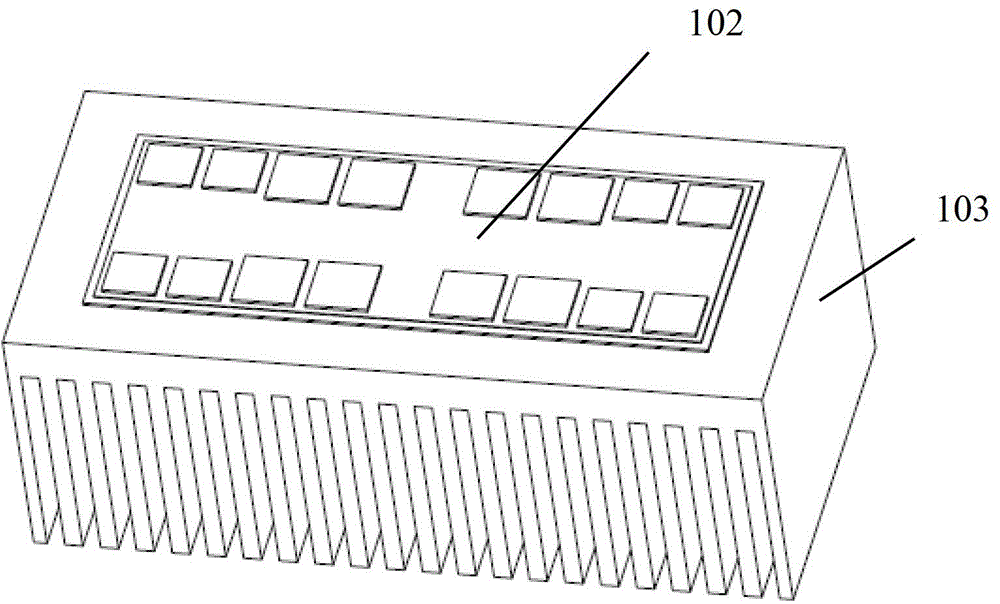

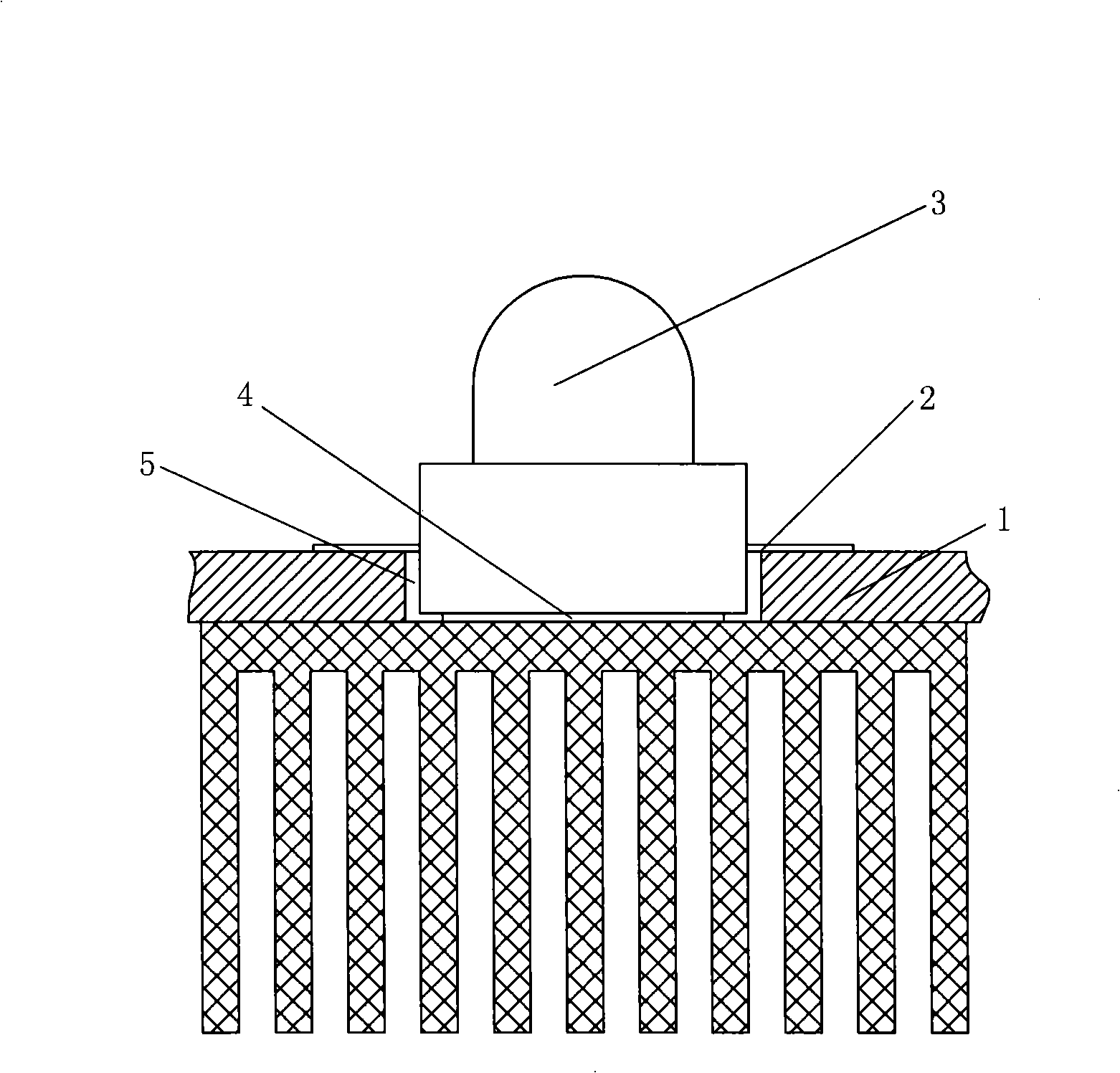

IGBT (Insulated Gate Bipolar Translator) module radiating structure

InactiveCN102881668AFaster and more direct conductionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesDBcHeat conducting

The invention discloses an IGBT (Insulated Gate Bipolar Translator) module radiating structure. The structure comprises a shell, a DBC plate and a radiator, wherein the DBC plate is tightly stuck to the radiator through the longitudinal pressure applied by the shell; and a heat-conducting silicon grease layer is arranged between the DBC plate and the radiator. By the heat-conducting silicon grease layer arranged between the DBC plate and the radiator, the heat generated in an application process of an IGBT module can be more quickly and directly transferred, the medium required in a heat transferring process is reduced, the radiation effect of an IGBT product is greatly improved, and the reliability, the stability and the safety of a product are further ensured. Meanwhile, an AlSiC bottom plate which is widely adopted in the current IGBT module and a welding material of the AlSiC bottom plate are omitted, the cost of the materials as well as the thickness of the IGBT product are reduced, and the space occupied by the product is reduced.

Owner:XIAN YONGDIAN ELECTRIC

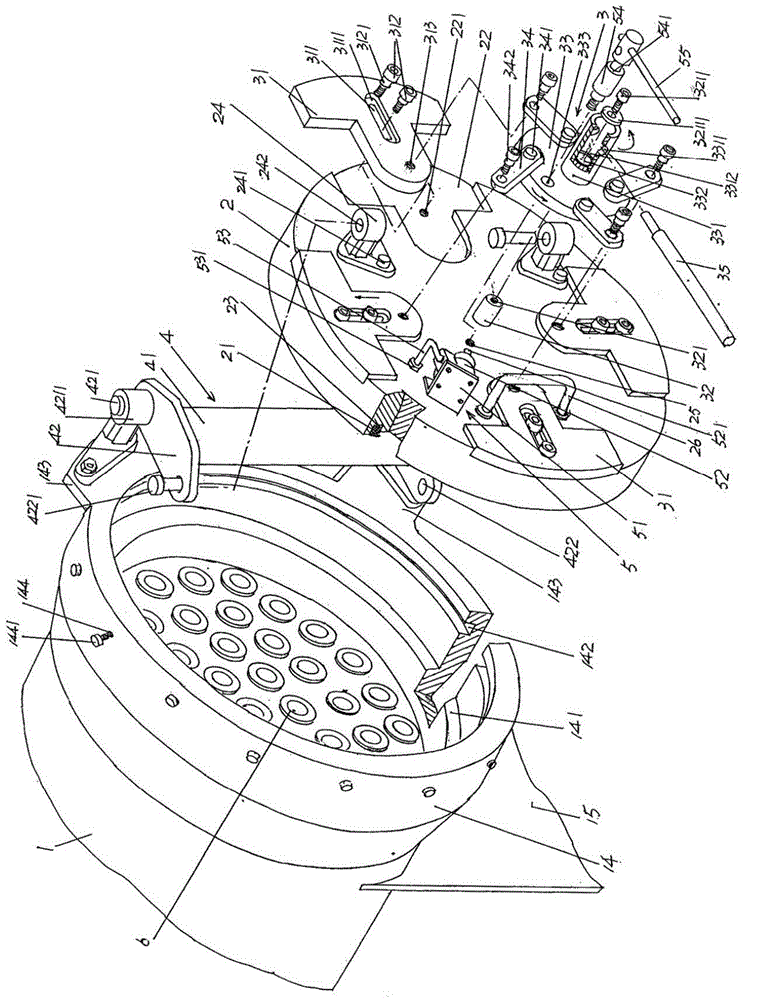

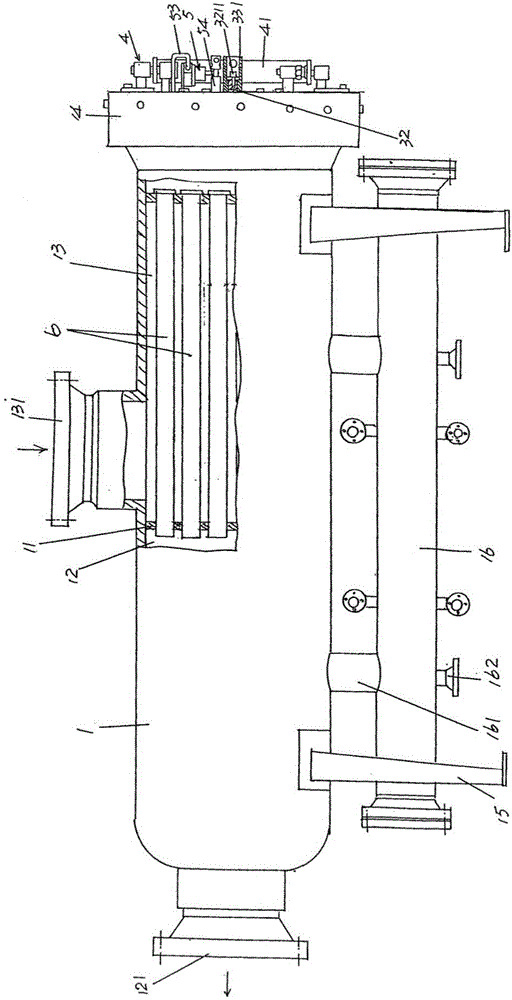

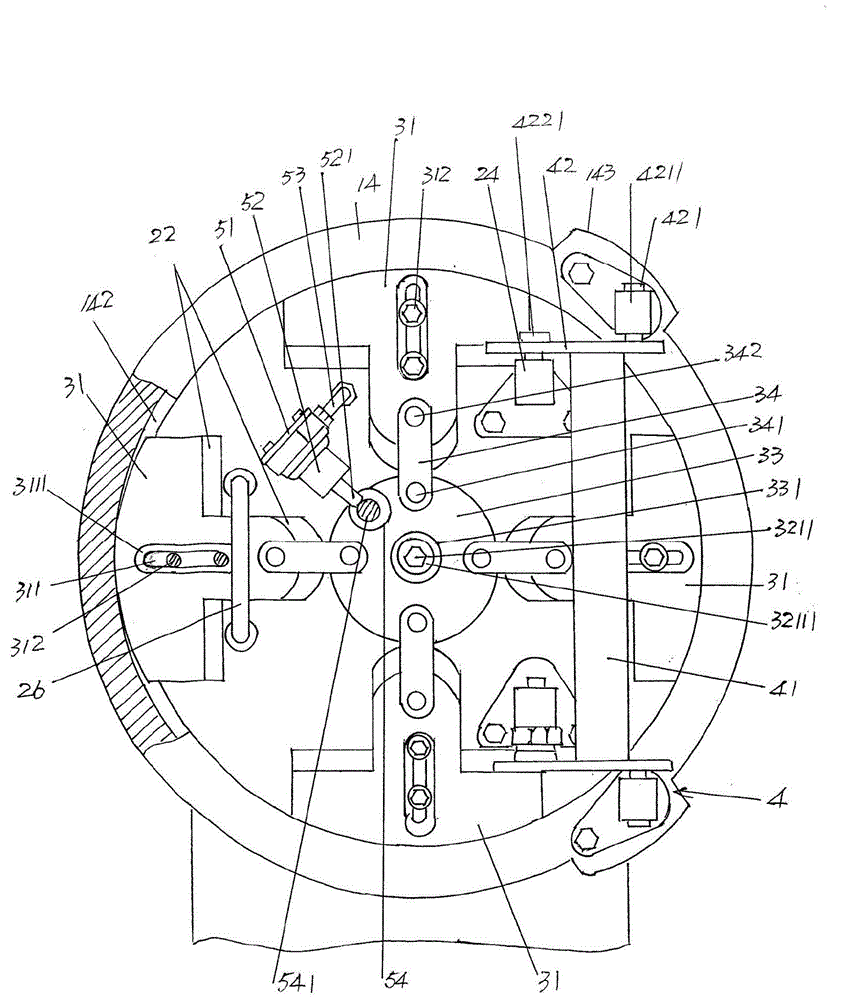

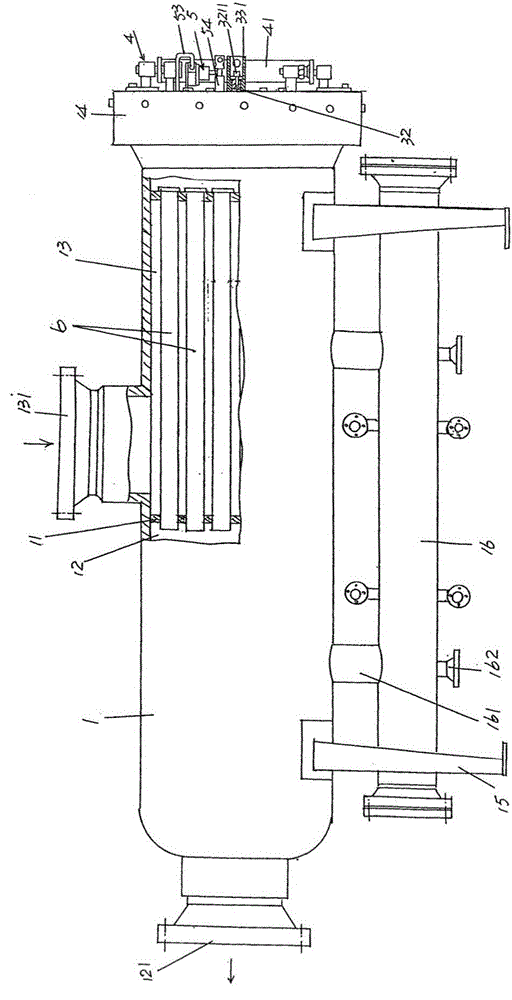

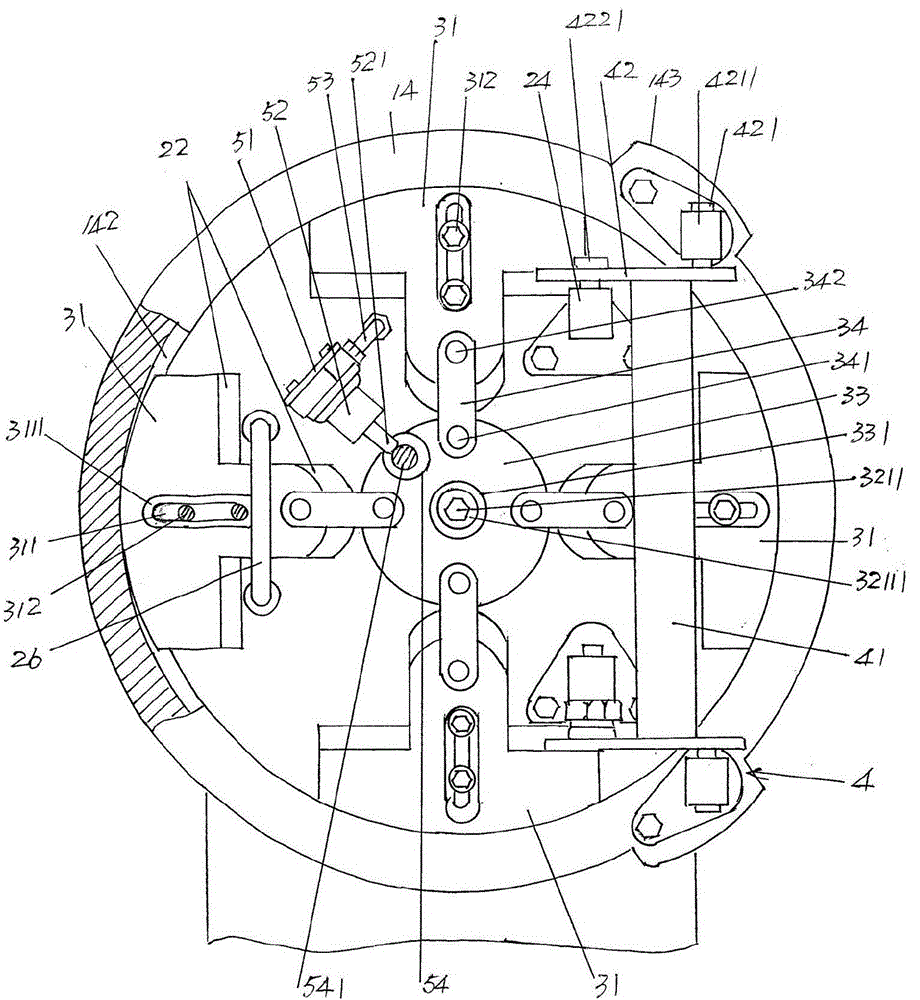

Multifunctional horizontal natural gas separation filter

ActiveCN104056503ASimple structureEasy to manufacture and assembleDispersed particle filtrationGaseous fuelsNatural gasLocking mechanism

The invention discloses a multifunctional horizontal natural gas separation filter belonging to the technical field of filter devices. The multifunctional horizontal natural gas separation filter comprises a cylinder, a blind plate and a blind plate locking mechanism, and is characterized in that latch plate sliding cavities are formed in one side, back on to a separation filter cavity, of the blind plate; the blind plate locking mechanism comprises latch plates, a center disk shaft, a center disk, a traction plate and a center disk operation handle; a center disk sleeve is fixed on one side, back on to the blind plate, of the center disk and is perpendicular to the center disk; a cylinder depressurizing response mechanism is arranged on the wall body of one side, back on to the separation filter cavity, of the blind plate, and is matched with the center disk; a clean hole is formed in the circumferential direction of a blind plate matching opening and in the position corresponding to a blind plate locking groove; a sealing screw is arranged on the clean hole in a matching manner. The multifunctional horizontal natural gas separation filter has the advantages that the structure is simple; the ideal effect of latching all the latch plates and the blind plate locking groove can be enduringly kept; the blind plate is prevented from being deformed; when natural gas exists in the cylinder, the blind plate cannot be opened; the blind plate locking groove can be quickly and conveniently cleaned.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

Seal construction for a fuel cell electrolyser and process for making a fuel cell with same

InactiveUS7422818B2Simple and cost-effectiveFacilitated and particularly more process-secure mountingFuel cells groupingFinal product manufactureFuel cellsMechanical engineering

A sealing structure in a fuel cell and / or an electrolyzer (particularly a solid-oxide fuel cell and / or a solid-oxide electrolyzer) is arranged between neighboring separator plates of a cell stack. The sealing structure is constructed in at least two layers, including at least one insulating layer and at least one sealing layer.

Owner:BAYERISCHE MOTOREN WERKE AG +1

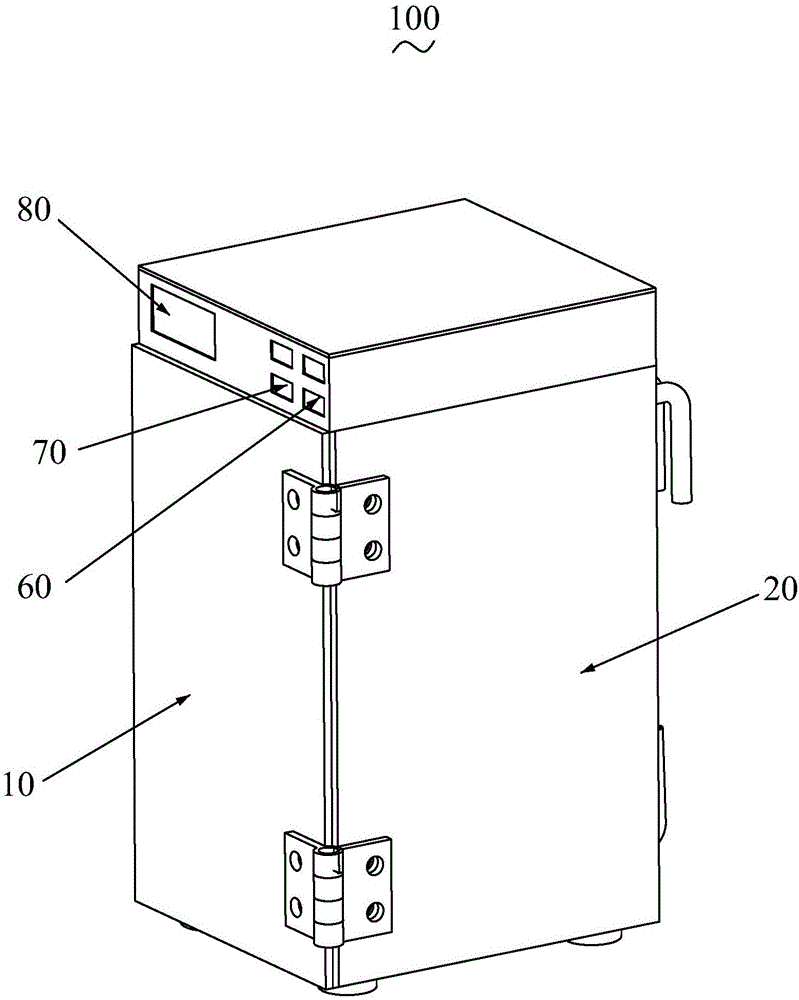

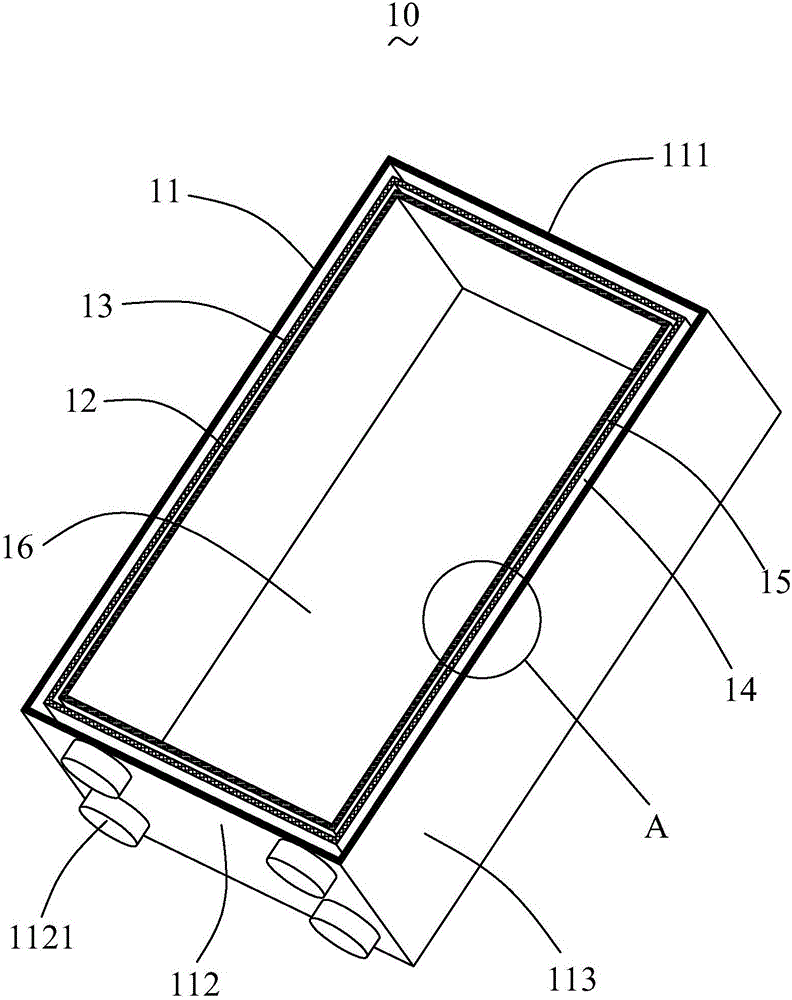

Oven

InactiveCN106679350ASolve uneven temperatureShorten heating and cooling timeDrying gas arrangementsDrying chambers/containersInterior spaceEngineering

The invention provides an oven. The oven comprises an oven body with an opening in one side, an oven door, an upper liquid delivery pipe, a lower liquid delivery pipe, an upper ventilation pipe, a lower ventilation pipe and a vacuum pipe, wherein the oven body comprises an outer wall, an inner wall arranged in the outer wall in a sleeving manner, and a sandwich layer which is located between the outer wall and the inner wall and is spaced from the outer wall and the inner wall; an airtight outer hollow layer is enclosed by the outer wall and the sandwich layer, and an airtight inner hollow layer is enclosed by the sandwich layer and the inner wall; one side of the oven door is movably connected with the oven body, the oven door can be in seal fit with the oven body, and an inner space is formed by the oven door and the inner wall; the upper liquid delivery pipe and the lower liquid delivery pipe are separately located at the two ends of the oven body and communicate with the inner hollow layer; the upper liquid delivery pipe, the lower liquid delivery pipe and the inner hollow layer are used for the circulation of heat conducting liquid; the upper ventilation pipe and the lower ventilation pipe are separately located at the two ends of the oven body and communicate with the inner space, and the upper ventilation pipe, the lower ventilation pipe and the inner space are used for the circulation of dry air; and the vacuum pumping pipe communicates with the outer hollow layer.

Owner:OPTIMUM BATTERY CO LTD

Preparation method of high anti-corrosion coating on surface of sintered Nd-Fe-B magnet

InactiveCN108364780AImprove anti-aging propertiesExtend corrosion resistance timeMagnetic materialsPermanent magnet manufacturePorosityAging resistance

The invention discloses a preparation method of a high anti-corrosion coating on the surface of a sintered Nd-Fe-B magnet. The method comprises the steps that a machined and shaped Nd-Fe-B magnet is preprocessed, the preprocessed Nd-Fe-B product is soaked with a pre-processing solution, and the pre-processing solution is prepared by mixing distilled water, a coating agent and an accelerator; priming coating of a ZnAl coating solution is performed on the surface of the soaked Nd-Fe-B magnet, and the Nd-Fe-B magnet with the ZnAl coating obtained after priming coating is obtained; top coating ofa Al-enriched coating solution is performed on the surface of the Nd-Fe-B magnet obtained after priming coating, and the high anti-corrosion Nd-Fe-B magnet is obtained. Due to two times of coating processing, the porosity between the magnet and a corrosive medium is effectively lowered, the binding force between the coating and the magnet is improved, and the sintered Nd-Fe-B magnet has the good corrosion resistance. Due to the ZnAl coating obtained after priming coating, the quantity of a medium entering the deeper layer of the coating is greatly reduced, and therefore the high temperature and high pressure resistance and the ageing resistance of the magnet are greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

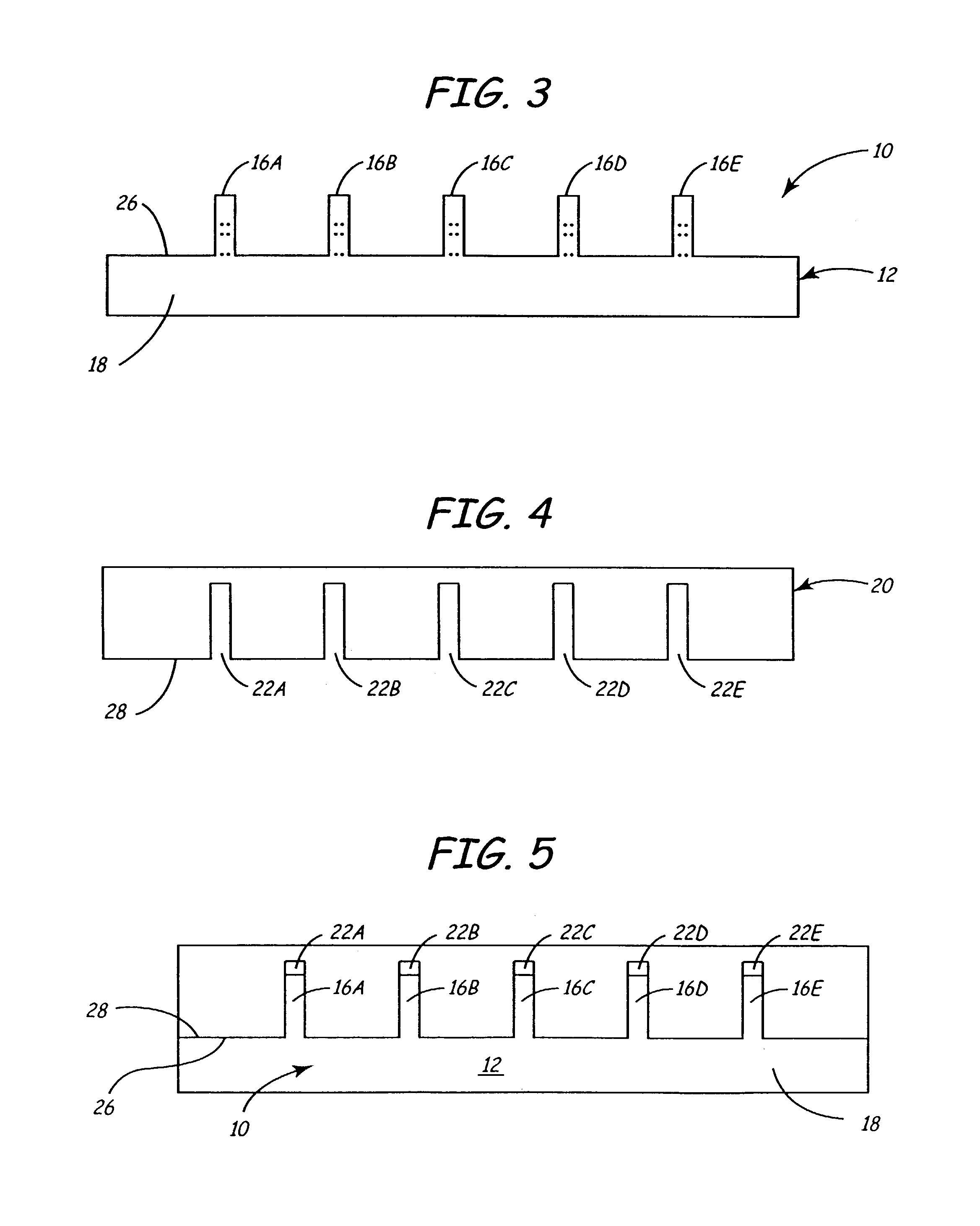

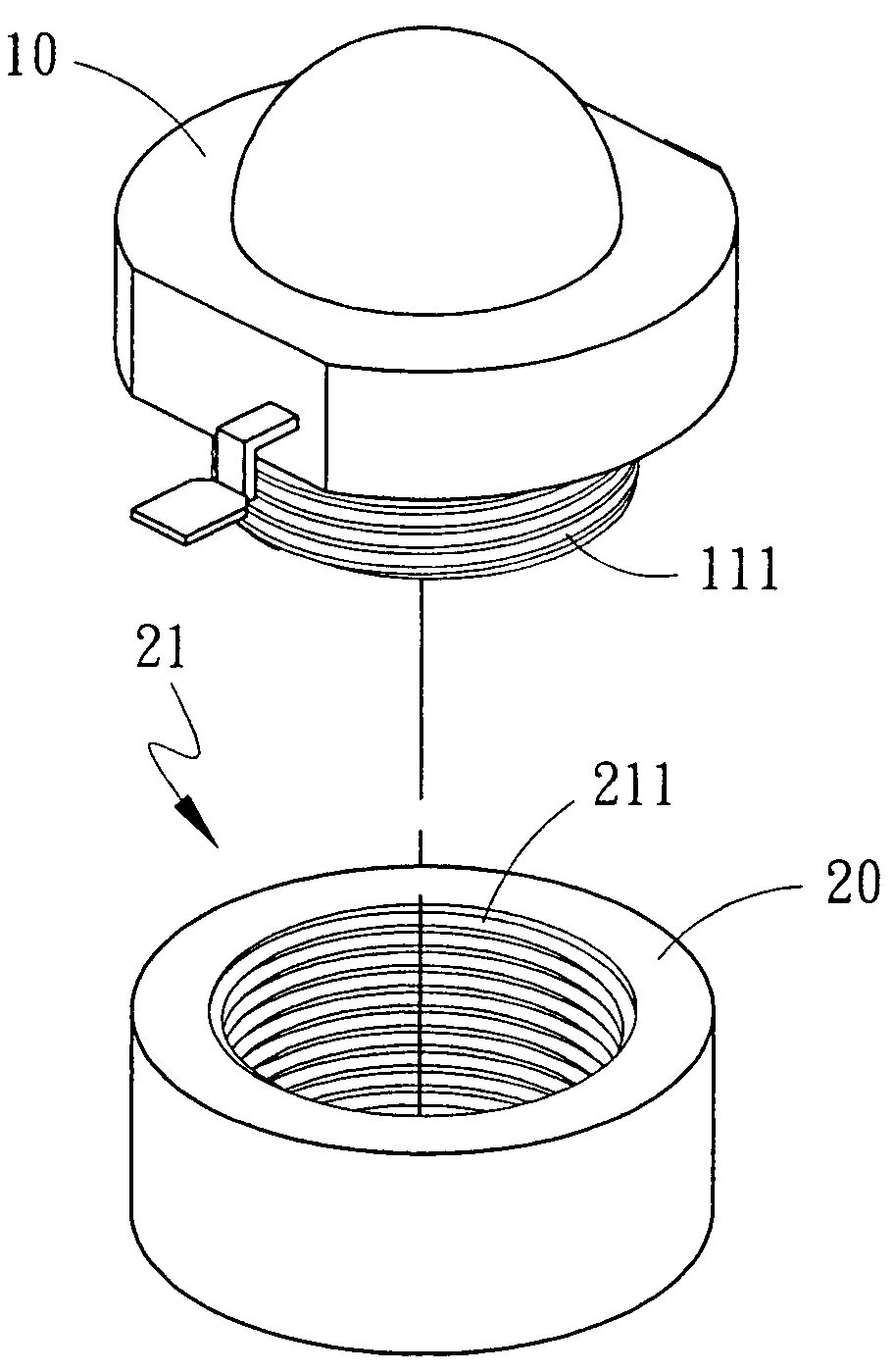

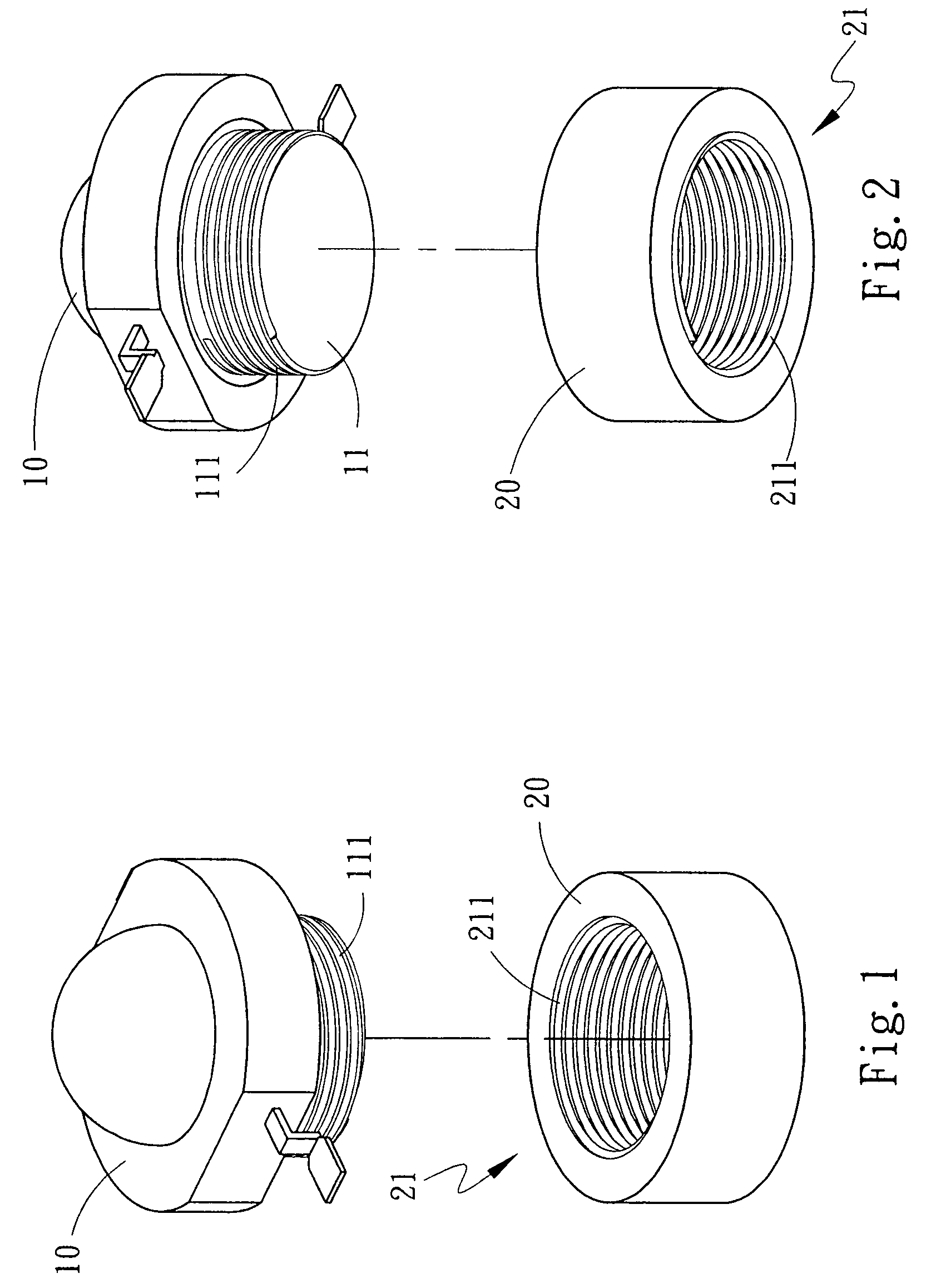

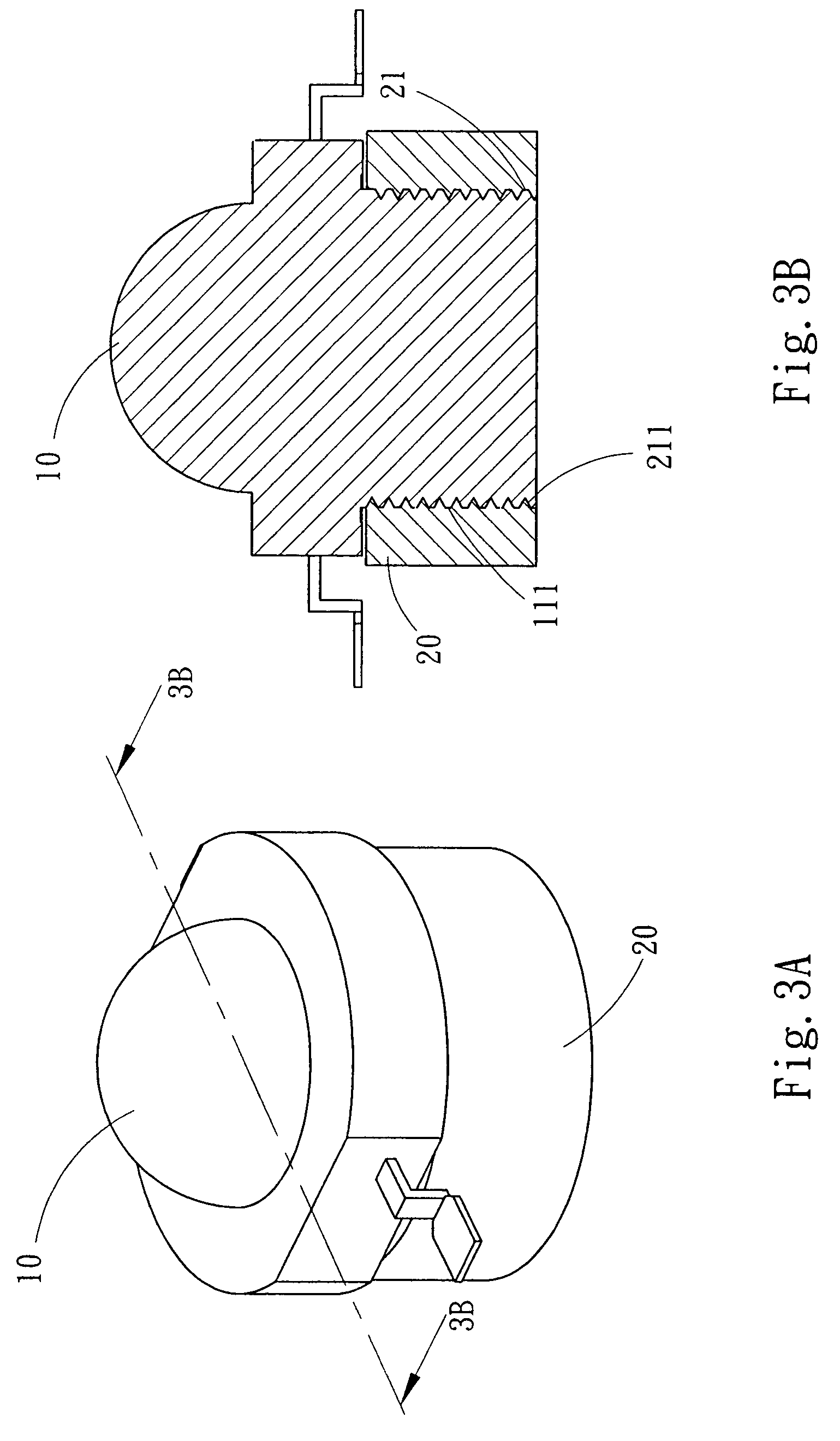

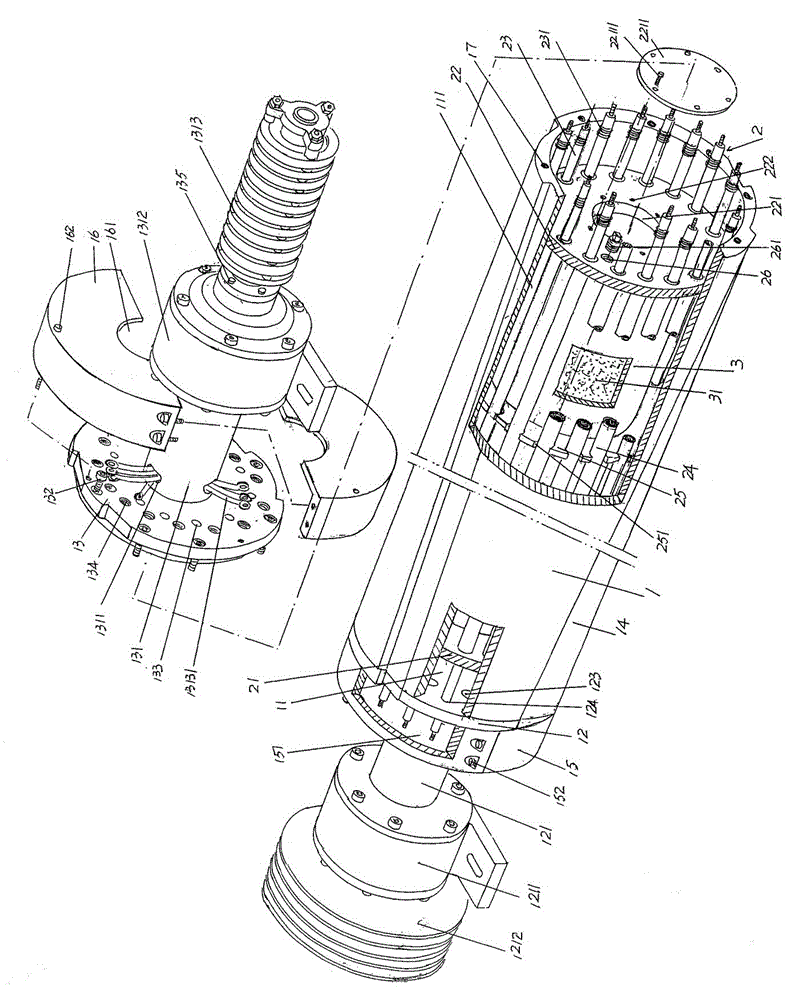

LED light structure and combination device thereof

ActiveUS7594748B2Light structureHigh heat sinking efficiencyCoupling device connectionsLighting support devicesEngineeringLED lamp

An LED light structure with combination device has at least including plural LED lights and plural fixing bases, wherein the LED light having a protruding portion mounted at one side thereof and the protruding portion having a thread mounted thereon for fixing with the fixing base which is a metal base with high heat sinking efficiency, and the fixing base has a through trough with a thread mounted thereinside, which is matching to the thread on the protruding portion of the LED light, so as to screw with the protruding portion of the LED light in a tight matching. Here, the protruding portion of the LED light can be a T shaped track and the fixing base can correspondingly have a T shaped trough matching to the shape of the protruding portion of the LED light, so that the LED light and the fixing base can be tightly embedded together.

Owner:LI HONG TECHNOLOGICAL

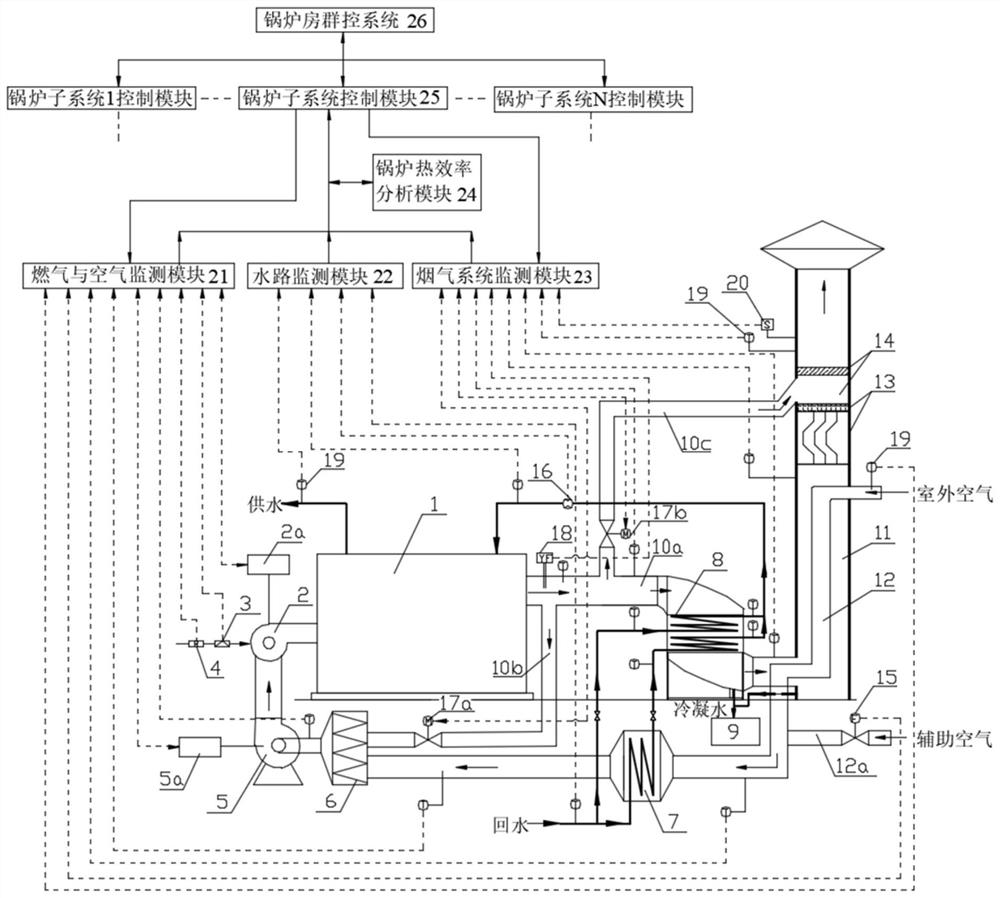

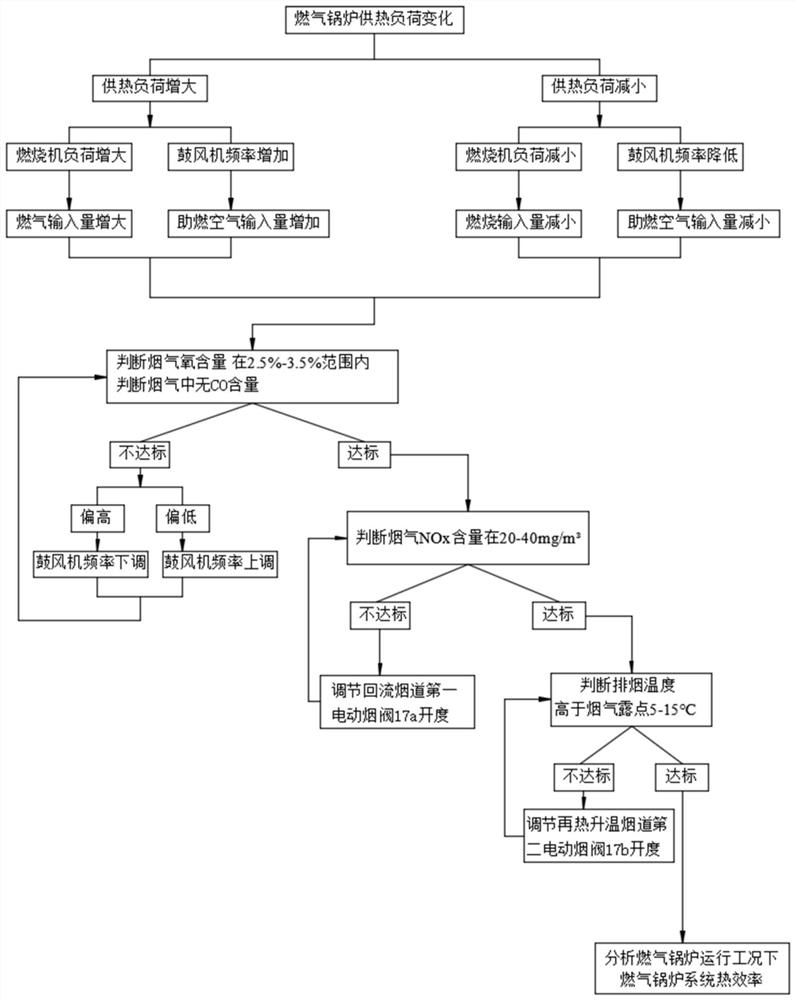

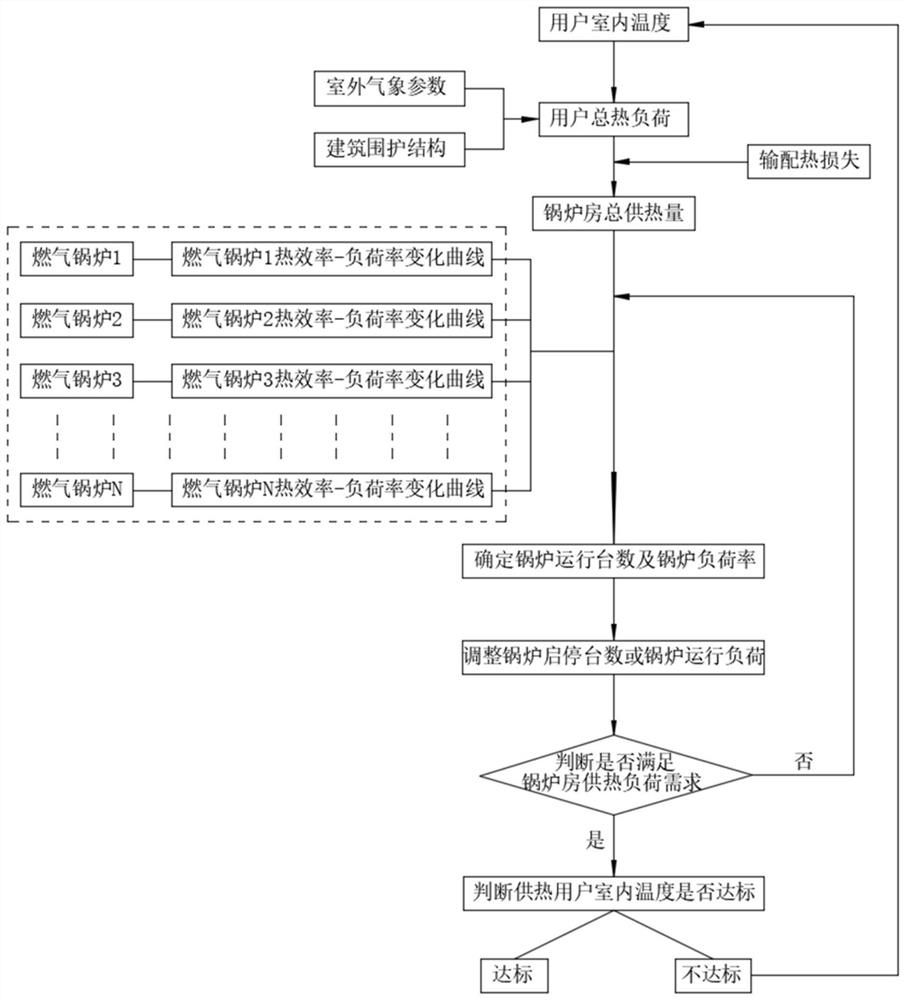

Low-nitrogen gas-fired boiler synergy and white smoke eliminating integrated heat supply system and regulating and control method

ActiveCN111981505AImprove diffusion abilityEmission reductionFuel supply regulationIndirect carbon-dioxide mitigationAir preheaterAir blower

The invention discloses a low-nitrogen gas-fired boiler synergy and white smoke eliminating integrated heat supply system and a regulating and control method. The system comprises a boiler room groupcontrol system and at least one heat supply subsystem, wherein each subsystem comprises a gas-fired boiler, a low-nitrogen combustion engine, a gas calorific value detector, an air blower, a horizontal flue, a vertical flue, a flue gas condensation heat energy recovery device, an air preheater, a flue gas-air uniform distribution mixer, an air duct, a flue gas sampling analyzer, a temperature andhumidity sensor, a flue gas white eliminating and defogging section, a flue gas heating uniform distribution section, a boiler subsystem control module and the like. According to the system and the method, not only can the corrosion of backflow flue gas condensation on the air blowers, the low-nitrogen combustion engines and the like after the low-nitrogen transformation of the gas-fired boilers be effectively solved, but also the emission of white smoke mist is effectively reduced, and on the premise of ensuring that a boiler room supplies heat as required, through the overall operation regulating and control method, the high-heat efficiency operation of the boilers is realized, the overall gas utilization efficiency of the boiler room is further improved, and the energy waste and pollutant emission are reduced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +2

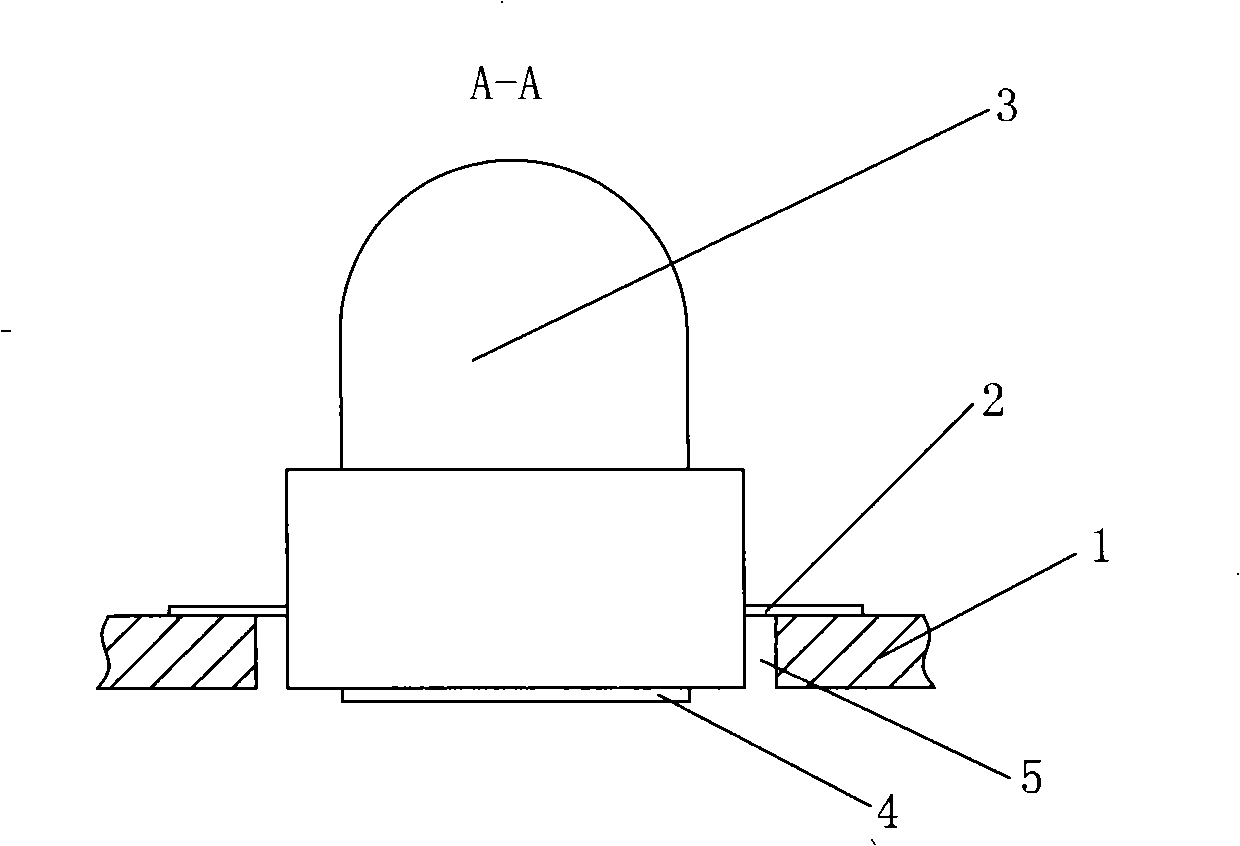

LED luminous module with heat radiation structure

InactiveCN101329057AImprove cooling effectReduce thermal resistancePoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention discloses an LED module provided with a radiating structure, which has low cost, simple structure and better radiating effect. The structure of the LED module comprises a base plate, and the primary technical points of the invention are that an aperture is arranged on the base plate and an LED light is put in the aperture; a thermal pad is arranged at the bottom of the LED light, and the anode and cathode of the LED light are respectively connected with welding spots on the base plate through a bus-bar, and the welding spots are respectively connected with the anode and cathode of a power supply. The thermal pad directly contacts a radiating body, and then the generated heat is transmitted to the radiating body, therefore, the better radiating effect is ensured.

Owner:陈怀中

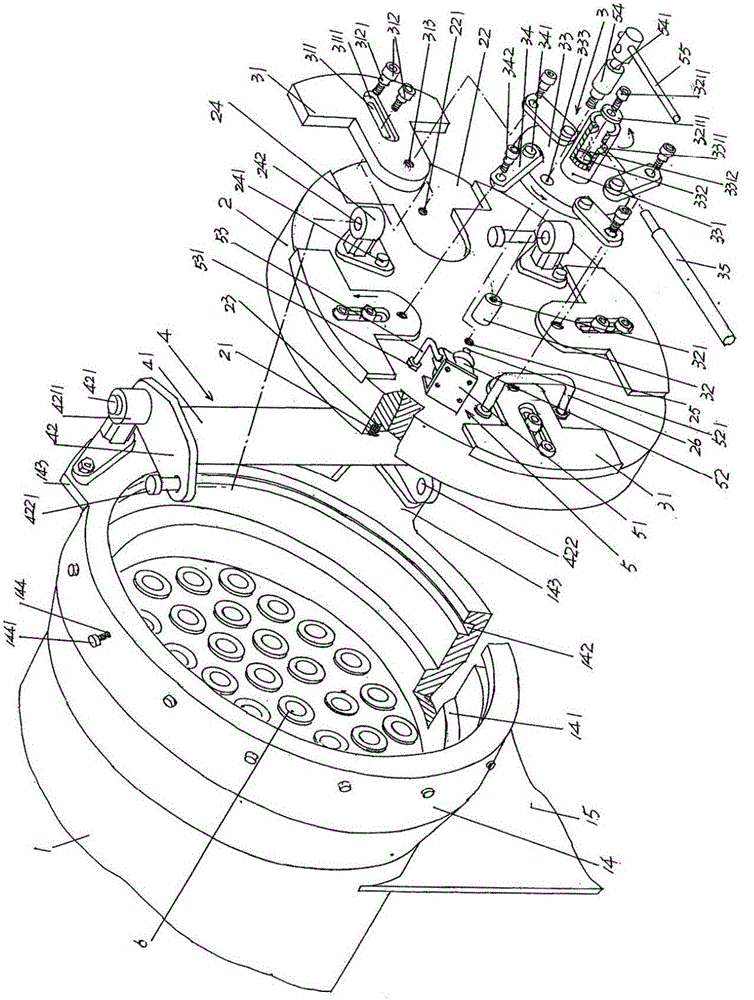

Multifunctional horizontal natural gas separation filter

ActiveCN104056503BAvoid deformationSimple structureDispersed particle filtrationGaseous fuelsLocking mechanismEngineering

The invention discloses a multifunctional horizontal natural gas separation filter belonging to the technical field of filter devices. The multifunctional horizontal natural gas separation filter comprises a cylinder, a blind plate and a blind plate locking mechanism, and is characterized in that latch plate sliding cavities are formed in one side, back on to a separation filter cavity, of the blind plate; the blind plate locking mechanism comprises latch plates, a center disk shaft, a center disk, a traction plate and a center disk operation handle; a center disk sleeve is fixed on one side, back on to the blind plate, of the center disk and is perpendicular to the center disk; a cylinder depressurizing response mechanism is arranged on the wall body of one side, back on to the separation filter cavity, of the blind plate, and is matched with the center disk; a clean hole is formed in the circumferential direction of a blind plate matching opening and in the position corresponding to a blind plate locking groove; a sealing screw is arranged on the clean hole in a matching manner. The multifunctional horizontal natural gas separation filter has the advantages that the structure is simple; the ideal effect of latching all the latch plates and the blind plate locking groove can be enduringly kept; the blind plate is prevented from being deformed; when natural gas exists in the cylinder, the blind plate cannot be opened; the blind plate locking groove can be quickly and conveniently cleaned.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

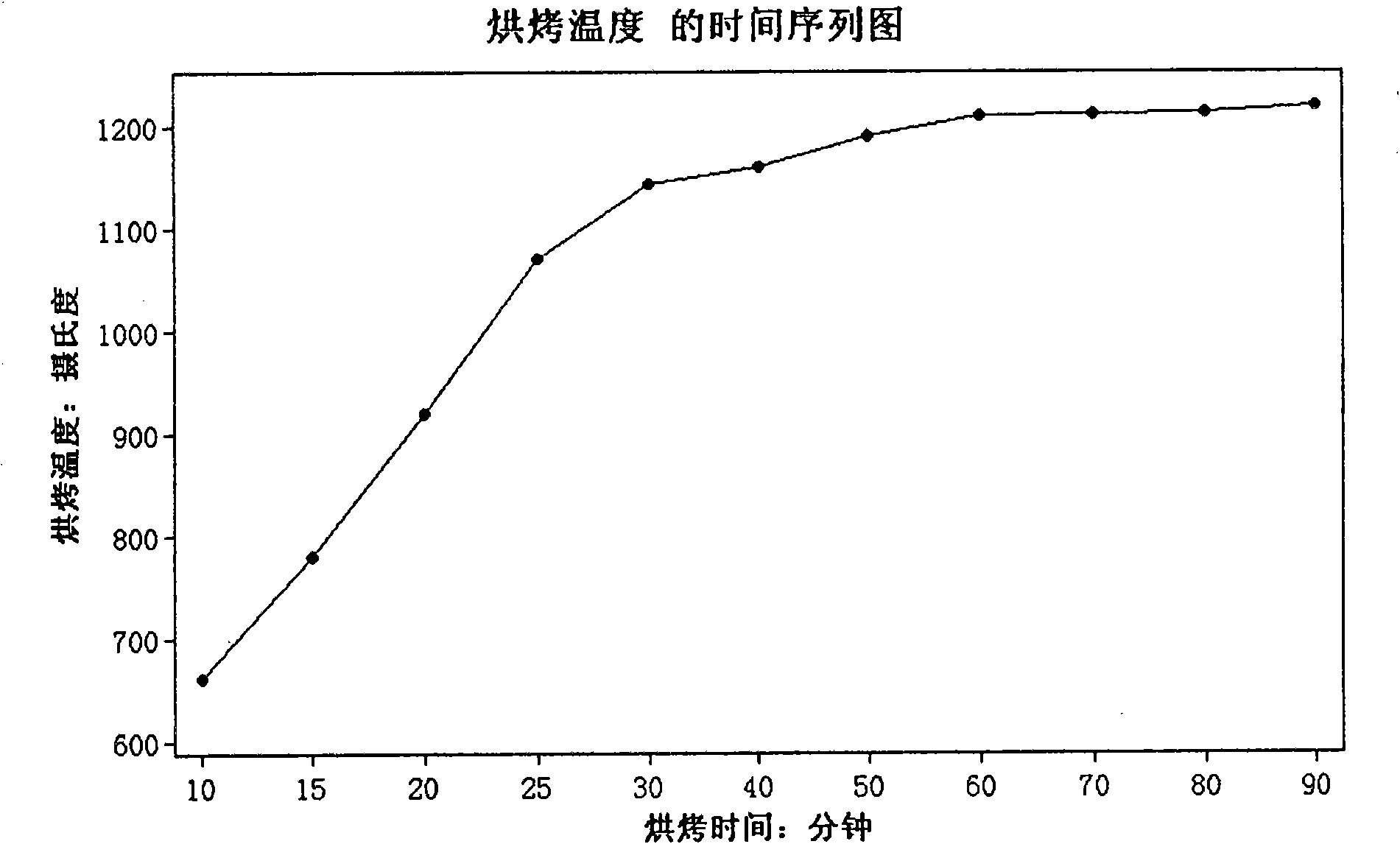

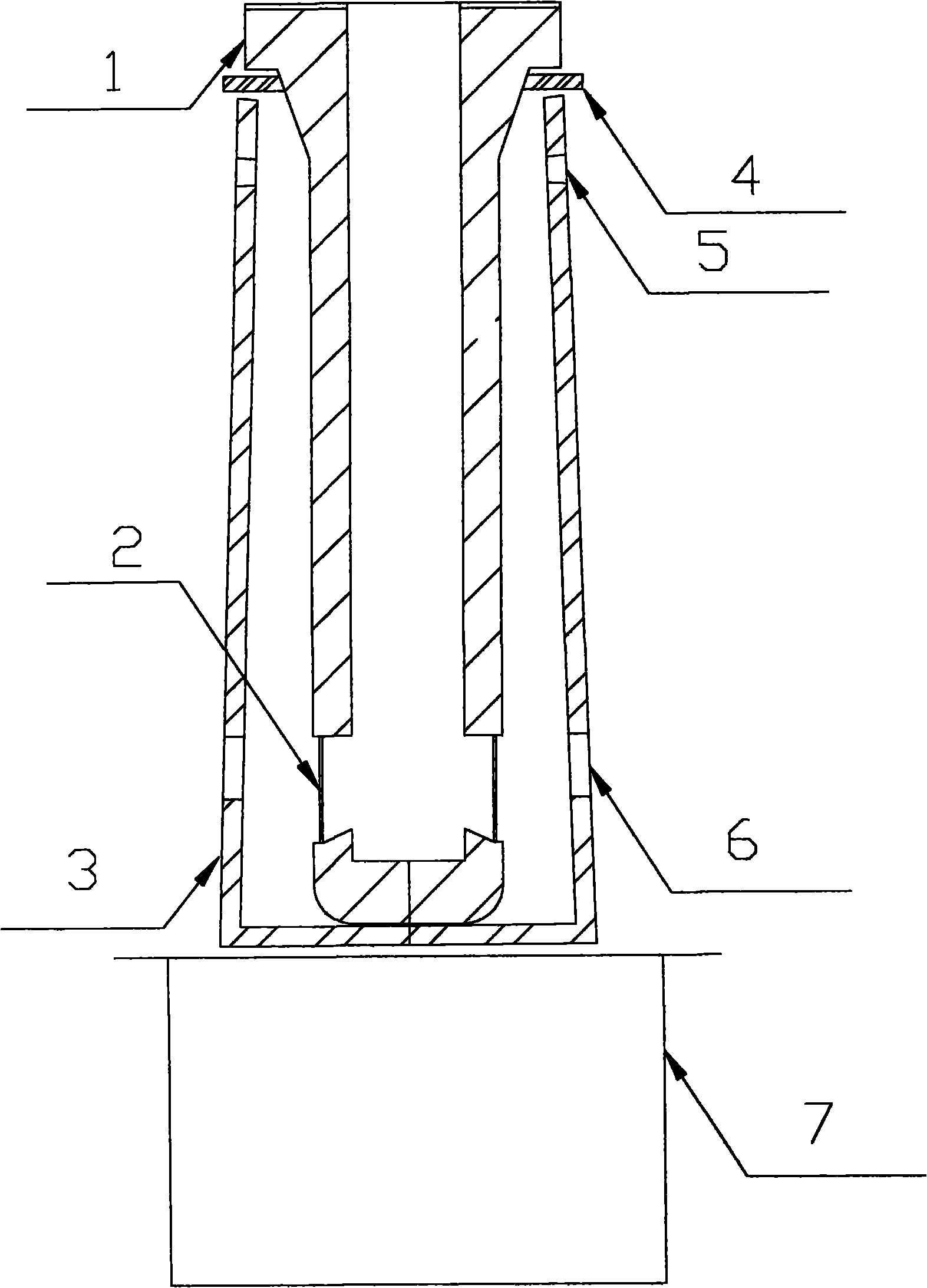

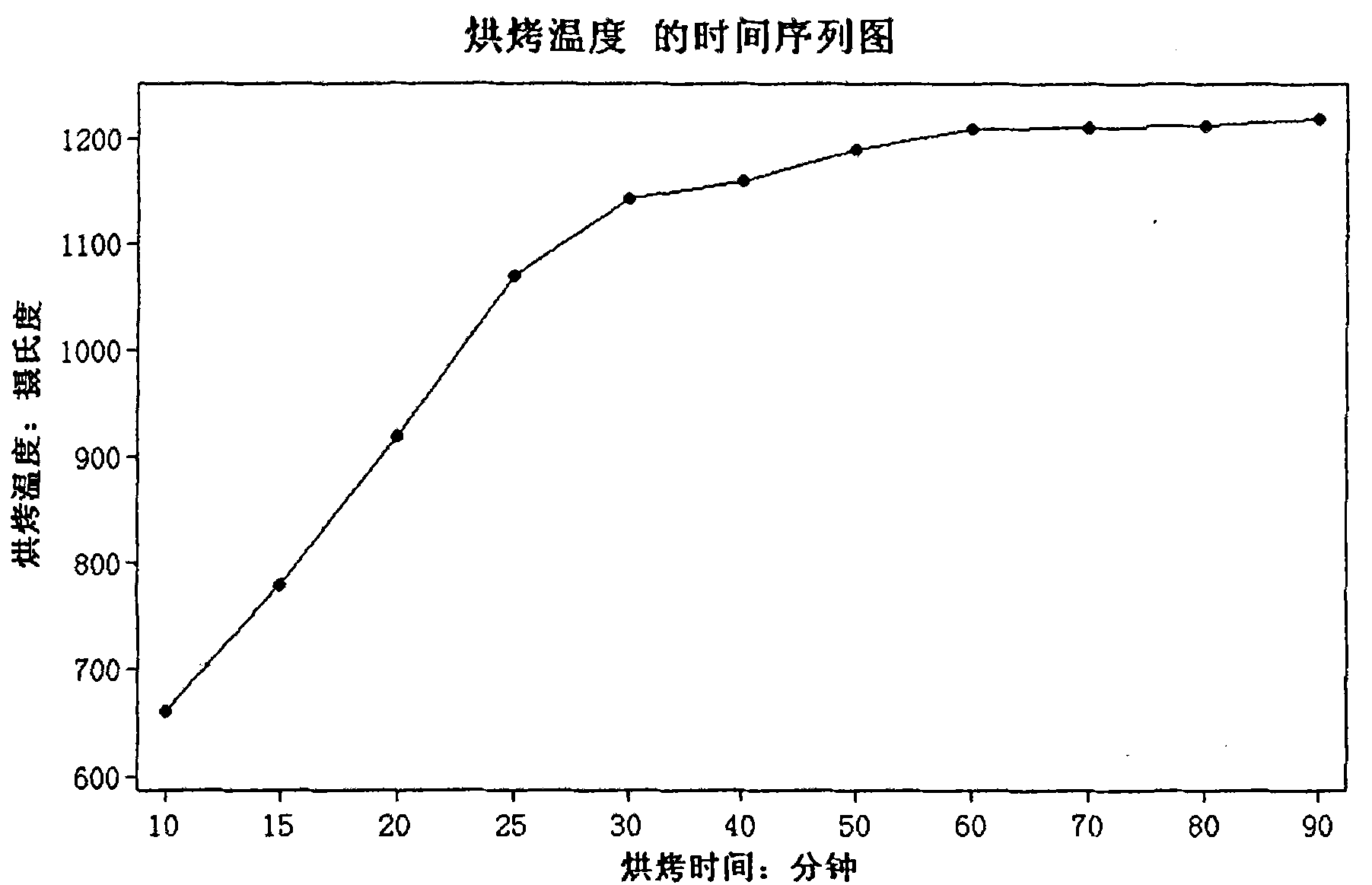

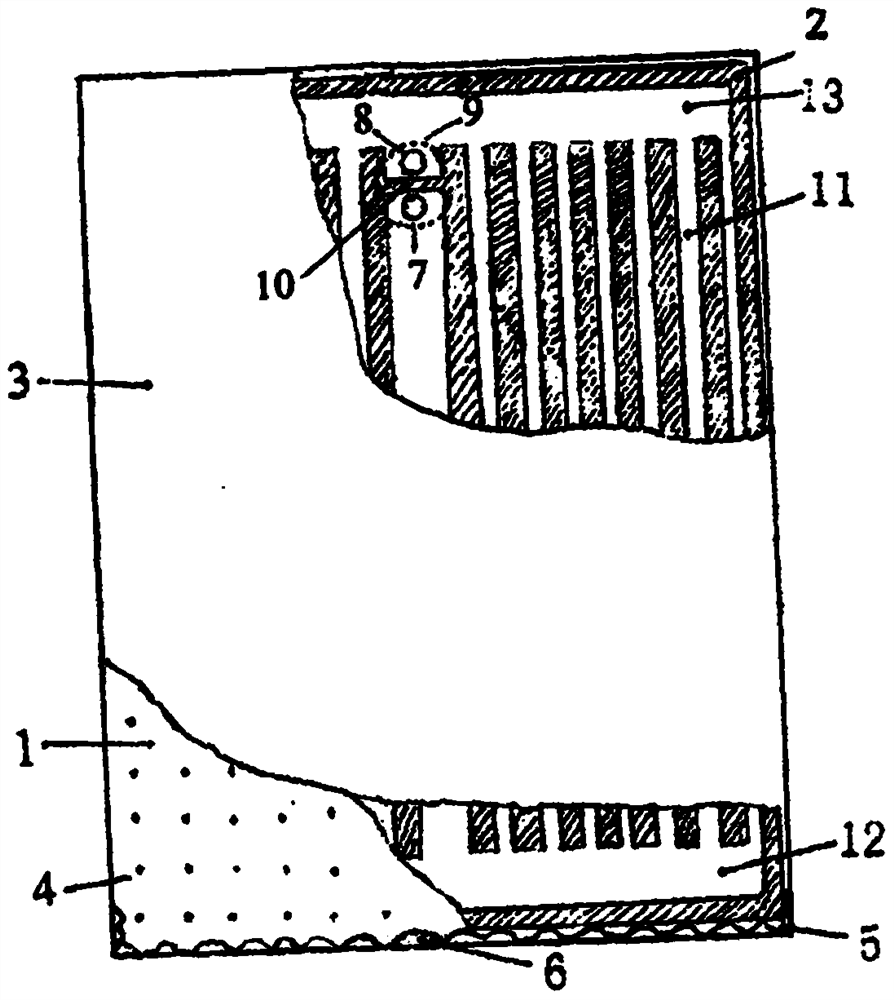

Continuous casting tundish submerged nozzle on-line roasting apparatus and roasting method

ActiveCN101879590AGuaranteed baking qualityUniform baking temperatureMelt-holding vesselsEnergy conservationMaterials science

The invention discloses a continuous casting tundish submerged nozzle on-line roasting apparatus and a roasting method, and belongs to the field of metallurgical continuous casting. The apparatus comprises a tundish roaster, an upper tundish nozzle, a nozzle quick-change mechanism, a submerged nozzle, a sealing ring, a roasting sleeve and a support frame, wherein a sealing ferrule is sleeved at the neck of the submerged nozzle, the internal diameter is in close contact with an iron cover of the submerged nozzle, the lower part of the sealing ring is provided with a roasting sleeve, the upper edge of which is in close contact with the sealing ring, and the bottom part is lifted by using the support frame. The invention has the advantages of saving a lower suction device and daily maintenance cost and reducing a large amount of cost along with simple structure. Meanwhile, the device and the method make full use of roasting heat from the tundish and save a large amount of energy medium so as to fulfill the aims of energy conservation and consumption reduction.

Owner:BEIJING SHOUGANG CO LTD

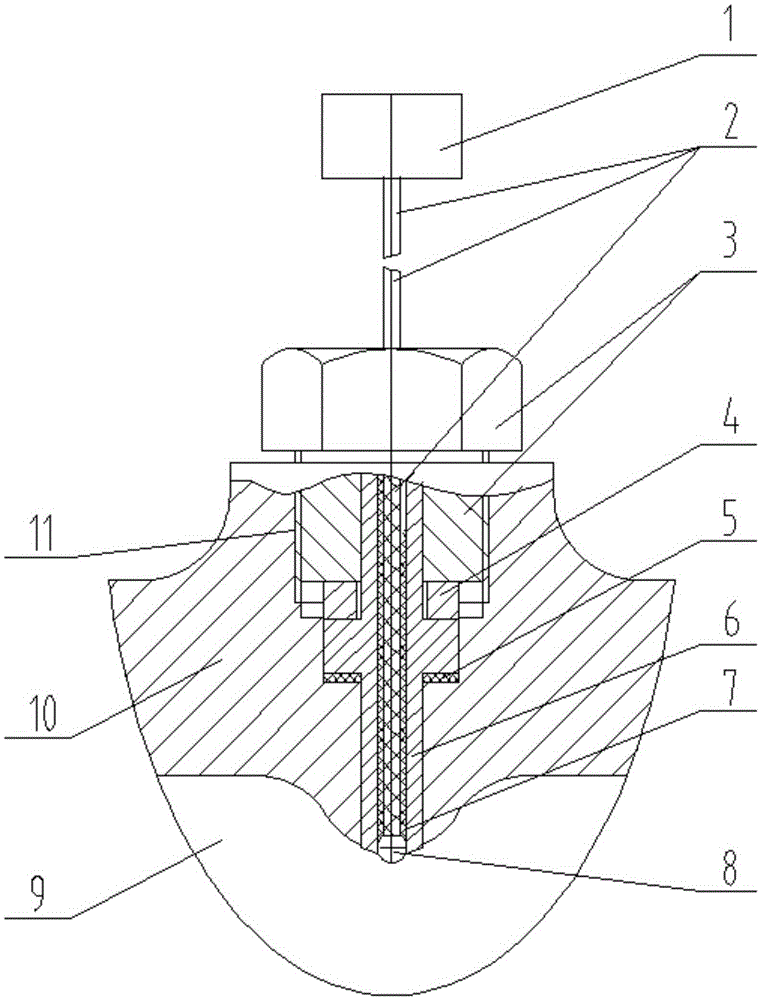

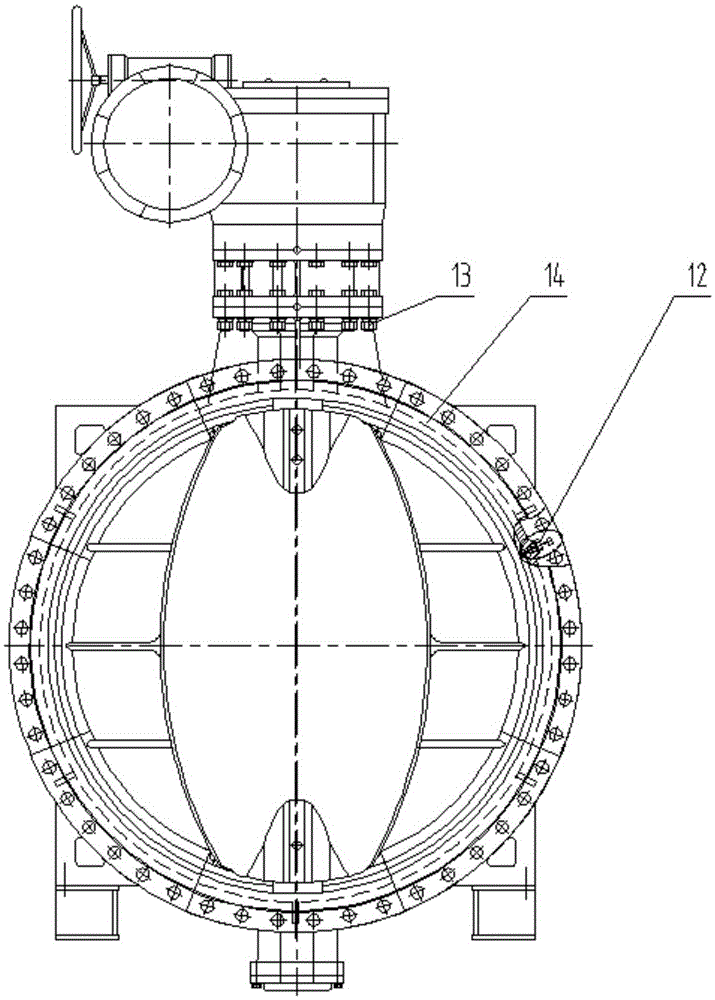

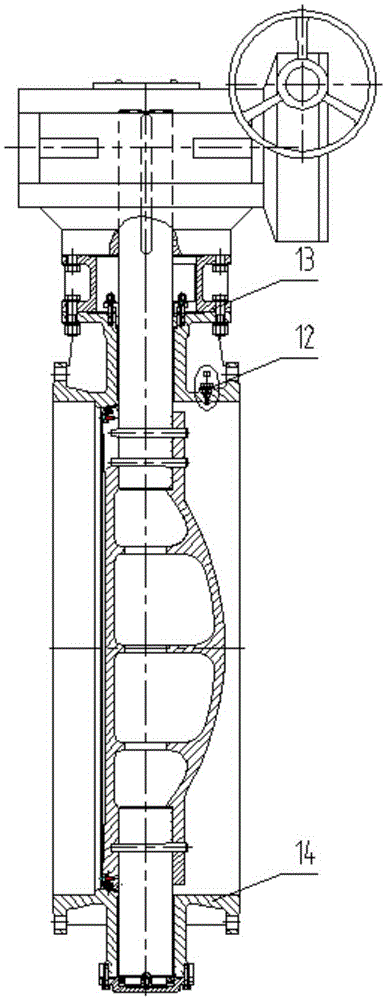

Valve interior observing device provided with self-luminous industrial endoscope

InactiveCN106678437AContinuous safe and stable operationObservation saves time and effortValve arrangementsLine tubingLight guide

The invention relates to a valve interior observing device provided with a self-luminous industrial endoscope. The valve interior observing device comprises a through duct, an industrial endoscope pilot end part with a self-luminous function, a conductive light guiding beam, a resin sleeve, a guide pipe and a working eye lens part, wherein the through duct, the industrial endoscope pilot end part with the self-luminous function, the conductive light guiding beam, the resin sleeve and the guide pipe are arranged in a valve body, and the working eye lens part is arranged outside the valve body. One end of the through duct communicates with an inner cavity of the valve body, and the other end of the through duct extends onto the outer surface of the valve body. The industrial endoscope pilot end part is tightly arranged at one end of the through duct, the other end of the industrial endoscope pilot end part is connected with one end of the conductive light guiding beam, and the other end of the conductive light guiding beam stretches out of the through duct to be connected with the working eye lens part. The valve interior observing device is applied to a valve, the interior condition of the valve can be observed and known at any time or at regular times through the endoscope, time and labor are saved, media are also saved, the working procedure is simplified, and the working efficiency is improved; and by adoption of the device, the requirements for learning about the interior condition of the valve in time and enabling a medium delivery pipeline to operate continuously, safely and stably can be met.

Owner:天津澳特斯阀门制造有限公司

Method for concentrating sample constituents and amplifying nucleic acids

InactiveCN102453710AReduce work stepsReduce the numberBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acidChemistry

Owner:ROBERT BOSCH GMBH

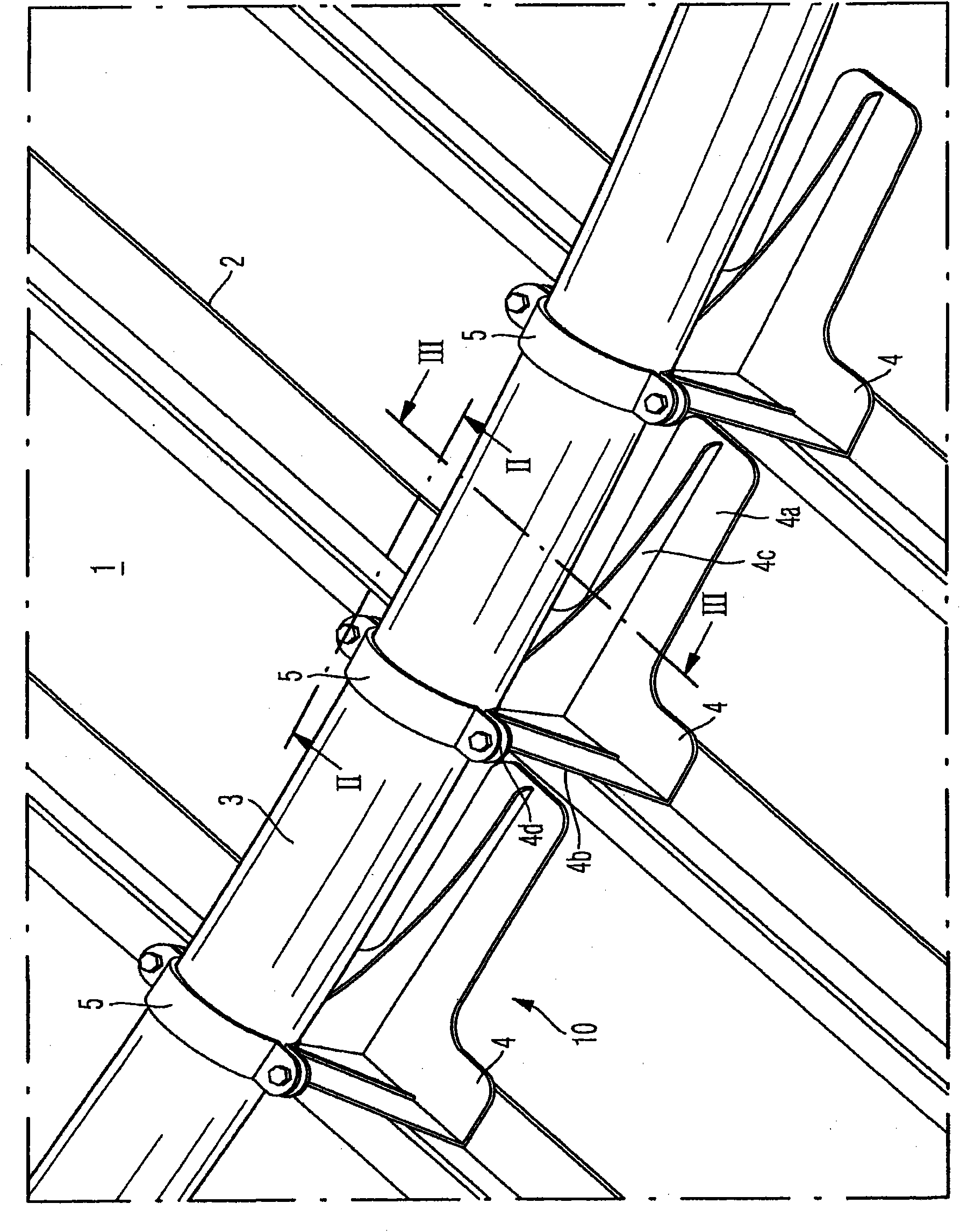

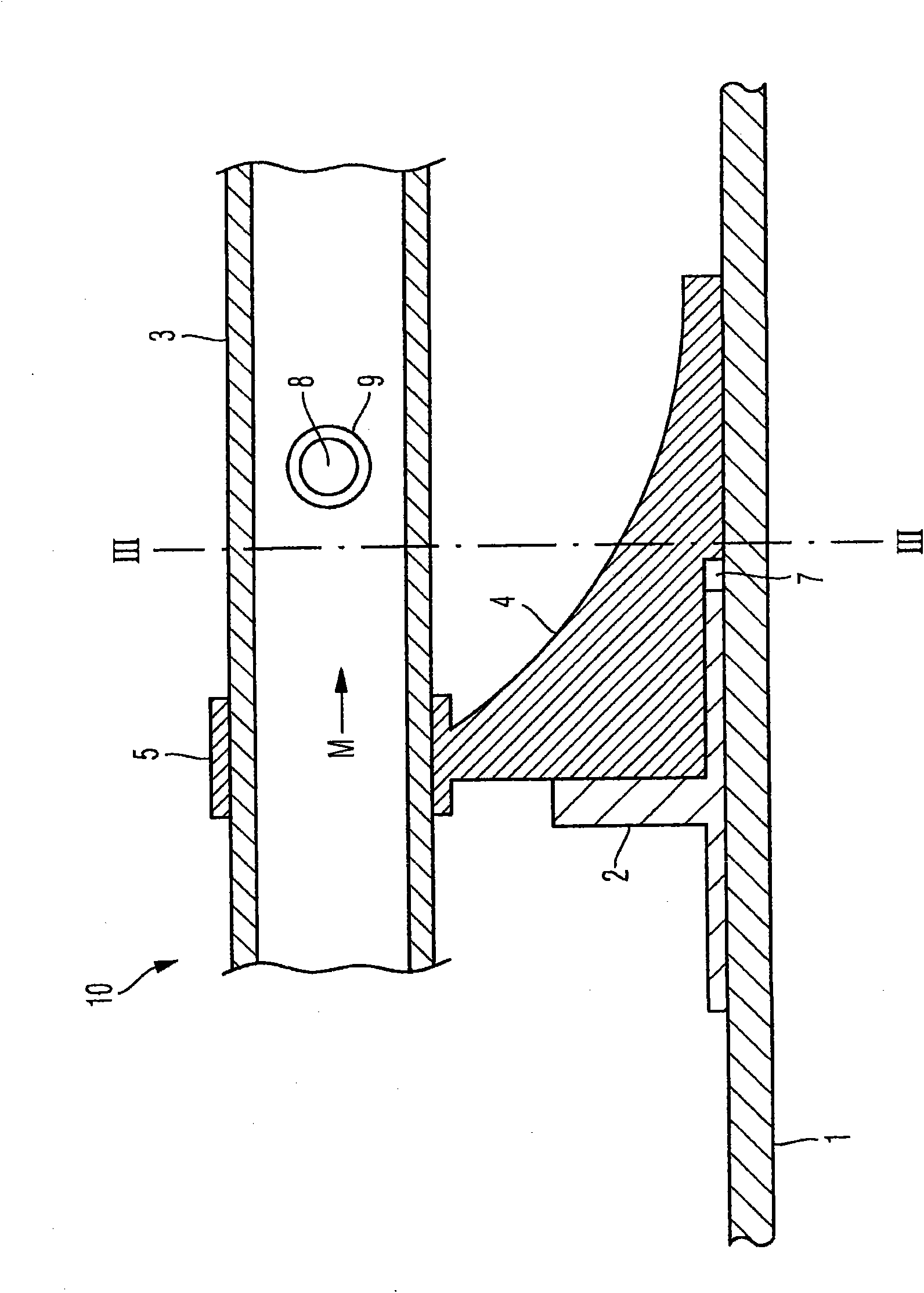

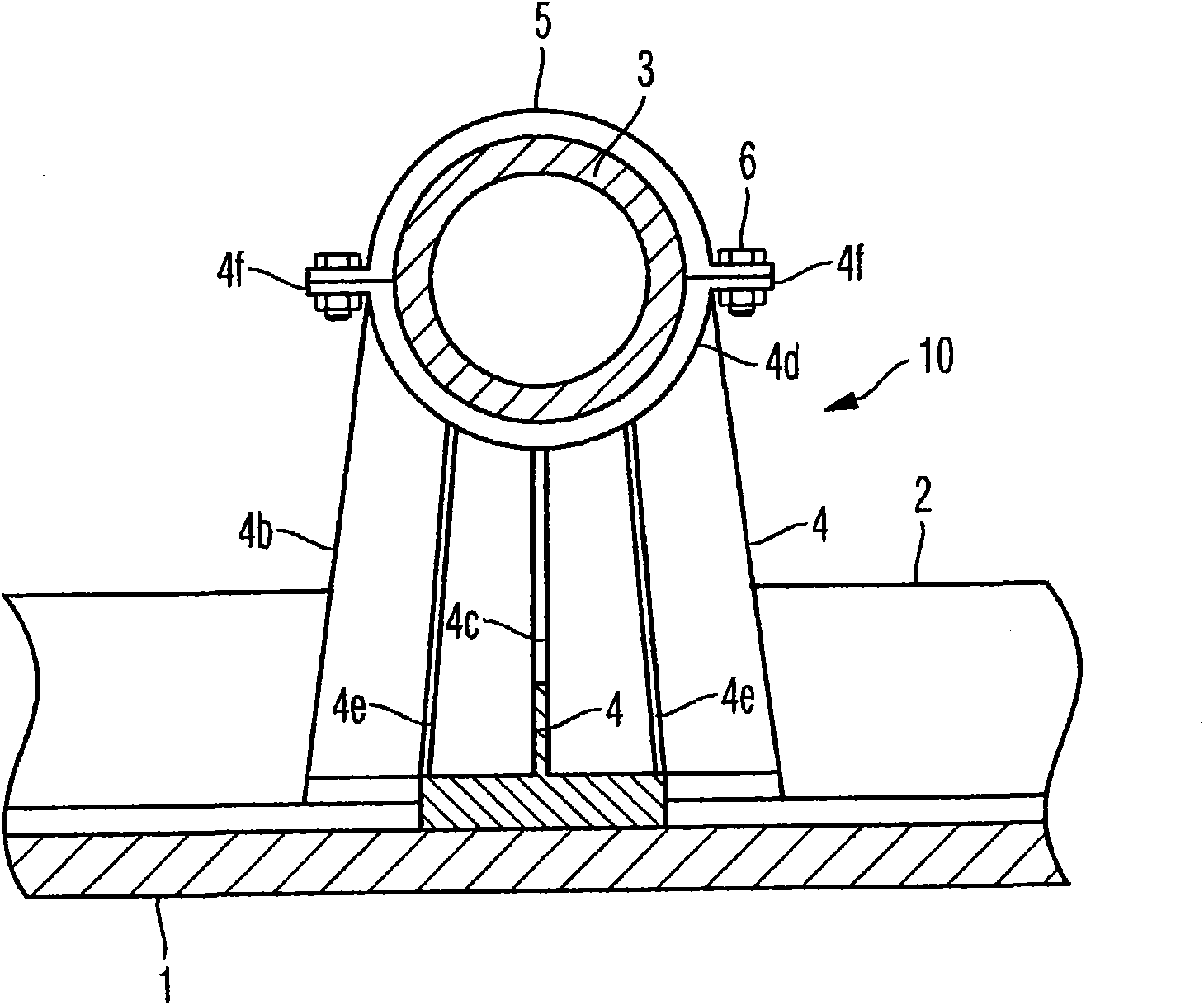

Structural component and fuselage of an aircraft or spacecraft

The invention relates to a load-bearing component (10) for strengthening the skin of an aircraft or spacecraft, such as a stringer or frame, wherein said component is designed as a closed profile (hollow profile) (3) such that a system medium (M) can be conducted through the structural component. To this end, the hollow profile (3) serves as load-bearing component.

Owner:AIRBUS OPERATIONS GMBH

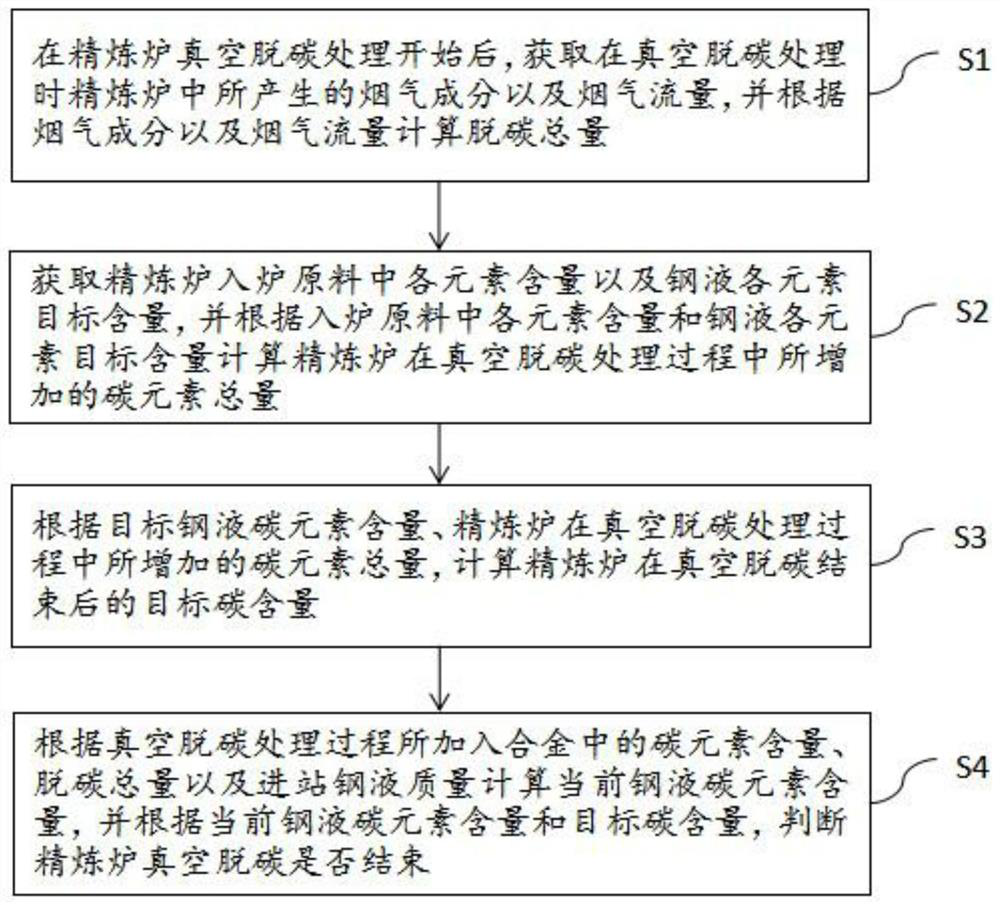

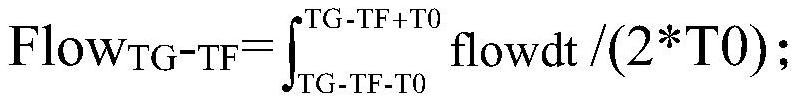

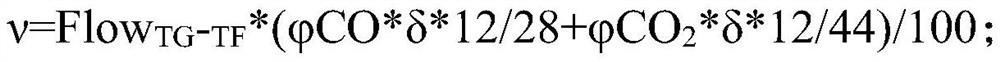

Refining furnace decarburization end point detection method and detection system

The invention discloses a refining furnace decarburization end point detection method. The refining furnace decarburization end point detection method comprises the following steps that 1, flue gas components and flue gas flow in a refining furnace are acquired, and the total decarburization amount is calculated; 2, the content of each element in a charging raw material of the refining furnace and the target content of each element in molten steel are acquired, and the total amount of carbon elements added in the vacuum decarburization treatment process of the refining furnace is calculated; 3, the target carbon content of the refining furnace after vacuum decarburization is calculated according to the target molten steel carbon content and the total amount of the carbon elements added in the vacuum decarburization treatment process of the refining furnace; and 4, the current molten steel carbon element content is calculated according to the carbon element content in alloy added in the vacuum decarburization treatment process, the total decarburization amount and the mass of the molten steel entering the station, and whether vacuum decarburization of the refining furnace is finished or not is judged according to the current molten steel carbon element content and the target carbon content. The refining furnace decarburization end point detection method can predict the carbon content of the molten steel in real time and judge a decarburization end point.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Vacuum flat plate heat collector and manufacturing method and equipment thereof

PendingCN111947323AHigh mechanical strengthImprove thermal shock resistanceSolar heating energySolar heat storageThermodynamicsBuilding energy

The invention discloses a vacuum flat plate heat collector and a manufacturing method and equipment thereof, and belongs to the field of solar energy application. The popularization of a vacuum pipe heat collector enables a flat plate heat collector to be marginalized, so that people know the importance of vacuum heat preservation in solar low-temperature heat collection application. A blow-up type plate core is arranged in the middle of a vacuum glass flat box, supporting columns are arranged between the plate core and the glass box, a heat absorption coating is manufactured on the front faceof the plate core, an inlet pipe nozzle and an outlet pipe nozzle are adjacent on the center line of the back face of the plate core and are vertically led out of a round hole of the same glass backplate, and the problems of heat stress and sealing are well solved. The heat collector in which the ultra-thin plate core is arranged in the vacuum glass box with the homogeneous integrated supportingcolumns is small in heat storage amount, fast in starting and high in heat collection efficiency, and is combined with a building and mounted on a steel structure to form a solar wall which saves energy and generates energy, and the building energy consumption can be effectively reduced. The vacuum flat plate heat collector is combined with a heat pump or a medium-temperature heat collector to produce steam as solar industrial energy, so that the device has a wider application prospect.

Owner:余华阳

Preparation method of baking-free magnesium vibration material

The invention discloses a preparation method of a baking-free magnesium vibration material. The vibration material is prepared from 93-96% of magnesite, 3-6% of composite binder, 0.2-0.8% of setting accelerator and 0.2-0.8% of polycarboxylate water reducing agent. The preparation method has the advantages of single raw material, fewer production steps, less material accumulation and lower cost; and besides, the vibration material is free of baking, thereby saving the baking medium and enhancing the turnover utilization ratio of the tundish.

Owner:浙江攀盛冶金材料有限公司

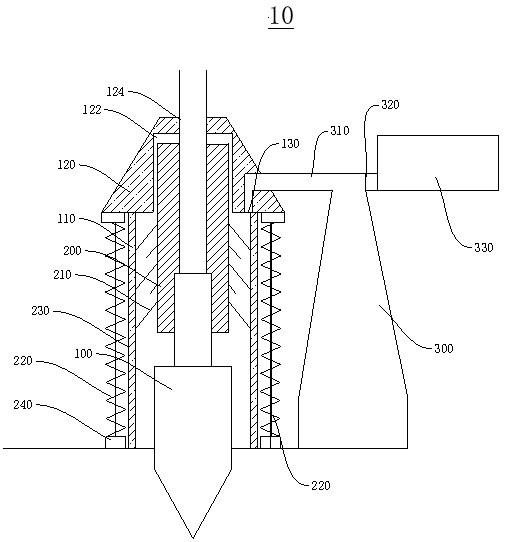

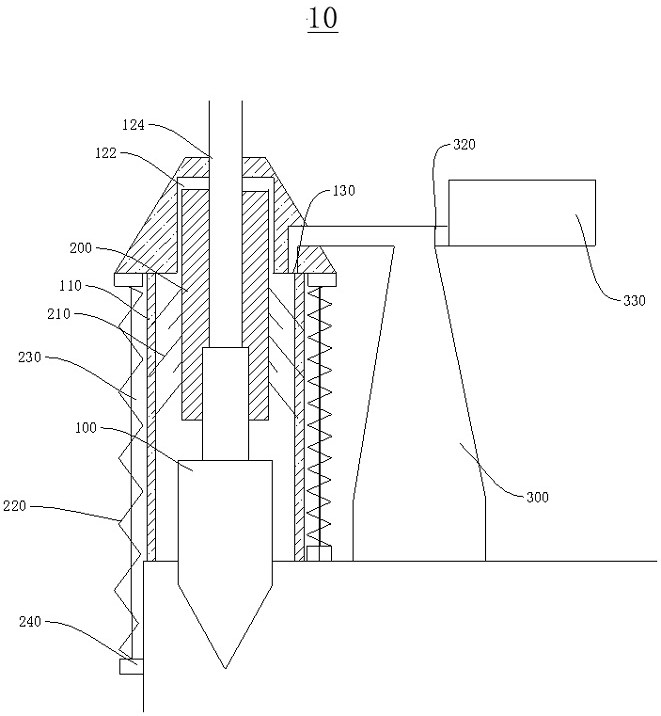

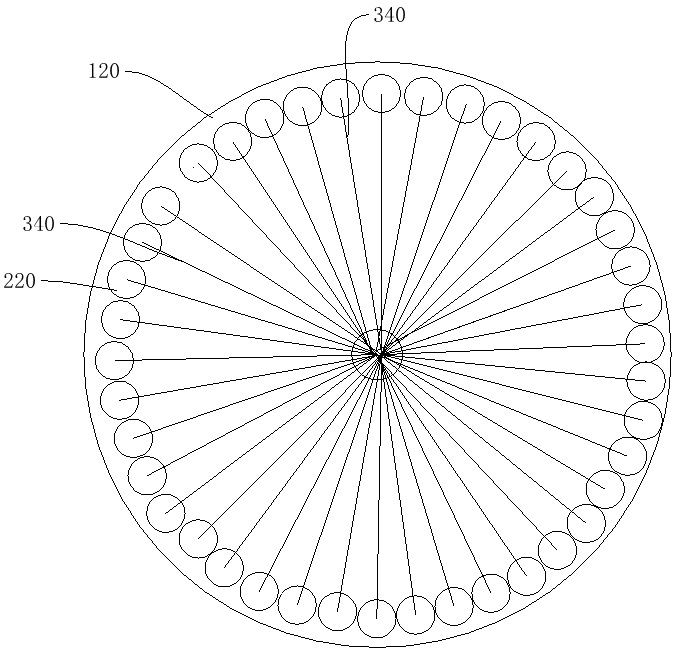

Rig Noise Reduction Device

InactiveCN112096297BIncrease reflectionIncrease scatteringEarth drilling toolsSound producing devicesEngineeringNoise reduction

The present application relates to a noise reduction device for a drilling rig, which includes: a sealing cylinder and a sealing cover, the sealing cylinder is arranged on one side of the sealing cover, and the sealing cover is provided with a through hole for passing a drill bit, the axis of the drill bit The axis is the same as that of the sealing cylinder; the sleeve is arranged coaxially with the sealing cylinder and arranged in the sealing cylinder, the sleeve has internal threads, the drill bit has external threads, the sleeve and the The drill bit is threaded and fixed relative to the drill bit; the surface of the sleeve away from the drill bit is provided with a plurality of sound insulation sheets, and the end of the sound insulation sheet connected to the sleeve is movable relative to the sleeve , the sound-insulating sheet has different lengths and widths; a plurality of springs are arranged adjacently around the edge of the sealing cover to form a housing cavity, one end of each spring is fixed to the edge of the sealing cover, and the other end is set There are counterweights.

Owner:SHANDONG GEOLOGICAL ENG INVESTIGATION INST

Ironing roller for ironing machine

The invention relates to an ironing machine ironing roller, and belongs to the technical field of textile printing and dyeing post-finishing machinery. The ironing machine ironing roller comprises: an ironing roller body, wherein a left shaft head cover is fixed on the left end of the ironing roller body, the center forms a left support shaft head, a right shaft head cover is fixed on the right end, the center forms a right support shaft head; a heating mechanism arranged in a cavity; and an inner bush arranged in the cavity, wherein the heating mechanism comprises a left sealing disk, a right sealing disk, electric heating pipes and an electric heating pipe protection casing, the number of the electric heating pipes is a set, the left ends of the electric heating pipes and the left shaft head cover are fixed, the right ends and the right shaft head cover are fixed, the left and / or right sealing disk is provided with a medium introduction hole, and the position corresponding to the medium introduction hole is provided with a medium introduction hole sealing cover. The ironing machine ironing roller is characterized in that a thermal insulation filler is arranged inside the inner bush cavity of the inner bush, the center position of the right sealing disk is provided with a filler introduction port, the filler introduction port is corresponding to the inner bush cavity of the inner bush, and a filler introduction port sealing cover is arranged. The ironing machine ironing roller has characteristics of fabric ironing quality assurance, rapid heating and energy saving.

Owner:苏州花之皇纺织科技有限公司

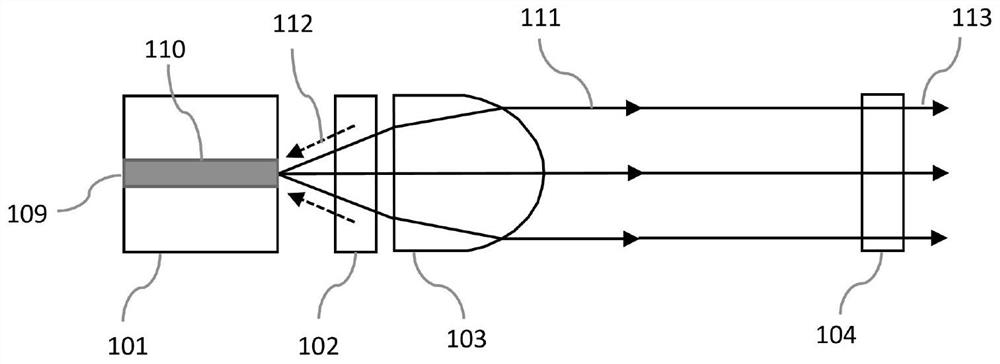

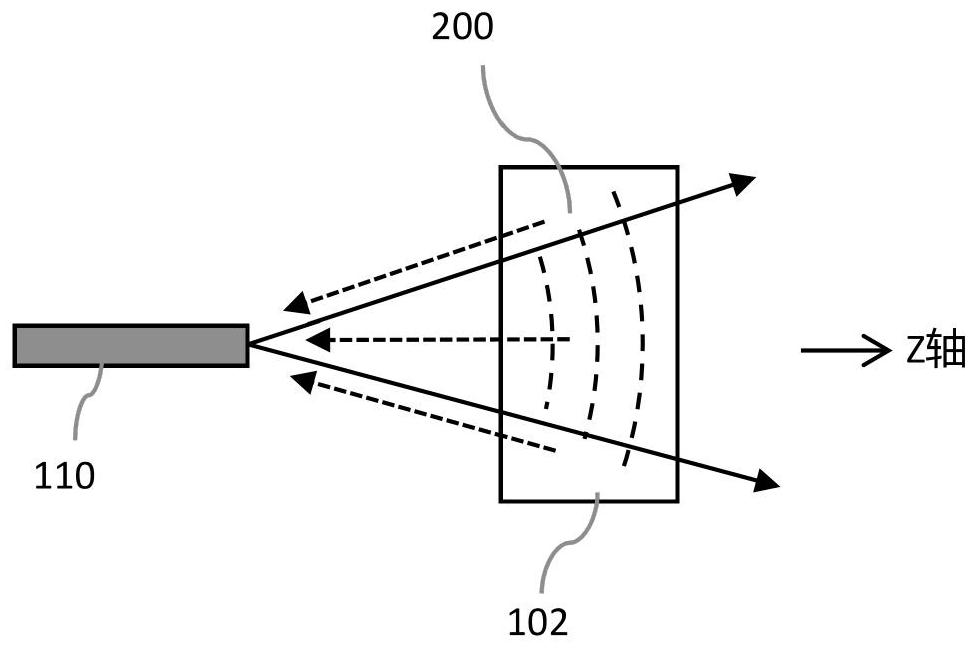

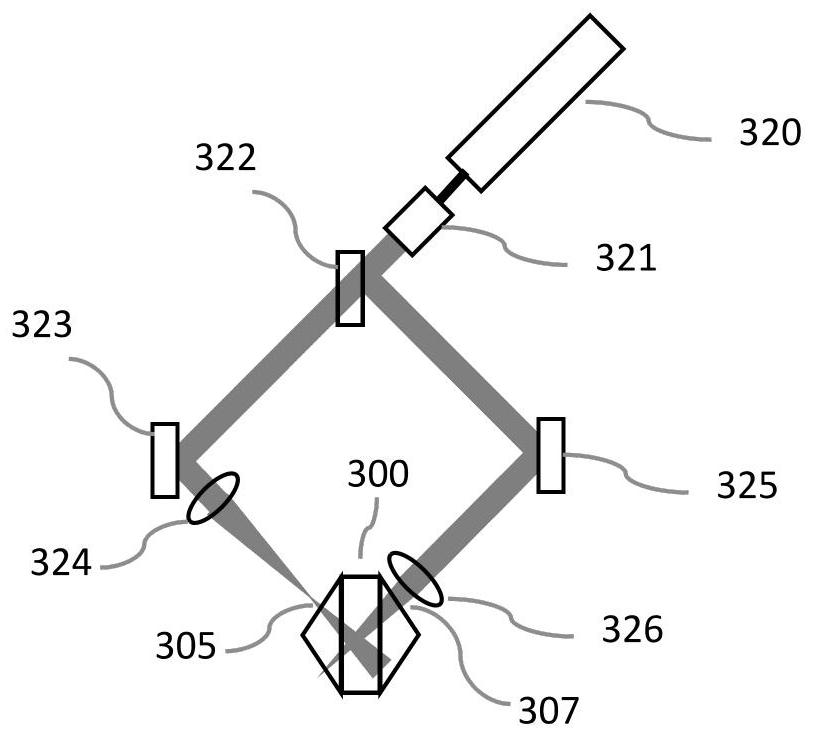

Novel mode-locked laser

PendingCN114725773ASingle laser wavelengthLaser wavelength stabilizationLaser detailsSemiconductor lasersGratingLine width

The invention discloses a novel mode-locked laser, and relates to the technical field of lasers. The device comprises a laser chip; one side of the laser chip is provided with a VBG grating, one side of the VBG grating is provided with a fast axis collimating lens, and one side of the fast axis collimating lens is provided with a slow axis collimating lens; the laser chip comprises an active layer, the rear end face of the laser chip is plated with a high-reflectivity thin film, the front end face of the laser chip is plated with an antireflection film, and the high-reflectivity thin film corresponds to the VBG grating. The volume grating is arranged on one side of the laser chip, the laser chip emits light, and the light is partially reflected back to the laser chip by the volume grating, so that the emission wavelength of the laser chip is single and stable, and the laser which is output and coupled by the volume grating has the advantages of small output line width and high temperature stability; the structure is compact, medium in the laser cavity is less, and the property is more stable.

Owner:FUZHOU OPTOWIDE TECH CO LTD

Polyisocyanurate cold insulation block and pipeline adjusting device comprising same

InactiveCN111793350AHigh strengthImprove seismic performancePipe supportsThermal insulationVertical vibrationPolyisocyanurate

The invention provides a polyisocyanurate cold insulation block, which is formed by pouring modified polyisocyanurate. The invention further provides a pipeline adjusting device comprising the cold insulation block. According to the invention, the cold insulation block prepared from the modified polyisocyanurate, provided by the invention, is excellent in strength, compression resistance, shock resistance, water resistance and moisture resistance, has excellent ultralow-temperature heat conductivity, reduces a medium, and is in a semi-circular ring shape, wherein the width of the cold insulation block is gradually reduced from one end to the other end, and it is guaranteed that a gap is reserved for horizontal left-right movement of the pipeline. The novel pipeline adjusting device is provided, wherein adjustment can be conducted according to vertical vibration of the pipeline, and stable transportation of the pipeline is guaranteed.

Owner:江苏嘉德管道工程有限公司

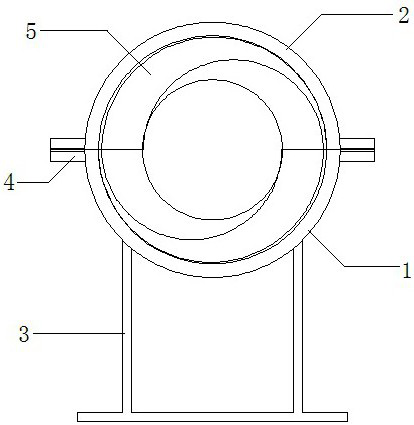

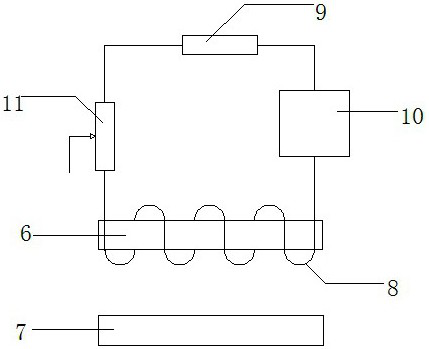

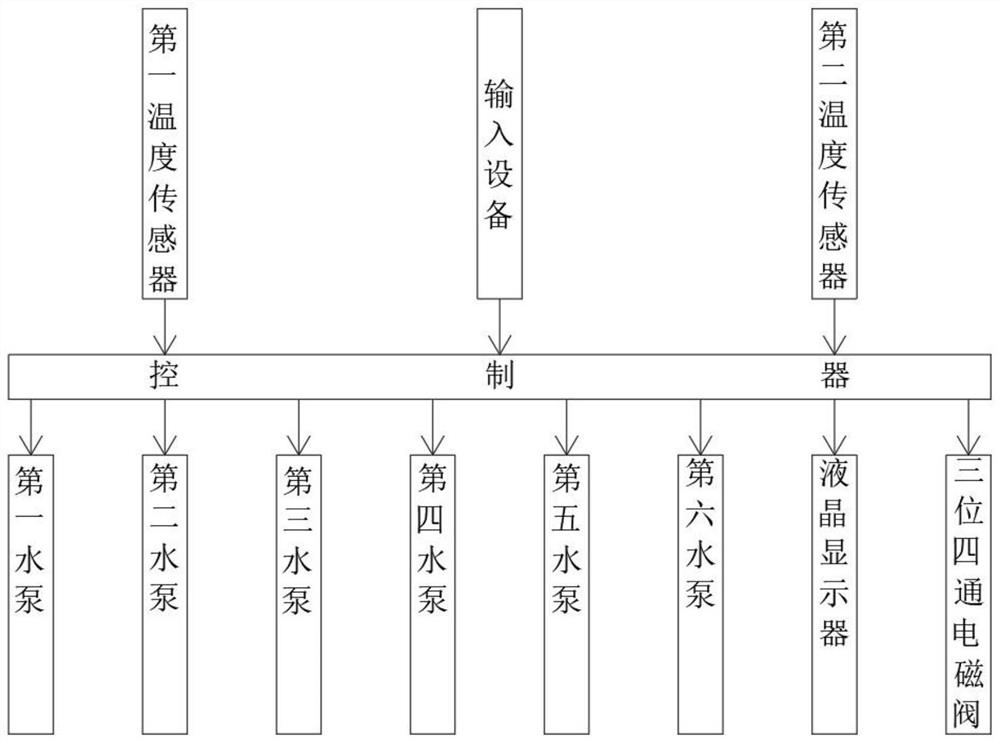

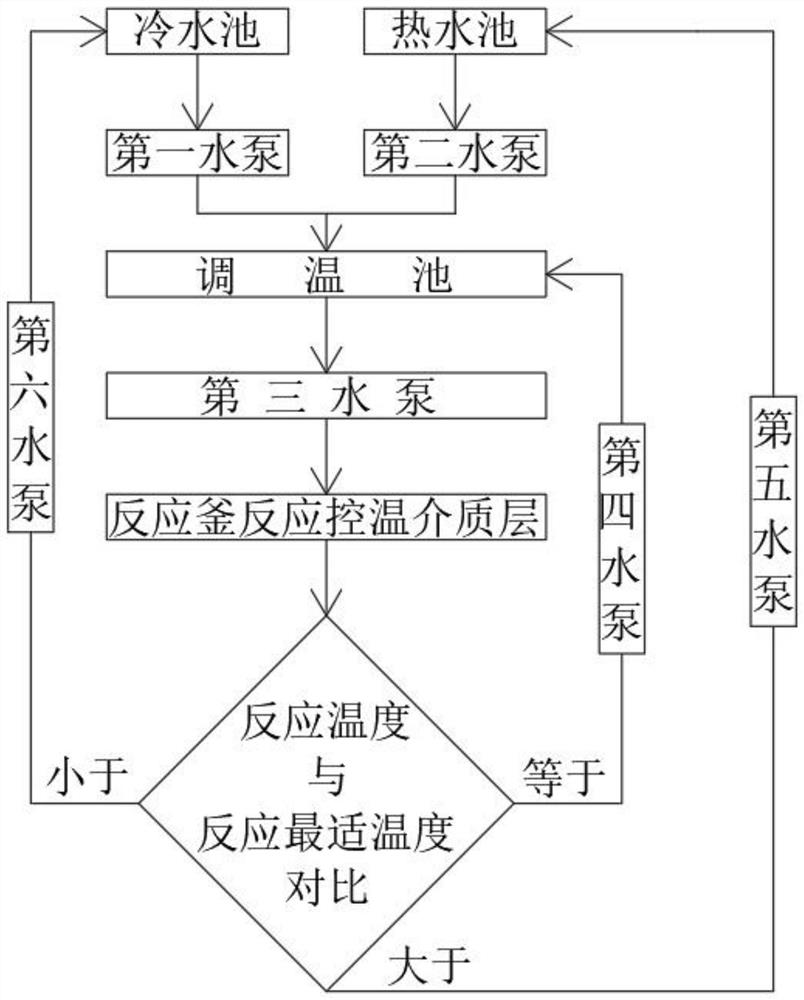

Chemical reaction temperature control adjusting system and method

InactiveCN114721447ALabor savingReduce mediumProcess control/regulationTemperatue controlTemperature controlChemical reaction

The invention relates to a chemical reaction temperature control adjusting system and method. The system comprises a cold water pool, a hot water pool, a temperature adjusting pool, a reaction kettle and a control system, the outer layer of the reaction kettle is a temperature control medium layer; the control system comprises a first temperature sensor, input equipment, a second temperature sensor, a controller, a water pump, a liquid crystal display and a three-position four-way electromagnetic valve; the method comprises the following steps: 1, inputting the optimum reaction temperature of the reaction kettle to the controller through the input equipment; the first temperature sensor senses the temperature in the temperature control medium layer of the reaction kettle reaction; the second temperature sensor senses the temperature in the temperature adjusting pool; 2, the controller calculates a reaction error temperature; and thirdly, the controller controls the three-position four-way electromagnetic valve and all the water pumps. According to the invention, fine adjustment can be carried out; more energy and media are saved; automation is achieved, and manpower is saved.

Owner:NANTONG WEILIKE CHEM

Preparation method of baking-free magnesium vibration material

The invention discloses a preparation method of a baking-free magnesium vibration material. The vibration material is prepared from 93-96% of magnesite, 3-6% of composite binder, 0.2-0.8% of setting accelerator and 0.2-0.8% of polycarboxylate water reducing agent. The preparation method has the advantages of single raw material, fewer production steps, less material accumulation and lower cost; and besides, the vibration material is free of baking, thereby saving the baking medium and enhancing the turnover utilization ratio of the tundish.

Owner:浙江攀盛冶金材料有限公司

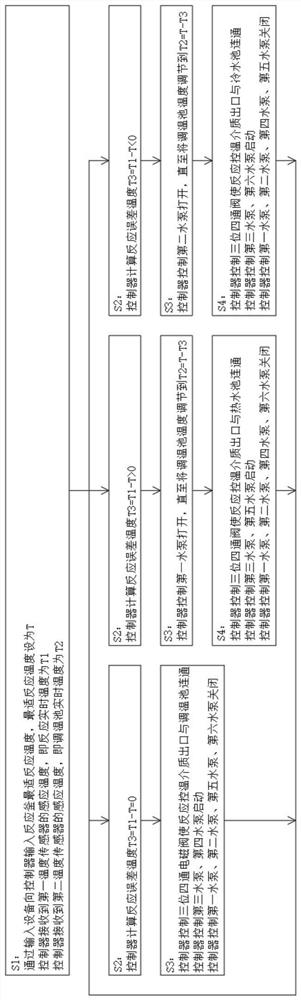

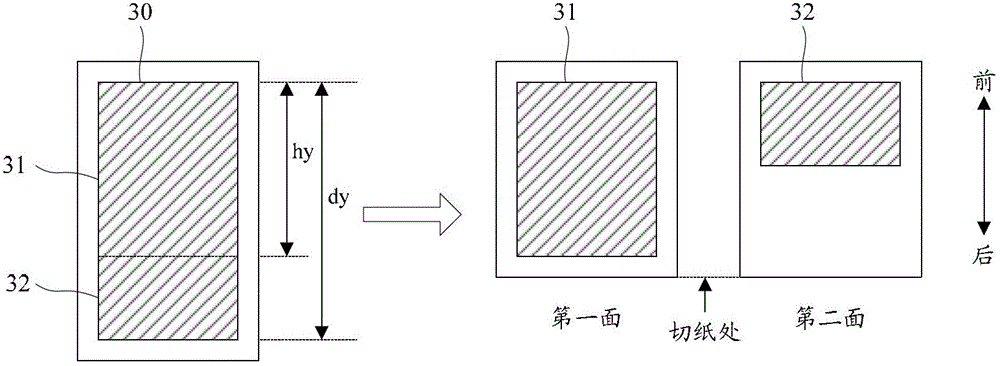

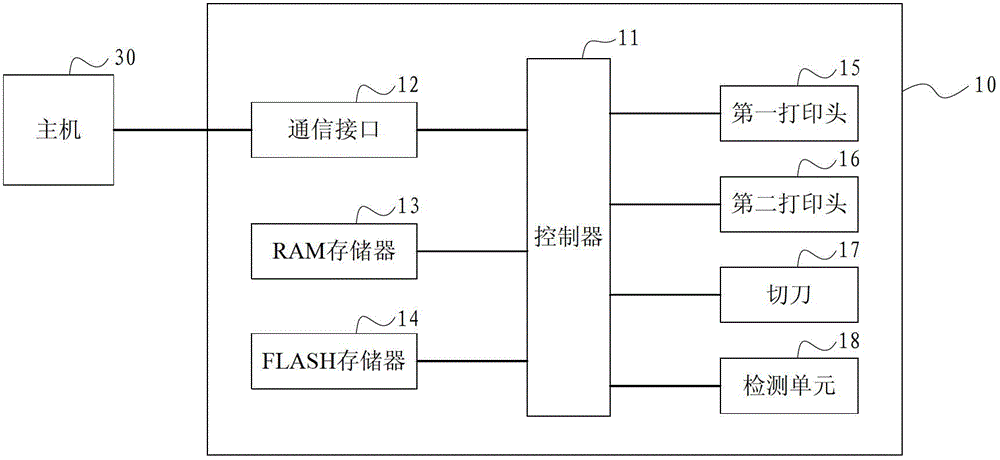

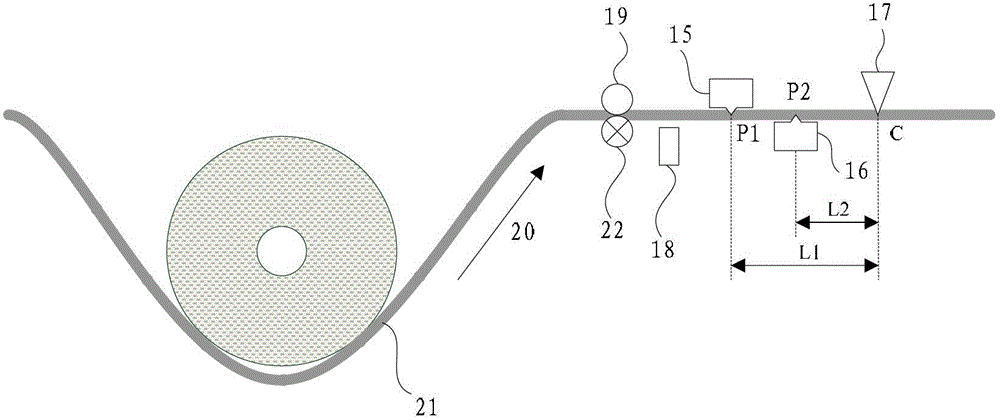

Double-sided printing control method and device, and double-sided printer

ActiveCN103777908BSolve wasteIncrease profitDigital output to print unitsComputer scienceData splitting

The invention discloses a double-sided printing control method and device and a double-sided printer. The double-sided printing control method includes the steps that the length of printing data is calculated after the printing data are received; a first reference length and a second reference length are calculated; the printing data are divided into first data and second data, wherein the printing length of the first data corresponds to the first reference length, and the printing length of the second data corresponds to the second reference length; the first data are printed on a first side, and the second data are printed on a second side. By the adoption of the double-sided printing control method and device and the double-sided printer, the problem that in the correlation technique, paper is wasted when webs are used for double-sided printing is solved, and therefore the utilization rate of the second side of a medium can be increased, and the medium can be saved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Pipeline compensator

InactiveCN102588705BExtended service lifeReduce corrosionThermal insulationPipeline expansion-compensationEngineeringCheck valve

The invention relates to a pipeline compensator provided with a flow-guiding sleeve and a metal bellows which are both arranged along the horizontal direction. The rear end of the flow-guiding sleeve is provided with a ventilating ring gap communicated with the metal bellows. The pipeline compensator is characterized in that a sealing pipe structure arranged along the horizontal direction is positioned between the flow-guiding sleeve and the metal bellows, a seal cavity is formed between the metal bellows and the sealing pipe structure, the sealing pipe structure is provided with an extensible rubber bellows, the top side and the bottom side of the sealing pipe structure are respectively provided with check valves, the lower portion of each check valve is provided with a check valve opening, and the lower portions of all the check valves are tightly connected with the sealing pipe structure. When a medium circulates in the pipeline compensator, due to the seal cavity, a medium corroding the metal bellows is only a non-flowing medium in the seal cavity, corrosion to the metal bellows caused by corrosion molecules in a pipeline medium is reduced, and accordingly the service life of the pipeline compensator is prolonged.

Owner:李春光 +1

Preparation method of composite sound-absorbing material for automotive interior parts

ActiveCN107571578BImprove insulation performanceImprove sound absorptionLamination ancillary operationsSynthetic resin layered productsPolyesterMechanical property

The invention discloses a preparation method for a composite sound-absorbing material of an automotive interior trim part, and relates to the technical field of processing of automotive interior trimparts. According to the invention, a soundproofing mat is composed of two layers of soundproofing cotton felts; and the preparation method comprises the following steps: regenerated polyester fiber / polypropylene fiber spinning, hot press molding of a composite felt, premolding of a glass fiber mesh with a steam mold, cooling and molding, water cutting, and packaging and warehousing. The compositesound-absorbing material provided by the invention is prepared by compounding a plurality of layers of a sound-absorbing material, comprises six layers, and has good sound-absorbing effect and compactness and excellent aesthetic properties. The preparation method provided by the invention uses the regenerated polyester fiber and frequently-used polypropylene fiber as raw materials; a fiber composite sheet material applied to automotive interior trim parts is prepared by adopting a method provided by the invention; the regenerated polyester short fiber is a reinforcing body, and the polypropylene fiber is a matrix, so the effects of binding and reinforcing are exerted; and the composite felt prepared by strictly controlling parameters like temperature, time and pressure of a hot press molding machine has excellent mechanical properties.

Owner:宁波尚唯汽车饰件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com