Low-nitrogen gas-fired boiler synergy and white smoke eliminating integrated heat supply system and regulating and control method

A gas-fired boiler and heating system technology, applied in combustion methods, combustion regulation, fluid heaters, etc., can solve the problems of lack of overall operation control strategy, serious exhaust gas, corrosion of boiler rooms, etc., to improve the overall gas utilization efficiency , the effect of reducing energy waste and pollutant emissions, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The structure, principle and specific implementation of the present invention will be described in detail below in conjunction with the drawings and embodiments.

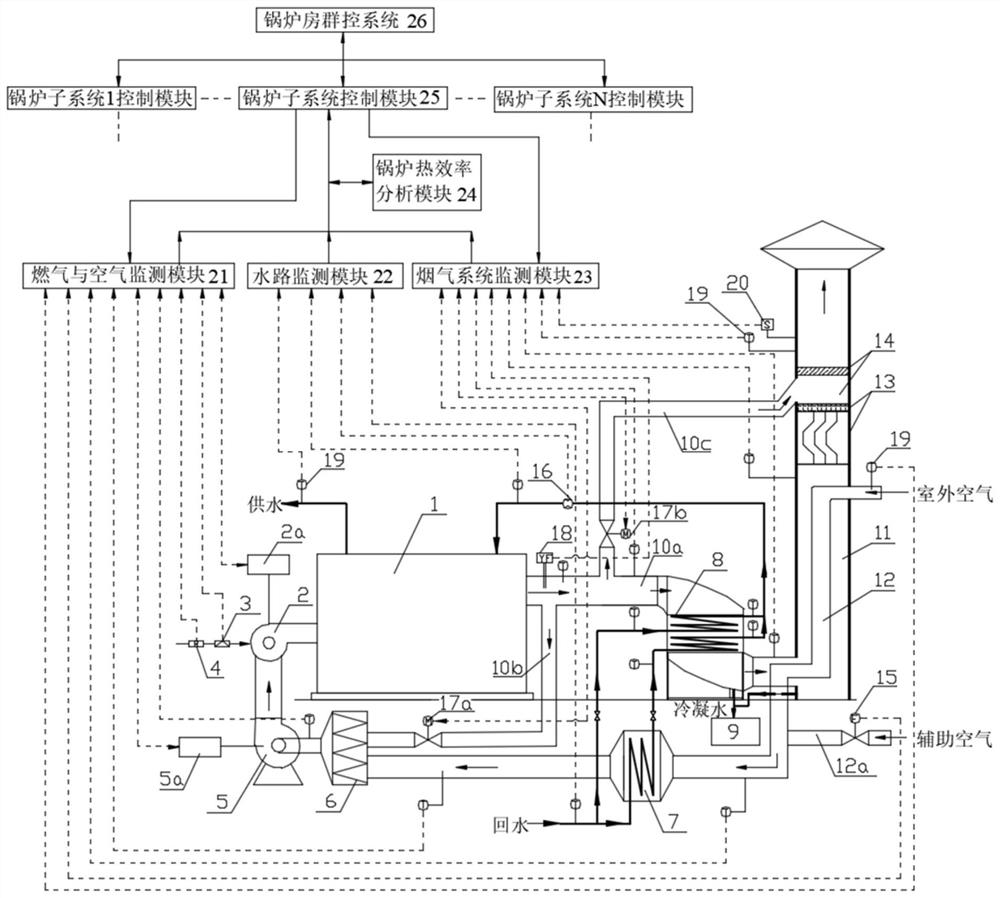

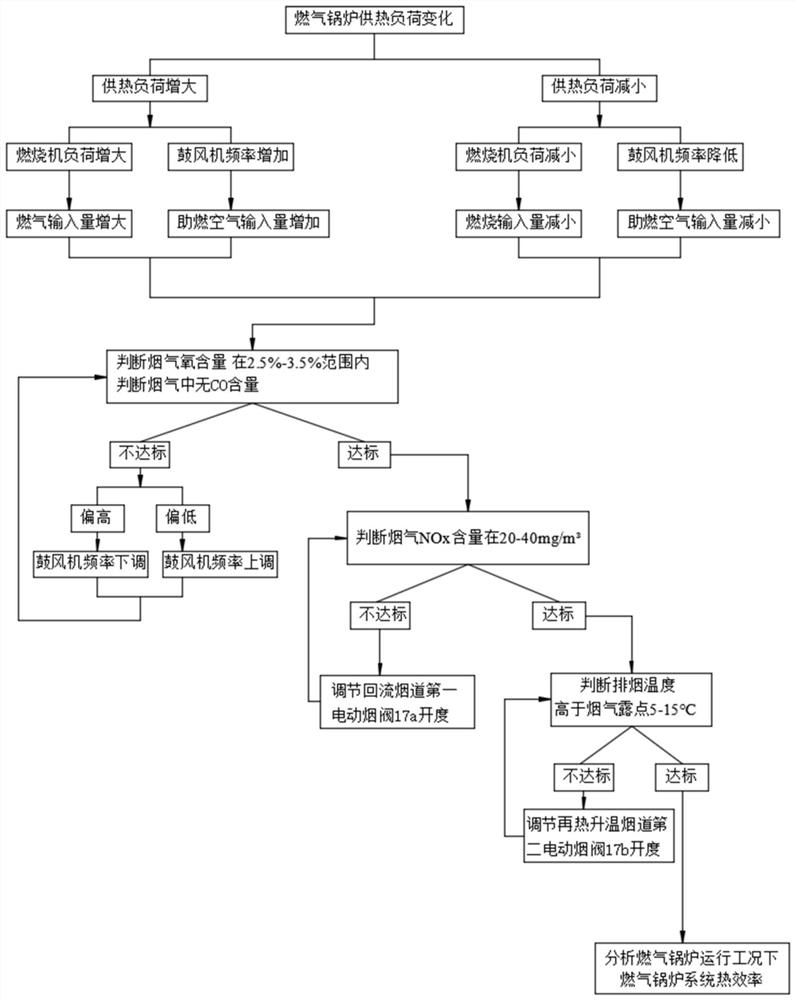

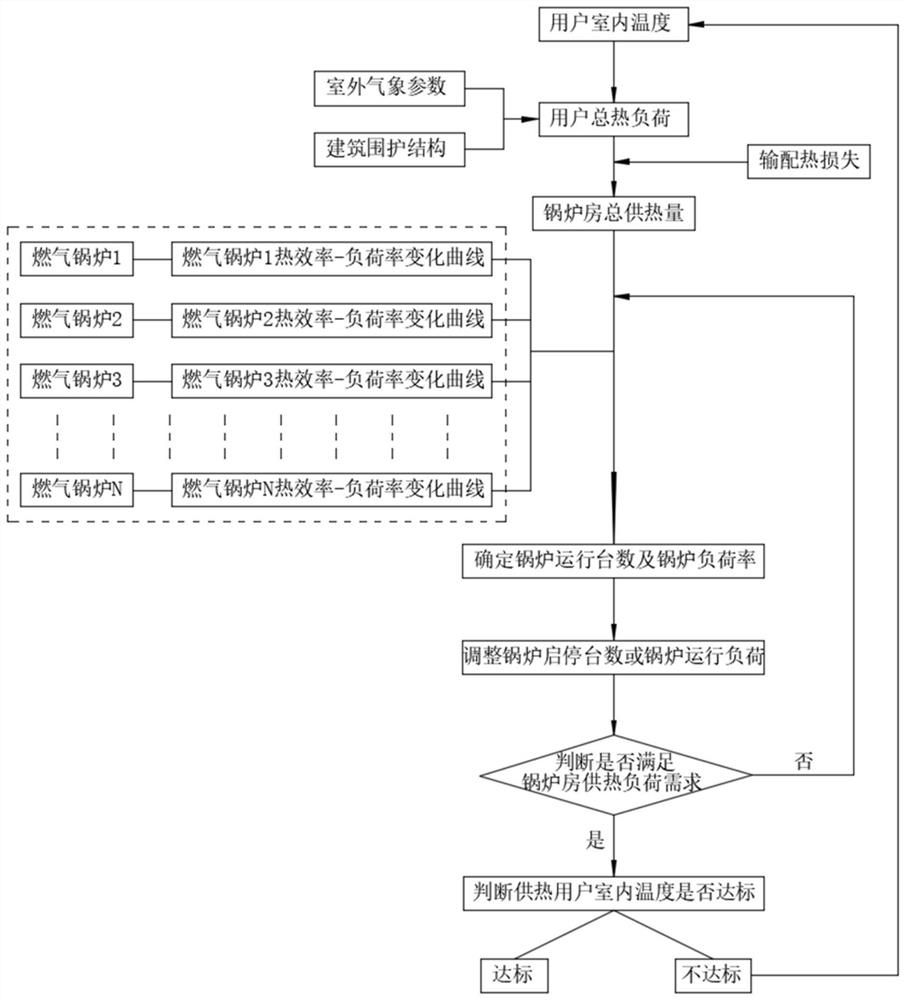

[0037]figure 1 It is a schematic structural diagram of an embodiment of a low-nitrogen gas-fired boiler efficiency and whitening integrated heating system embodiment. The system includes a boiler room group control system 26 and at least one heating subsystem. Each subsystem includes a gas-fired boiler 1, Low nitrogen burner 2, low nitrogen burner control cabinet 2a, gas flow meter 3, gas calorific value detector 4, blower 5, blower control cabinet 5a, flue gas-air uniform mixer 6, air preheater 7, Flue gas condensation heat energy recovery device 8, flue gas condensate water tank 9, horizontal flue, vertical flue 11, air duct 12, flue gas whitening and defogging section 13, flue gas heating uniform distribution section 14, electric damper 15 , ultrasonic flow meter 16, first electric smoke valve 17a, flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com